The working environment of underground mines is complicated, making it difficult to construct an underground mine production plan. In response to the requirements for the preparation of a short-term production plan for underground mines, an optimization model for short-term resource planning was constructed, with the goal of maximizing the total revenue during the planning period.

- haulage equipment dispatch plan

1. Introduction

2. Optimization Results

2.1. Resource Plan

| Number | Result | Total Storage/t | Remaining Storage/t | Grade/% |

|---|---|---|---|---|

| (1, 1, 4, 3) | 1 | 2883.92 | 2883.92 | 24.03 |

| (1, 1, 8, 3) | 1 | 2951.56 | 2951.56 | 61.74 |

| (1, 1, 11, 3) | 1 | 2631.26 | 2631.26 | 44.26 |

| (1, 1, 1, 2) | 1 | 2951.37 | 2951.37 | 36.46 |

| (1, 1, 6, 2) | 1 | 2601.16 | 2601.16 | 49.15 |

| (1, 1, 9, 1) | 1 | 2667.56 | 2667.56 | 49.28 |

| (1, 1, 12, 1) | 1 | 2916.49 | 2916.49 | 56.74 |

| (2, 1, 1, 3) | 1 | 2643.29 | 2643.29 | 35.77 |

| (2, 1, 4, 3) | 1 | 2708.67 | 2708.67 | 42.90 |

| (2, 1, 10, 3) | 1 | 2947.29 | 2947.29 | 31.48 |

| (2, 1, 2, 1) | 1 | 2938.19 | 2938.19 | 52.25 |

| (2, 1, 5, 1) | 1 | 2646.24 | 2646.24 | 54.64 |

| (2, 1, 8, 1) | 1 | 2951.56 | 2951.56 | 61.74 |

| (2, 1, 11, 1) | 1 | 2969.06 | 2969.06 | 44.26 |

| (2, 1, 7, 3) | 1 | 2671.67 | 2671.67 | 48.00 |

| Others | 0 | / | / | / |

2.2. Haulage Equipment Dispatch Plan

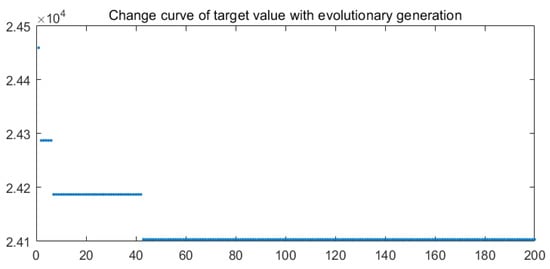

In order to prove the superiority of the non-dominated sorting genetic algorithm, the calculation results of the non-dominated sorting genetic algorithm are compared with the results of the traditional genetic algorithm. Solving a multi-objective problem using the traditional genetic algorithm method involves transforming the multi-objective problem into a single objective by weighting to select the superior individual and generating the superior scheme. Since the single running time of the electric locomotive is longer than that of the scraper, the proportion of F2 is relatively low, at 10%, while the proportion of F1 is 90%. The change curve of the target value in the calculation process with the evolutionary generation is shown in Figure 2.

3. Conclusions

This entry is adapted from the peer-reviewed paper 10.3390/met11111848

References

- Topal, E. Early start and late start algorithms to improve the solution time for long-term underground mine production scheduling. J. South. Afr. Inst. Min. Metall. 2008, 108, 99–107.

- Sandanayake, D.S.S.; Topal, E.; Ali Asad, M.W. A heuristic approach to optimal design of an underground mine stope layout. Appl. Soft Comput. 2015, 30, 595–603.

- Wu, H.; Li, J. Open-pit Mine Production Planning: The Current, Problem& Strategies. Met. Mine 2005, 4, 4–6+42.