Table of Contents

- Introduction

1.1.Polymers Used in Hybrid Hydrogels

1.2.Types of Hybrid Hydrogels

1.2.1. Microgel

1.2.2. Hybrid Nanogels

1.2.3. Multifunctional Hybrid Nanogels

1.2.4. Hybrid Polymer Nanogel/Hydrogels

1.2.5. Physical Hydrogels

1.2.6. Chemically or Covalently Crosslinked Hydrogels

1.2.7. Self-Assembling Hybrid Hydrogels

1.2.8. Interpenetrated and Semi-Interpenetrated Polymer Networks

1.2.9. Core-Shell Polymer Networks

1.2.10. Supramolecular Hydrogel

2. Preparation Procedures for Polymeric Hybrid Hydrogels

2.1. Routes to Obtain Hybrid Hydrogels

2.1.1.Chemical Modifications

2.1.2. Functionalization

2.1.3. Stealth Functionalization

2.1.4. PEGylation

2.2. Processing Methods

3. Properties

3.3.Swelling

3.2. Mechanical Properties

3.3. Responsiveness

3.4. Porosity and Permeation

- Applications

- Homopolysaccharides-Based Hybrid Hydrogels

5.1. Ability of Homopolysaccharides to Form Hybrid Hydrogels

5.2. Biomedical Applications of Homopolysaccharides-Based Hydrogels

5.2.1. Tissue Engineering

5.2.2. Wound Dressing

5.2.3. Drug Delivery

5.2.4. Other Biomedical Applications of Polysaccharides

- Heteropolysaccharides-Based Hybrid Hydrogels

6.1. Ability of Heteropolysaccharides to Form Hybrid Hydrogels

6.2. Biomedical Applications of Heteropolysaccharides-Based Hybrid Hydrogels

6.2.1. Tissue Engineering

6.2.2. Wound Dressing

6.2.3. Drug Delivery

7. Hybrid Proteins Based Hydrogels for Biomedical Applications

7.1. Ability of Proteins/Peptides to Form Hybrid Hydrogels

7.2. Properties of Proteins to Form Hybrid Hydrogels for Biomedical Applications

7.2.1. Collagen

7.2.2. Gelatin

7.2.3. Keratin

7.2.4. Bovine Serum Albumin

7.2.5. Silk

7.2.6. Resilin

7.2.7. Whey Proteins

7.2.8. Soy Protein Isolate

7.2.9. Elastin

7.3. Biomedical Applications of Protein Based Hybrid Hydrogels

7.3.1. Tissue Engineering

7.3.2. Bone Tissue Engineering

7.3.3. Cartilage Tissue Engineering

7.3.4. Wound Healing

7.3.5. Drug and Molecule Delivery

8. Nucleic Acids Based Hybrid Hydrogels for Biomedical Applications

8.1. Nucleic Acids Ability to Form Hydrogels

8.2. Biomedical Applications of Nucleic Acids-Containing Hybrid Hydrogels

8.2.1. Drug Delivery

8.2.2. Immunotherapy

8.2.3. Biosensing Applications

- Hybrid Hydrogels Containing Lignin for Biomedical Applications

9.1. Bioactive Compounds Delivery

9.2. Applications as Antimicrobial, Antioxidant, Antifungal materials

- Conclusions and Future Trends

1. Introduction

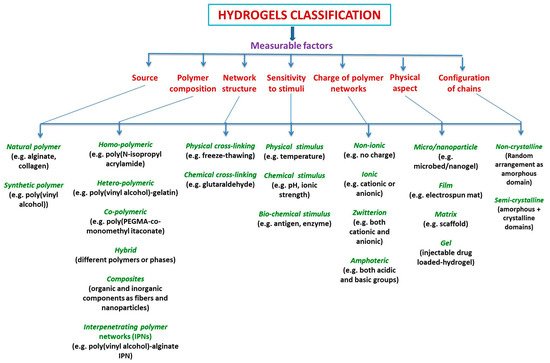

Hydrogels can be classified by taking into consideration many factors, such as source; preparation methods; network structure (as permanent (chemically crosslinked or irreversible), and non-permanent (physically crosslinked or reversible, hydrogen-bonded hydrogels); dimensions (macrogels, microgels, nanogels); sensitivity to stimuli (such as physical, chemical, and biochemical stimuli); charge of polymer network (nonionic, ionic, zwitterion, and amphoteric); physical aspect (micro-/nanoparticle, film, matrix, gel, etc.); configuration (amorphous and semicrystalline); composition (homopolymeric, multipolymeric or heteropolymeric, copolymeric, and interpenetrating polymer networks, hybrids, composites); degradability (biodegradable, bioabsorbable, bioerodible, and degradable in a controlled manner) (

Scheme 1) [

1,

2].

Scheme 1. Classification of hydrogels [

1,

2].

Generally, hydrogels contain polar/charged functional groups which offer them hydrophilicity, water absorption capacity and, respectively, swelling in a certain medium, enhancement of their susceptibility to stimuli, etc. [

3,

4]. They can also differentiate in respect with their equilibrium swelling grade (SWD) as those low SWD hydrogels (20–50%), medium SWD hydrogels (50–90%), high SWD hydrogels (90–99.5%), and superabsorbent hydrogels (>99.5%) [

5,

6]. The hydrogels with high SWD show good permeability and biocompatibility [

7] being preferred for use in the medical field.

Hybrid hydrogels definition is still debatable. They are defined either as a complex composed of hundreds of chemically or physically cross-linking nanogels [

8], or it refers to systems combined with different polymers and/or with nanoparticles, such as plasmonic, magnetic, and carbonaceous nanoparticles, among others, or they are constituted by chemically, functionally, and morphologically distinct building blocks from at least two distinct classes of molecules, which can include biologically active polymers as polysaccharides and/or proteins, peptides, or nano/microstructures, interconnected via physical or chemical means [

9]. Depending on the size and the nature of the building blocks, the hybridization can occur at molecular level or at microscopic scale [

10,

11](

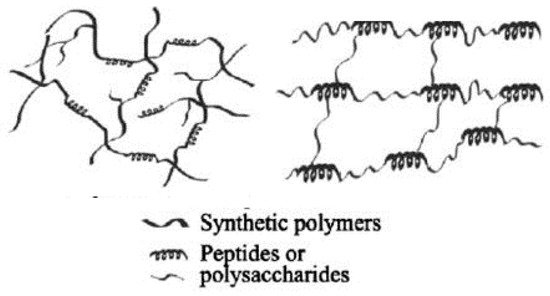

Figure 1).

Figure 1. Schematic representation of organic hybrid hydrogels systems (adapted from [

11]).

Each medical application involves the unique choice of a combination of the component materials, with the goal to match both desired structural and functional properties which must effectively produce an advanced polymeric system, with a new profile [

12]. One of the most relevant examples is the combination protein/other polymers. Such combinations can be resulted by polymerization or conjugation (click chemistry) with synthetic polymers resulting compatible hybrid hydrogels both in vitro and in vivo as it was demonstrated by cell differentiation, proliferation, migration studies and drug delivery, tissue engineering, wound healing applications [

13,

14], respectively or sequestration of growth factors from the surrounding medium [

15]. Commonly, the hybrid hydrogels are heterogeneous and this property is important to assure cell adhesion, organization, and cell–cell interactions required for medical applications [

16,

17,

18,

19].

1.1. Polymers Used in Hybrid Hydrogels

There are four main types of natural biodegradable polymers used in hybrid hydrogels described in this review—

Table 1, including [

20]: (1) homopolysaccharides, as: cellulose and derivatives, pullulan, dextran, starch, etc.; (2) heteropolysaccharides from which can be mentioned: chitosan/chitin and their derivatives [

21], dextran, agarose, alginic acid and alginates, hyaluronic acid (HA), chondroitin and derivative sulphates, heparin, pectin, etc. (3) polypeptides/proteins, such as gelatin, collagen, albumin, fibrin and fibrinogen, soy and whey proteins, silk, Matrigel™, etc., and genetically engineered proteins [

22,

23,

24] (calmodulin (a calcium-binding protein), elastin-like polypeptides, leucine zipper) [

25]; (4) deoxyribonucleic acid (DNA) and ribonucleic acid (RNA) [

26]. The protein/polysaccharide hybrid polymers like fibrin/cellulose, collagen/HA, gelatin/alginate and many others etc. were studied [

27] and other many combination make now topics of undergoing researches. Lignin was also used [

28,

29]. Most of them are components of the extracellular matrix (ECM) in vivo. Their composition (bovine fibrinogen, rat tail collagen, etc.) may vary with source and processing method, being difficult to control their microstructures, properties and reproducibility between experiments.

Table 1. Natural polymers used in organic hybrid hydrogels for medical applications.

|

Polysaccharides

|

Polypeptides and Proteins

|

Polynucleotides and Others

|

|

Homopolysaccharides

|

Heteropolysaccharides

|

|

Cellulose and derivatives (carboxymethylcellulose, hydroxyethyl cellulose; hydroxypropylcellulose methylcellulose hydroxypropylmethylcellulose; cellulose acetophphalate)

-

Pullulan and derivatives

-

Gelan

-

Curdlan

-

Scleroglucan

-

schizofillan

-

Starch and derivatives

-

Dextran

-

Dextrins and cyclodextrins

-

Carrageenan (K-, L-λ, etc) and derivatives (sulphates)

-

Glycogen

-

Inulin

-

Guar gum

-

Gum Acacia

-

Pectin

|

-

Chitosan and derivatives

-

Chitin

-

Alginic acid and derivatives

-

Hyaluronic acid

-

Chondroitin and derivative sulphates

-

Xanthan gum

-

Heparin

-

Keratan sulphate

-

Dermatan sulphate

-

Pectin

-

Glycosaminoglycans (mucopolysaccharides)

-

Glucan and beta-glucan

-

Glucomanan

-

Laminarin

-

Proteoglycans

-

Agar

-

Gum Arabic

-

Gum tragacanth

-

Arabinixilans

-

Konjac glucomanan

-

Locust bean gum

|

-

Gelatin

-

Collagen

-

Albumins (bovine serum albumin, ovalbumin)

-

β-lactoglobulin

-

Elastin

-

Fibrin

-

Fibronectin

-

Resilin

-

Fibrinogen

-

Immunoglobulins

-

Soy Protein

-

Whey protein

-

Silk (silk fibroin and sericin)

-

Lactoferrin

-

Keratin

-

Zein

-

Casein

-

Synthetic proteins (Calmodulin, elastin-like polypeptides, leucine zipper)

-

Prolamins (gluten, gliadin)

-

Protamins and derivatives

-

Polylysines

-

Lysozyme

-

Histones

-

Enzymes

-

Myoglobin

-

Hemoglobin

-

Cytochrome C

-

Proteic hormons

-

Interferon

|

|

Synthetic polymers commonly used in the hybrid hydrogels preparation can be classified into three main types: non-biodegradable [

30,

31], biodegradable [

32], and bioactive polymers [

33]. Most common synthetic polymers are: poly (lactic acid) (PLA), poly (ε-caprolactone) (PCL), poly(glycolic acid) (PGA) and copolymers [

34], poly (ethylene glycol) (PEG) and poly(vinyl alcohol) (PVA) [

35,

36,

37,

38] to produce biodegradable hydrogels. Hydrogels may include vinyl monomers like 2-hydroxyethyl methacrylate (HEMA), N-isopropyl acrylamide (NIPAAm), 2-hydroxypropyl methacrylate (HPMA), acrylamide (AAm), acrylic acid (AAc) or macromers [

37,

38,

39], methoxyl poly(ethylene glycol) (PEG), monoacrylates (mPEGMA or PEGMA), and diacrylates (PEGDA), ethylene glycol diacrylate (EGDA), Pluronic

® polymers, etc. [

39].

By combining the properties of synthetic and natural polymers to form hybrid hydrogels, a direct approach is created for bioactive hydrogel scaffolds for tissue engineering.

Comparatively with natural polymers, the synthetic polymers are easily synthesized even at large scale by polymerization, cross-linking, and functionalization (modification by block structures, by blending, copolymerization), their molecular structure, molecular weight, physical and chemical properties (mechanical strength, biodegradability [

40,

41]) are more reproducible, this aspect being critical for the medical applications mainly scaffolding. Unfortunately, applications of synthetic hydrogels as biomaterials are limited by their absence of bioactivity. The protein-polymer hybrid networks with complex abilities, including bioactivity, stimuli-responsiveness, catalytic activity, or ability to regulate cell behaviors have been/are created to overcome this limitation, maintaining good mechanical properties of materials [

42,

43,

44,

45,

46].

1.1.1. Microgel

The term microgel describes a variety of particles that differ substantially in structure, physico-chemical properties, preparation and application and is interchangeably with terms such as nanogel, microsphere and macrogel depending on the numerous particle types falling within the broad sphere of nano-/microparticle shapes and sizes [

47,

48,

49,

50].

1.1.2. Hybrid Nanogels

Hybrid nanogels later developed are highly crosslinked nano-sized hydrogel systems [

47,

48] with diameter less than 100 nm [

49,

50] having a non-fluid colloidal/polymer network that combine the properties of both hydrogels and nanomaterials. The nanoscale provides a large surface area for bioconjugation, long time of circulation in blood, and the possibility of being actively or passively targeted to the desired site of action (e.g., tumor sites) [

10]. Hybrid smart hydrogels/nanogels show the ability to respond to biomedically relevant changes like pH, temperature, ionic force/concentration, redox environment, light, glucose, magnetic field, electrical field, chemicals or specific biomarkers etc., by changing their volume, refractive index, and hydrophilicity/hydrophobicity etc. Micro- and nano-sized hydrogels are faster in responding to changes in their environment than their macroscopic or bulk counterparts and can be used more efficiently in medical and sensor applications [

51].

1.1.3. Multifunctional Hybrid Nanogels

Multifunctional hybrid nanogels found applications in medical field/nanomedicine for continuous monitoring by optical sensing to mentioned stimuli in complex samples such as blood and bioreactor fluids as well as for intracellular imaging, contributing to the explanation of intricate biological processes, the development of novel diagnoses and therapy toward clinical applications. [

52].

1.1.4. Hybrid Polymer Nanogel/Hydrogels

Hybrid polymer nanogel/hydrogels include interpenetrated networks (IPNs) and core-shell particles. The core-shell strategy is especially useful for targeting therapy, while the interpenetration allows the development of multiresponssive nanogels and the control of the drug release profile [

53].

1.1.5. Physical Hydrogels

Physical hydrogels result by ionic and physical interactions, such as hydrogen bonds, coordination bonds, electrostatic and hydrophobic interactions in certain conditions and physico-chemical interactions (stereo-complexation, charge condensation, or supramolecular chemistry) [

54]. By changing the temperature, pH, ionic strength or solvent composition, they form a homogeneous solution and re-gel when they return to their initial conditions, being reversible gels, generally unstable and mechanically weak [

55]. The physical cross-links are also formed by crystallization, [

56] between amphiphilic block and graft copolymers [

57], and protein interactions [

58]. Physically crosslinked hydrogels show stimuli-responsiveness and self-healing properties, but their mechanical strength is low and they often exhibit plastic flow [

59].

1.1.6. Chemically or Covalently Crosslinked Hydrogels

Chemically or covalently crosslinked hydrogels with a permanently fixed shape at rest, exhibit a low fracture toughness and extensibility. Therefore, it is preferred to create both physically and covalently crosslinking hydrogels [

60,

61], resulting doubly-crosslinked hybrid gels that combine all mentioned properties [

62]. Many double network (DN) hydrogels prepared by double chemically crosslinking or by hybrid physical/chemical crosslinking imply crosslinking agents, but they present toxicity which is an important disadvantage. Designing a new generation of DN gels comprising two non-covalent associated networks is a promising technique.

Kondo and coworkers [

63] prepared a dually-crosslinked polymer gel with a very homogeneous network architecture, using a tetra-arm star-shaped poly(ethylene glycol) (PEG), PEG and poly(dimethylsiloxane) (PDMS) building blocks linked by orthogonal cross-coupling, The obtained network from hydrophilic and hydrophobic components regularly and uniformly distributed is non-covalent hydrophobic association whose strength is tuned by the molar ratio of the hydrophilic PEG and the hydrophobic PDMS segments [

64].

1.1.7. Self-Assembling Hybrid Hydrogels

Self-assembling hybrid hydrogels containing peptides provide the desired biological functionality and biodegradability, are able to mimic biological structures and materials having direct biomedical applications, namely as carriers for drug and cell delivery (e.g., incorporation of bioactive sequences from natural proteins). To control mechanical, biocompatibility and degradation properties, the peptides are combined with polymeric networks [

65,

66] by chemical modification, covalently linking or non-covalent interactions between peptides and polymers [

67].

Hybrid hydrogels self-assembled from graft copolymers via formation of coiled coil antiparallel heterodimers was also demonstrated [

68], based on HPMA copolymers backbone and a pair of oppositely charged peptide grafts. The formation of these hybrid hydrogels was reversible [

68]. A DNA/poly(lactic-

co-glycolic acid) (PLGA) hybrid hydrogel (HDNA) was prepared for water-insoluble ophthalmic therapeutic delivery of dexamethasone and it may be applied in treatment of various eye diseases [

69].

1.1.8. Interpenetrated and Semi-Interpenetrated Polymer Networks

To enhance the mechanical strength, the swelling/deswelling response, and to add new sensitivities to a nanogel, multicomponent networks as full IPNs and semi-IPNs (sIPNs) were prepared by simultaneous synthesis and sequential synthesis involving two or more polymers [

70,

71]. The reaction can take place in the presence of a crosslinking agent, in order to form a complete IPN or in the absence of the crosslinking initiator, to form a sIPN.

1.1.9. Core-Shell Polymer Networks

The most common techniques of synthesis of core-shell nanogels are the seed precipitation polymerization, crosslinking of amphiphilic micelles preformed by self-assembly or the reversible addition–fragmentation chain-transfer polymerization (RAFT) [

72,

73,

74,

75,

76,

77].

Several examples of hybrid polymeric hydrogel include:

- (1) PEG-modified natural polymers [11,78,79], like fibrinogen, heparin (Hep), dextran, HA, and albumin;

- (2) PNIPAAm-modified natural polymers, like collagen, chitosan, and alginate [80,81,82,83].

1.1.10. Supramolecular Hydrogel

Supramolecular hydrogel are builded by blocks of peptides and polymers by the coupling/conjugation of specific peptide sequences (cell adhesive and/or enzymatically cleavable) to polymer chains. In such a way is obtained controlled cell responses (adhesion, migration, differentiation) because the components can self-assembly into hybrid hydrogels either, as peptide-polymer conjugates or combining individual components. These will determine the properties of the hydrogels (as stiffness, mesh structure, responsiveness, and biocompatibility) [

84], cooperative folding/unfolding transitions control over the structure formation at the nanometer level. The new produced materials may possess unprecedented levels of structural organization and novel properties [

85]. By optimizing the amino acid sequence, responsive hybrid hydrogels tailor-made for a specific application may be designed. Hybrid peptide/polymer molecular hydrogel design and synthesis showed significant research progress to mimic the natural proteins molecular architectures, dynamic responsiveness, and cellular functions, combined with tunability and processability provided by the synthetic polymer constituents.

4. Applications

Hydrogels remain the most appealing candidates for tissue engineering scaffolds. The development of hybrid hydrogels constituted from different polymers is based on numerous resources and they are applied for regenerative medicine, tissue engineering (including: bone regeneration [

107,

108,

109,

110], cartilage tissue, vascular tissue, cardiac tissue, cardiovascular tissue, meniscus tissue, human prostate tissue, skin tissue/wound, and other tissues), wound healing, artificial cornea, drug/gene delivery, cancer cells, nucleus pulposus bioelectronic interfaces due to their structural similarity to the natural ECM, inherent biocompatibility, tunable viscoelasticity, tunable physical and mechanical properties, and their ability to form scaffolds for different tissues, high-water content and high permeability for oxygen and essential nutrients [

11]. Biomedical applications of hydrogels as the first materials developed for uses inside the patient started from the decade of 70 s [

111].

It is considered that the development of the hydrogels for medical applications known three steps [

100,

112]. The first generation of hydrogels is characterized by various crosslinking procedures involving the chemical modifications of a monomer or polymer with an initiator to develop materials with high swelling and good mechanical properties. The second generation of materials is that capable to respond to specific stimuli (temperature, pH, ionic strength, different external fields or concentration of specific bioactive molecules etc.), known as smart hydrogels. Finally, the research for the third generation of hydrogels was focused on the investigation and development of hybrid, stereo complexed materials (e.g., PEG-PLA interaction) with a wide spectrum of tunable properties and trigger stimuli [

113,

114]. This last stage aimed to develop the so called “smart hydrogels” with a variety of possible applications. Hybrid hydrogels based on both natural and synthetic polymers offer infinite possibility to cells encapsulation, as matrices for repairing and regenerating a wide variety of tissues and organs [

115], are capable of responding to biological signals in vivo or remote triggers and other many possible applications in biomaterials, biomedicine and nanomedicine [

116].

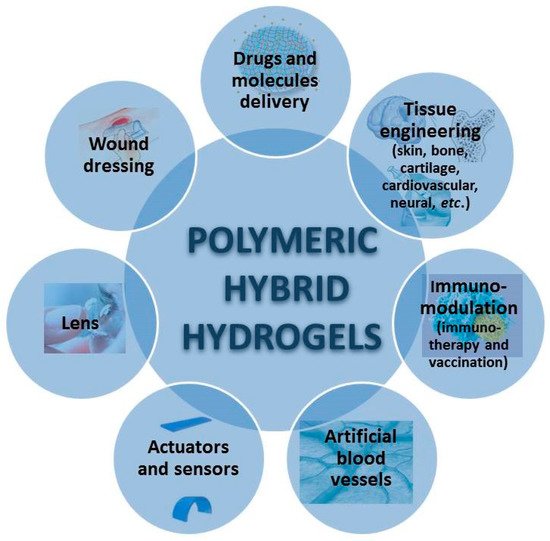

Other important applications are [

102] (

Scheme 2): wound dressing/healing, treatment of severe burns, drug delivery/controlled release, injectable hydrogels, vaccines, cancer treatment, autoimmune disease, neurodegenerative disease, anti-inflammatory, ophthalmology, etc.

Scheme 2. Biomedical applications of hydrid hydrogels based on natural and synthetic polymers.

Particularized examples of medical applications of hybrid hydrogels containing different classes of natural polymers as: homo and hetero polysaccharides, proteinsl, nucleic acids and lignin are described.

Some selective research studies have been summarized especially those from the last two decades, for the preparation of natural polymers-containing hybrid hydrogels and their potential in a wide range of medical applications. It was described both advantages and disadvantages of each hydrogel applied in different medical applications. Desired hybrid hydrogels may be developed for targeted applications by making changes in composition, use of specific biomolecules, antimicrobial agents, use of suitable cells, and selecting suitable synthesis routes and processing techniques. The successful use of a polymeric hybrid hydrogel consists in creating a three-dimensional micro-/nano environment that represents a synthetic ECM for the cells, which should provide biodegradability, biocompatibility, pore interconnectivity to assure the penetration and absorption of nutrient, modulation of proliferation for successful reconstruction of organs, cell-adhesion and regeneration certain tissue. In the most recent researches, injectable hydrogels and 3D-bioprinted hybrid hydrogels allow successful their interaction with the cells of damaged tissues. The hybrid nano hydrogel materials are able to convert external stimuli signals to heat, highly oxidative species etc., which are helpful for combinatorial therapies and theranostics. By a simple hybridization of the components of the hybrid hydrogels smart multiresponsive materials can be obtained by synergistic combination of the best properties of both components, useful toward applications in nanomedicine which exhibit an excellent targetability, minimal side effects in treatments and diagnostic. The industrial application of the new hybrid hydro/nanogels materials is in its first steps and it need more relevant clinical data concerning their safety and efficacy in vivo