Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Subjects:

Optics

|

Engineering, Electrical & Electronic

Micro-electro-mechanical systems (MEMS) is a well-known technology that mechanically reconfigures the metamaterial unit cells.

- metamaterials

- metasurfaces

- nanophotonics

1. Introduction

Metamaterial, an artificial periodic micro/nanostructure used to manipulate the propagation of electromagnetic (EM) waves, has drawn a great deal of attention due to its unique electromagnetic properties [1,2,3]. By properly engineering the geometrical dimensions and material compositions of their subwavelength periodic unit cells, the permittivity and permeability of metamaterials can be manually controlled. Owing to that, metamaterials are widely studied in cloaking devices, energy harvesting, medical imaging, negative refraction index, and so on [4,5,6]. The operating wavelength range of metamaterials can be spanned in the entire EM spectrum by physically scaling the geometry, starting from visible light [7,8,9,10] to infrared (IR) [11,12,13,14], terahertz (THz) [15,16,17,18,19,20], and microwaves [21,22,23,24]. Many metamaterial-based optical devices have been demonstrated to have powerful performances [25,26,27,28]. However, these rigid devices cannot be actively tuned once fabricated. The controllable metamaterials help to improve flexibility by using an external stimulus. To satisfy this requirement, there are many techniques proposed for tuning mechanisms, including micro-electro-mechanical systems (MEMS) technology [29], thermal annealing [30], phase-transition materials [31,32,33], two-dimensional material [34,35,36], laser pumping [37], and liquid crystals [38]. Among these, MEMS technology is a promising technique for actively tunable metamaterial due to its ability to directly modify the metamaterial unit cells. Moreover, MEMS tuning methods can provide an ideal platform for metamaterial, which is not limited by the nonlinear characteristic of natural materials and exhibits a large tuning range of resonant frequency [39,40].

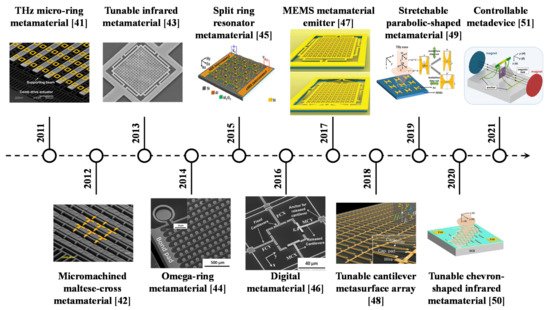

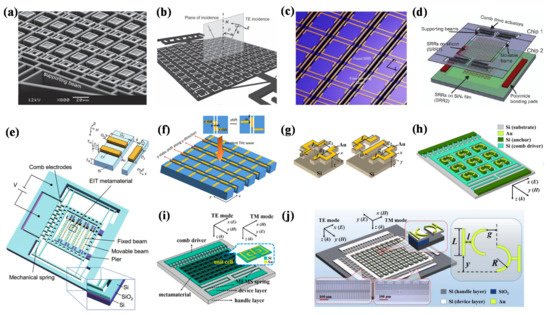

In recent years, active MEMS-based tunable metamaterial has become a hotspot in optoelectronics research as it provides the possibility to manually manipulate electromagnetic waves. By utilizing MEMS technologies, the metamaterial can be directly reconfigured and achieve wide applicability. Figure 1 illustrates the development of MEMS-based metamaterials in the last ten years, which indicates the diversification growth of MEMS tuning methods. In 2011, the geometric dimension of metamaterial was horizontally modified by exploiting the MEMS comb-drive actuator platform. Owing to that, Zhu et al. proposed a THz micro-ring metamaterial to achieve a large tuning range and the change of polarization-dependent states [41]. In 2012, by changing the configuration to the Maltese-cross pattern, they demonstrated a THz metamaterial with anisotropy tunable from positive to negative values [42], which showed the various applications of a stable MEMS-based metamaterial platform. In 2013, Liu et al. exhibited a mechanically actuated metamaterial capable of high-speed intensity modulation of IR radiation in a reflection configuration [43]. In the same year, Lin et al. demonstrated continuously tunable stress-induced curved cantilevers to form double split-ring resonators (DSRR) in a three-dimensional configuration to provide a higher tuning range of resonant frequency [44]. Since metamaterial can be highly integrated with MEMS technology, it is possible for metamaterial to be implanted in the actuator design. In 2015, Pitchappa et al. proposed interpixelated MEMS metamaterials for the realization of excellent switching performance [45]. Such switchable characteristics enable the realization of programmable metamaterials with higher intelligence. Along with the development of digital metamaterial, they demonstrated the microcantilevers integrated into a single unit cell for independent control of the orthogonal THz polarization response in 2016 [46]. Since then, the reconfigurable characteristic of MEMS-based metamaterial has been desired for its significant application, such as logic operation and sensing. In 2017, Liu et al. proposed a reconfigurable room temperature metamaterial IR emitter, whose displaying pixel is composed of MEMS metamaterial [47]. While the scope of application in MEMS-based metamaterial is gradually enlarged, Zhao et al. presented a tunable cantilever metasurface array to be used as a CMOS-compatible tunable quarter-wave plate in 2018 [48]. In 2019, Xu et al. demonstrated a stretchable THz parabolic-shaped metamaterial based on polydimethylsiloxane (PDMS) substrate and showed that flexible substrate can be exploited to mechanically control the metamaterial with high efficiency [49]. Mo et al. proposed a face-to-face chevron-shaped metamaterial to achieve vertical and horizontal tunings in 2020 [50]. In 2021, to enlarge the incident angle of received light and enhance the switching performance, Xu et al. proposed an actively tunable optical metadevice by integrating self-assembly electrothermal actuator and magnetic metamaterial [51]. Such a magnetic actuating method provides an ideal MEMS-based metamaterial platform with a large tilt angle and displacement. These milestone developments of actively MEMS-based metamaterial contribute a lot to the widespread applications of tunable optical devices, such as logic operation, sensing, energy harvest, display, and so on [52,53,54,55,56,57].

Figure 1. The development of MEMS-based tunable metamaterial in the last ten years.

2. MEMS-Based Metamaterial Emerging

The typical MEMS-based metamaterials exploit several actuating methods, including electrostatic actuators (ESAs), electrothermal actuators (ETAs), and electromagnetic actuators (EMAs). The stretchable MEMS-based metamaterials are realized by simply using a flexible substrate.

2.1. ETA-Based Metamaterial

2.1.1. Vertical Tuning Methods

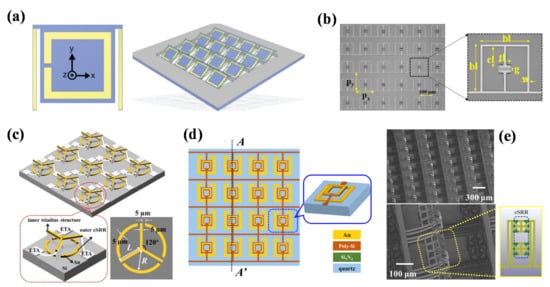

The geometrical dimension is a key factor to determine the EM wave characteristics of a metamaterial. Since the first ETA-based reconfigurable THz metamaterials were demonstrated by using a thermal stimulus, as shown in Figure 2a, ETA vertical tuning methods have been widely applied in metamaterials for large physical displacement [58]. Such methods are mainly based on microcantilevers to support the continuous tuning states of lifting up and lifting down. The microcantilevers are required to comprise a multi-layer with a large difference in thermal expansion coefficients between various materials. Through the heating process, the various thermal expansions provide tensile and compressive residual stress between different layers. Thus, ETAs can be deformed upwards by an initial strain force to perform a prestressed state. Figure 2b shows the electrical split-ring resonators (eSRR) based on metamaterial microarray [59]. With the increased external temperature from 77 K to 400 K, the resonant frequency can be continuously red-shifted 80 GHz for the advanced manipulation of THz waves. Meanwhile, ETAs are widely reported to modify the vertical gap between different metamaterial layers, as shown in Figure 2c,d [60,61]. In such designs, strong coupling resonances are induced between vertical layers. Thus, the vertical displacement of ETA is exploited to control the electromagnetic properties of metamaterials.

Figure 2. ETA-based vertical tuning methods of metamaterials: (a) schematic of thermally tunable split-ring resonators (SRR) based on the pre-stressed metamaterial [58]; (b) optical microscopy image of the eSRR based on metamaterial microarray [59]; (c,d) schematic of MEMS-based tunable THz metamaterial and unit cell by using ETA vertical tuning platforms [60,61]; (e) scanning electron microscope (SEM) images of eSRR–WCM array and unit cell [62].

While the external heating process is incompatible with CMOS-based devices, the voltage-controllable ETA tuning methods are desired to improve integration. Thus, resistance heat is exploited to increase the temperature of ETA. By applying voltage on the ETA-based metamaterial, a large amount of resistance heat can be induced by current flow to directly control the deformed height of ETA. Moreover, such voltage-controllable methods are reconfigurable. Figure 2e shows a winding-shaped cantilever metamaterial (WCM) array integrated with eSRR under a pre-deformed state [62]. The metamaterial layer is tailored to conduct the resistance heat—which can be induced—and the deformed height of ETA and then actively become tuned by applying a DC voltage. By modifying the driving voltage, the propagation of EM waves can be manually controlled to achieve electric-optical modulation. Such an ETA-based vertical tuning method provides a cost-effective platform to design metamaterials with a large tuning range.

2.1.2. Horizontal Tuning Methods

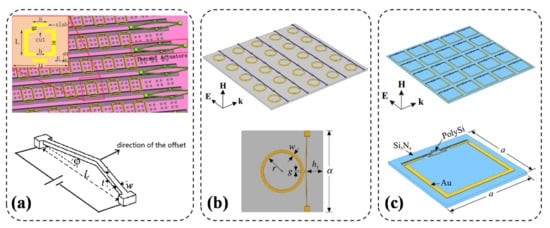

ETAs can further provide horizontal displacement for tunable metamaterial by using a chevron beam and a hot-cold arm. The chevron beam ETA is a typical design in MEMS actuators. By applying a voltage on the ends of ETAs to increase the temperature, the center shuttle of actuators can be moved due to the thermal expansion on both sides of the chevron beams. Figure 3a indicates a tunable metamaterial based on a two-cut SRR unit cell and the tuning mechanism [63]. While the center shuttle of the chevron beam actuator generates a displacement, the slabs move towards the cuts of the two-cut SRR, which achieves a continuous tuning method for the metamaterial by changing the gap between slabs and SRR. A reconfigurable THz metamaterial is obtained from the embedment of a chevron beam ETA as shown in Figure 3b [64]. By applying the appropriate actuation voltage on ETAs, the enhanced bandwidth tunability at two different resonances can be accomplished.

The cold-hot-arm based ETAs can achieve the increment of power consumption efficiency and larger curvature compared with the design of chevron beam ETA. In this method, by applying an external voltage, the electric current flows along the hot arms to generate resistive heating and thermal expansion. While the cold arms are not connected to the electric flowing loop and remain at low temperature, a large deflection can be induced owing to the thermal expansion difference between hot and cold arms. Figure 3c shows a tunable metamaterial based on the combination of two-hot-arm ETAs with an SRR [65]. The tuning methods provide the mu-negative behavior via a low voltage. These results prove that the horizontal ETA is a promising method for tunable metamaterial to be used in low voltage applications.

2.2. ESA-Based Metamaterial

2.2.1. Vertical Tuning Methods

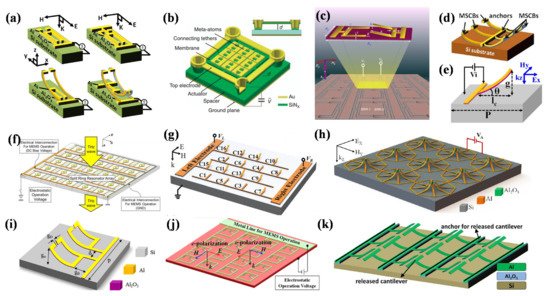

ESA is a commercial and mature MEMS actuating method, which induces an electrostatic motion by driving an electrical input. To enable the vertical displacement, the electrical potential difference is usually induced between different conductive layers, i.e., a metallic layer and a semiconductor substrate. Figure 4a shows a tunable THz filter based on a DSRR structure released from a silicon substrate [66]. By applying different DC bias voltages between metallic SRR layers and silicon substrates, the bending degree of micro-cantilever can be continuously changed to realize a large frequency tuning range and high quality (Q)-factor. Meanwhile, the released SRR cantilevers will be snapped down to silicon substrate with the DC bias higher than the pull-in voltage. Liu et al. designed and experimentally demonstrated ultrathin tunable THz absorbers based on MEMS-based metamaterial, as shown in Figure 4b [67]. These were composed of a metallic ground plane, a silicon nitride spacer, and a matrix of meta-atoms from bottom to top. The metamaterial membranes were suspended above the silicon nitride layer by a distance, which was adjustable with different driving electrostatic forces. By applying a voltage, the absolute absorption modulation range measured at the initial resonance could reach 65%. In Figure 4c, a MEMS-based metasurface is demonstrated for active control of the Fano-resonances [68]. Two SRRs can be independently and sequentially actuated by applying the voltages. With multiple inputs and outputs to represent on and off digital states, such designs are suitable for logic operations at the THz frequencies. Several planar arrays of eSRR with movable stress curved beams are proposed as shown in Figure 4d,e, which are actuated out-of-plane by electrostatic force [69,70]. Figure 4f shows a tunable THz filter and a modulator based on ESA-metamaterial [71]. A radio frequency-MEMS (RF-MEMS) capacitor is embedded in the center of each SRR unit cell to tune the electromagnetic resonant frequency, while the modulation speed can reach 2 kHz. Figure 4g indicates an active MEMS metamaterial for the THz bandwidth control, which consists of an array of sixteen cantilever resonators with gradually varying release lengths [72]. By electrostatically controlling the out-of-plane height of the released micro-cantilever-based resonators, the full width half maximum (FWHM) resonance bandwidth of the MEMS metamaterial can be actively switched to 90 GHz. With a supercell composed of several cantilevers, the switching range can be further improved, as shown in Figure 4h [73]. Each metamaterial unit cell consists of eight cantilevers placed at the corner of an octagon ring to achieve a large tuning range of 0.37 THz. Figure 4i shows a structurally reconfigurable metamaterial for active switching of near-field coupling in conductively coupled, orthogonally twisted SRRs [74]. SRRs structures are precisely tailored to excite the classical analogue of electromagnetically induced transparency (EIT) by the strong conductive coupling. In Figure 4j,k, the ESA-based tunable THz metamaterials using three-dimensional eSRR arrays are proposed to realize polarization-sensitivity and flow tuning capability, respectively [75,76]. It can be clearly observed that the ESA-based vertical tuning method provides a mature platform for metamaterial and opens an avenue for more potential applications, such as logic operation, EM wave modulation, flowing sensing, and so on [77,78,79].

Figure 4. ESA-based vertical tuning methods of metamaterial: (a) schematic of DSRR with single-side and double-side ESA structure under unreleased and released state, respectively [66]; (b) schematic of the unit cell of the THz absorber [67]—the vertical distance between the meta-atoms and the ground plane can be tuned electrostatically; (c) colored SEM image of the MEMS Fano metasurface [68]—the periodic unit cell comprises of two SRRs; (d) schematic of electric split-ring resonators with movable stress-curved beams (eSRR-MSCBs) after microstructures are released [69]; (e) schematic of an upward bent microcantilever as metamaterial unit cell [70]; (f) MEMS reconfigurable SRR design array of the unit cell [71]; (g) schematics of a bandwidth tunable MEMS metamaterial supercell formed by a 4 × 4 array of microcantilever resonators with varying fixed and released lengths [72]; (h) schematics of the proposed uniaxially isotropic MEMS metamaterial with eight released cantilevers in an octagon ring [73]; (i) schematics of the conductively coupled MEMS metamaterial [74]; (j) schematics of the chained eSRR array with a metal line connecting the eSRRs for MEMS operation [75]; (k) schematic of the mirrorlike T-shape metamaterial (MTM) device after release [76].

2.2.2. Horizontal Tuning Methods

Comb driver is a typical design of ESA that is suitable to horizontally modify the geometry of metamaterial. Comb drivers are composed of fixed combs and movable combs. By applying a voltage potential difference on combs, an electrostatic force can be generated to drive a movable comb to approach a fixed comb. Moreover, the comb driver can suitably provide a tunable platform for the whole metamaterial array to achieve better uniformity of deformation in each unit cell. Figure 5a shows reconfigurable asymmetric split-ring resonators (ASRRs) metamaterial [80]. Two identical electrostatic comb-drive actuators are employed on both sides for a mechanically balanced translation of the supporting frame, which can realize a horizontal displacement of 20 μm. Similarly, switchable ESA-based metamaterials are demonstrated by using fixed SRR and moveable SRR as shown in Figure 5b,c [81,82]. By reshaping the micromachined metamaterial unit cells, the surface resonance of the metamaterial is manually controlled. Figure 5d indicates a tunable metamaterial consisting of two SRR array layers [83]. The top SRR layer is on a movable silicon frame that can be actuated by a comb-drive actuator while the bottom SRR layer is fixed on a SiNx thin-film. By applying voltage on the comb driver, a continuous lateral shifting between the coupled resonators can be induced to 20 μm. A MEMS integrated device is proposed by using EIT metamaterial, as shown in Figure 5e [84]. The comb driver design is composed of a fixed beam and a movable beam based on a silicon on insulator (SOI) wafer. In Figure 5f, a reconfigurable metasurface is proposed to achieve both the polarization conversion and the polarization rotation in the THz frequency range by using the comb driver [85]. In the IR wavelength range, ESA-based metamaterials are also reported to realize active modulation of the polarization state, as shown in Figure 5g [86]. In Figure 5h–j, Xu et al. propose several SRR patterns integrated with the comb driver platform to be operated at different frequencies, which can be applied in many fields, such as tunable filters, frequency-selective detectors, polarization switches, high-efficient environmental sensors, and more [87,88,89]. From these literature reports, the ESA-based platform shows great applicability for the horizontal tunable metamaterial. The comb driver provides more mature tuning methods compared with other MEMS tuning mechanisms. The geometry of integrated metamaterial is rapidly reduced, which means the MEMS-based metamaterial can be gradually operated from THz and IR, as well as visible spectra [90].

Figure 5. ESA-based horizontal tuning methods of metamaterial: (a) SEM images of the reconfigurable ASRRs metamaterial [80]; (b) schematic of the switchable magnetic metamaterial consisting of two semi-square split rings separated by a gap [81]; (c) schematics of the micromachined metamaterial with the element consisting of a two-cut SRR and two free-hanging slabs [82]; (d) schematic of the tunable metamaterials, including broadside-coupled SRRs (BC-SRRs) [83]; (e) schematic of the MEMS integrated device—unit cell of the EIT metamaterial consists of a cut wire and a wire pair [84]; (f) schematics of the tunable metasurface for the polarization conversion and the polarization rotation [85]; (g) schematics of polarization-sensitive IR metamaterials (PSIMs) [86]; (h–j) schematic of a tuning eSRR array by using comb drive horizontal tuning platforms [87,88,89].

2.3. EMA-Based Metamaterial

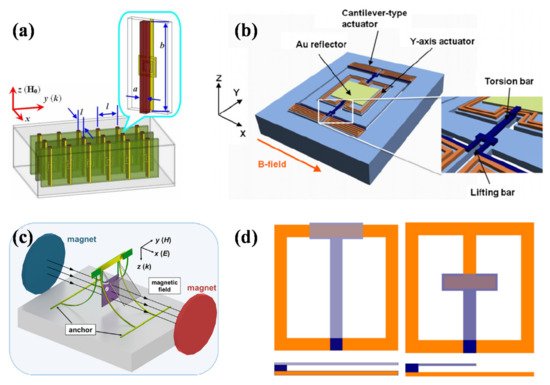

A change in the external magnetic field can cause a motion in EMA, which is composed of magnetic materials. Figure 6a shows a Ferrite-based magnetically tunable left-handed metamaterial by introducing yttrium iron garnet rods into SRRs/wires periodic array [91]. Thus, by using external DC applied magnetic fields, the left-handed passband of the metamaterial can be continuously and reversibly adjusted. Figure 6b indicates a low-voltage three-axis EMA-based micro-mirror to support optical devices [92]. The frame is connected to the robust torsion bar and lifting bar structure formed by bulk silicon to perform greater operating stability. A flexible and controllable metadevice is proposed by using self-assembly MEMS-based ESA, as shown in Figure 6c [51]. While the center metamaterial plate is released by the supporting arm, it can be actuated and rotated by a magnetic force to manipulate the incident electromagnetic response by driving the external electromagnetic field. Figure 6d shows a tunable THz metamaterial employing magnetically actuated cantilevers [93]. By coating a magnetic material on the cantilever surface, the released eSRR array can be actuated and the resonant frequency of the structures can be modified. These results indicate that the large displacement and rotation angle of EMA tuning methods provide a great possibility for metamaterial to receive light from a wide incident angle, which can greatly improve the sensitivity of metamaterial.

Figure 6. EMA-based tuning methods of metamaterial: (a) schematic of the magnetically tunable left-handed metamaterial (LHM) composed of SRRs/wires array and introducing yttrium iron garnet (YIG) rods in rectangular waveguide [91]; (b) schematic of the three-axis EMA-based micromirror for fine alignment among optical devices [92]; (c) schematic of active out-of-plane metadevice by driving a magnetic field [51]; (d) schematics of an eSRR modified to incorporate a parallel plate capacitor with a flexing cantilever [93].

2.4. Flexible Substrate-Based Metamaterial

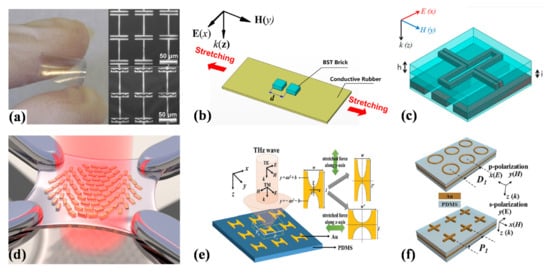

In addition to the conventional MEMS actuating mechanisms, the tuning optical characteristic of metamaterial can be realized by using stretchable and flexible substrates, such as PDMS, polyimide, and polyethylene terephthalate (PET) [94,95,96]. It is a simpler mechanical method to provide a large tuning range of resonant frequency. Figure 7a shows a THz metamaterial comprising a planar array of I-shaped resonators on a highly elastic PDMS substrate [97]. While such resonators are sensitive to mechanical stretching, the stretching range of metamaterial is over 8% to keep good repeatability over several stretching–relaxing cycles. Zhang et al. demonstrated a mechanically stretchable and tunable metamaterial absorber composed of a dielectric resonator stacked on a conductive rubber, illustrated in Figure 7b [98]. By applying different stretching strains to change the elementary cells’ periodicity, the operation frequency of the metamaterial absorber is blue-shifted in the microwave spectrum range. A three-layered stretchable metamaterial absorber by using liquid metal and PDMS is proposed in Figure 7c [99]. The resonant frequency of the device can be increased from 18.50 GHz to 18.65 GHz, with a stretching length of 1.2 cm, which is suitable to be used as a wireless strain sensor. Figure 7d shows a plasmonic antenna-based metasurface on the stretched PDMS [100]. By precisely positioning the Au nanorods, the optical phase is varied over the individual component by a certain amount. Furthermore, the position-dependent phase discontinuity can be further tuned by stretching the metamaterial geometry for reconfigurable flat optics application. Figure 7e indicates a stretchable THz parabolic-shaped metamaterial (PSM) to perform logic operations [49]. By stretching the PSM width and length, single-/dual-band switching and polarization switching characteristics can be realized for programmable metamaterials. A tunable perfect absorber with a ring-shaped (PA-RS) and a cross-shaped (PA-CS) on PDMS substrate is proposed in Figure 7f [101]. Stretching devices into different directions allows them to exhibit ultra-narrowband, polarization-dependent/independent, and switchable characterizations in the IR wavelength range. The typical advantages of such flexible substrate-based metamaterials are their flexibility and cost-effectiveness, which makes them potentially useful in wearable devices and a variety of sensor fields [102,103].

Figure 7. Flexible substrate-based metamaterial: (a) photograph and optical micrograph of I-shaped flexible metamaterial design [97]; (b) schematic of stretchable dielectric metamaterial absorber [98]; (c) schematics of stretchable metamaterial absorber by using liquid metal as the conductor and PDMS as the substrate [99]; (d) schematic of a gold nano-rod metasurface array on stretched PDMS [100]; (e) schematic of the PSM device operated by applying a stretching force along the x- and y-axis directions [49]; (f) schematics of stretchable perfect absorber with ring-shaped (PA-RS) and cross-shaped (PA-CS) structures [101].

This entry is adapted from the peer-reviewed paper 10.3390/electronics11020243

This entry is offline, you can click here to edit this entry!