Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Subjects:

Others

There is a worldwide interest in implementing collaborative robots (Cobots) to reduce work-related Musculoskeletal Disorders (WMSD) risk. While prior work in this field has recognized the importance of considering Ergonomics & Human Factors (E&HF) in the design phase, most works tend to highlight workstations’ improvements due to Human-Robot Collaboration (HRC).

- physical ergonomics

- cognitive ergonomics

- ergonomic requirement

- WMSD risk

- cognitive workload

- cobots

- HRC

1. Introduction

The need to decrease the substantial costs and impacts on the life quality of workers, motivated by the occurrence of Musculoskeletal Disorders (WMSD), is leading to a growing awareness of reducing WMSD ratios in industrialized countries [1]. WMSD are the major health problem in developed countries [2], and WMSD have been an important cause for absenteeism and productivity loss in the manufacturing industry [3,4]. The annual incidence of these occupational disorders ranges between a quarter and a third of all occupational diseases [5]. WMSD are defined as a set of painful inflammatory and degenerative conditions affecting the joints, spinal discs, cartilage, muscles, tendons, ligaments, and peripheral nerves. The origin of these disorders is frequently associated with physical risk factors of manual handling such as repetitive movements of body parts, heavy lifting, and awkward postures [5].

A recently added solution for reducing WMSD is collaborative robots (Cobots) [4]. The European Union is contributing significantly to increase the effort in this field by recognizing Cobots as one of the technologies that can positively influence the economy and society [5]. Cobots have been developed to support human operators in the physical workload of manufacturing tasks with a certain degree of flexibility, using intuitive programming interfaces to accomplish that [6]. Therefore, they can improve the working conditions of operators by reducing WMSD [4]. For that reason, Human-Robot Collaboration (HRC) has been pointed to as a good solution when a task is physically demanding and too complex to be fully automated [2]. Since Cobots present systems to limit speed and forces, there is no need to physically cage these robots, and they can work alongside humans as co-workers [6,7]. This relationship positively impacts productivity, flexibility, and the creation of new jobs instead of replacing workers [6,8]. The previous referred studies demonstrated a link between Cobots and improved work conditions; however, the inclusion of ergonomic criteria in the development and implementation of these technologies is far from being well-known. In fact, the role of E&HF on Cobots’ systems design is an emergent research topic and a fundamental parameter in industrial engineering to improve the efficiency and effectiveness of industrial processes [9].

The developments in industrial HRC have focused primarily on technology development [10] and determining and minimizing safety risks [8]. The issue of safety in HRC is mainly related to collision avoidance, reactive motion planning techniques, and ensuring that the human user is safe from immediate injury due to any failure or error [7]. In addition to these mechanical risks, physical and mental strains can be added, since the operator may have to take inappropriate postures to deal with the robot’s movements and, additionally, the operator moves up from a co-operant role to a position of supervising the work situation. This may lead to significant cognitive costs because of the allocation and reallocation of attentional resources [11]. Due to this, to achieve safer collaborative interactions between robots and human operators, it is needed to address the possible damage that may come due to the improper task execution or mental workload related to the introduction of these new technologies in the workstations [12], due to the use of more complex tasks or higher burden of cognition and decision making on the operator [13].

In order to accomplish the safest working conditions, E&HF must be considered as a requirement in the implementation of collaborative systems [14]. E&HF focuses on eliminating harmful and unsafe work practices in an industrial environment and aims to study human capabilities and limitations, and uses this knowledge to adapt the work to the worker while minimizing fatigue [15,16].

Recently, a minor number of studies have considered the ergonomic benefits of integrating robots into task plans for human workers. Gualtieri et al. [9], in a literature review of the research challenges on ergonomics and safety in industrial HRC, pointed out the lack of studies on ergonomics compared to safety-related topics. Furthermore, the few studies concerned with occupational health aspects tend to present benefits on the working conditions as outcomes rather than factor the ergonomics criteria as requirements [17].

The inclusion of ergonomic requirements in industrial HRC is a prior need for successful implementations of this technology, foreseeing the reduction of WMSD occurrence systematically and improving the cognitive workload of operators. The role of E&HF in HRC research seems to be addressed in two major ways: (i) offline, related to design and task allocation; and (ii) online, where a real-time assessment of the operator status can be performed, and a set of robotic actions can be performed by assisting the human to work in a more suitable configuration [12]. This designation (offline or online) will be used throughout the article, where offline applications include studies related to the design phase, and online applications include studies where a real-time assessment was performed.

In offline ergonomic applications, the ergonomic criteria are oriented towards workstation or Cobot mechanical design [18], where the central assumption is to combine the benefits of automation with the human workers’ skills and cognitive flexibility [6,12]. Therefore, the tasks that require a high level of knowledge, individual decision-making, and complex movements are allocated to the human, and tasks with repeatability and fatigue proof are allocated to the robot [19,20]. However, offline applications are not suitable in industrial functions with fast-reconfigurability demands (such as dynamic task variation or human workers’ limitations) since there is a need for real-time adjustments of the Cobots [21]. Hence, online ergonomic applications in HRC systems are being developed. These seem to be an innovative approach to dealing with the many issues of combining new technologies with human workers, putting the latter in the core role of the industrial workstations.

Online HRC applications are embedded with new instrumental-based tools for anticipating and evaluating human physical and cognitive states during work and setting appropriate robotic actions to deal with these. These instruments deal with an emerging issue: the worker assessment in dynamic environments. In addition to dealing with the improvement of the operator posture, these applications also care to provide the robot with the cognitive ability to communicate with the operator in real-time and make a job a true collaboration [22]. Ranavolo et al. [5] performed a literature review to investigate the need for revising the standards for human ergonomics and biomechanical risk assessment. The conclusions show that the need for revising these standards is mainly because of the use of innovative human augmentation technologies in the workplace, which makes traditional methods of WMSD risk assessment not applicable since they have relatively low reliability and cover only part of the workday [23].

2. Physical Ergonomics

Physical ergonomics is concerned with human anatomy, anthropometric, physiological, and biomechanical characteristics as they relate to physical activity. In this sub-field of ergonomics, relevant topics include working postures, materials handling, repetitive movements, WMSD, workplace layout, and safety and health [41]. Specifically, in HRC systems, physical ergonomics deals with the principles of reducing biomechanical workload by using Cobots to improve operator physical well-being and improve system performance [9]. Table 1 presents the summary of the reviewed studies related to physical ergonomics. It presents the aim, the number of subjects in the experimental setup, and the main results of each study. Some studies showed the digital transformation of a manual workstation into a collaborative one [16,19,27,28]. These studies rely on assessing the manual workstation through ergonomic tools to define the ones that cause more physical strains. Once this assessment is finished, the design of the collaborative workstation can be performed, considering the decrease in WMSD risk factors of the different tasks considered. Other studies showed the approach for allocating tasks either to the human operator or the Cobot [4,8,30,36]. These approaches are algorithm-based, among others, rely on ergonomic considerations to allocate a task to each collaborative counterpart. One other study assessed the ergonomic benefits of selecting different Cobots for a determined task [31]. In this study, the authors compared the benefits of two robots with different conformations in a simulated scenario, aiming to conclude which of the robots conferred a greater improvement in the worker’s posture. Another study showed the implementation of an end-effector to handle large working pieces [29]. In this study, a control strategy was implemented in the robotic manipulator to minimize the muscular fatigue of the operator since the robot became able to move the workpiece, ensuring that the human operator is always close to his most natural posture. All the referred studies have an offline application of ergonomic requirements. Related to online applications, the studies reviewed aimed at improving operator posture in real-time [1,12,18,22,40]. These studies rely on instrument-based systems to assess the physical state of the operator. According to deviations from the neutral posture, the robot is trigged to change its behaviour, leading the operator to take a more ergonomic posture in real-time.

Table 1. Summary of the reviewed studies related to physical ergonomics (presented in chronological order of publication). * denotes studies with online applications.

| Authors and Year | Objective | Subjects | Main Results |

|---|---|---|---|

| (Colim et al., 2021) [19] | Assessment of industrial implementation of a collaborative robotic workstation for assembly tasks. | n = 4 | WMSD risk decrease in all performed observational methods in the collaborative workstation. |

| (Palomba et al., 2021) [27] | Description of technical realization of a collaborative workstation developed for a real-industry case study. | n = 1 | Improvement of working conditions, since Rapid Upper Limb Assessment (RULA) results, showed a reduction of 50% for the left part of the body and 57% for the right part of the body when compared with the manual workstation. |

| (Ottogalli et al., 2021) [37] | Development of Virtual Reality simulation environment to address performance and worker ergonomics. | N.A. | The results show that most of the new proposed strategies improve the assembly time, worker cost, or ergonomics of the process. |

| (Dimitropoulos et al., 2021) [22] * | Development of an AI-based system that can capture the operator and environment status and provide customized operator support from the robot side for shared tasks, automatically adapting to the operator’s needs and preferences | n = 5 | Possible amelioration of ergonomic factors in 80% of the samples. |

| (Kim et al., 2021) [12] * | Development of novel HRC control method that can guide human co-workers to more ergonomic working configurations during dexterous operations. | n = 10 | Muscle arm activity in some tested configurations resulted in the lower effort. This approach only considered muscles of the arm. |

| (Gualtieri et al., 2020) [28] | Design of a collaborative workstation to improve the operators’ physical ergonomics while keeping or increasing the level of productivity. | n = 2 | Improvement of conditions in terms of manual handlings. The overall Occupational Repetitive Actions (OCRA) and RULA values were reduced. |

| (Liau & Ryu, 2020) [36] | Development and validation of a framework for task allocation for a workstation composed of one human and two collaborative robots. | N.A. | The average RULA score for the manual operation was 4.54. The introduction of two robot collaboration in the operation reduced the WMSD risk level on the human to 2.31. |

| (Shafti et al., 2020) [18] * | Development and validation of a novel approach in HRC driven by ergonomics. | n = 5 | Successful real-time robot-aided posture improvement. |

| (Lorenzini et al., 2019) [1] * | Development of a whole-body and subject-specific model to identify an individual’s fatigue progression over time while performing repetitive tasks involving light payloads. | n = 1 | When fatigue excessed a threshold in any joint, a body posture optimization was triggered, guided by the collaborative robot assistance, and the accumulation of further fatigue was thus avoided |

| (Zanchettin et al., 2019) [29] | Development of a motion control algorithm for a robotic manipulator to perform the gross of the motion, thus limiting the amplitude and the range of motion of the operator to perform an achieved task. | n = 19 | Lower exposition to WMSD and, in turn, no substantial modification in the quality of the production. |

| (Makrini et al., 2019) [4] | Development of a framework for task allocation in HRC assembly. | N.A. | The physical workload is set at the desired level. |

| (Pearce et al., 2018) [8] | Presentation of a framework for agent allocation (human or robot) minimizing task completion time and human physical “strain.” | n = 6 | Improvement of physical stress in some tasks. The best results happen for tasks where parallel work is enabled. |

| (Heydaryan et al., 2018) [30] | Development of human-robot collaboration workstation for the case of an automotive brake disc assembly |

N.A. | HRC solution improves human ergonomics considerably and reduces the operator injury risk. |

| (Kim et al., 2018) [40] * | Development of a real-time technique for reducing the overloading joint torque in humans while performing heavy manipulation tasks with robots. | n = 1 | Reduction of the shoulder and elbow joint torques in 40% to 50% more when compared to an initial experiment in which the robot trajectories were not optimized along the x-axis. |

| (Pini et al., 2016) [16] | Development of an approach to evaluate the operator relief, based on a modified model for the fatigue evaluation. | N.A. | Reduction of RULA scores for the HRC solution. Reduction of fatigue level of the operator in 42% when compared to the manual situation. |

| (Maurice et al., 2013) [31] | Development of a dynamic simulation framework to model the performing of a task jointly by a virtual manikin and a robot. | N.A. | One of the robots induces a significant decrease in the manikin efforts. The other one leads to a situation that is worse than without assistance. |

Overall, all studies showed its effectiveness in improving working conditions by considering ergonomic requirements in the process of digital transformation of manual workstations.

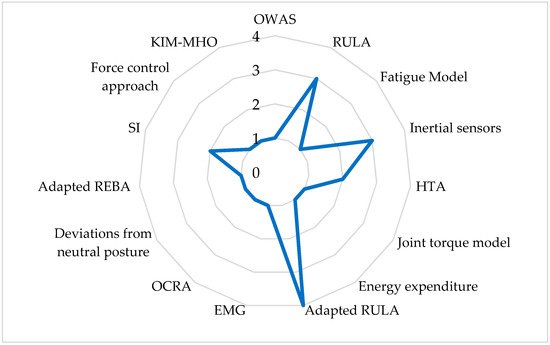

The ergonomic metrics used in some of the reviewed (Figure 1) studies still rely on observational methods in a traditional way. Ergonomic experts apply these methods through direct observation of the work activity to perform a risk assessment. They consider risk factors related to the occurrence of WMSD and assess the impact of these risks based on the external physical workload [42,43]. In the reviewed studies, the following observational methods were applied: RULA [19,27,28], OCRA [28], Key Indicator Method for Manual Handling Operations (KIM-MHO) [19], and Strain Index (SI) [8,19]. Notwithstanding, some studies already presented an adaptation to the traditional way of application of these tools. For instance, Liau & Ryu [36] and Pini et al. [16] applied RULA in a virtual scenario, using simulation software that allowed the application of this observational tool. Shafti et al. [18] and Dimitropoulos et al. [22] applied RULA. Its application is based on a vision tracking system of the human body, incorporated in the Cobot, which relies on an algorithm to calculate the final RULA score in real-time. Makrini et al. [4] applied an adaptation of Rapid Entire Body Assessment (REBA). In addition, Ottogalli et al. [37] applied Ovako Working posture Analysis System (OWAS) in a Virtual Reality scenario to assess the posture and its frequency. Vega-Barbas et al. [23] argue that real-time kinematic data helps to improve traditional assessment methods such as RULA and REBA that are mainly based on visual observations.

Figure 1. Distribution of physical ergonomics assessment methods used in the reviewed studies.

Additionally, some reviewed studies applied direct measurement ergonomic methods. These methods rely on sensors attached to the workers’ body to directly measure risk factors’ effect on physical and biomechanical parameters [37,38]. Kim et al. [12] applied surface electromyography (EMG) and Lorenzini et al. [1] and Kim et al. [12,40] used inertial sensors to estimate the position of the body joints.

Algorithm-based ergonomic methods were also applied. For example, Lorenzini et al. [1] applied an overload fatigue model that estimates the progression of fatigue by taking into account two major factors: the variability of the overloading on the joints in the presence of an external force and an individual’s subjective perception of fatigue. Kim et al. [40] applied a dynamic model of the human body to define the relationship between the centre of pressure and the interaction forces to estimate the overloading human joint torque. Zanchettin et al. [29] assessed the deviations from the neutral posture of the arm through the vision system, based on skeletal points, and specifically using the information about the position of the feet in the xy-plane. Finally, Maurice et al. [31] applied a force control approach based on a quadratic programming problem that relies on the centre of mass, contact forces, and the posture of the human body.

In our review, other methods were found. An example of that is Energy Expenditure, where energy is evaluated through the consumption of oxygen which is related to a metabolic cost [16], and Hierarchical Task Analysis (HTA) used for decomposing human tasks, regarding different ergonomics and human factors [8,30].

Our results show that the physical ergonomic tool more utilized in the context of HRC was the adaption of RULA (four studies). This RULA adaption allows to measure the physical workload during the entire workday. The second most used tool was the RULA (applied in the traditional way). With the same number of references (three studies), there is the application of inertial sensors. SI and HTA were applied in only two studies. All the other tools were applied in only one study each.

3. Cognitive Ergonomics

Cognitive ergonomics is concerned with mental processes, such as perception, memory, reasoning, and motor response, as they affect interactions among humans and other system elements. This ergonomics domain includes relevant topics, such as mental workload, decision-making, skilled performance, human-computer interaction, human reliability, work stress, and training, as these may relate to human-system design [41]. In HRC systems, cognitive ergonomics deals with interaction acceptability by minimizing mental stress provided to operators when sharing workspaces with Cobots [9]. Table 2 presents a summary of the reviewed studies related to cognitive ergonomics. It presents the aim, the number of subjects in the experimental setup, and the main results of each study. The studies where a cognitive ergonomic requirement was considered can be divided into two major topics: assessing the impact of a collaborative workstation on the well-being of workers [12,32] and developing a framework for a trust-based integrated scheme for HRC [34,35]. The studies in the first topic aim to investigate the consequences on operators of a shared workplace with a Cobot, while the studies in the second topic aim to implement HRC solutions based on cognitive workload improvement. The results of the reviewed studies show that most of the workers agreed that Cobots can improve working conditions through the support given by this technology, which reduces stress caused by industrial tasks. Additionally, the results of the reviewed studies also point out that the integration of trust-based approaches allows for decreasing perceived task load, leading to a better collaboration of the two elements of the collaborative systems. It is important to note that one of the critical elements of HRC for effective collaboration is trust. This key element determines humans’ use of autonomy, and improper trust can lead to either over-reliance or under-reliance on the robot, and thus an increased task load and reduced task performance [34].

Table 2. Summary of the reviewed studies related to cognitive ergonomics (presented in chronological order of publication).

| Authors | Objective | Subjects | Main Results |

|---|---|---|---|

| (Brun & Wioland, 2021) [11] | Investigation of the consequences of Human-Robot Collaboration on the operator’s activity and his feelings | n = 8 | All workers agreed that the collaborative system impacts the organization. Most of the workers (75%), also agreed that the implementation of collaborative robots improves working conditions and confidence, gives support and relief and decreases stress and fatigue. |

| (Lambrechts et al., 2021) [38] | Investigation of implementation the influence of human factors on the implementation of Cobots in assembly lines. | n = 4 | The results demonstrate the importance of planning the Cobots implementation process in phases, since employees are hesitant or resistant to the change due to a lack of information, experience, and communication. |

| (Rossato et al., 2021) [32] | Investigation of the extent to which users’ age (i.e., adults, senior workers) and cobot control modality (i.e., manual, tablet) affect the acceptance, UX, usability, and task load related to cobot usage. | n = 20 | Workers of different ages viewed the Cobot not as a replacement but as a supportive and independent ‘‘colleague’’ who is pleasant, attractive, and satisfying to interact with. |

| (Prati et al., 2021) [33] | Development a user experience (UX)-oriented structured method to investigate the human-robot dialogue to map the interaction with robots during the execution of shared tasks. | n = 1 | Results demonstrated the validity of the proposed tools to understand the human-robot interaction, describe the communication issues, and define the main interface features to support the following interface design activity. |

| (Charalambous et al., 2016) [35] | Development of Human Factors roadmap for the successful implementation of industrial HRC. | N.A. | The roadmap provides propositions in a guiding framework for practitioners to assist appropriate trust calibration to the robotic teammate, through a Training programme and Operator empowerment. |

| (Sadrfaridpour et al., 2016) [34] | Development of a trust-based integrated scheme for HRC in manufacturing to take into account human-in-the-loop considerations at the psychological levels. | n = 5 | The human-perceived task load is lowest in the trust-based integrated framework. Comparison of human perceived task load and subjective trust in the robot reveals that the human worker experiences a better collaboration during the trust-based integrated scheme. |

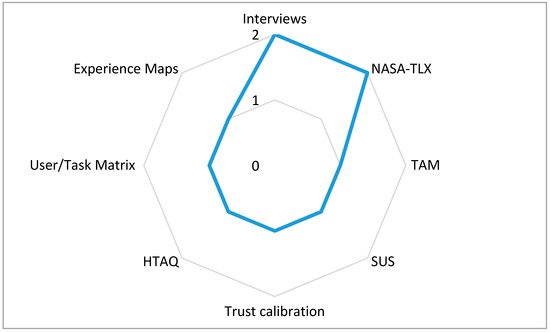

Related to cognitive ergonomic tools (Figure 2), our findings indicate that the most used were NASA-Task Load Index (NASA-TLX) [32,34] and interviews [11,38]. The other tools were applied only in one study each. NASA-TLX was used for assessing the task load [32,34]. Technology Acceptance Model (TAM) questionnaire was used to assess Cobot acceptance. This questionnaire has a revised version appropriate for evaluating the robot’s acceptance [32]. System Usability Scale (SUS) was applied to assess the usability of the HRC system [32]. The study of Brun & Wioland [11] used interviews to assess the operator’s activity and feelings. In addition, Lambrechts et al. [38] used interviews to identify human factors in the Cobot implementation process, resistance to change, and leadership during Cobot implementation. Some of the human factors found were communication, resistance to change, and culture. Human Trust in Automation Questionnaire (HTAQ) was applied to assess the operator’s trust in his robot teammate [34]. All tools mentioned above are based on subjective measures.

Figure 2. Distribution of cognitive ergonomics assessment tools used in the reviewed studies.

Another tool found was trust calibration. This tool relies on: (i) a training program that will enable operators to understand the abilities as well as limitations of the robotic teammate, which will allow human operators to develop an appropriate, and more realistic, mental model of the robot they will be requested to collaborate with; and (ii) operator empowerment through the experience of collaborating with the robotic teammate to enhance his ability during degraded events, such as robot failures, errors, or deviations [35].

The User/Task Matrix and Experience Maps are tools proposed by Prati et al. [33] oriented to user experience. The User/Task Matrix is appropriate for registering an interaction scenario between human workers and robots. Examples of this include tasks’ duration, actors, communication, cycle time, critical situations, possible solutions, and working conditions. The registration of the above-mentioned parameters should allow for understanding of the frequency of human-robot interactions, how complex they are, and how long they take. Experience maps represent a synthetic visualization of an entire end-to-end experience that a worker goes through to accomplish a certain task in collaboration with a robot. These also allow understanding human behaviour and further assist in the interaction design process between humans and robots.

The results point to the fact that cognitive ergonomics techniques are diversified. To the best of the authors’ knowledge, there is not yet a framework to follow in this matter.

This entry is adapted from the peer-reviewed paper 10.3390/safety7040071

This entry is offline, you can click here to edit this entry!