The biogas production technology has improved over the last years for the aim of reducing the costs of the process, increasing the biogas yields, and minimizing the greenhouse gas emmisions. To obtain a stable and efficient biogas production, there are several design considerations and operational parameters to be taken into account. Besides, adapting the process to unanticipated conditions can be achieved by adaquate monitoring of various operational parameters. This paper reviewa the research that has been conducted over the last years. This review paper summarizes the developments in biogas design and operation, while highlighting the main factors that affect the efficiency of the anaerobic digestion process. The study´s outcomes revealed that the optimum operational values of the main parameters may vary from one biogas plant to another. Additionally, the negative conditions that should be avoided while operating a biogas plant were identified.

- biogas plants

- anaerobic digestion

- plant monitoring

- bioenergy

- process optimization

1. Introduction

To meet the increased demand for energy needs and to reduce greenhouse gas emissions, the capacity of worldwide installed renewable energy systems has been doubled over the last decade [1][2][3][4][5]. This also applies to biogas as a source of renewable energy, where the number of biogas plants installed in Europe has been increased from 6227 in 2009 to reach 18,202 by the end of 2018 [6]. The total produced electricity from biogas reached 88 TWh in 2017, 40% of which was generated in Germany [4]. Hence, Germany is a leading country in this field [6]. Biogas can be utilized—after treatment—in numerous applications, like electricity and heat generation, connection to the natural gas grid, or as biofuel in vehicles [7].

Anaerobic digestion is a biological process, in which the microorganisms degrade the complex organic matter to simpler components under anaerobic conditions to produce biogas and fertilizer [6][8]. This process has many environmental benefits, such as green energy production, organic waste treatment, environmental protection, and greenhouse gas emissions reduction [2][9][10][11][12][13]. The biodegradation of the complex organic matter undergoes four main steps. Namely, hydrolysis, acidogenesis, acetogenesis, and methanogenesis [3].

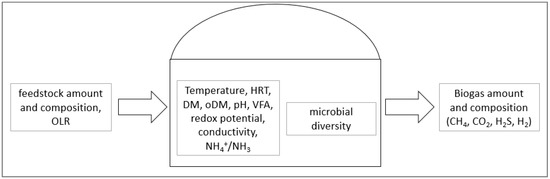

Biogas consists mainly of CH4 and CO2—the share of CH4 is determined by the type of the feedstock fed into the biogas plant [2]. The different operational conditions also have significant effects on the biogas production potentials. In order to obtain the optimum biogas production with the lowest costs, the biogas plant design has to be optimized as per the needs and potentials. The design criteria of biogas plants (explained in the following section) should be considered for their construction [3]. Additionally, several parameters have to be controlled to prevent problems causing inhibition in biogas plants (Figure 1). Temperature, pH value, retention time, and organic loading rate have a direct effect on the microbial activity. Moreover, the physical features of the feedstock can vary, and it may contain toxic substances which can influence the microbial activities [4][14].

Figure 1. Operational parameters of the biogas plant. Adapted from Theurel and coauthors [9]. OLR: Organic Loading Rate, HRT: Hydraulic Retention Time, DM: Dry Matter, oDM: organic Dry Matter, VFA (Volatile Fatty Acids).

2. Monitoring of the Operational Conditions in Biogas Plants

As mentioned before, the anaerobic digestion process includes four stages that come in sequence, where different kinds of microorganisms take part at each stage. In order to obtain a stable and efficient process, process monitoring is necessary [4][15][16]. Monitoring enables early detection of problems and disturbances and indicates the required adjustments to the operational parameters (to be within acceptable ranges).

In general, monitoring parameters of the biogas plants can be classified under three categories: parameters characterizing the process (feedstock type and quantity, biogas production amount and its quality, reactor temperature, dry matter concentration, ammonia concentration, and pH), parameters supplying early detection of instability (VFA, alkalinity, hydrogen concentration, redox potential, and other complex monitoring parameters), and variable process parameters defined by plant operators (OLR and HRT) [15].

The monitoring of the biogas plant’s operational parameters can be achieved by on-line, at-line, and off-line analyzers. There is an increased interest in the on-line monitoring applications, due to the fast and automated process control. There are several parameters that can be monitored at the biogas plant on a real-time basis. The frequently on-line-monitored parameters in biogas plants are summarized in Table 1.

Table 1. Studies conducted on biogas plants’ operational parameters and their monitoring methods.

|

Parameter |

Measurement method |

Reference |

|

Cobalt concentration in the high presence of iron concentrations |

Total reflection X-ray fluorescence spectroscopy |

[17] |

|

VOCs (volatile organic compounds) emitted from different units of food waste anaerobic digestion plant |

Portable GC-MS (gas chromatography–mass spectroscopy) |

[18] |

|

CH4 emissions from pressure relief valves of an agricultural biogas plant |

Flow velocity and temperature sensors |

[19] |

|

Ammonia in biogas |

Impedance measurement of biogas condensate in the gas room above the digester |

[20] |

|

Dissolved active trace elements in biogas |

Total reflection X-ray fluorescence spectroscopy in dried digester slurry |

[17] |

|

H2S in biogas |

Gas responsive nano-switch (copper oxide composite) |

[21] |

|

Microbial communities depend on the substrate combinations |

Sequencing of the 16S rRNA, biodegradable feedstock samples from eight different biogas plants |

[22] |

|

Controlling gas pressure in the digester |

Programmable logic controller (PCL) |

[23] |

|

Ammonia in biomethane |

Luminescent ammonia sensor based on an imidazole-containing Ru(II) polypyridyl complex immobilized on silica microspheres |

[24] |

|

pH, temperature, oxidation-reduction potential (ORP) |

via electrodes, on-line monitoring with PCL |

[25] |

|

CO2, CH4, H2O |

On-line monitoring with a Supercontinuum laser-based off-resonant broadband photoacoustic spectroscopy |

[26] |

|

Different volatile fatty acids |

On-line monitoring with total-reflectance Fourier-transformed infrared spectroscopy (ATR-MIR-FTIR) |

[2] |

The currently available technologies do not enable the monitoring of all operational parameters of the biogas plant. Therefore, samples have to be collected from the biogas plant and analyzed in individual facilities (off-line monitoring) [27]. Off-line monitoring takes place in the laboratory, where samples should be taken for the defined test. Unlike the off-line monitoring, on-line monitoring can provide real-time data on the plant’s operation without any time loss for sampling, transfer, and analysis. A study about the on-line monitoring system was done in 2013 in Germany, and it showed that the majority of the biogas plants are equipped with on-line systems to monitor the electricity generation. Additionally, on-line systems were used to determine produced heat, input solid feedstock, biogas temperature, parasitic electricity demand, biogas volume, biogas composition and input liquid feedstock [15].

To improve monitoring systems of the biogas reactors, near infrared spectroscopy (NIR) and mid-infrared spectroscopy (MIR) are seen as promising technologies [9]. In order to obtain operation flexibility at biogas plants (e.g., changing operational parameters and feedstock type and amount), improvements to the biogas plants’ monitoring technologies and applications are necessary [2][9][28].

3. Conclusions

Anaerobic digestion is an established technology, used to treat a wide variety of organic wastes. It is one of several biological processes that deliver economic and environmental benefits (i.e., producing bioenergy and/or biochemical while treating the organic fraction of waste). The anaerobic digestion process is complex—it includes various physical and biochemical reactions. The stability of the anaerobic digestion process is affected by many factors (e.g., the conditions inside and surrounding the reactor, the reactor’s design, the operational parameters, etc.). In order to maintain a stable, efficient, and sustainable biogas production, the operational parameters should be determined and controlled.

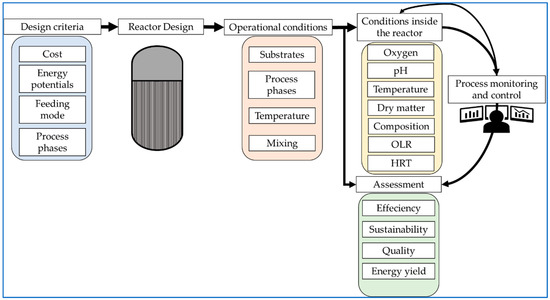

The aim of this paper was to review and evaluate recent studies in the field to determine the critical parameters and their impacts on the anaerobic digestion process, and consequently, on the biogas production. This paper presented a summary to the design parameters of the biogas plant, the significant environmental conditions in the reactor, and the available monitoring and controlling technologies of the anaerobic digestion process (Figure 2).

Figure 2. A summary of the paper’s discussed aspect.

This review concludes that decisions regarding biogas plants’ design, operation, and monitoring conditions depend on many factors (e.g., feedstock, temperature, pH, OLR, HRT, nutrients, inhibitors, biogas quality, etc.). However, the optimal range of the operational parameters varies from one biogas plant to another. Therefore, an inclusive monitoring system is required to enhance the performance of the anaerobic digestion process. Based on this review, it is recommended to improve and expand the available monitoring methods of the process in order to obtain an efficient, sustainable, and flexible operation of the biogas plants. To achieve that, further research needs to focus on the development of on-line, at-line, and off-line monitoring analyzers in the biogas plants.

This entry is adapted from the peer-reviewed paper 10.3390/en13153761

References

- Hren, R.; Petrovič, A.; Čuček, L.; Simonič, M. Determination of Various Parameters during Thermal and Biological Pretreatment of Waste Materials. Energies 2020, 13, 2262.

- Falk, H.M.; Benz, H.C. Monitoring the Anaerobic Digestion Process; IRC-Library; Information Resource Center der Jacobs University Bremen: Bremen, Germany, 2011.

- Rohstoffe, F.N. Guide to Biogas from Production to Use; Federal Ministry of Food; Agriculture and Consumer Protection; Fachagentur Nachwachsende Rohstoffe E.V. (FNR): Gülzow, Germany, 2012.

- Refai, S. Development of Efficient Tools for Monitoring and Improvement of Biogas Production. Ph.D. Thesis, Universitäts-und Landesbibliothek Bonn, Bonn, Germany, 2016.

- Ashraf, M.T.; Fang, C.; Alassali, A.; Sowunmi, A.; Farzanah, R.; Brudecki, G.; Chaturvedi, T.; Haris, S.; Bochenski, T.; Cybulska, I.; et al. Estimation of Bioenergy Potential for Local Biomass in the United Arab Emirates. Emir. J. Food Agric. 2016, 28, 99.

- Piwowar, A. Agricultural Biogas—An Important Element in the Circular and Low-Carbon Development in Poland. Energies 2020, 13, 1733.

- Rosén, T.; Ödlund, L. System Perspective on Biogas Use for Transport and Electricity Production. Energies 2019, 12, 4159.

- Gómez, D.; Ramos-Suárez, J.L.; Fernández, B.; Muñoz, E.; Tey, L.; Romero-Güiza, M.; Hansen, F. Development of a Modified Plug-Flow Anaerobic Digester for Biogas Production from Animal Manures. Energies 2019, 12, 2628.

- Theuerl, S.; Herrmann, C.; Heiermann, M.; Grundmann, P.; Landwehr, N.; Kreidenweis, U.; Prochnow, A. The Future Agricultural Biogas Plant in Germany: A Vision. Energies 2019, 12, 396.

- Sarker, S.; Lamb, J.J.; Hjelme, D.R.; Lien, K.M. A Review of the Role of Critical Parameters in the Design and Operation of Biogas Production Plants. Appl. Sci. 2019, 9, 1915.

- Daniel-Gromke, J.; Rensberg, N.; Denysenko, V.; Stinner, W.; Schmalfuß, T.; Scheftelowitz, M.; Nelles, M.; Liebetrau, J. Current Developments in Production and Utilization of Biogas and Biomethane in Germany. Chem. Ing. Tech. 2017, 90, 17–35.

- Gemmeke, B.; Rieger, C.; Weiland, P.; Schröder, J. Biogas-Messprogramm II, 61 Biogasanlagen im Vergleich; Fachagentur Nachwachsende Rohstoffe E.V. (FNR): Gülzow, Germany, 2009. [Google Scholar]

- Stolze, Y.; Bremges, A.; Maus, I.; Pühler, A.; Sczyrba, A.; Schlüter, A. Targeted in situ metatranscriptomics for selected taxa from mesophilic and thermophilic biogas plants. Microb. Biotechnol. 2017, 11, 667–679.

- Annibaldi, V.; Cucchiella, F.; Gastaldi, M.; Rotilio, M.; Stornelli, V. Sustainability of Biogas Based Projects: Technical and Economic Analysis. In Proceedings of the E3S Web of Conferences, Kitahiroshima, Japan, 27–29 August 2018; EDP Sciences: Les Ulis, France, 2019; Volume 93, p. 03001.

- Drosg, B. Process Monitoring in Biogas Plants; IEA Bioenergy Paris: Paris, France, 2013.

- Hess, J.; Bernard, O. Advanced dynamical risk analysis for monitoring anaerobic digestion process. Biotechnol. Prog. 2009, 25, 643–653.

- Arthur, R.; Scherer, P. Application of total reflection X-Ray fluorescence spectrometry to quantify cobalt concentration in the presence of high iron concentration in biogas plants. Spectrosc. Lett. 2019, 53, 100–113.

- Zheng, G.; Liu, J.; Shao, Z.; Chen, T. Emission characteristics and health risk assessment of VOC’s from a food waste anaerobic digestion plant: A case study of Suzhou, China. Environ. Pollut. 2019, 257, 113546.

- Reinelt, T.; Liebetrau, J. Monitoring and Mitigation of Methane Emissions from Pressure Relief Valves of a Biogas Plant. Chem. Eng. Technol. 2019, 43, 7–18.

- Wünscher, H.; Frank, T.; Cyriax, A.; Tobehn-Steinhäuser, I.; Ortlepp, T.; Kirner, T. Monitoring of Ammonia in Biogas. Chem. Eng. Technol. 2019, 43, 99–103.

- Paul, A.; Schwind, B.; Weinberger, C.; Tiemann, M.; Wagner, T. Gas Responsive Nanoswitch: Copper Oxide Composite for Highly Selective H 2 S Detection. Adv. Funct. Mater. 2019, 29.

- Kushkevych, I.; Kobzová, E.; Vítězová, M.; Vítěz, T.; Dordević, D.; Bartoš, M. Acetogenic microorganisms in operating biogas plants depending on substrate combinations. Boilogia 2019, 74, 1229–1236.

- Mudaheranwa, E.; Rwigema, A.; Ntagwirumugara, E.; Masengo, G.; Singh, R.; Biziyaremye, J. Development of PLC based monitoring and control of pressure in Biogas Power Plant Digester. In Proceedings of the 2019 International Conference on Advances in Big Data, Computing and Data Communication Systems (icABCD), Winterton, South Africa, 5–6 August 2019; Institute of Electrical and Electronics Engineers (IEEE): Piscataway, NJ, USA, 2019; pp. 1–7.

- Urriza-Arsuaga, I.; Bedoya, M.; Orellana, G. Tailored luminescent sensing of NH3 in biomethane productions. Sens. Actuators B Chem. 2019, 292, 210–216.

- Logan, M.; Safi, M.; Lens, P.; Visvanathan, C. Investigating the performance of internet of things based anaerobic digestion of food waste. Process. Saf. Environ. Prot. 2019, 127, 277–287.

- Selvaraj, R.; Vasa, N.J.; Nagendra, S.M.S. Off-Resonant Broadband Photoacoustic Spectroscopy for Online Monitoring of Biogas Concentration with a Wide Dynamic Range. In Proceedings of the Conference on Lasers and Electro-Optics, San Jose, CA, USA, 5–10 May 2019; The Optical Society: Washington, DC, USA, 2019; p. JW2A.20.

- Boe, K. Online Monitoring and Control of the Biogas Process. Ph.D. Thesis, Technical University of Denmark, Copenhagen, Denmark, 2006.

- Flexibierung von Biogasanlagen. Federal Ministry of Food, Agriculture and Consumer Protection; Fachagentur Nachwachsende Rohstoffe E.V. (FNR): Gülzow, Germany, 2018.