The release of air pollutants from the operation of wastewater treatment plants (WWTPs) is often a cause of odor annoyance for the people living in the surrounding area. Odors have been indeed recently classified as atmospheric pollutants and are the main cause of complaints to local authorities. In this context, the implementation of effective treatment solutions is of key importance for urban water cycle management. An overview of these technologies is given by discussing their strengths and weaknesses. A sensitivity analysis is presented, by considering land requirements, operational parameters and efficiencies, based on data of full-scale applications. Biofilters and biotrickling filters represent the two most applied technologies for odor abatement at full-scale plants, due to lower costs and high removal efficiencies. Innovative and sustainable technologies are also presented and discussed, evaluating their potential for full-scale applicability.

- Wastewater Treatment Plants

- Odor treatment technology (OTT)

- Photo-Bioreactor

- Biological Treatment

- Chemical-Physical Treatment

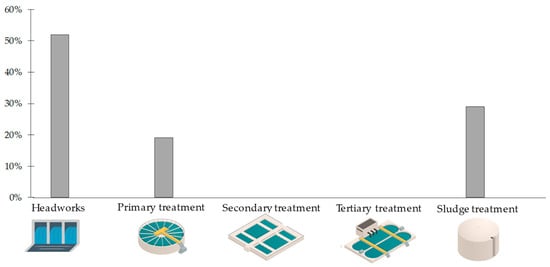

1. Odor Emissions Management in Wastewater Treatment Plants (WWTPs)

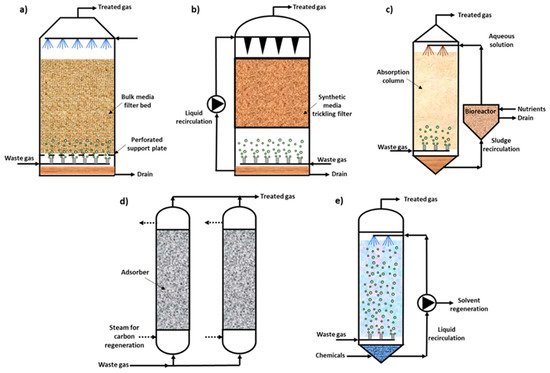

2. Full-Scale Odor treatment technology (OTT) in WWTPs

2.1. Biofilter

2.2. Biotrickling Filter

2.3. Scrubber System

2.4. Combined OTT

3. Photo-Bioreactor Based on Algae–Bacteria Synergism

This entry is adapted from the peer-reviewed paper 10.3390/w13243503

References

- Kraakman, N.J.R.; Estrada, J.M.; Lebrero, R.; Cesca, J.; Muñoz, R. Evaluating odour control technologies using reliability and sustainability criteria - A case study for water treatment plants. Water Sci. Technol. 2014, 69, 1426–1433.

- Iftekhar, M.S.; Burton, M.; Zhang, F.; Kininmonth, I.; Fogarty, J. Understanding Social Preferences for Land Use in Wastewater Treatment Plant Buffer Zones. Landsc. Urban Plan. 2018, 178, 208–216.

- Rousseille, F.; Ventura, A. Masking agent efficiency on odor removal from WWTP sludge drying process. Water Pract. Technol. 2018, 1–10.

- Muñoz, R.; Meier, L.; Diaz, I.; Jeison, D. A review on the state-of-the-art of physical/chemical and biological technologies for biogas upgrading. Rev. Environ. Sci. Biotechnol. 2015, 14, 727–759.

- Alinezhad, E.; Haghighi, M.; Rahmani, F.; Keshizadeh, H.; Abdi, M.; Naddafi, K. Technical and economic investigation of chemical scrubber and bio-filtration in removal of H 2 S and NH 3 from wastewater treatment plant. J. Environ. Manage. 2019, 241, 32–43.

- Ksibi, M. Chemical oxidation with hydrogen peroxide for domestic wastewater treatment. Chem. Eng. J. 2006.

- Tadda, M.A.; Ahsan, A.; Shitu, A.; Elsergany, M.; Arunkumar, T.; Jose, B.; Razzaque, M.A.; Nik, N.N. A review on activated carbon: Process, application and prospects. J. Adv. Civ. Eng. Pract. Res. 2016, 2, 7–13.

- Talaiekhozani, A.; Bagheri, M.; Goli, A.; Talaei Khoozani, M.R. An overview of principles of odor production, emission, and control methods in wastewater collection and treatment systems. J. Environ. Manage. 2016, 170, 186–206.

- Oliva, G.; Ángeles, R.; Rodríguez, E.; Turiel, S.; Naddeo, V.; Zarra, T.; Belgiorno, V.; Muñoz, R.; Lebrero, R. Comparative evaluation of a biotrickling filter and a tubular photobioreactor for the continuous abatement of toluene. J. Hazard. Mater. 2019, 380, 120860.

- Oliva, G.; Zarra, T.; Pittoni, G.; Senatore, V.; Galang, M.G.; Castellani, M.; Belgiorno, V.; Naddeo, V. Next-generation of instrumental odour monitoring system (IOMS) for the gaseous emissions control in complex industrial plants. Chemosphere 2021, 271, 129768.

- Oliva, G.; Zarra, T.; Massimo, R.; Senatore, V.; Buonerba, A.; Belgiorno, V.; Naddeo, V. Optimization of classification prediction performances of an instrumental odour monitoring system by using temperature correction approach. Chemosensors 2021, 9, 147.

- Zarra, T.; Galang, M.G.; Ballesteros, F.; Belgiorno, V.; Naddeo, V. Environmental odour management by artificial neural network—A review. Environ. Int. 2019, 133, 105189.

- Zarra, T.; Naddeo, V.; Belgiorno, V. Characterization of odours emitted by liquid waste treatment plants (LWTPs). Glob. Nest J. 2016, 18, 721–727.

- Baawain, M.; Al-Mamun, A.; Omidvarborna, H.; Al-Sulaimi, I.N. Measurement, control, and modeling of H2S emissions from a sewage treatment plant. Int. J. Environ. Sci. Technol. 2019, 16, 2721–2732.

- Belgiorno, V.; Naddeo, V.; Zarra, T. Odour Impact Assessment Handbook; John & Wiley Sons, Inc.: Hoboken, NJ, USA, 2012.

- Giuliani, S.; Zarra, T.; Naddeo, V.; Belgiorno, V. Measurement of odour emission capacity in wastewater treatment plants by multisensor array system. Environ. Eng. Manag. J. 2013, 12, 173–176.

- Zarra, T.; Reiser, M.; Naddeo, V.; Belgiorno, V.; Kranert, M. Odour emissions characterization from wastewater treatment plants by different measurement methods. Chem. Eng. Trans. 2014, 40, 37–42.

- Zhou, Y.; Hallis, S.A.; Vitko, T.; Suffet, I.H.M. Identification, quantification and treatment of fecal odors released into the air at two wastewater treatment plants. J. Environ. Manage. 2016, 180, 257–263.

- Kasperczyk, D.; Urbaniec, K.; Barbusinski, K.; Rene, E.R.; Colmenares-Quintero, R.F. Application of a compact trickle-bed bioreactor for the removal of odor and volatile organic compounds emitted from a wastewater treatment plant. J. Environ. Manage. 2019, 236, 413–419.

- Fisher, R.M.; Alvarez-Gaitan, J.P.; Stuetz, R.M. Review of the effects of wastewater biosolids stabilization processes on odor emissions. Crit. Rev. Environ. Sci. Technol. 2019, 49, 1515–1586.

- Naddeo, V.; Zarra, T.; Oliva, G.; Kubo, A.; Ukida, N.; Higuchi, T. Odour measurement in wastewater treatment plant by a new prototype of e.nose: Correlation and comparison study with reference to both European and Japanese approaches. Chem. Eng. Trans. 2016, 54, 85–90.

- Hayes, J.E.; Fisher, R.M.; Stevenson, R.J.; Mannebeck, C.; Stuetz, R.M. Unrepresented community odour impact: Improving engagement strategies. Sci. Total Environ. 2017, 609, 1650–1658.

- Lebrero, R.; Bouchy, L.; Stuetz, R.; Muǹoz, R. Odor Assessment and Management in Wastewater Treatment Plants: A Review. Crit. Rev. Environ. Sci. 2011, 41, 915–950.

- Ren, B.; Zhao, Y.; Lyczko, N.; Nzihou, A. Current Status and Outlook of Odor Removal Technologies in Wastewater Treatment Plant. Waste and Biomass Valorization 2019, 10, 1443–1458.

- Piechota, G. Multi-step biogas quality improving by adsorptive packed column system as application to biomethane upgrading. J. Environ. Chem. Eng. 2021, 9, 105944.

- Cadee, K.; Wallis, I. Odour containment and ventilation at Perth’s major WWTPs. Water 2007, 34, 54–60.

- Gao, L.; Keener, T.C.; Zhuang, L.; Siddiqui, K.F. A technical and economic comparison of biofiltration and wet chemical oxidation (scrubbing) for odor control at wastewater treatment plants. Environ. Eng. Policy 2001, 2, 203–212.

- Zheng, T.; Li, L.; Chai, F.; Wang, Y. Factors impacting the performance and microbial populations of three biofilters for co-treatment of H2S and NH3 in a domestic waste landfill site. Process Saf. Environ. Prot. 2021, 149, 410–421.

- Rabbani, K.A.; Charles, W.; Kayaalp, A.; Cord-Ruwisch, R.; Ho, G. Pilot-scale biofilter for the simultaneous removal of hydrogen sulphide and ammonia at a wastewater treatment plant. Biochem. Eng. J. 2016, 107, 1–10.

- Zhuang, L.; Keener, T.C.; Siddiqui, K.F. Long-term evaluation of an industrial-scale biofilter for odor control at a large metropolitan wastewater treatment plant. Environ. Prog. 2001, 20, 212–218.

- Liu, J.; Yang, K.; Li, L.; Zhang, J. A full-scale integrated-bioreactor with two zones treating odours from sludge thickening tank and dewatering house: Performance and microbial characteristics. Front. Environ. Sci. Eng. 2017, 11, 6.

- Patria, L.; Cathelain, M.; Laurens, P.; Barbere, J.P. Odour removal with a trickling filter at a small WWTP strongly influenced by the tourism season. Water Sci. Technol. 2001, 44, 243–249.

- Donaldson, F.H.; Dilego, T.J.; Higgins, M.S.; Padewski, E.A.; Peluso, J.S. Assessing and managing PCCP water transmission mains—Baltimore County, Maryland—A case study. In Proceedings of the 2006 Pipeline Division Specialty Conference-Pipelines, Chicago, IL, USA, 2 August 2006.

- Abdel-Jabbar, N.; Ahmed, W.; Shareefdeen, Z. System identification and control of a biotrickling filter. Chem. Prod. Process Model. 2015, 10, 39–53.

- Omri, I.; Aouidi, F.; Bouallagui, H.; Godon, J.J.; Hamdi, M. Performance study of biofilter developed to treat H2S from wastewater odour. Saudi J. Biol. Sci. 2013, 20, 169–176.

- Abraham, S.; Joslyn, S.; Suffet, I.H. Treatment of odor by a seashell biofilter at a wastewater treatment plant. J. Air Waste Manag. Assoc. 2015, 65, 1217–1228.

- Almarcha, D.; Almarcha, M.; Nadal, S.; Poulssen, A. Assessment of odour and VOC depuration efficiency of advanced biofilters in rendering, sludge composting and waste water treatment plants. Chem. Eng. Trans. 2014, 40, 223–228.

- Xie, B.; Liang, S.B.; Tang, Y.; Mi, W.X.; Xu, Y. Petrochemical wastewater odor treatment by biofiltration. Bioresour. Technol. 2009, 100, 2204–2209.

- Oliva, G.; Zarra, T.; Naddeo, V.; Munoz, R.; Lebrero, R.; Ángeles, R.; Belgiorno, V. Comparative analysis of AOPs and biological processes for the control of VOCs industrial emissions. Chem. Eng. Trans. 2018, 68, 451–456.

- Lafita, C.; Penya-Roja, J.M.; Sempere, F.; Waalkens, A.; Gabaldón, C. Hydrogen sulfide and odor removal by field-scale biotrickling filters: Influence of seasonal variations of load and temperature. J. Environ. Sci. Heal. Part A Toxic/Hazardous Subst. Environ. Eng. 2012, 47, 970–978.

- Yang, Z.; Li, J.; Liu, J.; Cao, J.; Sheng, D.; Cai, T. Evaluation of a pilot-scale bio-trickling filter as a VOCs control technology for the chemical fibre wastewater treatment plant. J. Environ. Manage. 2019, 246, 71–76.

- Wu, L.; Loo, Y.Y.; Koe, L.C.C. A pilot study of a biotrickling filter for the treatment of odorous sewage air. Water Sci. Technol. 2001, 44, 295–299.

- Cox, H.H.J.; Deshusses, M.A.; Converse, B.; Schroeder, E.D.; Vosooghi, D.; Samar, P.; Iranpour, R. Odor and Voc Treatment By Biotrickling Filters: Pilot Scale Studies At the Hyperion Treatment Plant. Proc. Water Environ. Fed. 2012, 2001, 297–315.

- Chen, Y.; Wang, X.; He, S.; Zhu, S.; Shen, S. The performance of a two-layer biotrickling filter filled with new mixed packing materials for the removal of H2S from air. J. Environ. Manage. 2016, 165, 11–16.

- Yang, K.; Li, L.; Wang, Y.; Xue, S.; Han, Y.; Liu, J. Airborne bacteria in a wastewater treatment plant: Emission characterization, source analysis and health risk assessment. Water Res. 2019, 149, 596–606.

- US EPA. Toxicological Review of Hydrogen Sulfide (CAS No. 7783-06-4). Summ. Inf. Integr. Risk Inf. Syst. 2003, 74.

- Ghawi, A.H. Design of Biofilter Odor. J. Ecol. Eng. 2018, 19, 7–15.

- Jones, K.D.; Yadavalli, N.; Karre, A.K.; Paca, J. Microbial monitoring and performance evaluation for H 2S biological air emissions control at a wastewater lift station in South Texas, USA. J. Environ. Sci. Heal. Part A Toxic/Hazardous Subst. Environ. Eng. 2012, 47, 949–963.

- Guerrero, R.B.S.; Bevilaqua, D. Biotrickling Filtration of Biogas Produced from the Wastewater Treatment Plant of a Brewery. J. Environ. Eng. 2015, 141, 04015010.

- Lakey, M.; Manager Victoria, G.; Pitt, M.; Manager, G.; TeQ Limited, C.; Michael Pitt, V. Dual phase biotrickling filter treatment of H2S and VOC’s. Water Ind. Oper. Work. 2011, 31, 80–86.

- Santos, A.; Guimerà, X.; Dorado, A.D.; Gamisans, X.; Gabriel, D. Conversion of chemical scrubbers to biotrickling filters for VOCs and H2S treatment at low contact times. Appl. Microbiol. Biotechnol. 2015, 99, 67–76.

- Lebrero, R.; Rodr, E.; De Juan, C.; Norden, G.; Rosenbom, K. Comparative Performance Evaluation of Commercial Packing Materials for Malodorants Abatement in Biofiltration. Appl. Sci. 2021, 11, 2966.

- Kerc, A.; Olmez, S.S. Ozonation of odorous air in wastewater treatment plants. Ozone Sci. Eng. 2010, 32, 199–203.

- Yang, S.; Li, Y.; Wang, L.; Feng, L. Use of peroxymonosulfate in wet scrubbing process for efficient odor control. Sep. Purif. Technol. 2016, 158, 80–86.

- Biard, P.-F.; Couvert, A.; Renner, C.; Zozor, P.; Bassivière, S.; Levasseur, J.-P. Hydrogen sulphide removal in waste water treatment plant by compact oxidative scrubbing in Aquilair PlusTM process. Water Pract. Technol. 2009, 4, 1–9.

- Raboni, M.; Torretta, V.; Viotti, P. Treatment of airborne BTEX by a two-stage biotrickling filter and biofilter, exploiting selected bacterial and fungal consortia. Int. J. Environ. Sci. Technol. 2017, 14, 19–28.

- Baawain, M.; Al-Mamun, A.; Omidvarborna, H.; Al-Jabri, A. Assessment of hydrogen sulfide emission from a sewage treatment plant using AERMOD. Environ. Monit. Assess. 2017, 189, 263.

- Hansen, N.G.; Rindel, K. Bioscrubbing: An effective and economic solution to odour control at sewage-treatment plants. Water Environ. J. 2001, 15, 141–146.

- Rada, E.C.; Raboni, M.; Torretta, V.; Copeli, S.; Ragazzi, M.; Caruson, P.; Istrate, I.A. Removal of benzene from oil refinery wastewater treatment plant exchausted gases with a multi-stage biofiltration pilot plant. Rev. Chim. 2014, 65, 68–70.

- Torretta, V.; Collivignarelli, M.C.; Raboni, M.; Viotti, P. Experimental treatment of a refinery waste air stream, for BTEX removal, by water scrubbing and biotrickling on a bed of Mitilus edulis shells. Environ. Technol. (United Kingdom) 2015, 36, 2300–2307.

- Martinez, A.; Rathibandla, S.; Jones, K.; Cabezas, J. Biofiltration of wastewater lift station emissions: Evaluation of VOC removal in the presence of H2S. Clean Technol. Environ. Policy 2008, 10, 81–87.

- Behnami, A.; Zoroufchi Benis, K.; Shakerkhatibi, M.; Derafshi, S.; Chavoshbashi, M.M. A systematic approach for selecting an optimal strategy for controlling VOCs emissions in a petrochemical wastewater treatment plant. Stoch. Environ. Res. Risk Assess. 2019, 33, 13–29.

- Vitko, T.; Cowden, S.; Erdal, Z.; Witherspoon, J.; Suffet, I.H. Innovative odor mapping and management method sets the stage for targetted foul air treatment. In Proceedings of the WEFTEC 2016-89th Water Environment Federation Annual Technical Exhibition and Conference, Milwaukee, WI, USA, 21–24 March 2016; 2016.

- Finke, G.; Oliver, P.; Thomas, M.; Evanson, I. Environmentally sustainable odour control for the Merrimac WWTP upgrade. Chemeca 2008, 1996–2005.

- Hansen, N.G.; Rindel, K. Bioscrubbing, an effective and economic solution to odour control at wastewater treatment plants. Water Sci. Technol. 2000, 41, 155–164.

- Senatore, V.; Buonerba, A.; Zarra, T.; Oliva, G.; Belgiorno, V.; Boguniewicz-Zablocka, J.; Naddeo, V. Innovative Membrane Photobioreactor for Sustainable CO2 Capture and Utilization. Chemosphere 2021, 273, 129682.

- Rajamanickam, R.; Baskaran, D.; Kaliyamoorthi, K.; Baskaran, V.; Krishnan, J. Steady State, transient behavior and kinetic modeling of benzene removal in an aerobic biofilter. J. Environ. Chem. Eng. 2020.

- Ángeles Torres, R.; Marín, D.; Rodero, M. Biogas treatment for H2S, CO2, and other contaminants removal. In From Biofiltration to Promising Options in Gaseous Fluxes Biotreatment; Elsevier: Amsterdam, The Netherlands, 2020; ISBN 9780128190647.

- Vermi, M.; Corpuz, A.; Borea, L.; Senatore, V.; Castrogiovanni, F.; Buonerba, A.; Oliva, G.; Ballesteros, F.; Zarra, T.; Belgiorno, V.; et al. Wastewater treatment and fouling control in an electro algae-activated sludge membrane bioreactor. Sci. Total Environ. 2021, 786, 147475.

- Pahunang, R.R.; Buonerba, A.; Senatore, V.; Oliva, G.; Ouda, M.; Zarra, T.; Muñoz, R.; Puig, S.; Ballesteros, F.C.; Li, C.W.; et al. Advances in technological control of greenhouse gas emissions from wastewater in the context of circular economy. Sci. Total Environ. 2021, 792, 148479.