Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Subjects:

Engineering, Environmental

The term eco-efficiency was first proposed in 1990 by Schaltegger and Sturm. However, it was in 1991 that the World Business Council for Sustainable Development (WBCSD) was responsible for introducing one of the main concepts of eco-efficiency to the world. The term was defined as the delivery of economically competitive goods and services that meet the needs of society in terms of quality of life and that the entire process of manufacturing and availability for consumption, that is, throughout its life cycle, should have the least possible impact on the environment.

- eco-efficiency

1. Eco-Efficiency

The term eco-efficiency was first proposed in 1990 by Schaltegger and Sturm. However, it was in 1991 that the World Business Council for Sustainable Development (WBCSD) was responsible for introducing one of the main concepts of eco-efficiency to the world. The term was defined as the delivery of economically competitive goods and services that meet the needs of society in terms of quality of life and that the entire process of manufacturing and availability for consumption, that is, throughout its life cycle, should have the least possible impact on the environment [1].

Eco-efficiency is presented as a combination of the economic and environmental performance of a given system, assessed using a widely applied and easily interpreted framework that can be employed in a wide variety of business sectors, while providing a common set of indicators. Thus, eco-efficiency in the form of Equation (1) is presented as [2]:

This concept of eco-efficiency is widely applied to obtain a form that combines environmental and economic performance, for the most diverse product systems, processes and/or companies. It can be understood that the term ‘value’ present in the eco-efficiency equation can also refer to the related cost in manufacturing up to replacement of the product. The definition of eco-efficiency is given by the ratio between the (added) value of what was manufactured/generated (GDP, income, high quality goods and services offered, etc.) and the (added) impacts of the product or service [3]. For Huppes and Ishikawa [4], eco-efficiency is an instrument to analyze sustainability, in a way that indicates an empirical relationship of economic activities (costs involved) with environmental value (impacts to the environment). Still, it can be pointed out that eco-efficiency presents a role of encouraging business opportunities, allowing companies to become responsible in relation to the environment, while presenting profits [1]. Thus, industrial organizations are expected to produce goods and services by using the least number of resources and generating the least amount of waste and other pollutants [2].

The WBCSD identified seven characteristics that can be considered a guide for companies to become more eco-efficient: reduce material intensity/quantity; reduce energy intensity; increase recyclability; maximize the use of renewable resources; increase product durability; and increase service intensity [1][5].

In the business context, eco-efficiency can be applied at the product, process, corporate or industry level [6][7] and can also be assessed in relation to a specific service [3]. However, the application of this term goes far beyond being introduced as a business concept and can also be used at regional, national and global levels, through the evaluation of the eco-efficiency of cities, regions and countries [8][9][10].

Koskela and Vehmas verified in their work that eco-efficiency can be seen both as an environmental performance indicator and as a business strategy for sustainable development. In their study, the authors pointed out that the definitions and applications of eco-efficiency are associated with some aspects, such as: high production but with lower use of natural resources (produce more with less); produce more added value with lower environmental impact (ratio between economic value and environmental influence); use eco-efficiency as a management strategy (offer companies the possibility to get a new vision of their processes and increase their ability to innovate); a guidance to improve the eco-efficiency of an organization [11].

A wide range of scientific literature is available on eco-efficiency techniques, instruments and models. A systematic review is carried out in the next section.

2. Systematic Literature Review (SLR) Methodology and Procedures

For the development of the work, theoretical research was conducted based on a systematic literature review (SLR), to substantiate and level the knowledge about the subjects involved in the proposal. The SLR process involves three main phases: planning the review, conducting the review and reporting the review [12][13]. In each phase there are specific steps that are further detailed in this section.

In Planning the Review there are two steps to be performed: formulating the research problem and developing and validating the review protocol. Thus, the research question was specified and the review protocol was developed.

In the Conducting the Review phase there are five steps: searching the literature, screening for inclusion, assessing quality, extracting data, analyzing and synthesizing data.

To search the literature, the databases Scopus, Web of Science, Science Direct were used and the following keywords were used: “Eco-efficiency”, “Assessment” and “Model”.

In the screening phase for inclusion, the articles were screened excluding the articles according to the exclusion criteria established according to the research question. Initially, the titles and abstracts were read to select the articles. Table 1 presents the research protocol, containing the aspects used for searching and selecting articles for the RSL.

Table 1. Research protocol.

| Aspects for Article Selection | |

|---|---|

| Database | Scopus, Web of Science, Science Direct |

| Search strings used | “Eco-efficiency” AND “Assessment” AND “Model” |

| Research fields | Article title, abstract and keyword |

| Language | English |

| Publication date range | No limit was set for the date range |

| Exclusion Criteria |

|

Subsequently, in the step of assessing the quality of the selected texts, the texts were read in full and it was considered whether the articles provide clear and objective information about eco-efficiency assessment models.

Thus, primary studies were identified and selected and extracted (extract step) and the data referring to the theme were analyzed and synthesized (analyze step), according to the criteria established in Table 1.

The last phase, the Review Report, is composed of the step of reporting the findings to describe in a systematized way the information obtained from the literature review.

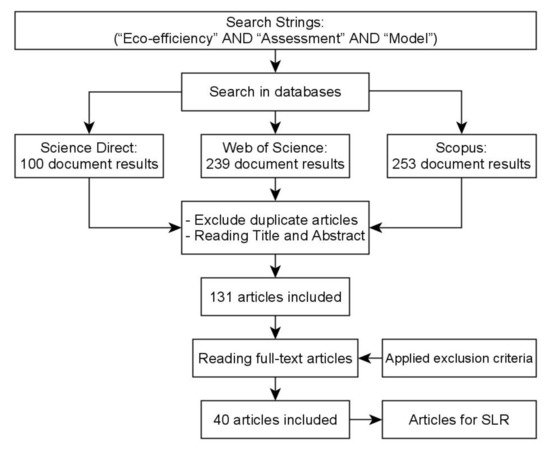

The results obtained from the literature search screening and quality assessment are presented in the flow chart shown in Figure 1.

Figure 1. Literature search and evaluation for inclusion of articles for SLR.

Initially, with searches in the three databases, as shown in Figure 1, 592 articles were found. Articles were exported to the StArt® (State of the Art through Systematic Review) software, a tool that provides support to carry out the systematic review process, facilitating the classification of articles to select which ones will be used for SLR [14]. Out of the 592 initial articles, 200 articles were excluded for duplication. By reading of the title and abstracts, 131 articles out of the 392 articles were selected as most aligned with the objective of the present research. Finally, 40 articles were selected as having a complete an eco- efficiency evaluation model and related application to evaluate processes, products, or services for eco-efficiency.

This entry is adapted from the peer-reviewed paper 10.3390/su132112121

References

- Council for Sustainable Development (WBCSD). Measuring eco-efficiency: A guide to reporting company performance WBCSD. 2000, pp. 1–39. Available online: https://www.gdrc.org/sustbiz/measuring.pdf (accessed on 30 September 2021).

- WBCSD. Introduction to the learning module WBCSD. 2006, pp. 1–231. Available online: https://docs.wbcsd.org/2006/08/EfficiencyLearningModule.pdf (accessed on 30 September 2021).

- Zhang, B.; Bi, J.; Fan, Z.; Yuan, Z.; Ge, J. Eco-efficiency analysis of industrial system in China: A data envelopment analysis approach. Ecol. Econ. 2008, 68, 306–316.

- Oliveira, M.; Fontes, D.; Pereira, T. Multicriteria Decision Making: A Case Study in the Automobile Industry. Ann. Manag. Sci. 2014, 3, 109–128.

- Diebold, W.; Schmidheiny, S. Changing Course: A Global Business Perspective on Development and the Environment. Foreign Aff. 1992, 71, 202.

- Lozano, S.; Adenso-Diaz, B.; Barba-Gutiérrez, Y. Russell non-radial eco-efficiency measure and scale elasticity of a sample of electric/electronic products. J. Frankl. Inst. 2011, 348, 1605–1614.

- Lucato, W.C.; Júnior, M.V.; Santos, J.C.D.S. Measuring the ecoefficiency of a manufacturing process: A conceptual proposal. Manag. Environ. Qual. Int. J. 2013, 24, 755–770.

- Xu, T.; Gao, P.; Yu, Q.; Fang, D. An Improved Eco-Efficiency Analysis Framework Based on Slacks-Based Measure Method. Sustainability 2017, 9, 952.

- Wang, C.-N.; Hsu, H.-P.; Wang, Y.-H.; Nguyen, T.-T. Eco-Efficiency Assessment for Some European Countries Using Slacks-Based Measure Data Envelopment Analysis. Appl. Sci. 2020, 10, 1760.

- Masternak-Janus, A.; Rybaczewska-Błażejowska, M. Comprehensive Regional Eco-Efficiency Analysis Based on Data Envelopment Analysis: The Case of Polish Regions. J. Ind. Ecol. 2016, 21, 180–190.

- Koskela, M.; Vehmas, J. Defining Eco-efficiency: A Case Study on the Finnish Forest Industry. Bus. Strat. Environ. 2012, 21, 546–566.

- Kitchenham, B. Guidelines for performing systematic literature reviews in software engineering. Tech. Rep. EBSE 2007, 1, 1–65.

- Brereton, P.; Kitchenham, B.; Budgen, D.; Turner, M.; Khalil, M. Lessons from applying the systematic literature review process within the software engineering domain. J. Syst. Softw. 2006, 80, 571–583.

- Fabbri, S.; Silva, C.; Hernandes, E.M.; Octaviano, F.; Di Thommazo, A.; Belgamo, A. Improvements in the StArt tool to better support the systematic review process. ACM Int. Conf. Proceeding Ser. 2016, 21, 5.

This entry is offline, you can click here to edit this entry!