Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Subjects:

Energy & Fuels

Energy has become the backbone of humanities daily activities. Heating, ventilating, and air conditioning systems (HVAC), which consume around 39% of energy in the residential sector, have turned into an essential constituent for providing fresh air, especially after COVD-19, not only in hospitals but also in any simple construction. Thus, decreasing this percentage or recovering part of the energy lost is an essential issue in today’s energy management scenarios.

- energy management

- heat recovery

- review

- HVAC

- heat exchanger

- classification

1. Introduction

Energy has always been an essential requirement for the existence of all living organisms, as it is essential for growth, movement, maintenance, and creating work. Nowadays, with the rise of technological evolution and the rapid development of applications that need work, the human lifestyle has become more and more energy-dependent, especially in developing urban cities [1]. For instance, India has witnessed a rapid increase in energy consumption of around 16 times during the last six decades [2]. The International Energy Agency (IEA) predicted that by 2050, global energy consumption will increase by 50% [3,4], and buildings will account for the largest source of emissions due to the rapid growth in industries. Likewise, the growing demand for energy is likely to be more intense in growing states due to the growth of new buildings [5].

Based on the first law of thermodynamics, rising energy demand, global warming, energy shortage, and the necessity of providing fresh air, particularly after COVID 19, makes reducing energy loss a significant challenge [6]. The reduction of energy loss leads to developing a new strategy that arranges the use of energy, and, most importantly, ensures that power, which would otherwise have been lost, is made use of and provides benefits [7]. This strategy is called recovering lost energy [8].

Energy management has been comprehensively studied for almost 40 years. Recently, it has emerged as one of the most challenging issues and popular research topics, where its importance is equal to that of finding a new source of energy [9]. This is because the percentage of lost energy sometimes surpasses 60% [10], and, in addition, 72% of all-inclusive primary energy consumption is wasted during energy conversion [11]. Thus, recovering part of this loss is very beneficial. Lately, in residential and commercial buildings, energy consumption has escalated firmly. The main reason for this was due to the HVAC systems in those buildings [12,13]. HVAC accounts for almost 50 to 82% of the energy, of which 40% of the world’s overall final energy is spent in buildings [14]. While in non-industrial buildings, HVAC is responsible for around 18–35% of the total energy consumption [15], in commercial buildings HVAC accounts for approximately 30% of energy consumption [16,17]. In some countries, like Sweden, HVAC is frequently used to reduce radon problems, which makes heat recovery a vital requirement to reduce energy consumption [18].

The high-energy consumption of HVAC contributes to Energy Management System (EMS) becoming a fundamental issue for improving efficiency and providing significant energy savings in construction, particularly in relation to hospitals due to their utility for removing contaminated air [19]. Nowadays, EMS has become a primary concern in building projects, with many types of research completed on the BEMS (Building Energy Management System) over the last decade [20]. In addition, statistical results indicate that the effect of savings of BEMS raises from 11.39% to 16.22% yearly. This is due to the effort of continuous research which has led to improving this area [21]. Despite the improvements and high interest in research in BEMS, it has been estimated that 90% of HVAC systems do not operate optimally [21]. This demonstrates the necessity for developing systems to be more effective and, above all, for systems to operate at a lower cost in order to ensure their rapid spread [22].

2. Energy Recovery Systems

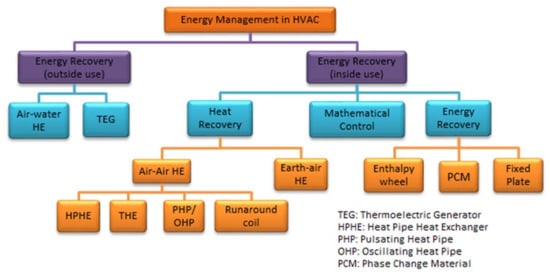

The chart, seen in Figure 5, divided energy management in HVAC into the following categories:

Figure 5. Energy management classified into categories.

-

Outside use, which means that the lost heat that is captured is used for external benefits. In other words, the saved energy is used for external systems, like generating electricity, in our case.

-

Inside use, which means air saved energy is used in the HVAC system that is equipped with the energy recovery device in order to improve the efficiency and heat/cool the supply. This section is divided into:

- i.

-

Heat Recovery: energy transferred in this case is just sensible heat; this energy can be transferred by different types of heat devices that will be discussed in detail in the upcoming sections.

- ii.

-

Mathematical Control which is related to the controlling and predicting system, such as a smart system, with which a positive impact on saving energy has been revealed.

- iii.

-

Energy Recovery or total energy recovery, which is described as total because it transfers both the latent and sensible heat; this advantage increases the efficiency and competency of the enthalpy devices in energy recovery.

2.1. Energy Recovery for Outside Use

In the following section, the saved energy is used for external systems, such as heating domestic water, or using the captured lost heat to generate electricity. This process shows remarkable results, as it is considered a free source of energy.

2.1.1. Air-Water HE

The concept of heating domestic water from the recovered lost heat is achieved by capturing the rejected heat from the condenser by using a heat exchanger, where the cold water is heated by the warm flow that is produced from the condenser. Table 2 summarizes the methodology and results of the main investigated papers that were related to energy recovery using an air-water heat exchanger.

Table 2. Summary of the investigated papers related to heating water for domestic use from the lost heat.

| Authors | Methodology | Result |

| Ramadan et al., 2015 [29] | Counter-flow concentric tube heat exchanger at the condenser is used. Hot air upcoming from the condenser warmth up the water inside the tube. | The outlet temperature of the water rises from 304 K to 347 K when the cooling load rises from 3.52 to 63.31 kW. |

| Stalin et al., 2012 [129] | One inlet and one outlet tank are used for water flow, a pump is used for circulating water from tank to the water-cooled condenser, and this procedure lasts until the desired temperature is reached. | 2.71 h are spent to raise the temperature of 350 L of water from 20 °C to 50 °C with a payback period of 6 months. |

| Lokapure et al., 2012 [130] | A refrigerant to water HE is placed between the compressor and the condenser. Water is propagated through one side of HE, and hot refrigerant gas from the compressor is transmitted over the other side. Heat is then transmitted from the hot refrigerant to the water. | Inlet water of 33 °C becomes 43 °C outlet water, the heat in the water is increased by 30.3%.The COP of the system is raised by 13.66% after using the HE with the air conditioner. |

From Table 2, it can be observed that the results obtained in the air-water HE system were considerable, and it is worthwhile heating domestic water from the lost heat. This system is efficient due to:

-

The high heat capacity of water which allows it to conduct heat at a rate which is about 25 times faster than air. Therefore, water is considered to be more efficient than air.

-

The increase of the outlet temperature of the water as the load increases. This indicates that applying air to the water heat exchanger in buildings that have a high use of HVAC is very efficient.

2.1.2. Thermoelectric Generator TEG

This system is also called a Seebeck generator. It is a solid-state device, which transforms the difference of temperature on its opposite sides into electricity following the phenomenon of the Seebeck effect. TEG is a considerable technology that recovers the lost heat in various applications [131]. Table 3 represents the methodology and results of the main investigated papers that were related to energy recovery using a Thermoelectric Generator TEG.

Table 3. Summary of the investigated papers related to generating electricity from the lost heat.

| Authors | Methodology | Result |

|---|---|---|

| Ramadan et al., 2017 [10] | Placing a flat plate TEG of 40 × 40 cm2 horizontally where the air of the condenser is considered the heat source and the exhaust airflow is used as a cooler. | At a load of 100 kW, TEG was able to generate 90 W of electrical power |

| Kumar et al., 2015 [132] | TEG in a vertical direction facing the condenser from a side and the outside air from another side. | 30% of waste heat is recovered by the condenser side. |

| Damanhuri et al., 2018 [133] | Six Peltier were arranged between Cu plates. 3 cases were monitor depended on the temperature difference of the cooling coil and condenser temperature. | A difference temperature of 9–10 °C and the load of 1.5 hp generated 1.61 V. |

| Trinidad et al., 2015 [134] | Experimental studies on a TEG array design were held to study the energy consumption of this device. The hot air and cold air entered a square channel with a wall separating them. The hot air entered the bottom section and the cold air entered the top section. The hot side had 1850W maximum capacity while the electrical loads ranged from 390 to 760 Ω. | Results show that the application of the electrical load has a high effect on the gradient temperature between the outlet and inlet of the hot air. On the other hand, the numerical analysis indicates that this system behaves differently compared to that of a conventional counter flow heat exchanger. |

As a conclusion drawn from Table 3, it is observed that:

-

TEG has low efficiency due to its design.

-

However, in some cases, it produces significant results due to higher gradient temperature.

-

When the temperature difference increases, the value of generating electricity increases.

-

TEG shows a positive effect in HVAC but some improvements should be made in order to increase its efficiency.

2.2. Energy Recovery for Inside Use

In this section, employing saved energy for internal use through previous published paper is discussed.

2.2.1. Heat Recovery

Air-Air HE

A method of capturing heat loss from hot air enclosures, the air-air HE is a type of system designed for exchanging heat. This, however, occurs in a passive way, whereby the design enhances the heat transfer. Table 4 shows the methodology and results of the papers that studied air-air energy recovery devices (HPHE, THE and PHP/OHP, Run around coil) [135].

Table 4. Summary of investigated papers related to air-air energy recovery devices.

| Authors | Methodology | Results | |

|---|---|---|---|

| HPHE | Yau et al., 2015 [136] | HPHE with 2, 4, 6, and 8 numbers of rows were tested. The coil face velocity was 2 m/s and the return air temperature was at 24 °C. The results of the HPHE were recorded for one week. | The results showed that a total amount of 2885 kWh can be saved yearly; this amount can be raised to 7023 kWh per year if eight-rows HPHX was used. The volumetric flow rate is increased, and a higher amount of energy recovery is expected as the face velocity is increased, but this results in a higher-pressure drop in the coil, which decreases the effectiveness. |

| Firouzfar et al., 2011 [137] | HPHE is placed in two streams of fresh air (32–40 °C) and return air (26 °C) in AC. Ratios of mass flow rates 1, 1.5, and 2.3 were tested to observe heat transfer and change in the temperature of fresh air. | The heat transfer and effectiveness rate of both the condenser and evaporator sections were raised to 48%. | |

| Sanaye et al., 2014 [138] | A HPHE, made from copper with water as working fluid and wick structure of 10 sheets of the 100-mesh bronze screen, is placed horizontally to recover heat from the exhaust air, in heating mode, and transfers it to the cold inlet fresh air; whereas, in cooling mode, it pre-cools the hot inlet fresh air. | The optimal point is with the effectiveness of 0.774 and a total cost of $1474, with a return period of about 2.5 years. | |

| Ahmadzadehtalatapeh, 2013 [139] | TRNSYS software was used to study the hourly influence of HPHE on HVAC. Eight-row HPHE was added with an average of 22.4 °C indoor temperature and 54.5% indoor air relative humidity (RH). | The results revealed that by reheating and pre-cooling, a total amount of 236.9 MWh energy could be saved yearly. This amount results in saving $24,572 annually. | |

| THE | Firouzfar et al., 2011 [137] | 3-row THE was investigated which consists of 48 wickless heat pipes organized in 6-row. | The cooling capability for the system was improved by 20 to 32.7%. In an evaporator and condenser, the equal value of air face velocities should be avoided. |

| Guoyuan Ma et al., 2013 [140] | THE is used in an AC system for outlet air heat recovery in a shopping mall in Beijing. | The results show that the seasonal temp effectiveness (STE) is 66.08% in winter and 55.43% in summer. | |

| Jouhara et al., 2018 [92] | Wraparound loop heat pipes (WLHP), are thermosiphons which are used commercially. It depends on gravity to return the condensed liquid. HP filled with R134a and water were investigated at two different air velocities: 2.56 m/s and 2.6 m/s. | The results show that the effectiveness declines with the rise of air velocity. The effectiveness of the HP filled with water varied from 20.14% to 19.61%, whereas it varied from 13.76% to 13.25% when it is filled with R134a. This means water HP was 46 to 48%, which is greater than R134a. | |

| Vanyasreet al., 2017 [141] | Thermosiphon of an outer diameter of 16 mm, and 570 mm long is used with a working fluid de-ionized water. Different flow rates are set in the test 10 mL/s, 15 mL/s, and 20 mL/s for various heat inputs of 155 W, 200 W, 250 W, and 300 W and different inclinations 30°, 45°, and 90°. | A comparison was done on the results obtained, and it was concluded that in thermosiphon, 45° is more efficient than other inclinations when de-ionized water is used as a working fluid. | |

| PHP/OHP | Mahajan et al., 2017 [142] | OHP consists of multiple finned OHP, organized in a staggered way (to increase the heat transfer). Typical HVAC is studied at 60.96 × 45.72 cm2. The ducted air streams have a constant volumetric flow rate of 1.18 m3/s opposite to each other. The outdoor temperature is assumed to vary between −8 °C and 48.9 °C. | The results show that the OHP system is energy and cost-effective since a reduction of total average consumption was observed, around 16% yearly. OHP can save, annually, more than $2500 in cities that have continental (warm to hot summer and severe cold winter) climatic conditions |

| Supirattanakul et al., 2011 [143] | Copper tubes closed-loop (CLOHP) was used with a diameter of 2.03 mm. Indoor design temperature varies between 20 and 27 °C with 50% RH. R134a, R22, and R502 refrigerants were used as working fluids. | When R134a was used as the working fluid, heat flux increased to 5.19 kW/m2 at a temperature of 27 °C. The CLOHP/CV resulted in an increase in the surface area and the heat capacity of the base fluid. | |

| Govinda Mahajan et al., 2015 [144] | OHP-HE was studied with a 70% fill ratio of n-pentane. The performance of OHP was compared with the empty tube, i.e., at vacuum pressure having the same overall dimension. | The results indicate that OHP can recover up to 240 W of heat from the waste exhaust air stream, with a low-pressure drop of almost 62 Pa in the cold air stream. The heat transfer rate with 70% n-pentane is two times that of the evacuated OHP. | |

| Pachghare, 2016 [101] | Closed loop pulsating heat pipe (CLPHP) consists of 10 turns of copper tubes of ID = 2.0 mm and OD = 3.6 mm. The evaporator, condenser, and adiabatic sections have a length of 50 mm. Different working fluids are used as methanol, R-134a, and water. | With R134a working fluid, PHP indicates, at all orientations, better thermal performance than water and methanol. When using water as a working fluid, PHP shows a negligible inclination angle effect, whereas, with methanol, a significant effect is detected since the better thermal performance was observed in a vertical position than the horizontal one. | |

| Chawane et al., 2013 [70] | PHP performance is compared by using three different working fluids: ammonia, water, and acetone. | Water-filled devices showed higher performance as compared to R-123 and ethanol in a vertical orientation. Ammonia shows desirable characteristics for heat transfer, as it has a high freezing point. | |

| Patil et al., 2016 [71] | OHP experiment was done in three different conditions: window, indoor, and outdoor. The working fluid used has a boiling point around 25 °C to deliver a suitable temperature. | The power consumption obtained is around 109 W (less than one ceiling fan). Outlet air temperature and humidity cannot be controlled, due to the inability to control the mass flow rate of the refrigerant. | |

| Barua et al., 2011 [145] | Mathematical models of falls in temperature in the condenser section were established concerning time for different diameters D and lengths L of the pipes of the evaporator sections. | Temperatures decline exponentially. For a fixed D, the temperature drop depends on the length of the evaporator. For a fixed L, the temperature reduces faster for the smaller diameter of the pipe. | |

| Runaround coil | J. Wallin et al., 2012 [61] | A summary on increasing the performance of transferring energy through run-around coil ventilation HRS. Studies have also investigated the methods to improve heat pump units by decreasing the energy used; this was done by conducting a modified design of a three-stage heat pump to the system the heat recovery rate per year which was obtained in Stockholm. | The Annual HR rate was improved from 47% to 66%. The system shows considerable and affordable results, for the three-stage heat pump design, the payback period was 5.7 years, for the variable heat pump capacity design 6.2 years. |

| R. Zaengerle, 2012 [95] | Integrated system of energy recovery with cooling and heating devices of runaround coil studied in cold climates. | This system is very valuable to recover energy in cold climates, and, thus, decreasing the power of the fan. |

Table 4 revealed that:

-

Air-to-air HE decreases considerably the energy consumption, but there are some limitations according to its characteristics and specific configuration.

-

Many factors affect efficiency such as working fluid, size, and climate.

-

It is highly recommended to combine other systems, such as PCM, in order to overcome its overheating problem.

-

It is noticed that OHP in continental climates can save higher energy.

-

The efficiency of THE in winter is higher than in summer. It is recommended to perform a comparative study for each of THE and HPHE in different climates.

-

Papers on integrating run-around coil with HVAC were not available as much as other heat recovery devices. However, it is concluded that this technology is noticed to be effective in cold climates

Earth-Air HE

EAHE is considered an encouraging technology, which can efficiently decrease the load of cooling/heating of a building by warming up the air in the wintertime and the same in summer. Table 5 shows the methodology and results of the papers that studied energy recovery from EAHE.

Table 5. Summary of the investigated papers related to energy recovery from earth to air HE.

| Authors | Methodology | Results |

|---|---|---|

| Reddy et al., 2015 [146] | Air conditioning system with a ground source heat exchanger (ACSWGSHE) is developed. HE, of helical shape, is placed in a hole of 0.2 m diameter and 15 m deep. The test was done under three different conditions: (i) open hole, (ii) hole filled with water at ambient temperature, and (iii) hole filled with sand. The tube was made of copper and the refrigerant was R22. | When the borehole was filled with water, the COP rose from 2.11 to 3.72. In addition, the power consumption of the AC decreased by 29%. When the bore was filled with sand, COP decreased significantly due to low heat transfer from the condenser to the ground. The cost of the ACSWGSHE system is high. However, after a specific time, savings and energy conservation are significant. |

| Woodson et al., 2012 [147] | EAHX at 1.5 m depth was designed with varied temperature varies from 25 °C to 43 °C, a 25 m length. | The designed system cooled the inside air from the outside air by more than 7.5 °C when the temperature was 30.4 °C. |

| Tiwari et al., 2014 [148] | In a room with a height of 2.6 m, and length of 4.5 m., two designs were used: (i) Design I: 5 air changes, 0.1 m pipe diameter, pipe length is 21m. A fan of 0.3 m diameter and 66 rpm requires 90W power to operate. (ii) Design II: 5 air changes and 0.05 m pipe diameter, pipe length is 15 m. A fan of 0.3 m diameter and 66 rpm requires 90 W power to operate. | Design I provides net thermal energy of 0.29 kW in summer and 0.36 kW in winter. Design II provides net thermal energy of 0.26 kW in summer and 0.34 kW in winter. The environmental cost for Design I and Design II is $10.1 and $13.9 respectively. |

| Congedo et al., 2016 [149] | Under the summer and winter conditions of the Mediterranean climate, a horizontal air-ground heat exchanger (HAGHE) system is studied with a 5 m pipe. | The best performance was at a pipe depth of 5 m with a ground conductivity of 3 W/(mK). A gain of about 23 kWh in winter and 37 kWh in summer. |

| Fazlikhani et al., 2017 [150] | This study compared the efficiency of the earth to air heat exchanger (EAHE) systems in hot-arid (Yazd) and cold (Hamadan) climates. | In Hamadan, the system works for 225 days and saves 50.1–63.6% energy. In Yazd, it works for 294 days which results in reducing consumption by 24.5–47.9%. |

It is observed that:

-

EAHE is effective in severely cold/hot weather, when the temperature is high, which results in a higher temperature gradient which means higher heat transfer.

-

It is noticed that the EAHE is most efficient in hot dry climates weather.

-

EAHE depends on some parameters to achieve optimum energy saving, such as the ground, soil properties, depth, climate, working fluid, geometry, and material of the pipes used. As such, location and climate should be taken into consideration.

2.2.2. Mathematical Control

Controlling and smart systems are great inventions that helped in many fields. These systems do not just facilitate the process, but also save energy, as will be shown in the methodology and results of the papers that studied the effect of mathematical control on HVAC systems in Table 6.

Table 6. Summary of the investigated papers related to mathematical control effect on HVAC systems.

| Authors | Methodology | Results |

|---|---|---|

| Elhelw 2016 [151] | A comparison between modified bin method and cooling load temperature difference/solar cooling load factor/cooling load factor (CLTD/SCL/CLF) method. | The overall energy efficiency ratio was increased by 45.57%. The energy efficiency ratio (EER) of the modified bin method was between 14.29 and 10.58, which was higher than the EER acquired from using CLTD/SCL/CLF method 10.89. Overall EER saved 33.42%. |

| Sayadi et al., 2016 [152] | Model predictive control (MPC) is used to foresee the situations of the system. | A reduction of about 43% and 31% in energy used when using MPC. |

| Wang et al., 2017 [153] | Detection of occupancy using Wi-Fi coverage, smart devices, and sensors. | The model showed over 80% accuracy. The designed model reduced the energy consumption of HVAC significantly. |

| Zlatanovic, 2011 [154] | Simple and cheap method is used for the energy-saving estimation model (ESEM). | The results show that ESEM has a positive effect on HVAC, and 55% of electrical energy savings can be accomplished. |

| Godina et al., 2018 [155] | Model predictive control (MPC), proportional integral derivative (PID), and ON/OFF control methods in an AC. | Up to 14.2% can be saved by applying the specific model. |

Mathematical control is related to controlling and predicting systems, such as the smart system. These systems have been revealed as having a positive impact on saving energy, as shown in Table 6, where it is noted that the model predictive control (MPC), building automation systems (BAS), estimation models, and automatic smart systems have acquired high attention in HVAC for their ease of use. However, these systems require a high cost and level of accuracy in their construction [156,157,158,159,160,161]. From Table 6, it is noticed that the model accuracy is acceptable. In addition, the model showed a significant positive effect on saving energy. Further research that involves a smart system in HR devices is recommended.

2.2.3. Total Energy Recovery

Enthalpy Wheel

An enthalpy wheel heat exchanger is one of the energy recovery devices that transfers sensible and latent heat. This criterion increases the efficiency of RW and helps in decreasing the moisture in the air. Table 7 shows the methodology and results of the papers that are related to the enthalpy wheel heat exchanger in HVAC.

Table 7. Summary of the investigated papers related to the enthalpy wheel effect on HVAC systems.

| Authors | Methodology | Results |

|---|---|---|

| Wang et al., 2012 [162] | Two simple design cases of energy recovery with and without air side economizer were studied and compared to a baseline case which is without energy recovery and an airside economizer case. | An airside economizer combined with energy recovery reduced 17% of HVAC energy consumption annually, which is the highest energy benefit. In the Miami climate in summer, the design increased the COP by up to 26%. |

| Ali et al., 2016 [163] | A comparison between two cases: (i) without heat recovery wheel, (ii) with heat recovery wheel. | After using the heat recovery wheel, the energy is reduced by 15% from 11.6 tons to 9.9 tons of cooling capacity. |

| Hussaini et al., 2017 [164] | A comparison of heat load calculations with and without a heat recovery wheel for energy-efficient using Eco-Fresh enthalpy wheel software. | When using HRW for sensible heat, a total reduction in the ton of refrigeration decreased to 46.02%, which means about half of the energy can be saved. |

| Bellia et al., 2000 [165] | An application is done for retail stores, in four Italian cities. An application is done in a theatre in Rome. | The maximum and profitable savings to the corresponding traditional system have been found to be around 22%. Savings are between 23% and 43%. For both cases, the needed electric power is reduced by about 55%. |

| Herath et al., 2020 [166] | Installing enthalpy wheels (EW) to central air conditioning systems. Energy saving is calculated for various operating conditions. The payback period for involving RW in AC is calculated. | EW can recover around 20% to 40% of total energy consumption compared to a configuration with no EW in operations. Energy recovery increased when the temperature of fresh air and the moisture content increased. The payback period for an EW is obtained to be in the range of 1 to 5 years. |

The results of Table 7 show that:

-

EW HE is effective in HVAC applications, due to its high efficiency and ability to transfer latent and sensible energy, which can be saved.

-

In addition, it was noticed that energy recovery increases when the temperature of fresh air and moisture content increases; consequently, the chance of recovering heat using EW rises.

-

It is also noticed that the efficiency of RW in hot and humid climates increases.

-

As such, it is recommended to study the effect of RW in a humid and cold climate. It is logical that the results will be positive where humidity has a positive effect on RW, as it recovers latent heat.

PCM

PCM is a material that releases and absorbs while phases change. This process provides heating and cooling by melting and solidification. PCM offers a storage ability, which makes it useful in many applications. Table 8 shows the methodology and results of the papers that are related to the PCM effect on the HVAC system.

Table 8. Summary of the investigated papers related to PCM effect on HVAC systems.

| Authors | Methodology | Results |

|---|---|---|

| Chaiyat et al., 2014 [167] | PCM of paraffin waxes material, which melts at around 20 °C was used in the Thai climate for better cooling efficiency of an AC. | 9.10% of the electricity cost was saved when PCM was used. The payback period was 4.15 years. |

| Tranto et al., 2013 [78] | A hybrid conditioning system that joins EAHEs and PCMs that considers surfaces to be sources of cooling or heating. The hybrid system was studied, for 24 h, with airflow rates of 0.02, 0.04, and 0.05 m3/s | PCM alone can reduce temperature swing by 33%. The hybrid system reduced temperature swings by 40, 47, and 46%, respectively under the given flow rate. |

| Madyira, 2017 [168] | 15 plates were 10 mm separated and assembled in a Plexiglas box, air mass flow rates of 0.027, 0.061, and 0.075 kg/s were provided by an axial fan. | For 0.027 kg/s, PCM discharged about 78% of its latent energy storage. During the day, around 95% of latent storage capacity was recharged |

The studies in Table 8 indicate that:

-

PCM possesses a significant effect in terms of energy-saving and storage.

-

The PCM+EAHE system is encouraging, especially due to its enhancement in swing temperature reduction.

-

As such, it is recommended that PCM is used to aid the storage system in order to store the excess heat and discharge it gradually, such as PCM combined with HP, THE, or EAHE where PCM offers the storage which helps in extending the lifetime of the system.

Fixed Plate

The fixed plate uses metallic plates to transfer the heat between fluids. Its novelty is that it can expose the fluid to a greater surface area, as fluids blowout over different plates. This helps in increasing the heat transfer rate for the compacted size. FPHE can transfer latent energy as well as sensible energy, especially when combined with a liquid desiccant dehumidification system (LDDS) [39]. Table 9 shows the methodology and results of the papers that are related to the fixed plate membrane energy recovery effect on the HVAC system.

Table 9. Summary of the investigated papers related to the fixed plate effect on HVAC systems.

| Authors | Methodology | Results |

|---|---|---|

| Zafirah et al., 2016 [171] | Tests were performed in a range of airflow rates from 1 to 3 m/s and with an intake relative humidity of 70%, 80%, and 90%. | As airflow and RH rise, efficiency is reduced. The efficiency of the system varied between 40 and 74%, and the highest recovered energy was 1456 W. |

| Nasif et al., 2015 [172] | Quasi-counter-flow HE designs including L-shaped, Z-shaped, Z-shaped opposite flow heat exchanger (HE) were studied. | The results showed that L-shaped HE saved up to 75 GJ energy compared to Z-shaped and Z-shaped opposite HE. L-shaped HE recovered 90 GJ more energy compared to other HE configurations. |

| Shen et al., 2017 [39] | Fixed plate heat exchanger is united with the hybrid mass and heat transfer model in the regenerator. | 16 to 19% of the total energy consumption was recovered from the outlet air which leads to an energy-saving of about 14 to18%. |

| Nasif et al., 2010 [173] | Performance of Z type flow enthalpy membrane coupled in AC is investigated annually to measure the effectiveness of different climates. | The results showed that in a tropical (humid) climate, this system saved up to 8% of energy annual consumption. But, in a moderate climate, it spent 4% less energy than a conventional AC. |

| Nasif, 2018 [174] | Investigating the effectiveness of applying for fixed plate energy recovery heat exchangers for HVAC in buildings. | The results showed that this system recovered energy in a humid climate higher than that in moderate and dry climate conditions. |

Table 9 exhibits the following conclusions:

-

FPHE is a promising method to save energy in HVAC applications.

-

It is noticed that the intake air conditions affect the performance of the system, such as increasing the airflow rate and RH, because fixed plate HE transfers latent and sensible energy.

-

The shape of the fixed plate has a significant effect on the amount of recovered energy, whereby results show that the L shape fixed plate shows higher recovered energy.

-

In addition, it is noticed that the amount of recovered energy is higher in humid climates than in dry and moderate climate environments.

3. Effect of Weather Conditions

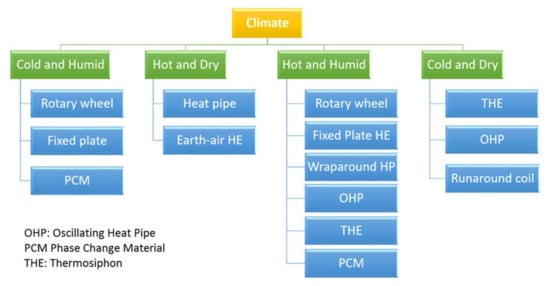

Based on the above-investigated papers, it is observed that climate has a considerable effect on the performance of each device [175,176]. As such, in this section, energy recovery devices will be classified according to their best climate conditions based on previous research.

All of the papers agreed that the cost savings and efficiency of the systems are higher in winter than in summer [177]. Thus, heating is more efficient than cooling for the same system [178,179,180]. In addition, Wu et al. [181] indicated that when relative humidity exceeds 70% in hot and humid climates, latent heat becomes a significant constraint. Therefore, energy recovery devices are suitable for such climates due to their ability to transfer both latent and sensible heat systems [139,178]. As such, rotary wheel and fixed plates can be used in cold humid climates, but there is a freezing problem at very low temperatures. In addition, for the fixed plate, the condensation builds up problems, limiting its implementation in severely cold weather. In winter, it is found that enthalpy devices recover over 25% more energy than sensible heat devices. Whereas, in summer, the energy recovery device recovers about three times as much energy as the sensible heat devices [182].

Ground heat pump (GHP) systems have been widely implemented in cold climates. Results show that GHP in cold climate regions is slightly improved, where energy savings are around 7.2% and energy cost savings are on average 6.1% [85]. A horizontal air-ground heat exchanger (HAGHE) system, which is a type of geothermal energy, reduces the consumption of energy in all seasons. These systems show high effectiveness in various climates (hot and humid, cold climate, tropical climate, Mediterranean climate, moderate climate, etc.) [183]. However, they perform optimally in a hot-arid climate, where a reduction of 66% in the gradient temperature between the highest and lowest daily temperatures occurred over the year [149]. Whereas, in the cold climate, the reduction was lower [150]. Thus, EAHE performs in a hot-dry climate better than in a cold climate. These results demonstrate that GHP and EAHE are applicable in hot dry-climate regions.

An experiment was completed in India which showed that heat pipes (HP) saved maximum energy in warm and humid, or hot and dry climates [2]. The results also revealed that wraparound heat pipes, HPs wrapped around a cooling coil, are applicable for hot and humid climates [92]. Thermosiphon is also recommended to be used in a subtropical climate (hot and humid summers, cold winters) [184]. As such, HP is mainly reliable in a hot climate. However, there is a lack of research about HP in cold climates. As such, it is recommended that an experimental study that compares the use of HP in a cold dry climate and cold humid climate is undertaken.

OHPs are most efficient and cost-effective in continental climatic conditions (hot summers and cold winters). G. Mahajan et al. [142] estimated that when OHP was involved in heat recovery ventilator (HRV) systems, more than $2500 were saved yearly in cities with continental climatic conditions. OHP-HRV offers a total average reduction of 16% in energy consumption annually, so it shows a high potential for dropping energy consumption, as well as reducing the operating costs. In addition, it was shown that OHP is suitable for a sub-humid tropical climate, where the WHR of the heating mode exceeds 80% of the total annual WHR. Thus, OHP is reliable in a hot humid climate. It is recommended that OHP efficiency in a hot dry climate is studied and compared to a hot humid climate.

PCM revealed good results for both heating and cooling [76]. Yet, its optimal performance depends on the chosen material. For example, in a cold climate, the material’s melting point should be around 26 °C, while in hot climates, a 20 °C melting point leads to better energy savings [185]. Research revealed that PCM is reliable in a tropical climate, like Chennai [186,187]. Thus, PCM is most efficient in a non-arid climate.

Figure 6 proposes a classification of the devices according to their best climatic condition, where each device achieves its optimal effectiveness. For example, RW showed high effectiveness in all climates, but its efficiency in humid climates is better than in arid climates, and thus it is placed in humid climate. This is similar for EAHE, which shows significant results in a hot dry climate, as mentioned in this section. The same procedure goes for the other devices that offer their optimum performance according to the climate.

Figure 6. Heat recovery devices according to the climate.

This entry is adapted from the peer-reviewed paper 10.3390/en14185869

This entry is offline, you can click here to edit this entry!