2.1. Accumulation of Plastic Waste in the Environment

Research and development related to synthetic polymers has largely focused on their useful properties and applications [

213]. These inherent advantages of plastic materials are converted into their most serious disadvantages when they become waste; for example, they do not oxidize like metals or degrade chemically like cellulose- and protein-based materials. Another factor is related to contamination in water bodies; the density of these residues can be close to that of water and for this reason, plastic waste floats near the surface of the water where fish and the rest of aquatic life are [

214]. As a result, post-consumer plastic waste disposal has led to plastic pollution in landfills and waterbodies and now represents a global environmental challenge [

213]. The excessive use of disposable products has led to an exponential increase in the amount of plastic waste from land and sea activities, resulting in considerable economic, environmental and social problems [

210,

211].

The non-biodegradability and poor management of plastic waste can cause several environmental risks regarding the safety and clogging of sewage in urban cities and other production areas [

19]. In addition to the contamination caused by plastic waste in the environment, climate-induced degradation is also a problem. Plastic waste can heat up to 40 °C on beaches, which further accelerates wear and degradation by sunlight, potentially causing the formation, for example, of microplastics. Literature often classifies plastic waste present in water bodies by size. The most common classification is microplastics, mesoplastics and macroplastics, but their size ranges are not uniform, as explained by Ronkay et al. (2021) [

215] and by Shah et al. (2015) [

216]. The ingestion of plastics by aquatic organisms is an emerging environmental crisis due to the spread of these contaminants in water bodies [

217,

218,

219]. These plastic residues, when ingested, can cause physical obstruction of their digestive systems [

220]. Therefore, the overall potential impact of microplastic pollution on aquatic systems can have serious consequences [

219,

221].

Pollution from plastic waste is an emerging global environmental problem [

222]. These wastes have drawn a lot of attention due to their increasing numbers in the global economy, their low material recovery rates and the environmental impact associated with current disposal methods. Pillai (2021) [

223], in his recent study, presented important information, such as a report by the United Nations Environment Program (UNEP) showing that around 400 million tons of single-use plastic waste is produced annually (47% of total waste plastic) and estimating that only around 9% of this plastic waste is being recycled worldwide. The numbers are worrying, and the efforts currently being made by several economies are very timid compared to the desired goals [

223]. Due to inadequate waste management practices, plastic waste disposed of arbitrarily generates serious environmental pollution [

224,

225]. Strengthening waste management practices (segregated waste collection and waste processing through material recovery facilities in cities) can help put plastic waste back into the circular economy cycle [

211]. While each country is responsible for developing unique waste management initiatives, cleaning up our planet is, in fact, a collaborative effort. It is vital that nations inspire each other and adopt contemporary, innovative, and sustainable practices that help solve the growing problem of plastic waste around us [

223].

Recycling refers to the waste management method that collects waste and transforms it into raw materials that can be reused for the manufacture of other valuable products that are suitable for use in the production of new products applied in different sectors [

226]. It is also known as “renew or reuse” to prevent harmful effects on society and the protection of the environment [

226]. The conversion and/or recycling of plastic waste encompasses any method where plastic waste is transformed rather than discarded. [

227,

228]. Plastics have inherent properties to be reused, and this is attributed to the quality of the recovered waste fraction. Common plastic wastes primarily include polyethylene (PE), polystyrene (PS), polyvinyl chloride (PVC), polyethylene terephthalate (PET), high-density PE (HDPE) and polypropylene (PP), and it is estimated that over 60% of plastic waste urban solids are composed of polyolefins, mainly low-density PE (LDPE), linear LDPE, HDPE, and PP [

229]. Plastic waste from these polymers has complex mixtures of additives to configure specific properties in the final material, including, for example, thermal stabilizers, lubricating pigments, heat and light stabilizers, antioxidants, flame retardants and plasticizers [

230,

231]. The literature has reported that some of these additives have characteristics of endocrine-disrupting chemicals (EDCs), such as bisphenol A (BPA) and diethylhexyl phthalate (DEHP) [

231], and these and other additives were classified as persistent contaminants [

231]. As the content of additives in different waste products with different purposes can vary greatly, the chemical composition of recycled plastic is often unknown [

232], which causes concern about the inappropriate disposal of this plastic waste into the environment, and the high degree of contamination, mainly in water bodies, with contaminants that are normally difficult to remove in conventional treatments.

Despite the significant development of various technologies to deal with plastic waste and its conversion into molecules of industrial interest or the manufacture of new value-added materials in different sectors, this conversion remains a challenge [

233]. The reuse of plastic as an aggregate in the manufacture of new materials can contribute to the elimination of this waste and help protect the environment and achieve sustainable development [

234,

235]. These new materials can be obtained through different processes, and each process depends on the characteristics and destination of plastic waste. Recently, a study presented by Zhao et al. (2022) [

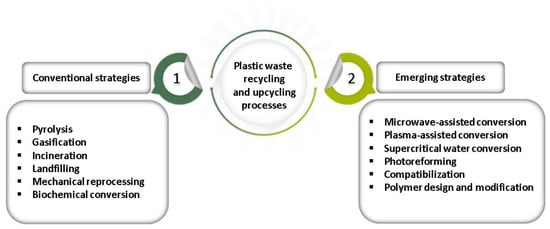

228] showed different recycling routes for plastic waste. Different processes have already been investigated according to each destination, as they need to be applied to specific plastic waste due to their advantages and disadvantages, as shown in

Figure 2. To understand the processes used to transform plastic waste into valuable products to pursue sustainable development, it is essential to understand the different plastics, the waste management chain, and the distribution components. This is essential to understand the nature of the problem and perform the best measures to reduce plastic waste improperly dumped into the environment [

231].

Figure 2. Plastic waste conversion strategies. A comparison of conventional and innovative strategies for converting plastic waste. Reprinted with permission from ref. [

228]. Copyright 2022 Elsevier.

Importantly, the use of evolving innovative technologies and practices can increase the efficiency of supply chains as well as organizations, while reducing environmental degradation through its economic flourishing. Resource recovery leads to the evolution of new value-added materials from plastic waste [

226,

236]. While recycling has different benefits for the community, it also has some disadvantages that should be emphasized and discussed. During the recycling process, chemicals may be released into the environment. Among these chemicals, some are volatile gases from plastic waste compositions and organic chains of monomers that can be harmful to plant structure and affect wildlife when inhaled by different animals that live near the recycling zone. That said, this emphasizes the importance of management and care [

226,

236].

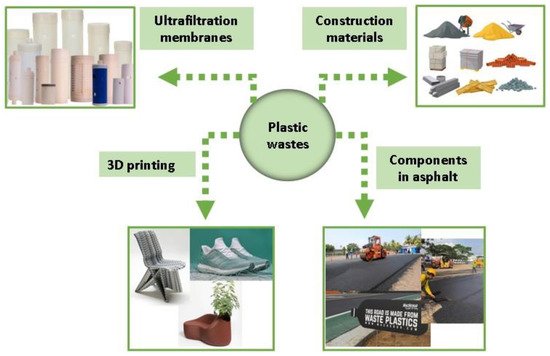

The use of plastic waste as a starting source to produce value-added products and/or materials has been proposed as the necessary impetus to increase the attractiveness of plastic recycling [

237]. When plastic waste is transformed into these new products, there are many essential factors that need to be considered, as the addition of plastic waste can affect the performance of the composite materials produced [

238]. In particular, the scientific community has focused on suggesting alternatives for the inclusion of plastic waste in various sectors, such as construction materials [

238,

239,

240,

241,

242], ultrafiltration membranes for water treatment [

243,

244,

245], 3D printing [

246,

247,

248,

249], components in asphalt [

250,

251,

252,

253], wall-paper [

254], and the agricultural sector [

255], among others, as shown in

Figure 3. Plastic waste can also be recycled and used to make composite materials. A composite is a material of superior quality resulting from the combination of two or more other components, whose properties are not separately satisfactory for a specific purpose [

256].

Figure 3. Possibilities of applying plastic waste towards products of added value and industrial interest.

In this context, the incorporation of plastic waste in matrices of certain materials can improve mechanical properties in addition to improving other properties. In this sense, several successful attempts to obtain composites from plastic waste are already reported in the literature [

257,

258], some of which will be discussed in the following topic.

Circular economy (CE) has a significant sustainability potential [

259]. CE, whether considered as a concept or an industrial system, has gained interest among practitioners, politicians, and scholars alike [

260]. The circular economy of plastics is a possibility for the executed linear system, where plastic is obtained, applied, and discarded. CE’s objective is to maximize the amount of plastic that is reused or recycled back into the system [

261], and it was created from the concept that we can create sustainable human systems, mimicking the sustainable processes of nature. The principles of circular economy are based on abandoning the idea of products and materials ever becoming waste and instead, the circular economy concept envisions “an economic system that replaces the ‘end-of-life’ concept with reducing, alternatively reusing, recycling and recovering materials in production/distribution and consumption processes. It operates at the micro level, meso level and macro level, with the aim to accomplish sustainable development, thus simultaneously creating environmental quality, economic prosperity and social equity, to the benefit of current and future generations. It is enabled by novel business models and responsible consumers” [

262,

263,

264].

2.2. Polymeric Composites for Waste Recovery

The recycling of plastic waste represents not only an opportunity to update waste management practices, but also a path to sustainable economic development through revaluation [

265]. Composite materials can be defined as a combination of at least two different materials that are combined to obtain a third material with mechanical properties superior to the properties of its individual components [

266]. The recovery of waste and its application in obtaining composites for different applications has been increasingly investigated, with significant results and applications in different areas.

PET is one of the most-recycled polymers in the world and has about 22% recycling fraction in its current supply [

267,

268]. Its properties, uses and industrial innovations that increase the demand of its consumers result in the generation of tons of waste discarded into the environment [

269]. Taking into account two serious problems for the environment, namely the high amount of air pollutants from anthropogenic activities and plastic waste discarded in the environment, where almost 40% is polyethylene terephthalate (PET), recently, Kakoria et al. (2021) [

270] sought to bridge the gap between plastic waste and personal protection using discarded PET bottles as a reference material, and developed PET-based nanostructured composites for the fabrication of membranes for air filters and/or face masks. The authors showed that ultra-fine PET nanofibers were successfully manufactured from plastic bottles for application as face masks or air filters [

270]. The use of PET waste in adequate proportions to obtain composites can improve some properties [

271]. Recently, Aydogmus et al. [

272], produced a biocomposite reinforced with polyethylene terephthalate waste, and it was observed that the behavior of the biocomposite at high temperatures improved with increasing PET waste content. The use of PET waste presents an environmentally correct and economical solution [

272].

Concern about plastics is also heightened when it comes to polypropylene, which is one of the least-recycled plastics, with a recycling rate of just 0.6%, according to a report by the Environment Protection Authority (EPA-USA) [

273], representing a serious environmental concern. Recently, Pasternak et al. (2021) [

274] used polypropylene waste to obtain composites and manufacture ceramic membranes applied in microbial fuel cells (MFCs). It is important to mention that this study is a pioneer of using polymeric residues for this purpose. According to Pasternak et al., polypropylene waste has increased the useful life of ceramic MFCs, mainly suggesting strong antifouling effects, using a sustainable approach where, at the same time, problematic plastic waste is being recycled. Furthermore, according to the authors, what promotes these properties is the interaction of the interface between the ceramic and polymer layers where they can play an important role in establishing the proper morphology of the polymer coating to facilitate the transfer of protons and inhibit biofouling [

274]. Polypropylene waste has also been used in other applications, for example, in the search to produce composites to obtain panels that can be used as commercial support materials, as presented by Sezgin et al. (2021) [

275]. In this study, the authors recycled plastic bottle lids of polypropylene and polyethylene, which are generally used in food and cleaning containers, to become matrix material to produce composites and panels. These panels were investigated in terms of air permeability and thermal and acoustic insulation behavior. The results indicate that the developed panels are applicable as commercial support materials and offer improved thermal and acoustic insulation properties [

275]. In the civil construction sector, polypropylene waste and polyethylene waste were investigated in the production of composites for obtaining polyester-based polymeric mortars by Martínez-López et al. (2021) [

276], and the results indicated that there was a significant improvement of 82% in flexural deformation in the presence of polypropylene residue. They also observed a 30% improvement in compressive deformation with polyethylene waste and a 27% improvement in compressive strength with polypropylene waste [

276].

Lin et al. (2020) [

277] investigated the recovery of acrylonitrile butadiene styrene (ABS) residues to obtain laminar mortar-polymer composites for applications in the civil construction sector, specifically in 3D printing. Polymer reinforcement allowed the mortar-containing residual materials to maintain high ductility [

277]. The study by Li et al., in addition to other investigations, provides alternatives for reusing ABS waste to manufacture high value-added products, which represents a promising way of recycling waste and mitigating environmental problems with inadequate disposal [

277,

278]. Zulkernain et al. (2021) [

279] also investigated the use of plastic waste applied in the civil construction sector. The authors investigated the use of plastic as an aggregate in terms of physical, mechanical and durability properties of construction materials, as well as environmental and cost analysis. According to the study, it was observed that the mechanical and durability properties of the materials produced were changed after the addition of plastic as an aggregate, but the materials met the requirements of construction materials.

Polyvinyl chloride (PVC) is one of the most-used thermoplastic materials in relation to the worldwide consumption of polymers [

280]. As a result of the increased consumption of PVC products in recent years, the amount of used PVC items entering the waste stream has increased gradually [

281]. Processes such as incineration and the disposal of PVC waste in landfills typically release hazardous compounds such as polychlorinated dibenzo-p-dioxins (PCDD) and dibenzofurans (PCDF) [

282]. Therefore, seeking alternative processes for the environmentally correct disposal of this waste is necessary. PVC waste has been extensively investigated in composite fabrication application for filtration and ultrafiltration membranes [

283,

284,

285]. PVC waste was investigated by Aji et al. (2020) [

286] to obtain ultrafiltration membranes. PVC waste was blended with cellulose acetate to overcome the hydrophobic nature of PVC in membrane manufacturing. The results showed that the hydrophilicity of the prepared membranes was increased to about 25%. Thermal stability was improved in membranes blended with PVC. These results provided the insight that PVC waste can be used to manufacture ultrafiltration membranes [

286].

Polystyrene (PS), as one of the top five most-consumed plastics, has been widely applied in the electronics, construction, transportation, packaging and other daily supply industries. Due to its wide ranges of production and use, a large amount of polystyrene waste is dumped into the environment every year, especially into the marine environment, severely threatening the global biosphere [

287]. However, research has shown satisfactory results in the disposal of polystyrene waste for various applications, for example in the use of these materials as an adsorbent in environmental remediation. Mehmandost et al. (2019) [

235] manufactured a composite from polystyrene and cotton waste, and the material obtained allowed the removal of oil and polycyclic aromatic hydrocarbons (PAHs) from the water. The polystyrene residues investigated by the authors came from yogurt packaging. The composite showed significant potential for the removal of fluorene, anthracene, fluoranthene and pyrene. An important observation in this study is that despite the conversion of polystyrene waste into a useful destination material for the quality of environmental systems, chloroform is used during its synthesis, and the risk associated with any leakage must be considered; this observation is also reported by the authors [

235]. Recently, Gao et al. (2022) [

288] showed that polystyrene residue can be reused to obtain composites with flame retardant properties and has potential for obtaining electromagnetic interference (EMI) protection materials. The authors noted that the segregated structure can influence the formation of a compact conductive network to improve electromagnetic shielding properties [

288]. Polystyrene residue was also investigated in composites for applications in the civil construction sector [

289,

290,

291,

292,

293], as well as in other sectors [

294,

295,

296,

297], and demonstrated viability and improvement of the resulting material for the recovery of residues that are inserted into the environment, in most cases, inappropriately.

The real possibility of manufacturing the described materials from plastic waste is related to the peculiarity of plastics as materials to produce various basic products, especially the fact that they preserve some properties even after being discarded and classified as waste [

298]. Through the aforementioned investigations, many advantages of these new composites generated from polymeric waste can be observed, such as obtaining value-added products, which can be applied in various sectors [

289]. It is important to mention that, here, we focus on the approach of composites filled with metallic nanoparticles and nanostructured oxides; however, composites from plastic waste mixed with other filling materials are also reported, such as layered silicates [

4], graphene [

238], and POSS [

256]. It is worth mentioning that, in addition to the applications mentioned above for the destination of polymeric waste, these wastes have also been investigated as catalytic supports, ensuring quality in environmental systems. This investigative line has been the focus of many researchers in recent years, and some of the studies will be addressed in the next topic.

2.3. Catalysis Opportunities: Supports for Heterogeneous Catalysts

Homogeneous and heterogeneous catalysis plays an important role in industrially important organic transformations that produce some significant chemicals used in the petrochemical, pharmaceutical and fine chemical industries [

299]. While homogeneous catalysts offer many advantages like high reaction rates, easy accessibility of active sites, and minimal diffusion barriers, separation from the reaction mixture is a tedious task, and, in some cases, it is a challenging process [

300]. Heterogeneous catalysis is preferably used in industrial applications because of its easy separation, which usually results in lower operating costs [

301]. Heterogeneous catalysis and solid catalysts play an essential role in the field of chemical engineering, renewable energy and batteries [

302], but one of the challenges is to obtain catalytic systems that can be recovered and reused in subsequent reaction cycles, thus minimizing costs, and also obtaining materials with a high surface area. Since catalysis takes place on the surface of nanocatalyst particles, catalysts are prepared in order to expose a large area of metal, and supports for solid catalysts contribute strongly to that end. Plastic waste is considered a technically viable material for use as catalytic supports since it is used in large quantities and at a low cost. Supported catalysts are in high demand because their mesoporous supports expose metal active centers, favoring catalytic action to destroy and/or produce desirable products [

216,

303,

304]. Nanocatalyst-support interactions in these materials can have a substantial influence on catalysis, making nanocatalyst-support interaction modulation one of the few tools able to enhance catalytic performance [

305]. Further on, some investigations on polymeric supports for catalysts that stood out in the last five years will be discussed.

Water contamination with nitrates is prevalent worldwide, and it was with this concern that Sandhu et al. (2020) [

306] investigated efficient photocatalytic systems for denitrification. For this, the synthesis of TiO

2 nanoparticles immobilized on polystyrene (PS-TiO

2) was investigated. According to the authors, the fluctuating nature of the catalysts allowed their easy recovery, with 98% catalyst recovery rates after 5 cycles of denitrification experiments [

306]. The idea of immobilizing the photocatalyst on a floating support can support minimizing photocatalyst recovery and powder filtration problems, offering greater adaptability in using the supported photocatalyst for scale-up structures [

306,

307]. In addition to the concern with nitrate-contaminated water, as discussed above, phosphorus has been causing emerging concern in water bodies. Phosphorus is an essential nutrient for all living beings; however, excess phosphorus is the limiting factor for eutrophication [

308,

309]. One of the main sources of phosphorus pollution is the discharge of wastewater [

308,

309]. Therefore, recently, Zhao et al. (2021) [

308] manufactured a polystyrene-based composite (host) to support nanostructured ZrO, and the resulting material was applied to remove phosphate by adsorption. The results showed that the polymeric host facilitated the formation and dispersion of nanoparticles with smaller sizes compared to another investigated composite (with macroporous anion exchanger), exposing a greater amount of highly accessible surface hydroxyl groups to phosphate. In fact, the embedded nanoparticles increased the porosity and affinity of phosphate with the gel polymer. This relatively cheaper host (polystyrene) can be an alternative to the macroporous anion exchanger, providing a new strategy for the immobilization of functional nanoparticles for phosphate mitigation in water [

308]. Patel and Vasava (2020) [

310] presented an interesting discussion between the combination of support from polystyrene for metallic nanoparticles and the observed better responses of catalytic systems [

310].

In addition to investigations using polystyrene, other polymers have also been studied in the manufacture of supports for catalysts, as demonstrated by Sandoval, et al. (2017) [

311], who in addition to polystyrene residues also used polyethylene terephthalate residues (PET) as supports for TiO

2 and ZnO. The materials were applied as photocatalysts for the degradation of two commonly used azo dyes: Acid Brown 83 (AB83) and Direct Blue 1 (DB1). According to the authors’ observations, no statistically significant differences were found between the use of PET and PS as substrates in the degradation rate constants for both dyes; however, the adsorption of both dyes was greater in TiO

2 than in ZnO. The complete photocatalytic degradation of AB83 and DB1, being TiO

2- and ZnO-supported on PS and PET, did not exceed 50 reaction minutes. Considering that both PET and PS are generally discarded materials after their primary use, the recovery of these materials for water treatment purposes is an attractive alternative [

311].

Important results were also presented by Mossmann et al. (2019) [

312], who synthesized zero-valent iron catalysts (ZVI/Fe°) supported on low density polyethylene (LDPE), resulting in a floating composite which was applied in the photo-Fenton process for the treatment of a synthetic effluent containing Ponceau 4R, a dye widely used in food industries, but which has high solubility in water and significantly affects aquatic photosynthetic activity due to reduced light penetration [

313]. Furthermore, according to Mossmann et al., the resulting material showed satisfactory catalytic activity, reaching total discoloration of the Ponceau 4R dye after 15 min of reaction. In addition, the floating catalyst exhibited other advantages, such as easy separation from the aqueous solution, good stability, and recyclability [

312].

Polyvinyl chloride (PVC) is an important polymer in industry and society, and in investigations presented by Linda et al. (2016) [

314], the authors evaluated the fabrication of a composite (cellulose/PVC) to immobilize nanostructured ZnO which was to be applied in the ultraviolet light-assisted photodegradation of Congo red and crystal violet dyes. According to reaction observations, almost 90% of the dyes were degraded after 120 min. The results indicated that the presence of cellulose improved surface and structural properties, increased the affinity of the composite with the reaction medium, and increased the photocatalytic efficiency when compared to PVC/ZnO. Given the above, the ZnO photocatalyst supported on polymer composite can be considered promising for the photodegradation of organic dyes [

314].

The notable advantage of such supports from plastic waste for catalysts lies in their conversion, reuse, their low price, and the possibility of their use in important procedures for the quality of environmental systems [

315]. Catalyst reuse is as important as catalytic activity for the application of hazardous species degradation. As discussed in the examples mentioned above, using polymeric supports from waste to manufacture supports for nanostructured catalysts is an alternative that offers the possibility of developing catalysts with different benefits, such as increased surface area, and this helps in maximizing the use of the efficiency of the light, since there is the possibility of reaching a greater number of active sites, high degradation efficiency, easy post-treatment recovery and possibility for reuse over several cycles without significantly decreasing efficiency [

316,

317]. Porous supports are crucial to guarantee the uniform distribution of the metallic particles and to avoid the agglomeration of the catalyst particles. The surface, structural and electronic properties of catalysts supported on plastic waste can be adapted according to the requirements of the desired product and application as well. The methods of preparation of these materials directly influence these properties [

315].