The brick making industry, despite its contribution to environmental pollution, plays a major role in the economic growth of many nations, with the traditional technology accounting for a significant proportion of the total clay brick production. This writeup gives an overview of the origin of brickmaking, its socioeconomic importance, the environmental impacts and improvements made in the art of brickmaking over the years. The environmental impacts from brickmaking cannot be overruled, however, this impacts could be minimized and managed through the adoption of more sustainable and environmentally friendly firing innovative.

1. Historical Perception of Brick Making

The art of masonry and ‘stone dressing’ from time immemorial to about 2500 BC originated in Ancient Egypt [

21]. Clay bricks began from Mehrgarh in 7000 BC during pre-Harappa time [

1,

22]. Mason and Lee [

23] stated that the deposition of mud which cracks and forms cake on the Nile, Euphrates, or Tigris rivers after flooding initiated moulding into crude building units for construction of sheds. Availability, flexibility as well as economical production of clay bricks in comparison with stones resulted in the gradual shift in construction material from stone to clay brick [

24].

The first true building of sun-baked brick was made about 4000 BC in Mesopotamia now known as Iraq [

23]. Primitive brick units basically made up of mixture of mudbricks with straw were extensively used before the advent of technological advancements resulting in the production of fired bricks [

25]. Baked brick technology emerged in the Indus Valley culture [

1,

22]. Recently, fired clay bricks which are more durable, heat resistant and tough are produced via combustion of mud bricks in kiln [

23]. The Mesopotamians were reported to have developed tougher and more durable bricks. The toughness and durability features in bricks produced in Mesopotamia was attributed to the baking of bricks produced from the combination of clay and straw [

21]. Amanda [

21] emphasised that the toughness as well as lightness of the bricks makes it relatively easier for stacking, loading and transporting without damage, an added advantage of fired brick over the use of stone.

Fired clay bricks was introduced in South Africa during the first year of Jan van Riebeeck’s arrival in Cape. In August 1654, the first house made with red fired bricks was constructed in Cape. Mass production of bricks was initiated in Africa in the year, 1655 [

15]. However, Clay brick production became popular in South Africa during the period of British occupation in 1795 [

15]. The most common brick dimension for construction purpose is 5.5 × 9.5 × 20 centimetres [

23]. In the 19th Century, various innovations serving as the bedrock for the current industrial brick making technology were invented in Europe and the USA. The innovations include extruder and press for shaping of bricks, Hoffmann and tunnel kilns for burning of bricks and chamber drier [

1]. Industrial revolution conceived the transition from manual method to automated mass production of bricks resulting in the explosion of brick as a modern building material, hence the preferred material for commercial buildings [

7,

25].

2. Influence of Brick making on Climate Change

In addition to air pollutants released from brick making, is the generation of Greenhouse gases (GHGs), mainly from combustion of fossil fuel. Significant release of GHGs such as carbon dioxide, nitrogen oxides (NO

x), nitrous oxide (N

2O), nitric oxide (NO) and methane are partly responsible for the unusual changes in climatic condition [

34,

35,

39]. Globally, about 70% of total GHG emissions are attributable to the burning of fossil fuel from the industrial sectors [

37]. On a similar note, South Africa was announced as the 14th chief emitter of GHGs [

67]. In 2016, the global annual emission report indicated CO

2 as the key player in global emission contributing 74.4% of total emissions. Other GHGs namely: methane, nitrous oxide and fluorinated compounds accounted for 17.3%, 6.2% and 2.1%, respectively [

68].

The continual increase in anthropogenic emissions of GHGs, as it is currently being experienced, is dynamically modifying the climatic conditions, both at the international and local level [

69]. Today, climate change is becoming a global issue, owing to its increasing multifaceted and interconnected adverse effects [

39,

70]. The effects of climate change on meteorological processes and environmental events are well documented [

38]. The extreme weather events such as water scarcity, severe drought, elevated precipitation and tropical cyclones, result in increased instability in food production in many localities [

51]. These effects become progressively intense, prompting injuries, serious communicable diseases and mortalities [

37,

38].

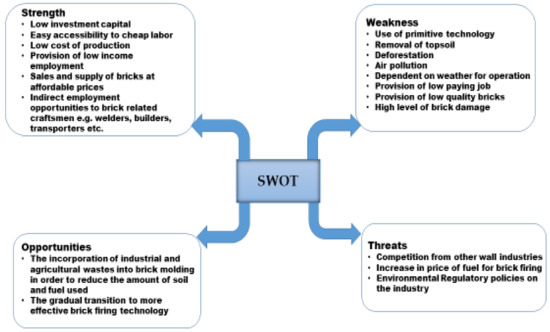

3. SWOT Analysis of the Traditional BMI

A SWOT analysis is a framework which evaluates the internal and external environments of an organization so as to pinpoints the strengths, weaknesses, opportunities and threats encountered by the organization [

71]. For effective operation of the traditional BMI, it is highly essential that the industry leverages its strength, lessen the threats and make best use of the opportunities. Below is the SWOT analysis of the traditional BMI (

Figure 1). The major weaknesses of traditional BMI include the removal of topsoil meant for agricultural purpose, the falling of trees and the release of gaseous and particulate emissions into the atmosphere. All these weaknesses result in the degradation of the environment. Bricks could be manufactured in a more sustainable way through the incorporation of industrial and agricultural wastes such as dry water treatment sludge, thermal plant bottom ash, mining tailings, fly ash, rice husk ash, sugarcane bagasse ash into the clay mixture. This green method of brick production embraces recycling of waste, thus reducing the extent of soil exploitation and use of fuelwood. Since air pollutants emissions in brick making processes are mostly generated from the combustion of fuel, the reduction of the amount of fuel used, therefore could bring about reduction in air pollution. In addition, the use of alternative cost-effective technique can be employed.

Figure 1. SWOT analysis of the traditional BMI.

Additionally, the gradual transition from traditional method of brickfiring to a more efficient brickfiring technology is essential to foster a sustainable environment. A modern brick making technology such as the Vertical Shaft Brick Kiln (VSBK) which accommodates the traditional method of brick moulding could be employed for a start pending the full automation of the modern technology. The establishment of a community owned energy efficient kiln such as the VSBK, in which local brick makers can bring in their own moulded bricks for firing would go a long way in reducing air pollutants emissions. Furthermore, it would be helpful if co-operative societies could be established, to strengthen the means of operation adopted by brick makers. This would, in turn, increase the overall financial output.

3. An Environmentally Sustainable Technology for Brick Firing

There are several brick making techniques used in South Africa, however, the Vertical Shaft Brick Kiln (VSBK) is the predominantly used modern technology for brick making in Vhembe District, due to its high efficiency, energy saving and environmentally friendly attributes relative to other modern technologies. To this effect, we determined the energy efficiency of the VSBK by comparing the energy utilised in the combustion of 1000 bricks by the VSBK and the clamp kiln.

In all, 303 kg and 68 kg of wood and coal, equivalent to 5393.4 MJ and 2109.2 MJ of energy were used for the combustion of 1000 bricks in the clamp kiln and VSBK, respectively. This resulted in 61% reduction in fuel consumption as shown in

Table 2. De Giovanetti and Volsteedt [

72] claimed energy reduction of 30–50% through the replacement of clamp kiln with VSBK. On the other hand, Maithel and Heierli [

1], and Erbe [

73] reported over 60% and 70% energy reduction per kilogram of fired bricks, respectively, with the use of VSBK technology over clamp kilns. These results [

1,

72,

73] are comparable with the 61% energy reduction attained in this study.

Table 2. Comparison between fuel consumption per 1000 bricks with the use of clamp kiln and VSBK. technologies in Vhembe District.

| Technology |

Fuel Consumed

per 1000 Bricks (kg) |

Energy Content of Fuel Used

per 1000 Bricks (MJ) |

% Reduction in

Fuel Consumption |

| Clamp |

303 |

5393.4 |

|

| VSBK |

68.0 |

2109.2 |

61% |

In addition, the advantages of the VSBK over the clamp kiln technology, in terms of the technique, space utilised, firing cycle and monthly production capacity, obtainable in Vhembe District are presented (Table 3).

Table 3. The merits of VSBK over the Clamp kiln technology.

| |

|

Clamp |

VSBK |

| 1 |

Technique |

Temporary structure, crude, batched, seasonal, no chimney |

Mechanised, fixed structure, operates all through the year, presence of chimney |

| 2 |

Space Utilization |

Large |

Small |

| 3 |

Firing cycle |

48–96 h |

22–24 h |

| 4 |

Monthly production |

About 36,000 bricks per kiln |

About 0.82 million bricks ≈ 23 times of clamp kiln production |

This entry is adapted from the peer-reviewed paper 10.3390/su131910659