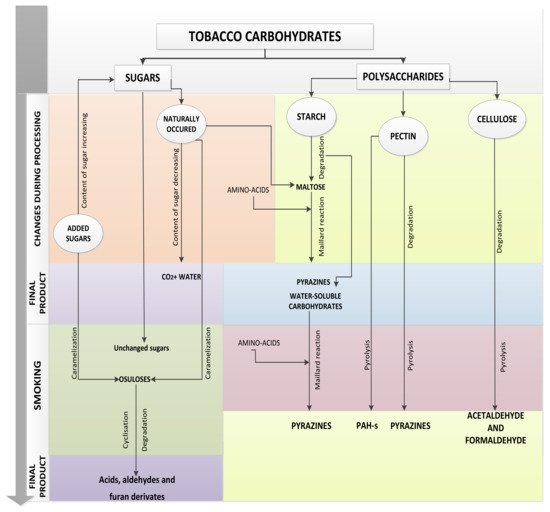

Carbohydrates are important compounds in natural products where they primarily serve as a source of energy, but they have important secondary roles as precursors of aroma or bioactive compounds. They are present in fresh and dried (cured) tobacco leaves as well. The sugar content of tobacco depends on the tobacco variety, harvesting, and primarily on the curing conditions (temperature, time and moisture). If the process of curing employs high temperatures (flue-curing and sun-curing), final sugar content is high. In contrast, when air curing has a lower temperature, at the end of the process, sugar level is low. Beside simple sugars, other carbohydrates reported in tobacco are oligosaccharides, cellulose, starch, and pectin. Degradation of polysaccharides results in a higher yield of simple sugars, but at the same time reduces sugars oxidization and transfer into carbon dioxide and water. Loss of sugar producers will compensate with added sugars, to cover undesirable aroma properties and achieve a better, pleasant taste during smoking.

1. Introduction

Tobacco (

Nicotiana tabacum L.) is the most widely cultivated non-food crop in the world. Although not consumed as a food, it is partially consumed by digestive system (mouth) and its sensory properties such as aroma, flavor and odor are the most important attribute to define consumer acceptance of tobacco and tobacco products. Besides consuming by smoking, a small part of total tobacco production (less than 10%) is for consummation by chewing and sniffing [

1,

2]. Sensory properties of products may help to determine whether a product will be preferred over another. To control sensory qualities of these types of products, it also appears necessary to understand the mechanisms involved in the retention and releasing of aroma compounds [

3]. Different complex chemical reactions are involved in tobacco aroma formation, including degradation of carbohydrates, degradation of chlorogenic acid, degradation of proteins, Maillard reaction, Strecker degradation and caramelization reactions, and many others. For centuries, carbohydrates were considered as primary compounds with high nutritional value. Today it is well known that carbohydrates have both digestive and psychological role. The term carbohydrates is generally considered as neutral compounds of carbon, hydrogen and oxygen and is used to refer to sugars, oligosaccharides, and polysaccharides combined. The term sugars has been applied to simple carbohydrates (monosaccharides and disaccharides). The more complex carbohydrates containing 3 to 10 sugars refers to term oligosaccharides, and the term polysaccharides was used for even more complex carbohydrates (starch, cellulose and pectin). Some of them are digestible in whole (sugars) and some of them represent totally indigestible nutrients (indigestible fibers) [

4]. Tobacco is a complex mixture that consists of 6–15% cellulose, 10–15% pectin, roughly 2% lignin, variable contents of sugars, and a variety of other components (

Table 1). The exact composition depends on the tobacco part or variety and the growing conditions [

5]. Tobacco variety, growing conditions, chemical composition, and many parameters during processing have an influence on carbohydrate contents. Thus, uniform quality of final products is the main goal, and a critical point in tobacco production. Better understanding of tobacco carbohydrates and their impact on tobacco flavor and aroma as well as on the formation of undesirable compounds could be crucial. Present knowledge about tobacco carbohydrates and their impact on aroma profile originates from recently published articles [

6,

7,

8,

9,

10,

11,

12,

13]. Together with nitrogen compounds, tobacco carbohydrates are the most important aroma precursors [

6,

14]. Since they have low vapor pressure, they are sensitive to high temperatures and oxidation processes [

15]. Besides carbohydrates, other aroma compounds are derived from carotenoid degradation products [

8].

Table 1. Chemical composition of three the most important varieties of tobacco.

|

(%)

|

TOBACCO VARIETY

|

|

Burley

|

Virginia

|

Oriental

|

|

Nicotine

|

2.07

|

2.26

|

1.18

|

|

Sugars

|

1.2

|

11.1

|

10.7

|

|

Proteins

|

10.1

|

7.8

|

7.8

|

|

Chlorine

|

0.51

|

0.53

|

0.84

|

|

Crude Ashes

|

18.4

|

12.8

|

16.4

|

2. Tobacco Carbohydrates

Carbohydrates are naturally present in tobacco but some extra amounts are frequently added during processing. Content of complex carbohydrates decreases during processing, but sugar content is mostly constant, because loss of sugars during processing is compensated with starch decomposition and addition of sugars.

2.1. Tobacco Sugars

Most abundant naturally present sugars in dried tobacco leaves are glucose, fructose and sucrose [

16]. Noteworthy differences in sugar content were found between tobacco varieties, i.e.,

Virginia has high level of sugar (8–30%) while

Burley is characterized with low content of sugars (1–2%) [

17]. On the other hand,

Oriental tobaccos possess significant amounts of sugars (10–20%) and lower amounts of proteins, probably because they are usually planted on low nutrient soils with limited amounts of nitrogen and water, and cured directly on the sun [

6,

18]. As a consequence, acetate accumulates in the Krebs cycle, resulting in biosynthesis of aromatic compounds—terpenoids. These types of terpenoids are usually synthesized from mevalonic acid, carbohydrates, acids, and resins, which contain nitrogen [

19].

2.2. Tobacco Oligosaccharides

Oligosaccharides are a less-represented group of carbohydrates in tobacco. In tobacco seeds, the presence of planteose is reported, in green leaf raffinose and stachyose, and in dry tobacco leaves erlose and theanderose are present [

24]. Malto-oligosaccharides are mostly products of starch degradation, but later in the process they decompose and contribute to Maillard reactions [

28]. Nagai et al. [

24] investigated oligosaccharides (fructo-oligosaccharides and malto-oligosaccharides) in tobacco fresh and dried leaves. Results showed that fructo-oligosaccharides were completely absent in fresh leaves and their content increased during processing due to enzymatic reactions, while malto-oligosaccharides degraded during processing due to the influence of heat. Increasing contents of fructo-oligosaccharides could be explained by the degradation of carbohydrates, because tobacco is a non-fructan plant [

29].

2.3. Tobacco Polysaccharides

2.3.1. Starch

Starch is important primary metabolite in tobacco, accumulated during growing and decomposed during processing. At the end of processing, almost all starch is converted into water-soluble carbohydrates, and subsequently into aroma compounds. Although starch is necessary for aroma formation, its presence in tobacco products can cause bitterness and flavor changes [

30]. Moreover, it can affect changes in color and odor of cured tobacco [

11]. Therefore, complete degradation of starch is one of the important steps in tobacco processing [

30]. Degradation of starch is one of the most important changes during leaf processing and will be discussed in more details separately.

2.3.2. Pectins

Along with cellulose and hemicellulose, pectins are among the major compounds of tobacco cell walls, mainly composed of D-galacturonic acid, followed by D-galactose and L-arabinose [

31,

32]. They are widely used because of their gelling and thickening properties. Recent research by Zhang et al. [

33] showed that tobacco agricultural waste-stem contains between 11.27% and 8.88% of pectins and could be a good source of pectin. Pectin content is important for tobacco quality determination. With increasing pectin content, tobacco blend becomes soft and sensitive at high air humidity, or rigid and fragile at low air humidity [

34]. However, pectin is considered as an undesirable compound in tobacco product because of poor smoking characteristics [

35]. Even though it is an undesirable compound in leaf processing, pectin has an important role in the production of reconstituted tobacco. Reconstituted tobacco are sheet-like papers, composed of tobacco stem and leaf particles. Sometimes it is added into tobacco blends, especially for low-price cigarettes. There are few commercial processes for reconstituted tobacco production. One of the most commonly used processes includes treatment of tobacco waste material solution with diammonium phosphate in order to dissolve tobacco pectins. During that process, under heat influence, part of the ammonia content is volatilized and pectin acts as binding material and keeps reconstituted tobacco sheets together. In addition to adhesive property, in this case, pectin plays an important role for smoking quality because the content of some aroma compounds (pyrazines) increases [

19,

36].

2.3.3. Cellulose

Primary and secondary cell walls of tobacco are composed of cellulose, hemicellulose and pectin [

36]. Content of cellulose can be up to 40% for stem parts, up to 15% for midrib and up to 15% for leaf lamina [

19]. In tobacco plant metabolism, cellulose is not a reserve material but mechanical strengthener and protector from outside factors. Earlier, cellulose was considered as a neutral compound, which did not affect tobacco aroma [

37], but today it is well known that high cellulose content contributes to negative aroma properties. Since pyrolysis of cellulose delivers undesirable taste, using stems in cigarette production is avoided [

19,

38]. The volatile fraction of tobacco contains furancarboxaldehyde and its derivatives and it is assumed that they originate from cellulose in lamina cells [

39]. Torikaiu et al. [

40] also proved an increase of formaldehyde yield and decrease of aromatic amines with increasing content of cellulose in tobacco leaves, while Sanders et al. [

41] reported that pyrolysis of tobacco cellulose had resulted in a high level of low molecular compounds, such as ketones and aldehydes.

3. Changes during Processing of Tobacco Leaves

In order to achieve favorable physical and chemical properties, tobacco leaves are subjected to different processes, injury, and heat and osmotic stresses [

42]. During the process of curing, which includes aging, yellowing, browning, drying, and fermentation, different chemical changes occur in controlled conditions of temperature, moisture content and ventilation. The first phase of curing is yellowing, marked with many chemical changes and changes in color. During this phase, chlorophyll starts to degrade and the green color of leaf is changed into the characteristic yellow color of tobacco. Yellowing is followed by 4-day-long drying on higher temperatures for

Virginia blends (around 55 °C). In that stage, enzymatic processes are stopped but it does not affect degradation of starch [

6]. On the other hand,

Burley’s yellowing phase is prolonged for a few weeks at relatively low temperatures (up to 40 °C), where almost all sugar is decomposed. Throughout the fermentation process, high initial moisture content is decreased, heat is generated and loss of weight occurs. The fermentation process requires precise selection of temperature (maximum 60 °C) and moisture (above 10%) conditions. For example, at a moisture content between 10% and 27%, changes in tobacco are conditioned primarily by enzymatic reaction; above 27% moisture, microbiologic reactions are dominant, and at moisture content below 10%, all enzymatic reactions stop [

17]. Total carbohydrate content remains almost the same during processing, because starch content decreases while water-soluble sugar content increases (

Figure 1). Sweet, roast smell appears as a result of curing [

42]. On the other hand, aging is a mild fermentation process. Major reactions that take place during the process of aging are Maillard reactions between reducing sugars and amino compounds, which result in CO

2 and melanoidins [

13]. The slow process of curing at low temperatures (up to 40 °C) lasts longer and enables the enzyme system in the leaves to remain active. As a result, dry leaves have very low sugar content [

6]. The process of curing is highly dependent on tobacco variety and sugar contents in fresh leaves, but it can be improved by adjusting variables such as temperature, relative humidity, air velocity, and time [

43].

Figure 1. Changes in carbohydrates during tobacco processing and smoking.

4. Changes during Smoking

During smoking, temperature reaches between 700 °C and 900 °C and almost all carbohydrates are decomposed (pyrolysed). Products of pyrolysis of carbohydrates depend mostly on applied temperatures [

5]. At temperatures up to 200 °C, all reducing sugars are decomposed. Temperatures between 200 and 250 °C are followed by the decomposition of pectin and hemicellulose [

36] and at 250 °C starts degradation of pectin [

35]. At temperatures above 250 °C, cellulose starts to degrade [

36]. Decomposition (pyrolysis) of carbohydrates leads to an increasing level of aldehydes such as acetaldehyde and formaldehyde [

53]. Formaldehyde is predominately formed by the hydroxymethyl group of sugars [

6,

35]. Along with pyrolysis, another process can occur, and that is pyrosynthesis. Pyrosynthesis is a process occurring under pyrolysis of tobacco where different high molecular weight compounds (larger than precursor) are formed. Combustion is another process occurring during pyrolysis, but with the presence of oxygen [

6].

5. Tobacco Carbohydrates as Bioactive Compounds

For a long time, carbohydrates were considered only as primary plant metabolites but in recent times they have started to be considered as secondary metabolites (bioactive compounds) as well. Bioactive compounds are widely found in plants and have been used for the prevention of different illnesses and in the treatment of a wide range of diseases. Plants produce those compound as defense from biotic and abiotic stresses [

58,

59]. In 2013, Xu et al. reported for the first time that tobacco carbohydrates possess antioxidant activity [

60]. They found that in tobacco leaf extracts, carbohydrate content correlated with antioxidant activity. The proposed mechanism suggested that COOH, -C- and C=O groups have the potential to reduce free radicals by donating electrons. By the proposed mechanism, more stable forms are formed or involved in further reactions with free radicals. Liu et al. [

61] showed that in tobacco extracts, the polysaccharide content increased radical scavenging activity, showing the antioxidant potential of tobacco carbohydrates. They attributed radical scavenging activity to monosaccharides content, because extracts with higher content of monosaccharides expressed higher antioxidant activity.

Sugar esters are compounds that have been shown to possess many biological activities such as insecticidal, antifungal, and antibacterial properties [

62]. Tobacco sugar esters provide pest resistance and could be considered as potential green pesticides. They are derived by acyl moieties esterified to the hydroxyl groups of sugars (sucrose or glucose). They are produced by glandular trichomes on the leaf surface of the

Solanaceace family and are recognized as the main flavor precursors in

Oriental tobacco [

63,

64]. Puterka et al. [

65] claimed that sugar esters had higher insecticidal and miticidal properties than insecticidal soap. Generally, carbohydrate-based bioactive compounds are characterized with very complex chemical structure. That makes research on them very slow, but in the future their high bioactive potential and contribution in many physiological and pathological functions of organisms probably will be investigated more deeply [

66].

This entry is adapted from the peer-reviewed paper 10.3390/molecules25071734