Companies have been trying continuously to reduce their logistics costs in the current competitive markets. Warehouses are important components of the logistics systems and they must be managed effectively and efficiently to reduce the production cost as well as maintain customer satisfaction. Order-picking is the core of warehouse operations and an order-picking system (OPS) is essential to meet customer needs and orders. Failure to perform the OPS process properly results in high costs and customer dissatisfaction.

1. Introduction

Manufacturing companies confront different challenges to fulfill customer orders and distinguish between them. Many manufacturing companies consider reducing and eliminating costs and improving productivity in their logistic system important improvement activities. On the other hand, the warehouse is one of the most critical in-house logistics components, playing a crucial role, among other activities, in the supply chain of any manufacturing company. To meet customer needs, the OPS, as part of the warehouse preparation process, has an important place in studies. Sixty percent of all productive activities and 55% of warehouse operating costs include order-picking processes [

1]. In each supply system, there are parts-warehousing-related activities, such as receiving parts, warehousing, ordering, and shipping along product lines [

2]. For reducing warehouse operating costs, in assembly lines, it is highly significant for the company to supply necessary materials within the factory to promote its competitive power. In a factory, materials should be provided with high efficiency and flexibility. The complexity of the material and parts transportation system will lead to an increase in production simultaneously. Researchers, in recent years, have been increasingly motivated to develop OPS enhancement policies [

3]. Internal logistics aspects also need a great deal of attention due to the constraints and resources available to reduce costs and increase the flexibility of production schedule changes to meet customer demands by expanding the ability of line feeding systems and offshore components. In this regard, using new methods of feeding materials and parts such as picking seem necessary [

4]. Picking refers to some factors, including moving, picking, deploying, and packing parts according to the amount of the order required to meet the production schedule [

5]. Receiving materials and parts from the warehouse, preparing them, and moving them along product lines are the most strenuous activities in an internal logistic system. According to studies by Zulj et al. [

5], order picking activities account for 65% of total operating costs in the internal logistics process. The order pickings are based on the workforce and the flexibility of the workforce against changes due to existing constraints [

6]. Other concepts used in the picking process are as follows: travel distance, travel time, layout, channel configuration, dimension and size of the picking, order batching, ordering of picking parts, minimizing travel distance, maximizing occupational health, picking list (required orders), stress, and psychological conditions [

7]. The process of OPS is performed in different ways, as discussed below:

In the part assignment method for picking parts, the picker is carried, by a parts transporter or courier container, or he picks up the pieces himself [

8]. In this method, the picking station is defined separately for each individual. The type of transfer operation is also proportional to the kind of concerned picking process. The part assignment method is also ergonomically beneficial to the operator [

4]. On the other hand, the method of assigning a piece refers to time, when each part has its picker in a specific place [

8].

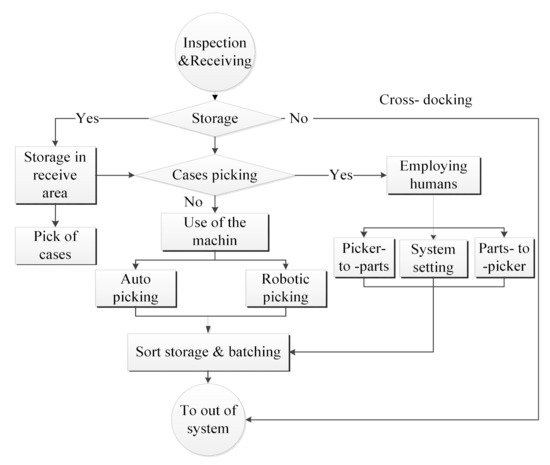

Figure 1 shows the process map of the picking operation. As seen, picking begins with receiving parts from the warehouse. There are two different ways of warehousing: batching and picking operations. If the received items do not meet the quality standards and documentation required for the factory, they will be returned to the manufacturer’s dock. Picking operations are performed either manually or automatically, using semi-robotic or robotic equipment. Each moving part to the picking area is also selected based on batching order and picking operations. New market developments encompassing e-commerce, globalization, increasing customer expectations, and new regulations have intensified the competition between warehouses. It has forced warehouses to manage large numbers of small orders in limited opportunities [

9]. A successful e-commerce ordering process contains multiple different suppliers and programs that need to be quickly implemented.

Figure 1. Process map of the picking operation [

10].

In this regard, completing orders is one of the most important fundamentals to succeed in the on-line business. Moreover, to overcome shortcomings in the ordering process, several aspects should be carefully considered. The easier the process for the end customers is, the more satisfied they would be with you. Furthermore, to decrease the warehouse costs and applying new methods in the internal procurement system, some recent trends need to be more efficiently performed in the procurement industry.

The concepts and definitions of OPS are described in Table 1.

Table 1. The concepts and definitions.

| Order-Picking |

Order picking refers to the operation of retrieving items from storage locations to fulfill customer orders [11]. |

| Makespan |

Makespan is the time when all batches are picked [12]. |

| Tardiness |

Tardiness defines as the positive value between the completion time of a customer order with its due date [13]. |

| Routing |

Routing policies define the sequence of storage locations that should be visited in each pick round to retrieve all items on a pick list [2]. |

| Assignment |

Orders should be retrieved by order pickers within tight time windows. The job assignment planning problem determines the sequence according to which orders or batches of orders should be retrieved, as well as the assignment of these (batches of) orders to a limited number of order pickers [14]. |

Order

Batching |

Order batching policies define rules on which customer orders to combine in a single pick round. These policies can be either static (i.e., all orders are known at the beginning of the planning period) or dynamic (i.e., customer orders become available over time) [2]. Order batching is the grouping of customer orders into picking orders (batches) [14]. |

2. Order-Picking System

2.1. Order-Picking Planning and Their Combination

2.1.1. Warehouse Layout

A warehouse comprises various areas and domains, including transportation operations, parts receiving area, parts warehousing area, and order-picking area [

28]. Aisle is also referred to as the path between the rows of a cellar. Moreover, in the recent literature related to customized picking, three types of assignments have been introduced to determine the optimum anchors.

Generally, in the design of a warehouse, all operational processes and the type of system that uses the design must be considered. Product characteristics and demand can also affect the selected system. On the other hand, in a design, compatibility between areas and requirements should be considered and the design should be so as to improve the performance of the system [

29].

Figure 5 graphically depicts a typical order-picking area.

According to Table 2, most of the studies in the warehouse were on parallel aisles and other methods were less favored by the researchers.

Van Gils et al. [

2] and Scholz et al. [

20] stated that the process of picking and selecting pieces for picking is complete when the picker returns to the original location after selecting the last batch. In these papers, the authors used the mathematical model to solve small samples. In contrast, for larger samples, they used a variable neighborhood descent (VND) algorithm followed by numerical experiments, showing that the algorithm offers excellent solutions for path optimization.

Figure 6 introduce items, such as storage location assignment, zone assignment of the warehouse, picking area, ordering, routing, labor assignment, labor force level, and labor assignment in an interconnected structure.

2.1.2. Study of the Components of the Order-Picking Process

Investigating the assignment and sequencing of the batch to multi-pickers concurrently with the optimal routing problem, checking the overall time of the custom multi-picker picking process, or applying a categorized warehousing method are generally done to maximize profit. In Figure 7 and Table 3, components of the order-picking process can be observed. As shown, it tries to optimize order assignment (sorting and routing of the shippers resulting in minimizing process time). In addition, the workload balanced between the shippers is maintained.

Chackelson et al. [

62] used both simulation solutions to simultaneously examine picking processes to reduce operating costs and a hybrid algorithm to generate batches and assignment and sequencing customer needs. Several studies studied scheduling problems together in a multi-block warehouse, while combining batching and routing into a single scheme. After assigning the order to the packer, any order picker can begin the journey to the warehouse to select and pick. The orders should be prioritized according to the production plan and delivered to the pickings. In the meantime, the lost time is one of the most important factors to consider to prevent tardiness and increase productivity. For example, when a picker stops to prepare an order batch, it is one of the cases of tardiness in the order-picking process. The studies reviewed in Van Gils et al. [

2] addressed the reduction or elimination of tardiness through redesigning the picking process, batch organization, routing, prioritization, and picking activities.

Moreover, to find the most economical routes, warehouse layout, piecewise assignment, and parallel scheduling of equipment pickings, travel routes have been studied in all logistic processes and are mainly the most influential factors in terms of costing and timing.

2.2. Performance Measure

2.2.1. Tardiness

Table 5 is an overview of tardiness minimization in the order-picking process considered in selecting the literature. Accordingly, assignment, routing, batching, and sequencing could affect tardiness minimization of the assumed goal. Table 5 also shows six research works aimed at tardiness minimization.

As can be seen, few studies have examined the issue of tardiness, and only Schulz et al. [

20] simultaneously examined the four issues of assignment, routing, batching and sequencing to reduce tardiness. In a parallel warehouse, Scholz et al. [

20] studied a routing problem, which is a special model of the traveling salesman problem (tsp), and using mathematical modeling, they showed that the problem under study is superior to the tsp formulation. Previous research has focused on only one of the problems with ops, but the study by Scholz et al. [

20] is only about a specific issue on a small scale and in the form of manual picking. On the other hand, five of the six studies were related to 2015 onwards, suggesting that the issue of tardiness has been considered in recent years, although few studies have been conducted on the impact on OPS.

2.2.2. Cost

The process of receiving materials and parts from the warehouse and preparing is the most costly activity in the intra-factory logistics system [78]. Table 6 shows the focus of the studied articles to minimizing the cost.

2.2.3. Productivity

-

Small size orders are performed with a great variety of parts.

-

Some orders will affect the efficiency of the order-picking process due to either the seasonality of the order, the intention of moving the order forward, or various delivery locations based on point-of-sale information. Table 7 shows an overview of the studied articles regarding the maximum productivity of the order-picking process.

As can be seen in

Table 7, most studies have focused on routing and batching. However, Matusiak et al. [

67] simultaneously studied categories of assignment, routing, and batching to maximize the productivity in OPS. Chen et al. [

22] also simultaneously evaluated the effect of routing, batching, and sequencing on efficiency. Matusiak et al. [

67] tried to reduce the total processing time by focusing on the skill level of the operator and the individual difference between the pickers. They changed the batching methods and saved a total of 6% in time. They further used multi-level modeling and used the Adaptive Large Neighborhood Search algorithm to solve the model. In the warehouse, Chen et al. [

22] used a routing problem with a limited domain, which is not applicable to large-scale problems. They employed an integer model focusing on sequencing, batching, and routing, and used genetic algorithms to solve the problem.

2.2.4. Space Optimization

Warehousing management policy is a crucial issue in logistic management. It must be managed effectively and efficiently to reduce the production cost as well as the customer satisfaction. Synchronized zoning system is a warehousing management policy that aims to increase the warehouse utilization and customer satisfaction by reducing the customer waiting time [

18].

Table 8 shows the studies performed to optimize the space available for OPS.

2.2.5. Makespan

To minimize the order-picking makespan, it is necessary to simultaneously solve order batching, assignment and pickers routing. Table 9 shows six research works aimed at makespan minimization.

New market developments such as e-commerce, globalization, rising customer expectations, and new market regulations have forced warehouses to handle more orders in less time. In this matter, awareness of the impact of individual planning on picking planning for performance management and thus increasing customer service are required in overall performance.

As different industry managers look for ideal, simple, intuitive, and reliable solutions, cost reduction solutions are suggested in the order-picking process. Table 3 indicates an insufficient balance between decision-making variables about planning problems as well as a tendency towards more studies about routing and storage space at a higher speed than other aspects.

Furthermore, based on Table 10, mathematical programming methods have been mainly used for routing and batching problems to explore the aspects of the picking process simultaneously. This suggests that the majority of researchers have tried to minimize distance in order to reduce cost and time, mainly because routing is metric and calculable. Moreover, at the operational level, there is still a need to integrate more planning problems and calculate the real-world features.

Despite the importance of human resources in the warehouse environment, a small number of articles have evaluated the labor planning problems, such as determining the daily labor force level, assigning the labor in order-picking areas, and assigning jobs to pickers [

6,

7,

65].

It should be further noted that as the warehouses offer multiple services to customers, the availability and performance of human resources ensure the quality of service to customers and the performance of order-picking. For instance, determining the level of the workforce combined with the assignment of order pickers and the planning problem makes focusing on the number of pickers a challenging opportunity for future research. Previous studies have mainly focused on reducing order-picking time. Working in an atmosphere with increasing pressure and limited time raises the likelihood of selection errors. In recent years, the number of articles analyzing multi-objective picking planning problems has risen dramatically. Nonetheless, currently, research works are mostly on the storage location, order batching, and routing. At a tactical level of picking problem, little attention has been paid to research. Previous studies have not only combined planning problems but have also simplified the order collection systems. The results developed in this paper indicate the need for more research on the congestion of warehouse aisles and the combination of picking operations problems in the future. In terms of cost reduction, the combination of tardiness with other planning problems has not yet been investigated. In addition, to improve efficiency, few studies have been performed in the field of assignment, sequencing, and tardiness, and the effect of different combinations of these problems on productivity improvement has not been studied. Moreover, the effect of combining planning problems has been only studied by Ardjmand et al. [

12,

46] and has received less attention. On the other hand, the effect of labor fatigue as well as workload balance on the combination of tardiness and other planning problems can be examined.

This entry is adapted from the peer-reviewed paper 10.3390/app112210641