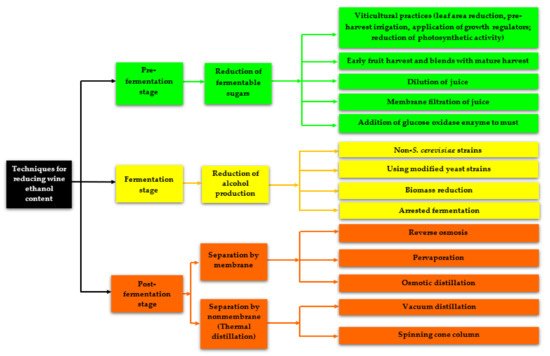

To adapt to the trends in wine styles, and the effect of climate change on wine alcohol content, different techniques have been used at the various stages of winemaking, among which the physical dealcoholization techniques, particularly membrane separation (nanofiltration, reverse osmosis, evaporative perstraction, and pervaporation) and thermal distillation (vacuum distillation and spinning cone column), have shown promising results and hence are being used for commercial production.

- dealcoholization

- reduced-alcohol wine

- alcohol-free wine

- non-alcoholic wine

- phenolic composition

- volatile composition

- aroma compounds

- sensory quality

1. Introduction

2. Techniques for Wine Alcohol Reduction

|

Stage of Wine Production |

Ethanol Removal Process |

Technology |

Alcohol Content Reduction |

References |

|---|---|---|---|---|

|

Pre-fermentation |

Reduction of fermentable sugars |

Viticultural practices (leaf area reduction, pre-harvest irrigation, application of growth regulators; reduction in photosynthetic activity) |

Up to 2% v/v |

|

|

Early fruit harvest and blends with mature harvest |

Up to 3% v/v |

|||

|

Dilution of grape must |

Up to 7% v/v |

|||

|

Filtration of must |

Up to 5% v/v |

|||

|

Addition of enzyme (glucose oxidase) |

Up to 4% v/v |

|||

|

Fermentation |

Reduction of alcohol production |

Use of Non-Saccharomyces cerevisiae yeasts |

Up to 2% v/v |

[90,91,92,93,94,95,96,97,98,99,100,101,102,103,104,105,106,107,108,109,110,111,112,113,114,115,116,117,118,119,120] |

|

Use of modified yeast strains |

Up to 3.6% v/v |

|||

|

Biomass reduction |

Up to 4% v/v |

|||

|

Arrested fermentation |

High reduction |

|||

|

Post-fermentation |

Separation by membrane |

Nanofiltration (NF) |

Up to 4% v/v |

|

|

Reverse osmosis (RO) |

Up to 0.5% v/v or less |

|||

|

Osmotic distillation (OD) |

Up to 0.5% v/v or less |

|||

|

Pervaporation (PV) |

Up to 0.5% v/v or less |

|||

|

Vacuum distillation (VD) |

Up to 1% v/v or less |

|||

|

Spinning cone column (SCC) |

Up to 0.3% v/v |

|||

|

Multi-stage membrane-based systems |

Up to 0.5% v/v or less |

3. Impact of Dealcoholization Techniques on Wine Quality

3.1. Impact on phenolic composition

|

Wine Type |

Dealcoholization Process |

Alcohol Reduction |

Reported Effects on Phenolic Composition |

Reference |

|

|---|---|---|---|---|---|

|

Co (% v/v) |

Cf (% v/v) |

||||

|

Red wine |

NF |

12.0 |

6.0–4.0 |

Reduction in wine alcohol volume by a factor of 4 leads to 2.5–3 times more anthocyanins and resveratrol in the wine concentrates |

[138] |

|

Cabernet Sauvignon–Merlot–Tempranillo red wine |

RO |

12.7 |

4.0–2.0 |

No significant differences were observed in total anthocyanins and phenolic compounds for both original and dealcoholized wines. Colour intensity increased by around 20% in dealcoholized wines (due to the concentration effect from the removal of ethanol as well as the retention of anthocyanins by the membrane), while the tonality diminished by around 15% |

[229] |

|

Cabernet Sauvignon red wine |

RO |

14.8 |

13.8–12.8 |

The total phenolic index, total proanthocyanidins, and percentages of procyanidins, prodelphinidins, and galloylation of partially dealcoholized wines and the control wine remains almost unchanged and did not differ. Control wine and partially dealcoholized wines have statistically similar total anthocyanin concentrations with no observed color differences between these wines |

[22] |

|

Grenache–Carignan red wine |

RO |

16.2 |

15.1–14.1 |

The total phenolic index and total proanthocyanidins of partially dealcoholized wines and the control wine remain almost unchanged and do not differ. Slight but statistically significant differences were observed in the percentages of procyanidins, prodelphinidins, and galloylation during alcohol reduction. Total anthocyanin concentrations of partially dealcoholized wines were statistically significantly higher than that of the control wine |

[22] |

|

Montepulciano d’Abruzzo red wine |

RO |

13.2 |

9.0 |

Increase in total phenols and decrease in total anthocyanins during ethanol reduction in wine samples. Color intensity increases during ethanol removal |

[146] |

|

Aglianico red wine |

OD/EP |

12.8 |

4.9–0.4 |

Higher amount of total phenols in dealcoholized wine samples compared to the original wine. Color intensity decreased slightly at the end of dealcoholization |

[197] |

|

Aglianico red wine |

OD/EP |

15.4 |

13.5–10.8 |

The alcohol removal process did not affect the content of vanillin reactive flavans and total phenolics. A loss of 49% of total monomeric anthocyanins was observed after dealcoholization while total anthocyanins remained almost unchanged with no significant differences. Color parameters of dealcoholized wines were not significantly different compared to the original wine after alcohol removal |

[150] |

|

Merlot red wine |

OD/EP |

13.8 |

11.1–8.9 |

The alcohol removal process did not affect the content of vanillin reactive flavans and total phenolics. A loss of 57% of total monomeric anthocyanins was observed after dealcoholization while total anthocyanins remained almost unchanged with no significant differences. Color parameters of dealcoholized wines were not significantly different compared to the original wine after alcohol removal |

[150] |

|

Piedirosso red wine |

OD/EP |

13.6 |

11.5– 8.4 |

The alcohol removal process did not affect the content of vanillin reactive flavans and total phenolics. A loss of 52% of total monomeric anthocyanins was observed after dealcoholization while total anthocyanins remained almost unchanged with no significant differences. Color parameters of dealcoholized wines were not significantly different compared to the original wine after alcohol removal |

[150] |

|

Aglianico red wine |

OD/EP |

12.5 |

10.6 |

No significant differences between base wine and dealcoholized wine in terms of total polyphenols and color intensity |

[152] |

|

Barbera red wine |

OD/EP |

15.2 |

5.0 |

Higher contents of total anthocyanins and total flavonoids compared to the original wine. Color: the intensity increases and the hue decreases (loss of orange notes) due to the increased content of total anthocyanins |

[160] |

|

Langhe Rosè wine |

OD/EP |

13.2 |

5.0 |

Higher contents of total anthocyanins and total flavonoids compared to the original wine. Color: the intensity increases and the hue decreases (loss of orange notes) due to the increased content of total anthocyanins |

[160] |

|

Verduno Pelaverga red wine |

OD/EP |

14.6 |

5.0 |

Higher contents of total anthocyanins and total flavonoids compared to the original wine. Color: the intensity increases and the hue decreases (loss of orange notes) due to the increased content of total anthocyanins |

[160] |

|

Falanghina white wine |

OD/EP |

12.5 |

9.8–0.3 |

At different alcohol content levels of wines, the total phenols and flavonoids do not differ significantly as they remain almost unchanged during the alcohol removal process |

[36] |

|

Montepulciano d’Abruzzo red wine |

OD/EP |

13.2 |

8.3–5.4 |

Both total phenols and total anthocyanins decrease in dealcoholized wines with no significant differences compared to the original wine. The color intensity remains almost unchanged during ethanol removal |

[146] |

|

Montepulciano d’Abruzzo red wine |

OD/EP |

13.2 |

8.3–2.7 |

Flavonoids and phenolic compounds remain almost unchanged in all dealcoholized samples compared to the base wine with no significant differences. Color intensity (evaluated by flavonoids and phenolic compounds) decrease slightly in all dealcoholized samples |

[35] |

|

Langhe Rosè wine |

VD |

13.2 |

5.0 |

Higher contents of total anthocyanins and total flavonoids compared to the original wine. Color the intensity increases and the hue decreases (loss of orange notes) due to the increased content of total anthocyanins |

[160] |

|

Barbera red wine |

VD |

15.2 |

5.0 |

Higher contents of total anthocyanins and total flavonoids compared to the original wine. Color: the intensity increases and the hue decreases (loss of orange notes) due to the increased content of total anthocyanins |

[160] |

|

Verduno Pelaverga red wine |

VD |

14.6 |

5.0 |

Higher contents of total anthocyanins and total flavonoids compared to the original wine. Color the intensity increases and the hue decreases (loss of orange notes) due to the increased content of total anthocyanins |

[160] |

|

Red wine |

SCC |

14.0 |

< 0.3 |

Increase in phenolic compounds, total phenolic, flavonol, tartaric ester, and anthocyanin contents by approximately 24%. Higher content of resveratrol than the original wine |

[163] |

|

Rose wine |

SCC |

14.0 |

< 0.3 |

Increase in phenolic compounds, total phenolic, flavonol, tartaric ester, and anthocyanin contents by approximately 24%. Higher content of resveratrol than the original wine |

[163] |

|

White wine |

SCC |

14.0 |

< 0.3 |

Increase in phenolic compounds content by approximately 24% |

[163] |

|

Montepulciano d’Abruzzo red wine (cv.) |

RO–OD/EP |

13.2 |

7.1–5.5 |

Total phenols increase while total anthocyanins decrease in the dealcoholized wine samples. Color intensity increases during ethanol removal |

[146] |

|

Cabernet Sauvignon red wine |

RO–OD/EP |

14.1 |

12.5 |

Significantly increase in color intensity due to increased content of anthocyanins during alcohol reduction compared to the base wine |

[168] |

|

Shiraz red wine |

RO–OD/EP |

15.2 |

12.6 |

Increase in color intensity due to increased content of anthocyanins during alcohol reduction compared to the base wine |

[168] |

3.2. Impact on Volatile Composition

|

Dealcoholization Process |

Wine Type |

Membrane |

Operating Mode/Conditions |

Alcohol Reduction |

Volatile Composition |

Sampling and Analytical Method |

Reference |

||

|---|---|---|---|---|---|---|---|---|---|

|

Co (% v/v) |

Cf (% v/v) |

Volatile Compounds |

Estimated Average Losses (%) |

||||||

|

NF |

White model wine |

TORAY–UB70 |

Batch retentate–recycling mode T = 15 P = 10 |

12.0 |

8.4 |

Diethyl succinate 2–phenyl–ethanol cis–3–hexenol Isovaleric acid |

2.4 2.9 12.6 11.7 |

HS/SPME–GC/MS |

[140] |

|

Red Wine |

Polyamide, NF9, Alfa Laval |

T = 30 P = 16 |

12.0 |

9.1 |

Total volatile aroma** |

30.0 |

GC–FID |

[33] |

|

|

RO |

Model wine |

Osmonics–SE |

Batch retentate–recycling mode T = 15 P = 17–29 |

12.0 |

8.4 |

Diethyl succinate 2–phenyl–ethanol cis–3–hexenol Isovaleric acid |

0.6–1.6 2.5–3.5 7.8–11 11.9–18.1 |

HS/SPME–GC/MS |

[140] |

|

Red Wine |

Cellulose acetate, CA995PE |

T = 30◦C P = 16 |

12.0 |

8.4 |

Total aroma** |

90.0 |

GC–FID |

[33] |

|

|

Montepulciano d’Abruzzo red wine |

RO membrane (100 DA) |

T = 10 P = ns Time = 40 |

13.2 |

9.0 |

Alcohols Acids Esters Phenols Lactones |

30.0 22.0 8.0 13.0 14.0 |

SPME–GC/MS |

[146] |

|

|

OD/EP |

Model wine |

Polyvinylidene fluoride (PVDF) Memcor |

Qf = 0.053 Qs = 0.093 T = 30 Time = 60 |

13.0 |

8.1 |

Isoamyl alcohol Ethyl acetate |

44.0 70.0 |

GC–FID |

[190] |

|

Falanghina white wine |

Liqui–Cel 0.5 × 1, PP hollow fiber |

Qf = 0.07 Qs = 0.14 T = 10 Time = 240 |

12.5 |

9.8–0.3 |

Higher alcohols Acids Esters Ketones lactones |

49.5–98.9 60.5–98.7 71.5–99.0 67.1–99.9 73.6–98.2 |

LE–GC/MS, LE–GC/FID |

[36] |

|

|

Xarelo white wine |

Liqui–Cel ExtraFlow |

Qf = 10 Qs = 10 T = room temperature Time = 20 |

11.5 |

10.1 |

Isoamyl acetate Ethyl hexanoate Ethyl octanoate Ethyl decanoate |

27.0 37.0 28.0 24.0 |

SBSE–GC/MS |

[148] |

|

|

Soave white wine |

PTFE hollow fiber (Teflon, Verona, Italy) |

Qf = 0.2 Qs = 0.2 T = 20 Time = ns |

ns |

* |

Alcohols Acids Esters Terpenes |

12.6–32.2 5.6–16.4 34.0–58.4 22.0–26.0 |

SPE–GC/MS |

[196] |

|

|

Verdicchio white wine |

PTFE hollow fiber (Teflon, Verona, Italy) |

Qf = 0.2 Qs = 0.2 T = 20 Time = ns |

ns |

* |

Alcohols Acids Esters Terpenes |

8.9–25.8 8.0–15.8 40.0–54.1 21.0–28.0 |

SPE–GC/MS |

[196] |

|

|

Aglianico red wine |

Liqui–Cel Extra–flow, PP hollow fiber |

Qf = 0.583 Qs = 0.183 T = 20 Time = 283 |

13.8 |

11.6–8.8 |

Alcohols Esters Acids Terpenes Others: Benzaldehyde ?–Butyrolactone |

8.4–31.8 42.9–60.9 12.5–17.1 13.8–32.3 55.3–65.9 4.5–13.6 |

SPE–GC/MS |

[32] |

|

|

Aglianico red wine |

Liqui–Cel Extra–flow, PP hollow fiber |

Qf = 0.583 Qs = 0.183 T = 20 Time = 283 |

15.5 |

13.5–10.8 |

Alcohols Esters Acids Terpenes Others: Benzaldehyde ?–Butyrolactone Vitispirane |

9.2–13.7 33.8–50.6 11–18.5 3.6–14.5 nf 12.9 Unc |

SPE–GC/MS |

[32] |

|

|

Aglianico red wine |

Liqui–Cel 0.5×1, PP hollow fiber |

Qf = 0.07 Qs = 0.14 T = 20 Time = 255 |

13.0 |

6.5–0.2 |

Alcohols Acids Esters Sulfur compounds Phenols Ketones and lactones Aldehydes |

57.9–99.9 23.6–78.9 12.8–89.9 2.1–78.7 66.7–100 23.6–97.9 unc–100 |

LE–GC/MS, LE–GC/FID |

[151] |

|

|

Merlot red wine |

Liqui–Cel Extra–flow, PP hollow fiber |

Qf = 5.8 Qs = 8.1 T = 20 Time = 60 |

13.4 |

11.3 |

Ethyl acetate Isoamyl acetate Isoamyl alcohol Ethyl hexanoate Ethyl octanoate Linalool 2–Phenylethyl acetate |

37.4 34.9 13.7 33.0 67.8 14.5 13.6 |

HS/SPME–GC/MS |

[147] |

|

|

Barbera red wine |

Polypropylene hollow fibers (JU.CLA.S. LTD, Verona, Italy) |

Qf = 1.6 Qs = 0.8 T = 10 Time = 360 |

14.6 |

5.0 |

Alcohols Acids Esters |

63.9 17.4 23.8 |

SPE–GC/FID |

[160] |

|

|

Tempranillo red wine |

Liqui–Cel ExtraFlow |

Qf = 5.8 Qs = 5.8 T = room temperature Time = 60 |

13.3 |

9.0 |

Isoamyl alcohol Ethyl hexanoate |

21.0 20.0 |

SBSE–GC/MS |

[148] |

|

|

Garnacha red wine |

Liqui–Cel ExtraFlow |

Qf = 5 Qs = 5 T = room temperature Time = 60 |

13.9 |

9.3 |

Isoamyl acetate Ethyl hexanoate |

24.0 36.0 |

SBSE–GC/MS |

[148] |

|

|

Verduno Pelaverga red wine |

Polypropylene hollow fibers (JU.CLA.S. LTD, Verona, Italy) |

Qf = 1.6 Qs = 0.8 T = 10 Time = 360 |

14.6 |

5.0 |

Alcohols Acids Esters |

59.9 23.6 45.2 |

SPE–GC/FID |

[160] |

|

|

Montepulciano d’Abruzzo red wine |

Liqui–Cel 0.5×1, PP hollow fiber |

Recycling mode Qf = 1.5 Qs = 0.5 T = 10 Time = 240 |

13.2 |

8.3–2.7 |

Alcohols Acids Esters Lactones Phenols Others: Benzaldehyde α–Terpineol |

56.0–84.0 18.0–23.0 64.0–85.0 11.0–37.0 11.0–37.0 2.0–26.0 5.0–49.0 |

SPE– LE–GC/MS/FID |

[35] |

|

|

Montepulciano d’Abruzzo red wine |

Liqui–Cel mini module 1.7x5.5 Membrana |

Recycling mode Qf = 1.5 Qs = 0.5 T = 10 Time = 120 |

13.2 |

8.3–5.4 |

Alcohols Acids Esters Phenols Lactones |

2.0–3.0 18.0–25.0 15.0–19.0 5.0–10.0 7.0–25.0 |

SPME–GC/MS |

[146] |

|

|

Langhe Rosè wine |

Polypropylene hollow fibers (JU.CLA.S. LTD, Verona, Italy) |

Qf = 1.6 Qs = 0.8 T = 10 Time = 360 |

13.2 |

5.0 |

Alcohols Acids Esters |

60.4 30.9 47.8 |

SPE–GC/FID |

[160] |

|

|

PV |

Tokaji Hárslevelű white wine |

PERVAP.Sulzer 1060 PDMS |

‘‘Carrier gas mode’’ under atmospheric pressure T = 40–70 |

13.1 |

0.1 |

Total volatile aroma** |

70.0 |

Distillation/LE–GC/MS |

[29] |

|

Cabernet Sauvignon red wine |

PDMS JS–WSM–8040 (JiuSi High–Tech, Nanjing, China) |

Batch operation T = 45 VP = 0.05 |

12.5 |

0.5 |

Alcohols Acids Esters |

19.7–39.5 12.7–28.2 48.0–99.9 |

GC/MS |

[210] |

|

|

VD |

Barbera red wine |

– |

T = 15 |

15.2 |

5.0 |

Alcohols Acids Esters |

50.4 13.7 19.8 |

SPE–GC/FID |

[160] |

|

Verduno Pelaverga red wine |

– |

T = 15 |

14.6 |

5.0 |

Alcohols Acids Esters |

53.6 2.3 19.5 |

SPE–GC/FID |

[160] |

|

|

Langhe Rosè wine |

– |

T = 15 |

13.2 |

5.0 |

Alcohols Acids Esters |

51.4 2.5 22.9 |

SPE–GC/FID |

[160] |

|

|

SCC |

White wine |

– |

T = 25 VP = 0.08 Time = 60 |

10.6 |

0.3 |

Aliphatic alcohols Aromatic alcohols Acids Esters Ketones |

98.0 3.0 20.0 53.0 71.0 |

LE–GC/FID |

[164] |

|

Chardonnay white wine |

– |

T = 30 VP = 0.04 Time = 60 |

ns |

ns |

Total aroma** |

1.0–9.0 |

HS/SPME–GC/MS |

[162] |

|

|

Tempranillo red wine |

– |

T = 30 VP = 0.04 Time = 60 |

ns |

ns |

Total aroma** |

3.0–18.0 |

HS/SPME–GC/MS |

[162] |

|

|

Cabernet Sauvignon rose wine |

– |

T = 30 VP = 0.04 Time = 60 |

ns |

ns |

Total aroma** |

1.0–4.0 |

HS/SPME–GC/MS |

[162] |

|

|

RO-OD/EP |

Shiraz red wine |

Memstar AA MEM–074 and Liqui–Cel 2.5×8 Extra–flow PP hollow fiber |

Qf = ns Qs = ns T = ns P = ns Time = ns |

16.3 |

13.3–10.4 |

Alcohols Esters Monoterpenes C13–Norisoprenoids Lactones Others: Dimethyl sulfide |

14.9–38.9 29.8–49.5 9.2–20.8 9.4–14.5 17.1–21.4 52.6–71.9 |

HS–SPME–GC/MS |

[217] |

|

Montepulciano d’Abruzzo red wine |

RO membrane (100 DA) and Liqui–cel mini module 1.7×5.5 Membrane |

Recycling mode Qf = 1.5 Qs = 0.5 T = 10 P = ns Time = 120 |

13.2 |

7.1–5.5 |

Alcohols Acids Esters Phenols Lactones |

17.0–27.0 19.0–24.0 15.0–22.0 16.0–18.0 unc–14.0 |

SPME–GC/MS |

[146] |

|

|

Barossa Valley Shiraz – Cabernet Sauvignon red wine |

Spiral wound 4040 and hollow fiber perstractive membrane (VA Filtration, Nuriootpa, Australia) |

Qf = ns Qs = ns T = 55 P = 30 Time = 90 |

14.1 |

12.5 |

Alcohols Acids Esters |

15.5 10.0 5.1 |

SPME–GC/MS |

[168] |

|

|

McLaren Vale Cabernet Sauvignon red wine |

Spiral wound 4040 and hollow fiber perstractive membrane (VA Filtration, Nuriootpa, Australia) |

Qf = ns Qs = ns T = 55 P = 30 Time = 90 |

17.1 |

14.5 |

Alcohols Acids Esters |

13.6 6.1 18.8 |

SPME–GC/MS |

[168] |

|

|

Adelaide Hills Shiraz red wine |

Spiral wound 4040 and hollow fiber perstractive membrane (VA Filtration, Nuriootpa, Australia) |

Qf = ns Qs = ns T = 55 P = 30 Time = 90 |

14.9 |

14.2 |

Alcohols Acids Esters |

7.0 0.4 8.6 |

SPME–GC/MS |

[168] |

|

|

Barossa Valley Shiraz red wine |

Spiral wound 4040 and hollow fiber perstractive membrane (VA Filtration, Nuriootpa, Australia) |

Qf = ns Qs = ns T = 55 P = 30 Time = 90 |

15.2 |

12.6 |

Alcohols Acids Esters |

11.0 5.6 21.2 |

SPME–GC/MS |

[168] |

|

|

McLaren Vale Shiraz red wine |

Spiral wound 4040 and hollow fiber perstractive membrane |

Qf = ns Qs = ns T = 55 P = 30 Time = 90 |

14.7 |

12.3 |

Alcohols Acids Esters |

7.1 2.5 9.7 |

SPME–GC/MS |

[168] |

|

|

Cabernet Sauvignon red wine A |

Spiral wound 4040 and hollow fiber perstractive membrane (VA Filtration, Nuriootpa, Australia) |

Qf = ns Qs = ns T = 55 P = 30 Time = 90 |

17.0 |

14.5 |

Alcohols Acids Esters |

8.2 15.9 17.4 |

[169] |

||

|

Cabernet Sauvignon red wine B |

Spiral wound 4040 and hollow fiber perstractive membrane (VA Filtration, Nuriootpa, Australia) |

Qf = ns Qs = ns T = 55 P = 30 Time = 90 |

15.5 |

13.3 |

Alcohols Acids |

3.8 12.0 |

[169] |

||

|

Cabernet Sauvignon red wine C |

Spiral wound 4040 and hollow fiber perstractive membrane (VA Filtration, Nuriootpa, Australia) |

Qf = ns Qs = ns T = 55 P = 30 Time = 90 |

14.9 |

13.3 |

Alcohols |

16.4 |

[169] |

||

|

Cabernet Sauvignon red wine D |

Spiral wound 4040 and hollow fiber perstractive membrane (VA Filtration, Nuriootpa, Australia) |

Qf = ns Qs = ns T = 55 P = 30 Time = 90 |

14.5 |

13.2 |

Alcohols Acids Esters |

7.1 4.7 76.5 |

[169] |

||

3.3. Impact on Sensory Characteristics

|

Dealcoholization Process |

Wine Type |

Membrane |

Operating Mode/Conditions |

Alcohol Reduction |

Findings on Sensory Characteristics |

Reference |

|

|---|---|---|---|---|---|---|---|

|

Co (% v/v) |

Cf (% v/v) |

||||||

|

NF |

Red Wine |

Polyamide, NF97, NF99 HF Alfa Laval |

T = 30 P = 16 |

12.0 |

9.1 |

Increase in astringency and unbalanced aroma and taste due to alcohol reduction |

[33] |

|

RO |

Syrah red wine |

ns |

T = ns P = ns |

12.7 |

11.1–9.6 |

Decrease in wine length in the mouth and increase in red fruits and then woody and blackcurrant perceptions (using TDS and attributed to alcohol reduction). Decrease in heat and sweetness intensity (attributed to alcohol reduction) and red fruit intensity (attributed to RO) |

[189] |

|

Merlot red wine |

ns |

T = ns P = ns |

13.4 |

11.8–10.2 |

Decrease om wine length in the mouth and increase in astringent and then of fruity perceptions (using TDS and attributed to alcohol reduction). Decrease in heat and texture intensity (attributed to alcohol reduction) and increase in acid intensity (attributed to RO) |

[189] |

|

|

Syrah red wine |

ns |

T = ns P = ns |

13.4 |

11.4–7.9 |

Decrease in persistence, complexity, number of aromas and increase in balance, harmony, and familiarity. Decrease in familiarity and harmony after 4% v/v reduction |

[244] |

|

|

OD/EP |

white wine |

PTFE hollow fiber (Teflon, Verona, Italy) |

Qf = 0.2 Qs = 0.2 T = 20 Time = ns |

ns |

* |

Floral, fruity, and vegetable notes, as well as acidity, saltiness, and bitterness, were not significantly influenced. Decrease in wine body, persistence, and honey note. |

[196] |

|

Falanghina white wine |

Liqui-Cel 0.5x1, PP hollow fiber |

Qf = 0.07 Qs = 0.14 T = 10 Time = 240 |

12.5 |

9.8–0.3 |

Decrease in odor, sweetness, and body, resulting in unbalanced taste and overall unacceptable, with an unpleasant aftertaste |

[36] |

|

|

Aglianico red wine |

Liqui-Cel Extra-flow, PP hollow fiber |

Qf = 0.583 Qs = 0.183 T = 20 Time = 283 |

13.8 |

11.6–8.8 |

Decrease in cherry, red fruits, and sweet notes. Increase in flowers notes only within 2% v/v reduction. Increase in grass and cooked notes and increase in astringency within 5% v/v reduction. Increase in bitterness and acid sensations within 3% v/v reduction |

[32] |

|

|

Aglianico red wine |

Liqui-Cel Extra-flow |

Qf = ns Qs = ns T = ns Time = 180 |

12.8 |

4.9–0.4 |

Decrease in sweet and solvent aroma series (due to alcohol reduction) which characterize the wine |

[197] |

|

|

Aglianico red wine |

Liqui-Cel Extra-flow, PP hollow fiber |

Qf = 0.583 Qs = 0.183 T = 20 Time = 283 |

15.5 |

13.5–10.8 |

Decrease in cherry, red fruits, flowers, and grass notes. Increase in acid and astringent sensations |

[32] |

|

|

Montepulciano d’Abruzzo red wine |

Liqui-Cel 0.5×1, PP hollow fiber |

Recycling mode Qf = 1.5 Qs = 0.5 T = 10 Time = 240 |

13.2 |

8.3–2.7 |

Increase in acidity, a decrease in red fruits and spices notes, astringency, bitterness, and sweetness, resulting in lower acceptability |

[35] |

|

|

PV |

Cabernet Sauvignon red wine |

PDMS JS-WSM-8040 (JiuSi High-Tech, Nanjing, China) |

Batch operation T = 45 VP = 0.05 |

12.5 |

0.5 |

High retention of fruit aroma, producing wine with better smell and taste |

[210] |

|

SCC |

Chardonnay white wine |

– |

ns |

14.9 |

14.6–12.9 |

Decrease in overall aroma intensity and hot mouthfeel sensation |

[245] |

|

RO-OD/EP |

Shiraz red wine |

Memstar AA MEM-074 and Liqui-Cel 2.5 × 8 Extra-flow PP hollow fiber |

Qf = ns Qs = ns T = ns P = ns Time = ns |

16.3 |

13.3–10.4 |

Increase in dark fruit, raisin/prune, alcohol, and astringency in all dealcoholized wines with no significant effects. Increase in black pepper note and overall aroma intensity, and decrease in herbaceous note within 6% v/v reduction off alcohol |

[217] |

|

Cabernet Sauvignon red wine A |

Spiral wound 4040 and hollow fiber perstractive membrane (VA Filtration, Nuriootpa, Australia) |

Qf = ns Qs = ns T = 55 P = 30 Time = 90 |

17.0 |

14.5 |

Increase in dark fruit aroma and decrease of green aroma, dried fruit, and chocolate flavors with no significant difference in the overall intensity. A small decrease in acidity. Small but significant decreases in sweetness and saltiness. Increase in the sensation of astringency |

[169] |

|

|

Cabernet Sauvignon red wine B |

Spiral wound 4040 and hollow fiber perstractive membrane (VA Filtration, Nuriootpa, Australia) |

Qf = ns Qs = ns T = 55 P = 30 Time = 90 |

15.5 |

13.3 |

Decreases in hotness, bitterness, and body (attributed to lower ethanol level). Decrease in confection and ‘chocolate’ aromas. Significant decrease in the overall flavor intensity (largely due to the decreased intensity of dark fruit, sweet spice, and chocolate flavors) with no significant effect on the overall intensity |

[169] |

|

|

Cabernet Sauvignon red wine C |

Spiral wound 4040 and hollow fiber perstractive membrane (VA Filtration, Nuriootpa, Australia) |

Qf = ns Qs = ns T = 55 P = 30 Time = 90 |

14.9 |

13.3 |

Decrease in hotness (attributed to lower ethanol level). Decrease in confection, dried fruit, and chocolate aromas with no significant difference in the overall intensity. Decrease in the sensation of astringency |

[169] |

|

|

Cabernet Sauvignon red wine D |

Spiral wound 4040 and hollow fiber perstractive membrane (VA Filtration, Nuriootpa, Australia) |

Qf = ns Qs = ns T = 55 P = 30 Time = 90 |

14.5 |

13.2 |

Decrease in hotness (attributed to lower ethanol level). Increase in red fruit aroma with no significant difference in the overall intensity |

[169] |

|

|

Cabernet Sauvignon red wine E |

Spiral wound 4040 and hollow fiber perstractive membrane (VA Filtration, Nuriootpa, Australia) |

Qf = ns Qs = ns T = 55 P = 30 Time = 90 |

16.0 |

14.2 |

Decrease in hotness (attributed to lower ethanol level). Decrease in overall flavor intensity with no significant difference in the overall intensity. Small but significant decreases in sweetness and saltiness |

[169] |

|

This entry is adapted from the peer-reviewed paper 10.3390/foods10102498