1. Port Activities and Power Consumers

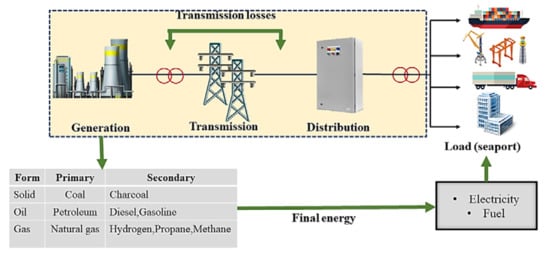

Port engagement with respect to energy can be classified into energy generation and power consumption mainly in the form of electricity and fuel. It is crucial to comprehend the load components and monitor energy-related activities taking place within the port before initiating any energy planning. The purpose is to analyze the amount of energy demand and ensure that there is enough power supply to prevent power shortages. However, load profile measures at seaports vary according to several factors such as the type of port and activities conducted at that particular port.

Seaports by definition can be viewed as centers of economic activities associated with any kind of arrival (tourist or goods), service of ships, and cargo [

6]. The most common ports can be categorized into commercial/industrial ports [

2], container terminal ports [

7], and intermodal ports [

8,

9]. In another classification provided in [

10], ports are classified into three types, such as local ports, national ports, and international ports. These classifications are based on the ports’ characteristics, region of the port, the volume of loads it serves, vessel type, port’s operation and services, the annual number of passengers, and the annual number of ships berthing in and out from the port. Different types of ports and their characteristics are summarized in

Table 1.

Table 1. Classification of ports [

10].

| Port Type |

Characteristics |

| Local port |

Serves for local needs

Limited space and capacity

Small size

No logistic activity handling

Do not support cruise ships

Boats, vessels, yachts, and small-sized ships < 500 passengers |

| National port |

Serves country needs

Medium-sized (larger than local port)

Cover all ships type with small logistic and cruise activities

Medium-sized ships < 2500 passengers, cargo (packages), and logistics (only trucks) |

| International port |

Serves international needs

Largest sized

Provide huge logistic infrastructure

Cruise ships > 2500 passengers, cargo, containerships, and RTG cranes |

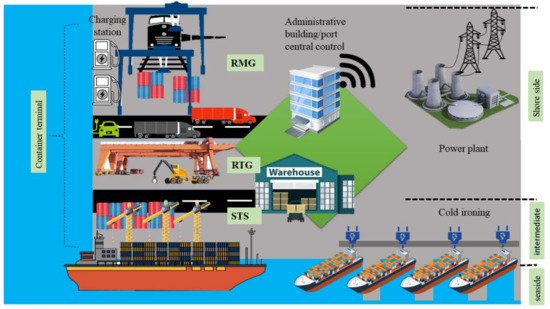

Geographically, a seaport is the point of interaction between land and sea, which involves two modes of transportation (water and road traffic) with different characteristics. From this perspective, the seaport area can be sorted into the seaside, shore side, and intermediate space. Each space is utilized for a different type of activity, transportation, and application, all of which have an impact on the amount of energy demand. Figure 3 illustrates the most common activities running in the seaport area and its load components.

Figure 3. Seaport activities and load components (abbreviations: rail mounted gantry (RMG), rubber tyred gantry (RTG), and ship to shore (STS)).

Loads on the shore-side: On the shore side, administrative buildings and a custom facility, as well as a warehouse for goods, are built. In this infrastructure, electricity is consumed mostly for lighting; Heating, Ventilation, and Air Conditioning (HVAC) system; and equipment [

11]. Many factors influence the building’s energy consumption, including weather conditions, building materials, occupant behavior, work durations, equipment, and electrical load used [

12].

In terms of transportation, different land vehicles such as trucks, cranes, yard tractors, and trains are powered by diesel fuel, and electricity is needed for electric vehicle (EV) charging stations. Typically, diesel is used as the primary source for motor movement in the cranes. However, recent research studies on electrical cranes show a lot of interest in energy storage systems for storing potential energy regenerated from lowering and lifting cranes operations [

13].

Loads on the seaside: The seaside is includes a marine vessel or any watercraft transportation voyages across the ocean that serves the purpose of carrying passengers or delivering cargo. Ships will make more voyages, consume more fuel, and increase the volume of water traffic as global trade expands. Normally heavy fuel oil (HFO) is consumed for big vessels and bulk carriers. General cargo vessels consume the most HFO, followed by oil tankers and cruise ships accounting for 66,000 t, 43,000 t, and 25,000 t of HFO annual consumption, respectively [

14]. The spill of fossil-based marine fuel into the water and its combustion into the air can become a major threat to the environment [

15]. Despite its undesired environmental impacts, HFO continues to be the preferred fuel of the maritime transport industry due to its relatively low cost, widely available resources, and the ability to suit engines that were originally designed for HFO [

14].

In order to prevent heavy utilization of HFO and to be in line with port development, ship technology is embracing the electrification concept by implementing an Integrated Power System (IPS) and storage system known as All Electric Ship (AES) [

16]. Energy usage for a vessel is hard to measure as it depends on numerous aspects such as the size of the vessel, onboard loads, vessel speed, sea waves, and weather conditions.

During berthing for transit or transferring goods, the auxiliary engines of the ships are kept operating in order to supply the energy for onboard loads [

17]. To overcome continuous fossil fuel burning, cold-ironing facilities are provided at the intermediate area between the sea and shore side. Power requirement varies from 300 kW to 7 MW depending on the type of ships and berthing duration [

18]. In addition to the onshore power supply, the port must accommodate shore charging facilities. Some of the vessels with storage components such as hybrid vessels and AES will need a charging station in the port area for recharging their batteries and supplying onboard loads.

Loads in the intermediate area: In this region, there are cold ironing, charging stations, and container terminal facilities. The container terminal is an important part of international logistics and requires a large amount of energy, both fuel and electricity [

19], for loading and unloading cargo as well as the transshipping goods to the next mode of transportation [

20]. Container terminals serve three primary functions: yard side, quayside, and landside [

21]. Each side has its operation and transportation needs. Cold storage facilities among the terminal operation consume a lot of energy, as it is a temperature-controlled storage solution for perishable goods. The Port of Wilmington built a 101,000 square foot refrigerated warehouse to refrigerate food, pharmaceutical, floral, and other items that require maintaining specific temperatures for storage [

22]. It allows distribution companies to deliver their goods locally, nationally, and globally in good conditions.

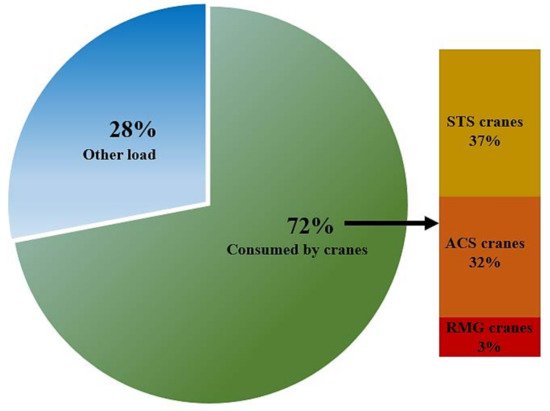

In the container terminal, there are various types of cranes in use, from ship to shore (STS)/quay cranes (QC) to automated guided vehicles (AGVs)/automated straddle carriers (ASCs), and, finally, rail-mounted gantry (RMG) cranes, before they are transferred into truck/trains [

23]. Considering peak power demand, cranes need about 72% of total energy (STS cranes about 37%, ASC cranes 32%, and RMG around 3%) [

24]. The breakdown of the cranes’ power demand is shown in the pie chart of

Figure 4.

Figure 4. Breakdown of cranes power demand during demand peak intervals.

From the appliances that are used and activities conducted within the marine port, it can be observed that the seaport sector has a large energy demand that makes the energy-handling problem a complex task. Hence, a reliable power system is required that can provide sufficient energy supply to all distribution loads. Any shortcoming in energy delivery will cause a big disruption to the seaport’s operations.

Therefore, it is very important to distinguish between critical and non-priority loads so that the critical loads will receive priority during emergencies in order to obtain energy supplies [

25].

Table 2 summarizes the findings regarding seaport-related services and their load.

Table 2. Seaport activities and loads variation [

2,

26].

| Seaport’s Services |

Load |

Factor Influence Energy Consumption |

Load Classifications |

Form of Energy |

| Vessel |

Passenger ships (cruise, ferry), container ships, electric ships, tugs, gliders, bunkers, boats, tankers, hovercraft, sailboats, submarines, yachts |

Size of the ship, activity conduct on the ship, time of operation, weather, wave, speed |

- (1)

-

Peak load

- (2)

-

Critical load

- (3)

-

Non-critical load

- (4)

-

Variable load

- (5)

-

Constant load

|

- (1)

-

Electricity

- (2)

-

Fossil fuel

|

| Goods handling |

Cargo, container, quay, logistic, freight forwarder, customs warehouse, storage, security, loading-unloading |

Number of cranes, amount of cargo, hours of operation |

| Administration |

Management and administrative building, planning, service solution, IT, monitoring |

Type of electrical equipment, weather, building material, hours of operation, occupant behavior |

| Transportation |

Electric vehicles, cranes, trucks, yard tractors, trains |

Number of transportation, hours of consumption |

| Electric Facility |

Cold ironing, charging station for electric vehicles |

Time of berthing, number of ships per berthing, size, and ship’s load |

| Maintenance |

Repair and maintenance |

Type of the maintenance |

2. Port Critical Concerns and Green Maritime Policy

The urgent need for a more efficient maritime system demands a great effort to increase the performance of every subsystem linked to it by implementing an energy efficiency program. It is critical to identify the root of the problem and core issues in the port in order to achieve a good outcome from planning.

The European Sea Ports Organisation (ESPO) in their latest report (October 2020) highlighted the top ten priorities of the port sector from 1996 to 2020 [

27].

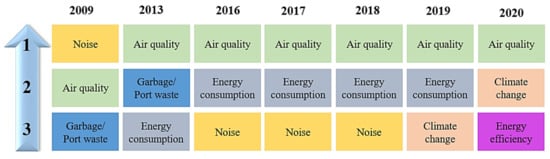

Figure 5 shows the top three port issues from 2009 until 2020. As observed in this figure, most of the issues listed have remained the same while their relative positions have changed over time. However, air quality and energy consumption remained mostly the highest priorities. These data are important as it identifies the vital concerns that port managing sectors are working on.

Figure 5. Top three issues in the port from 1996 to 2020 [

27].

According to the top three priority issues highlighted in

Figure 5, air quality has persisted as number one from 2013 to 2020 followed by energy consumption. The problem arises from the fact that air quality, noise, port waste, and climate change are strongly related to environmental concerns. This indicates that environmental issues are big problems in the port sector and require immediate action. Without fast action, the emissions from maritime transportations are predicted to rise by 250% in 2050 from the amount released in 2012 [

1]. Heavy utilization of fossil fuel in marine transportation and other areas contributes to serious air pollution from Carbon Dioxide (CO

2) and greenhouse gas (GHG) emissions. This is because the fossil sources encompass hazardous contents, which in burning it will emit chemical and dangerous gases such as particulate matter (PM); CO

2); sulphur dioxide (SO

2); nitrogen oxides (NOx); and black carbon (BC) to the air [

28]. Consequently, this emission results in acid rain and serious climate changes. It is also capable to reaching 400 km [

29] of land and produces a negative effect on human health such as asthma, tuberculosis, impact on children’s lung growth, cardiovascular disease, and lung cancer.

Meanwhile, ports’ energy consumption has increased due to various reasons. Development and expanded port functionalities over time raise the energy demand from many facilities and loads with low and heavy consumption. Continuous heavy use of energy will cause fast energy resources depletion. The inequality between energy production and demand results in frequent unplanned power outages. Poor power quality, lack of energy monitoring, and old instruments are also among the factors that cause the high energy consumption problem resulting in additional energy costs in ports’ daily operation. The need for improvement both in infrastructure and port power system will acquire a huge amount of investment. Lacking proper planning and a solid development framework will cause great losses. Based on these scenarios, three major issues related to seaports include energy, environment, and cost, as shown in Figure 6.

Figure 6. The three vital issues in the maritime sector.

Due to the serious environmental impacts caused by pollution from marine logistics, ports are moving toward a greener industry by implementing various alternatives. Particularly, in recent years, the arising awareness on environmental issues has made this target one of the compulsory goals in achieving high-energy efficiency levels. Authorities have formulated port policies consistently with tight regulation in order to ensure minimum GHG emissions. In this regard, the International Maritime Organization (IMO) in the latest regulation limits the sulfur content in fuel to 0.5% m/m, known as ‘IMO 2020’ [

30]. The change in sulfur limitation from 2000 to 2020 is shown in

Table 3. The five most important outcomes from IMO 2020 are as follows: (1) cleaner air, (2) higher quality fuel, (3) positive impact on human health, (4) ship operator role, and (5) changes for enforcement authorities.

Table 3. Change in fuel sulfur limit. Source: Marpol 2018, Marpol Annex VI.

| Date |

Sulfur Limit in Fuel (% m/m) |

| SOx ECA |

Global |

| 2000 |

1.5 |

4.5 |

| 2010 |

1.0 |

| 2012 |

3.5 |

| 2015 |

0.1 |

| 2020 |

0.5 |

In line with the green port objective, the Port Authority of Genoa (GPA) is developing a plan integrating renewable energy in their marine sector known as the Port Energy Environmental Plan (PEEP). The ultimate goal of the PEEP is to reduce 20,000 t of CO

2 annually by utilizing 12 plug cold ironing facilities, wind turbines, and photovoltaic power stations with an overall investment of 60 million Euros [

31].

In order to move towards a healthier environmental space, ports must plan and manage their operations and future potential expansion in a sustainable manner. Saeyeon Roh et al. [

32] in their research stated that the majority of the existing literature’s emphasis is on the environmental aspects for sustainable development, but they fail to clarify what factors influence this process. Several authors studied the causes that contribute towards air pollution and environmental damage from the operation of the harbors. Bunkering from the vessels generates the risk of oil spill with potentially disastrous impacts on the food chains of beaches [

33]. Matishov and Selifonova [

34] pointed out that the source of water resources damage comes from a high density of ship transportation via waterborne traffic. Meanwhile, Brigitte Behrends and Gerd Liebezeit [

35] addressed that the two leading destructive factors generated by shipping movement are atmospheric and seawater contaminations. In an attempt to safeguard nature and waterways, new legislation for future growth of ports and their construction at both international and domestic levels are released from time to time, aiming to handle environmental issues based on strict standards for core ports’ strategies. For instance, legislations in a few countries are listed in

Table 4 below [

33];

Table 4. List of legislations in a few countries.

| Country |

Legislation |

| EU |

Classification Societies—Regulation (EC) No 391/2009; Ship-Source Pollution—Directive 2000/59/EC; Marine Equipment—Directive 96/98/EC and Directive 2014/90/EU |

| Australia |

Environmental Protection Act 1986 (WA) |

| New Zealand |

Resource Management (Marine Pollution) Regulations |

| USA |

Diesel Emission Reduction Act (DERA) |

| Singapore |

Environmental Protection and Management Act (Cap.94A) |

Without a doubt, all of these environmental legislations offer vast advantages in terms of health, clean air, economy, energy, and potential for new technology if they are properly considered in port planning. Nevertheless, the great challenge is that all the planning steps must be compatible with the rules, from the initial step of research and development, collecting real-time data, collaboration among the parties, implementing, monitoring, and analysis. All of these stages are time consuming and involve high capital investment where payback period analysis is necessary. Cost is one of the main drivers to run all strategic planning. Due to this risk, the relevant parties, especially the ports themselves, are reluctant to implement any environmental program.