Electrical and electronic equipment, the owner of the product no longer uses and has discarded or abandoned (including all parts/components, elements/devices and materials, etc.), as well as those substandard products, scrap products and expired products generated during the production, transportation and sales processes by “Technical Specifications for Pollution Control in the Treatment of Waste Electrical and Electronic Products (HJ527-2010)”.

- WEEE

- The fund

- circular reutilization

- pollution management

- intelligent management

- value-added and automated reutilization

1. Introduction

E-waste, or electronic waste, with a formal name of waste electric and electronic equipment (WEEE), is attracting wide attention from both China and the world since it is bond of resources, such as Cu, and precious metals like Pd, Pt, Au and Ag, but potential hazardous to the eco-environment and human health. It is the core of “Urban mining”. Since “the Guiyu issue” of 2002, a series of successes have been achieved because either the industry or the management of e-waste circular recycle gained huge development. However, it still necessary to stress the concept of the ordinary people, to improve the management system and most importantly, to break and improve the simple and original e-waste recycling scene and to further innovate the e-waste recycling technologies with the aim to support the e-waste recycling industry and its management. Therefore, to improve the understanding of e-waste for ordinary people, we analyzed the development of e-waste in China, pointed out the achievements in e-waste circular recycling and pollution control from the concept of e-waste. Then, we deeply discussed the problems during the e-waste recycling industry and its management based on the four levels of solid waste circular reutilization: repair/reuse/remanufacture, waste-to-materials, waste-to-products and waste-to-energy. Finally, we pointed out the direction of e-waste recycling industry based on industry ecology or integrated solid waste management strategy.

2. Definition

The definition of WEEE, also named as e-waste, electronic waste, is slightly different across countries and associations, and its official name in China is also changed for several times. The official name of WEEE in China changed for few times though its defined slightly varied. In 2003, it named as “electronic waste” in “Announcement of the State Environmental Protection Administration on Strengthening the Environmental Management of Electronic waste” [1]. Its definition was specified in 2007 by the “Administrative Measures for the Prevention and Control of Environmental Pollution by Electronic Waste”: the discarded electronic & electrical products or electronic & electrical equipment, the discarded parts and components thereof, as well as the articles and substances that are subject to the management of electronic waste as prescribed by the State Environmental Protection Administration together with other relevant departments; and includes the obsolete products or equipment generated in the industrial production, the obsolete semi-finished products and residues, the obsolete products generated in the repair, renovation and reproduction of products or equipment, the products or equipment discarded in the daily life or in the activities of providing services for daily life, as well as the products or equipment that is prohibited to be produced or imported by any law or regulation [2]. Then, in 2009, after the promulgation of “Regulation on the Administration of the Recovery and Disposal of Waste Electrical and Electronic Products (revised in 2019)”, its official name was fixed to the same as international [3]. In 2010, its definition was further cleared as: electrical and electronic equipment that the owner of the product no longer uses and has discarded or abandoned (including all parts/components, elements/devices and materials, etc.), as well as those substandard products, scrap products and expired products generated during the production, transportation and sales processes by “Technical Specifications for Pollution Control in the Treatment of Waste Electrical and Electronic Products (HJ527-2010)” [4].

3. Chinese WEEE Management policy

On February 25, 2002, Basel Action Network (BAN) and the Silicon Valley Toxics Coalition (SVTC) issued a long report: “Exporting Harm: The High-Tech Trashing of Asia”, and pointed out that 80% of the world’s e-waste was transferred to Asia, 90% of which went to China [5]. Guiyu, China, has suffered an extremely serious ecological and environmental crisis due to the recycling of non-ferrous metals and precious metals from WEEE by primitive disposal methods, such as open burning, etc., known as Chinese “First village of E-Waste Dismantling”. In view of this, on July 3, 2002, the Ministry of Foreign Trade and Economic Cooperation, the General Administration of Customs and the State Environmental Protection Administration of the People’s Republic of China jointly announced “Catalogue of Prohibited Imports (Fifth batch, Announcement No.25, 2002)” [6] and prohibited in the import of 21 kinds of WEEE (Including its parts, disassembled parts, broken parts and smashed parts unless otherwise specified by the state). On August 26, 2003, the State Administration of Environmental Protection issued the “Announcement of the State Environmental Protection Administration on Strengthening the Environmental Management of Electronic waste”. This is the first enacted regulation in China about WEEE, the first landmark of Chinese electronic waste industry, declaring that WEEE management in China has entered a stage of rapid development from the initial stage.

Since then, China has promulgated “Technical Policy for Pollution Prevention and Control of Waste Household Appliances and Electronic Products (2006) ” [7], “Measures for the Control of Pollution from Electronic Information Products (2007)” [8], “Administrative Measures for the Recovery of Renewable Resources (issued in 2007 and revised in 2019)” [9], “Administrative Measures for the Prevention and Control of Environmental Pollution by Electronic Waste (2008)” [10], “Technical Specifications for Pollution Control in the Treatment of Waste Electrical and Electronic Products (HJ527-2010)” and other relevant laws and regulations one after another to guide the development of Chinese WEEE industry. However, the most important and well-respected "Regulation on the Administration of the Recovery and Disposal of Waste Electrical and Electronic Equipment" was officially announced on February 25, 2009, and formally implemented on January 1, 2011 (revised in 2019) [11], nearly ten years from incubation to publication and then to implementation. It established a multi-channel recycling and centralized processing system, a qualification licensing system, and required the establishment of a WEEE processing fund, known as the Chinese version of WEEE Directive. The formal implementation of this regulation is another landmark event in Chinese e-waste industry, announcing that Chinese WEEE management has entered a stage of gradual improvement from rapid development.

In order to coordinate and improve the implementation of the "Regulation on the Administration of the Recovery and Disposal of Waste Electrical and Electronic Equipment", many laws or regulations, such as “Measures for the Administration of Recycling of Waste Electrical and Electronic Products (Draft for Solicitation of Comments)” [12], “Measures for the Collection, Use and Administration of Funds for the Disposal of Wasted Electrical and Electronic Equipment” [13], “Notice on further clarifying the scope of products levied by the Waste Electrical Appliances Treatment Fund” [14], “Notice on Improving Policies for the Treatment of Waste Electrical and Electronic Equipment” [15], “Guidelines for Dismantling, Disposing and Production Management of Waste Electrical and Electronic Equipment (2015 Edition)” [16], “Guidelines for the Audit of the dismantling and treatment of waste electrical and electronic Equipment (2015 edition)” [17], “Disposal catalog of waste electrical and electronic Equipment (2014 edition)” [18], “Subsidy Standards for Waste Electrical and Electronic Equipment Treatment Fund” [19], “Administrative Measures for Eligibility License for Disposal of Waste and Discarded Electrical and Electronic Equipment” [20] and “Guidelines for the Audit of the dismantling and treatment of waste electrical and electronic Equipment (2019 edition)” [21], etc., have been issued one after another. Among them, “Measures for the Administration of the Restricted Use of the Hazardous Substances Contained in Electrical and Electronic Equipment” [22], which was announced on January 6, 2016, and implemented on July 1, 2016, proposed the management of the restricted use of hazardous substances, including the types of electrical and electronic equipment, the types of hazardous substances that are restricted, restricted use time and exemption requirements. At the same time, it increased the qualification audit system for restricted use of hazardous substances in electrical and electronic equipment, which is the Chinese version of RoHS Directive. In 2020, “Implementation Plan on Improving the Recycling and Treatment System of Waste Home Appliances and Promoting the Renewal of Household Appliances Consumption" run through the industrial chain of recycling and treatment of WEEE [23]. In the same year, the 17th Meeting of the Standing Committee of the 13th National People’s Congress reviewed and passed the revised “Law of the People's Republic of China on the Prevention and Control of Environment Pollution Caused by Solid Wastes” [24], which redefined the extended producer responsibility system, multi-channel collecting and centralized processing and disposal system for WEEE. It is expected that the e-waste industry will usher in new development opportunities, thereby promoting the transformation, upgrading and long-term development of the industry.

During this time, a large number of useful explorations were carried out. In 2004, the National Development and Reform Commission supported the construction of WEEE resource treatment projects in Qingdao, Hangzhou, Beijing and Tianjin with the funds of national debt. The campaign of “Home Appliances to the Rural Areas” was launched in December 2007 and was fully promoted in February 2009. From June 2009 to the end of 2011, the "replacement of old for new" activity for home appliance had greatly increased the formal recovery rate of WEEE and promoted the development of Chinese WEEE formal disposal system. The subsidy policy of WEEE was formally implemented in July 2012, which has become the main driving force to promote the recycling and disposal of WEEE. “The Implementation plan of the extended producer responsibility system” [25] put forward clear requirements for promoting the implementation of the extended producer responsibility system of electrical and electronic equipment. At present, China has initially formed a comprehensive, sound, legal and regulatory management system for e-waste recycling and pollution control, covering the collection, transportation, treatment and disposal, as well as the production, import and export, sales and other parts of electrical and electronic equipment.

4. Chinese WEEE Achievements in recent years

Under the vigorous promotion of WEEE related policies, Chinese e-waste recycling industry has also developed rapidly, mainly reflected in the following four aspects: effective containment of informal processing due to the rapid development of WEEE processing industry, continuous improvement of management methods, significant resource and environmental benefits, and an international leading recycling efficiency.

From 2012 to 2019, a total of 5 batches of 109 authorized WEEE recycling companies were included in the list of WEEE fund subsidies, distributed in 29 provincial administrative units, with an annual processing capacity of 163 million units. As shown in Tables 1 and 2, the amount of WEEE dismantling in China increased significantly. In 2019, 83.56 million WEEE were recycled and disposed of, including 43.19 million TVs, 10.77 million refrigerators, 15.73 million washing machines, 6.2 million air conditioners and 7.67 million computers. Compared with 2013, the amount of dismantling in 2014 nearly doubled, and the average growth rate from 2014 to 2019 exceeded 13% [26][27]. At the same time, a set of technical routes, combining labor and machinery, suitable for Chinese characteristics has been developed, and the company dismantling technology, equipment and production lines have been continuously standardized and improved, as shown in Figure 1.

Table 1. Dismantling volume of WEEE of 109 qualified enterprises from 2013 to 2019 10,000 units.

|

|

TV |

Refrigerator |

Washing machine |

Air conditioner |

Computer |

Total |

|

2013 |

4027 |

62 |

171 |

0.5 |

126 |

4386.5 |

|

2014 |

5764 |

158 |

328 |

11 |

785 |

7046 |

|

2015 |

5317 |

333 |

637 |

19 |

732 |

7625 |

|

2016 |

4425 |

615 |

1271 |

210 |

1492 |

8013 |

|

2017 |

4208 |

804 |

1360 |

398 |

1227 |

7997 |

|

2018 |

4253 |

922 |

1441 |

506 |

978 |

8100 |

|

2019 |

4319 |

1077 |

1573 |

620 |

767 |

8356 |

Table 2. Increasing rate of WEEE dismantling during 2013-2019.

|

Year |

2014 |

2015 |

2016 |

2017 |

2018 |

2019 |

Average |

|

Yearly increasing rate, % |

60.63% |

8.17% |

5.13% |

-0.20% |

1.29% |

3.17% |

13.03% |

Figure 1. Disassembling line of an e-waste recycling company in Sichuan.

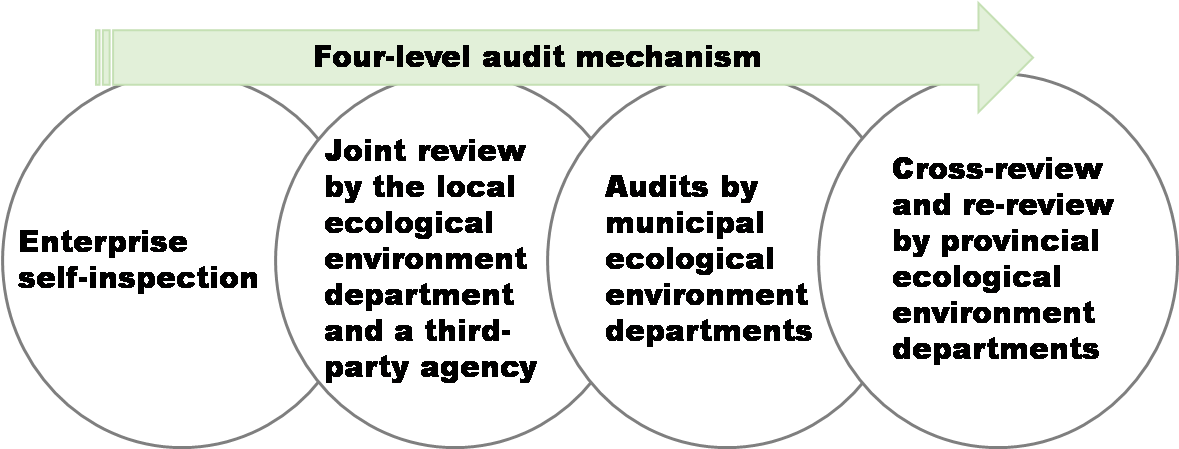

In 2012, qualification dismantling enterprises first adopted daily reports for the information management of its operation. In 2016, the technology of Internet of Things and video monitoring methods were comprehensively applied to achieve full coverage, no dead ends, and real-time dynamic monitoring for the production and operation process. Third-party professional organizations are adopted to conduct independent audits on the standardized management, key dismantling products, hazardous wastes of qualified dismantling companies every quarter. Taking Sichuan as an example, a “four-level audit mechanism” has been established, that is, enterprise self-inspection, joint preliminary review by the local ecological environment department and a third-party agency, audits by municipal ecological environment departments, and cross-review and re-review by provincial ecological environment departments, shown in Figure 2. At present, the supervision of qualified dismantling enterprises by governments at all levels has also shifted from the previous step-by-step management strictly in accordance with the guidelines to the environmental risk management of hazardous waste and other emissions, which is specifically reflected in the newly revised "Guidelines for the Audit of the dismantling and treatment of waste electrical and electronic Equipment (2019 edition)".

Figure 2. “Four-level audit mechanism” in Sichuan.

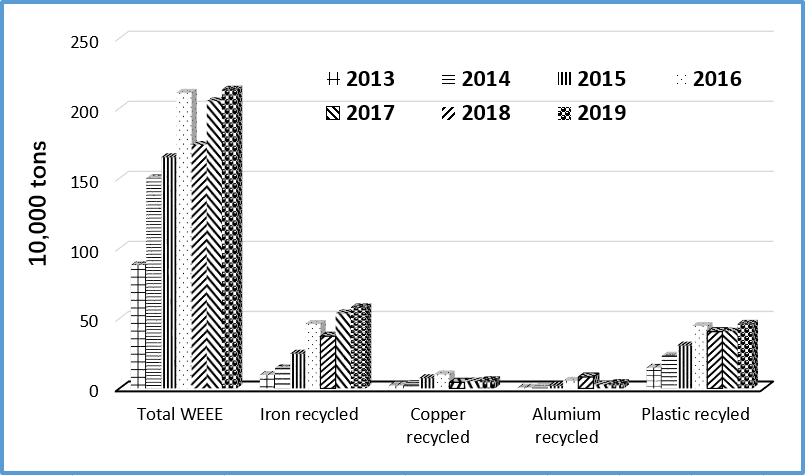

From 2013 to 2019, a total of 12,060,000.04 tons of key dismantling products were recycled from 109 qualified WEEE dismantling enterprises, including 2,437,300 tons of synthetic pig iron, 375,400 tons of recycled copper, 229,400 tons of recycled aluminum and 2,404,300 tons of recycled plastics, as shown in Figure 3[26][27]. Meanwhile, under the promotion of the “Implementation Plan on Improving the Recycling and Treatment System of Waste Home Appliances and Promoting the Renewal of Household Appliances Consumption”, Chinese WEEE recycling industry is transforming from simple dismantling to fine and high-value automation, Figure 1.

WEEE recycling show remarkable benefits, lead the development of Chinese “urban mining” industry, and greatly promote the construction of “zero-waste city” in China. In addition, due to the “Regulation on the Administration of the Recovery and Disposal of Waste Electrical and Electronic Equipment” and relevant supporting policies, the dismantling activities of 109 processing enterprises are forced to be standardized, and their production management has to be carried out the requirements of “the fund”. At the end, the standardization level of these 109 qualification enterprises are continuously improving.

Figure 3. E-waste and dismantling products recycled by the qualified e-waste recycling companies.

5. Four levels of e-waste circular reutilization

Previously, scholars classified resource circular reutilization into four levels: repair, reuse and remanufacture (3Re), waste-to-materials, waste-to-products and waste-to-energy. At present, 109 qualified dismantling enterprises recycle e-waste for the purpose of obtaining renewable resources, which belongs to the second level of resource recycling [6].

Repair, reuse and remanufacturing, more or less including refurbishment (refurbish, the repaired product that does not meet the quality standards before sales), are waste parts or components such as electronic components that have been repaired and restored to functional use before being consumed or used for the preparation of new products. Apple sells certified refurbished electric and electronic products with much lower prices than new ones. The most representative example of 3Re is the refilling of glass beer bottles, which has a history of more than 100 years. However, in the field of electrical and electronic products/equipment, 3Re still has a long way to go, although 3Re of WEEE and its parts/components has already formed a certain market in China with a clear division of labor and operation norms at different levels. One of the reasons is that the laws, regulations and industry-related standards relating to WEEE and its parts or components have not yet been enacted, remaining a grey area. In addition, it is worth noting that intellectual property rights of 3Re WEEE are still unresolved both at home and abroad. The ink cartridges case of Cannon, Inc. and Recycle Assist was so serious that any company that attempts to collect unusable or discarded electronic information products for selling in the market through 3Re has to face the risk of legal action [7]. However, according to the “Circular Economy Promotion Law of the People's Republic of China” [28] and the “Administrative Measures for the Circulation of the Used Electrical and Electronic Products” [29], 3Re WEEE, if it gives details of 3Re in a prominent position, meets quality standards and ensures traceability, could be sold without the permission of the trademark owner of the original product and is not an infringement. But in China, most of these activities are personal behaviors, while corporate behaviors are rare and mostly secretive.

According to the “Guidelines for Dismantling, Disposing and Production Management of Waste Electrical and Electronic Equipment (2015 Edition)” for the recycling of e-waste by 109 qualified enterprises in China, their recycling behaviors are all belong to the second level, material regeneration. In other words, WEEE is regenerated into various raw materials, such as recycled copper, iron, aluminum, plastics, etc., for new products by physical and chemical means, i.e., the mechanical physical approach adopted by most 109 enterprises and pyrometallurgy adopted by CECEP (SHANTOU) Recycling Resources Technology Co., Ltd.

Material transformation means that, after 3Re and high-value resources extraction, the remaining part of solid waste, such as WEEE, is transformed into other materials or products via physical, chemical, microbiological and/or other means. Of course, it also includes directly transformation if it is of little value. For example, the cement kiln, which now China is vigorously used to promote the co-processing of hazardous waste, has actually been widely used in the treatment of coal slag and steel slag before. Building materials is recognized as the main direction for bulk solid waste consumption and the most important way for the third-level of waste recycling. For electronic waste, because of its own characteristics, there are relatively few studies and applications at the third level; a typical example is waste resin powder, generated by mechanical and physical methods for copper recycling from waste printed circuit boards, which is used as wood-plastic materials with many successful industrial application cases. However, other solutions to such low-value added WEEE need to be further explored.

Energy recovery, in fact, is to convert the combustible components into heat energy through combustion. And then energy is used through the heat energy conversion device. The most typical example is power generation from municipal solid waste. In terms of WEEE, most of the researches in this area focus on waste resin powder after the mechanical-physical recovery of copper from waste printed circuit boards. Because these waste resin powders contain a large amount of persistent organic pollutants such as brominated flame retardants, currently there is no such industrial incineration treatment and disposal facilities. Meanwhile, waste polyurethane foam is in the same position as the waste resin powders, widely discussed for energy recovery but currently with no industrial application.

As mentioned previously, the recycling of WEEE in China mainly focuses on the second level but not the other three levels, especially the first level. Although the first level can greatly extend the life span of electronic and electrical equipment, significantly reduce the consumption of energy materials and greatly improve the social, economic and environmental benefits, there is still a lot of work to be done for its large-scale promotion, i.e., the extremely complexed intellectual property and the logistics tracking of 3Re products. There are also issues of environmental risk control since the deeper the recycling of resources, the higher the environmental risk may be. Besides, there remains environmental risk transfer during the process of resources recycling. For example, waste resin powder could be used to prepare park benches. By this process, hazardous waste, waste resin powder, is converted to new products, tremendous changes in its nature. Therefore, it should be carefully and deeply considered if this process is free of environmental risk transfer.

6. Conclusions and Perspective

Recently, China has made great achievements in WEEE recycling and pollution control: a significant rising in dismantling number and dismantling technology, continuously improving in WEEE equipment and information management, and significant social, economic and environmental benefits from the recycled resources. Although Chinese WEEE management has begun to turn to the intelligent management of emissions supervision, especially hazardous waste; recycling technology has also turned to high-value added and automated utilization, it still needs to be noted that Chinese WEEE industry remains in the third level while other levels, especially 3Re, are seriously inadequate. In-depth recycling technology remains in the exploratory stage, and WEEE recycling industry transformation and upgrading is also imminent. In addition, there is still a lot of work to be done on intellectual property, environmental risk control and transfer during the process of resource recycling.

References

- Notice on Strengthening Environmental Management of Waste Electronic and Electrical Equipment . SEPA. Retrieved 2021-12-5

- Administrative Measures for the Prevention and Control of Environmental Pollution by Electronic Waste . State Administration of Environmental Protection. Retrieved 2021-12-5

- Regulation on the Administration of the Recovery and Disposal of Waste Electrical and Electronic Products . State Council. Retrieved 2021-12-5

- Technical specifications of pollution control for processing waste electrical and electronic equipment . Ministry of Ecology and Environment of the People's Republic of China. Retrieved 2021-12-5

- Jim Puckett, BAN Leslie Byster, SVTC Sarah Westervelt, BAN Richard Gutierrez, BAN Sheila Davis, MFF Asma Hussain, SCOPE Madhumitta Dutta, Toxics Link India. Exporting harm: the high-tech trashing of Asia; Jim Puckett, Ted Smith, Eds.; Diane Publishing Co: Pakistan, 2012; pp. 1-54.

- The Ministry of Foreign Trade and Economic Cooperation, the General Administration of Customs and the State Environ-mental Protection Administration issued the announcement of the List of Goods Prohibited from Import (the fourth and fifth batches) . SEPA. Retrieved 2021-12-5

- Notice on the release of "Waste Household Appliances and Electronic Products pollution prevention and Control technology Policy" . SEPA. Retrieved 2021-12-5

- easures for the Control of Pollution from Electronic Information Products . State Development & Reform Commission. Retrieved 2021-12-5

- Administrative Measures for the Recovery of Renewable Resources . Ministry of Commerce State Development & Reform Commission. Retrieved 2021-12-5

- Administrative Measures for the Prevention and Control of Environmental Pollution by Electronic Waste . State Administration of Environmental Protection. Retrieved 2021-12-5

- Regulation on the Administration of the Recovery and Disposal of Waste Electrical and Electronic Products (2019 Revision) . State Council. Retrieved 2021-12-5

- Administrative Measures for the Recovery of Waste Electrical and electronic products . Ministry of Commerce of the People's Republic of China. Retrieved 2021-12-5

- Administrative measures for the collection and Use of waste electrical and electronic products disposal funds . Ministry of Environmental Protection. Retrieved 2021-12-5

- Notice on further clarifying the scope of products to be levied from waste electrical and electronic products processing fund. . SAT. Retrieved 2021-12-5

- On the improvement of waste electrical and electronic products processing fund and other policies notice . Central People's Government of the People's Republic of China. Retrieved 2021-12-5

- Specification of Waste Electrical and Electronic Products Disassembly treatment Operation and Production Management Guide (2015 edition) . Ministry of Environmental Protection. Retrieved 2021-12-5

- Notice on Further Clarifying the Scope of Products to Be Levied from Waste Electrical and Electronic Products Processing Fund . SAT. Retrieved 2021-12-5

- On the Improvement of Waste Electrical and Electronic Products Processing Fund and Other Policies Notice . Central People’s Government of the People’s Republic of China. Retrieved 2021-12-5

- Specification of Waste Electrical and Electronic Products Disassembly treatment Operation and Production Management Guide (2015 edition . Ministry of Environmental Protection. Retrieved 2021-12-5

- Guidelines for Reviewing the Disassembly and Disposal of Waste Electrical and Electronic Products . Ministry of Environmental Protection. Retrieved 2021-12-5

- Disposal Catalogue of Waste Electrical and Electronic Products (2014 Edition) . National Development and Reform Commission. Retrieved 2021-12-5

- Waste Electrical and Electronic Products Processing Fund Subsidy Standard . The Ministry of Finance. Retrieved 2021-12-5

- Administrative Measures for disposing qualification of Waste Electrical and electronic Products . Ministry of Environmental Protection. Retrieved 2021-12-5

- Law of the People's Republic of China on the Prevention and Control of Environmental Pollution by Solid Waste . Ministry of Ecology and Environment. Retrieved 2021-12-5

- Implementation plan of extended producer responsibility system . General Office of the State Council. Retrieved 2021-12-5

- The Implementation Plan of Improving the Recycling and Processing System of Waste Home Appliances to Promote the Renewal Consumption of Home Appliances . Central People’s Government of the People’s Republic of China. Retrieved 2021-12-5

- Law of the People’s Republic of China on the Prevention and Control of Environmental Pollution by Solid Waste . Ministry of Ecology and Environment. Retrieved 2021-12-5

- Implementation Plan of Extended Producer Responsibility System . General Office of the State Council. Retrieved 2021-12-5

- China's renewable resource recycling industry development report . China National Resources Recycling Associatio. Retrieved 2021-12-5