Elongational flow is a particular kind of flow involved in many industrially relevant processing operations of thermoplastics (such as fiber spinning, film blowing, foaming and thermoforming) in which the velocity gradient develops in the same direction as the flow itself.

- elongational flow

- elongational viscosity

- film blowing

- fiber spinning

- strain hardening

- morphology evolution

- multiphase polymer systems

1. Introduction

A large number of processing operations for polymeric materials having high industrial relevance are dominated by elongational flow, i.e., a stretching deformation that, depending on the specific process, can be uniaxial or biaxial [1][2]. Fiber spinning, film blowing, blow molding and foaming, among a few others, are typical examples of processing techniques, in which the polymer melt is subjected to elongational flow [3][4]. Actually, elongational deformation also occurs in some processes essentially dominated by shear flow, such as extrusion and injection molding [5]; the variation of the flow channels and the entrance in the die section in extrusion, or the injection of the melt into the mold gate, represent some examples in which the melt is subjected to components of elongation flow [6]. Besides, during the past few decades, plasticizing conveying methods and related devices (such as vane, eccentric rotors extruders and extensional flow mixers) based on elongational flow have been continuously developed, demonstrating shorter processing times and higher mixing effectiveness as compared to conventional shear-flow-dominated techniques [7][8].

The great relevance of these processing operations justifies the interest in the study of the rheological behavior of polymer melts when subjected to elongational flow, documented by a massive number of scientific papers in the last 50 years. In fact, a thorough knowledge of the processing behavior of polymeric materials when subjected to the elongational flow is of fundamental importance for predicting the melt behavior and obtaining straightforward criteria that allow for the selection of the proper material, as well as the optimization of the processing conditions [9][10].

Additionally, a characteristic feature of the elongational flow is its potential ability to modify the morphology of homogeneous polymer systems, through the occurrence of orientation phenomena of the macromolecular chains along the flow direction [11]. As a result, significant variations of the polymer microstructure and, thus, of its mechanical, optical or barrier properties can be obtained [12][13]. Interestingly, the ability of the elongational flow in inducing morphological changes has been documented also for polymer-based materials showing a multiphase microstructure, such as polymer blends [14][15] and micro- and nano-composites [16][17]. In particular, the application of the elongational flow during the processing of polymer blends causes a deformation of the droplets of the dispersed phase, leading to a modification of the blend morphology with a remarkable influence on the material final properties [18][19]. Similarly, it has been documented the effectiveness of the extensional flow in ameliorating the state of dispersion of micro- and nano-fillers in polymer-based composites. Besides, especially for composite systems containing anisotropic fillers, the application of the elongational flow during processing brings about some preferential orientation of the embedded particles along the flow direction [20][21], with beneficial effects on the overall performances of the material.

2. Rheological Properties in Elongational Flow

The rheological behavior in isothermal elongational flow has been widely studied especially for polymeric materials with a great industrial relevance, such as polyethylene (both high- and low-density), polypropylene and, in the recent years, polylactic acid and other biopolymers that attempt replacing traditional fossil fuel-based thermoplastics in many industrial applications. From a general point of view, it is well established that the content of long-chain branching has a remarkable effect on the elongational behavior of the polymer melt, leading to the occurrence of a strain-hardening behavior [22][23]. An interesting study by Wolff et al. [24] on the elongational properties of a commercial low-density polyethylene (LDPE) demonstrated that, in the linear regime of deformation, the Trouton law was fulfilled, while, in the nonlinear regime, the presence of a large amount of long-chain branching induced the occurrence of strain hardening, with a rapid increase of the elongational viscosity as a function of the applied stress.

Most of the studies reported in the literature on the evaluation of the polymer rheological properties in elongational flow have been carried out in isothermal conditions, while less attention has been devoted to the rheological behavior of polymer melts experiencing non-isothermal elongational flow, notwithstanding its technological relevance for the assessment of the processing behavior of polymer melts. Similar to what was observed for isothermal elongational flow, polyethylene- and polypropylene-based systems are the most investigated materials, given the widely exploitation of these polyolefins in processing operations, in which the non-isothermal elongational flow is prominent [25][26]. As far as polyethylene-based materials are concerned, typically LDPE shows high values of melt strength and low deformability, while HDPE exhibits an opposite behavior [27]; the differences between the two materials can be ascribed to their dissimilar macromolecular architecture, pointing out the remarkable effect of the molecular weight and of the content of long-chain branching on the polymer rheological response.

3. Effect of Elongational Flow in Modifying Morphology and Mechanical Properties of Homogeneous Polymers

A fundamental characteristic of the elongational flow is related to its ability to induce a preferential orientation of the polymer macromolecules along the flow direction, thus affecting the material morphology. Furthermore, for semicrystalline polymers, the application of the elongational flow influences the crystallization kinetics and the morphology and orientation of the formed crystalline structures [28][29]. In fact, the alignment of the polymer chains along the flow direction reduces the energy barrier for the crystallization, as the state of the polymer chains is closer to that of the final crystal when they are in oriented configuration rather than arranged in random coils [30].

All these structural evolutions induced by the application of the elongational flow have, in turn, a remarkable influence on the material final properties and, especially, on its mechanical performances [31]. In particular, a very different behavior for semicrystalline and amorphous polymers has been reported. Briefly, for semicrystalline polymers, the application of an elongational flow usually results in an increase of the stiffness and a drastic decrease of the ductility as a function of the applied stretching [32][33]. In fact, it was demonstrated that the stable orientation of the macromolecular chains along the stretching direction achieved when these systems are subjected to elongational flow (especially in non-isothermal conditions) causes a progressive strengthening and stiffening of the material as a function of the draw ratio [34].

Otherwise, for amorphous polymers, the elongation at break typically increases upon extension, and a kind of brittle-to-ductile transition is observed. In this context, La Mantia et al. [35] studied the variation of the elongation at break for polystyrene filaments subjected to a spinning-like experiment as a function of the birefringence (which is indicative of the macromolecular orientation). The obtained results showed that the elongation at break abruptly increases at a specific birefringence value of -6*10-3, after which a regular decrease is observed. Lastly, the elongation at break further increases at higher orientation values. This peculiar behavior, involving the occurrence of a sort of brittle-to-ductile transition, was ascribed to microstructural changes that occurred upon the application of the elongational flow; in particular, it was inferred that the more ordered morphology, involving oriented and stretched macromolecular chains, facilitates the macromolecular motion and improves the chain slippage. Furthermore, the compact arrangement of the parallel oriented and aligned polymer chains suppresses the formation and growth of cracks, bringing about to a ductile fracture [36].

Therefore, the knowledge of the structure-process-properties relationships in processing operations involving the elongational flow is fundamental for predicting the physical and mechanical properties of the final product, as well as for tailoring the processing conditions and/or the polymer properties according to the envisaged performances.

4. Morphology Evolution of Polymer-Based Blends under Elongational Flow

During the past years, the continuous demand for innovative materials caused a steadily increasing interest towards the production of polymer-based blends, thanks to the possibility to achieve functional materials with tailored properties using polymer commodities. However, most polymers are thermodynamically immiscible in the molten state, due to unfavorable interactions between the components and the small gain in entropy, resulting from the mixing of high-molecular-weight species [37]. As a consequence, polymer blends usually exhibit a heterogeneous morphology, which is characterized by the size and shape of the domains constituting the dispersed phase, as well as by their distribution in the matrix. Most commercial blends exhibit a typical droplet-like morphology, consisting in droplets of the dispersed phase embedded in the matrix, though fiber-like or lamellar structures can be also achieved [38]. Since the microstructure of a polymer blend has a predominant influence on the material final properties, the prediction and control of the blend morphology are of fundamental importance for its end-use applications.

The phase morphology of a polymer blend surely depends on the chemical nature of the components and on their ratio; additionally, due to the deformability of the minor phase embedded in the matrix, when processed in the melt, an in situ morphology can be developed [39]. Therefore, the kind of flow that polymers underwent during the melt processing operation greatly affects the mechanism of deformation of the dispersed phase, thus remarkably influencing the evolution of the blend morphology and, consequently, the material final properties. It has been widely documented that the extensional flow is more effective than shear in deforming and breaking-up the droplets of the dispersed phase [40]. Besides, for immiscible blends containing high amounts of dispersed phase, the formation of elongated fibrils was frequently reported [41].

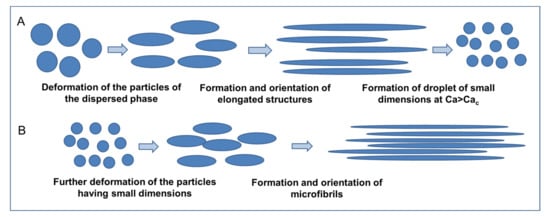

Figure 1 schematically depicts a possible mechanism explaining the droplet-to-fibril transition observed in immiscible blends subjected to elongational flow. During the application of the extensional flow, the macromolecules constituting the matrix phase, similarly to a homogeneous system, tend to orient and align along the flow direction; at the same time, the particles of the dispersed phase deform, giving rise to the formation of elongated structures, preferentially oriented in the stretching direction (Figure 1A). Once the critical capillary number is reached, the breakup of these elongated structures occurs, causing the formation of droplets of small dimensions that are further deformed by the action of the elongational flow, until the formation of microfibrils mainly oriented along the flow direction (Figure 1B).

Another fundamental factor influencing the development of the phase morphology during melt processing operation dominated by the elongational flow is coalescence; in fact, in the presence of intense interactions among the particles of dispersed phase, due to high concentration or restricted geometries, numerous collisions occur, hence possibly causing coalescence phenomena [42]. For instance, during melt spinning, the shrinking matrix compresses the droplets of dispersed phase, enabling them to migrate form the surface toward the center of the fiber and promoting coalescence events [43].

5. Morphology Evolution of Polymer-Based Composites under Elongational Flow

Polymer micro- and nano-composites are an interesting class of materials for studying the effect of the elongational flow in promoting microstructural variations, as the state of dispersion, the size and, possibly, the orientation of the embedded nanoparticles can evolve upon the application of uniaxial or biaxial stretching.

Some studies on composite materials containing graphite [44], halloysite nanotubes [45], hydrotalcites [46] or carbon nanotubes [47][48] documented a beneficial effect of the application of elongational flow on the final morphology and properties of the materials. More specifically, upon uniaxial or biaxial elongation, a partial destruction of the filler agglomerates usually observed in composites obtained through melt mixing occurs; besides, a preferential alignment of anisotropic filler and/or of particle clusters along the flow direction has been reported. Furthermore, it has been shown that all these morphological changes directly affect the final performances of the resulting materials; in general, superior stiffness, strength and optical and barrier properties are obtained for composite systems subjected to elongational flow, as compared to the isotropic counterparts.

The most striking results in terms of elongation-induced morphology evolutions have been obtained for polymer nanocomposites containing layered silicates [49][50][51]. Several studies documented a progressive orientation of the embedded clays as a function of the applied stretching, hence showing the already described typical behavior of other polymer-based nanocomposites. In addition, it has been shown that the presence of small amounts of dispersed clays can facilitate the alignment of the matrix macromolecules, as the presence of well-dispersed platelets suppresses the relaxation of the polymer chains, thus promoting a high orientation degree [52]. Furthermore, for nanoclay-polymer systems, two different phenomena can occur upon elongational flow, i.e. flocculation and re-aggregation of dispersed clays [53] or improvement of intercalation/exfoliation [54]. Therefore, the final morphology achieved in these materials upon extension depends on the prevailing mechanism. It has been demonstrated that flocculation events are favoured when the elongational flow is applied in the molten state to nanocomposites already showing an exfoliated morphology [54]. Furthermore, the polymer/clay interaction degree plays a fundamental role, as the achievement of a good adhesion between the two phases promotes the development of a “face-to-edge” morphology, causing clay re-arrangements and flocculation [55]. Finally, it has been documented that the amount of clay is a critical parameter in determining the prevailing mechanism, since an improved exfoliation upon extension was achieved for nanocomposites embedding low particle loadings; on the contrary, filler aggregation phenomena are favored in the presence of high clay loadings, as this condition magnifies the electrostatic interactions among the particles [56].

This entry is adapted from the peer-reviewed paper 10.3390/polym13203529

References

- Denn, M.M.. Polymer Melt Processing - Foundations in Fluid Mechanics and Heat Transfer; Denn, M.M., Eds.; Cambridge University Press: New York, 2014; pp. 1.

- Maria Mistretta; Luigi Botta; Rossella Arrigo; Francesco Leto; Giulio Malucelli; Francesco La Mantia; Bionanocomposite Blown Films: Insights on the Rheological and Mechanical Behavior. Polymers 2021, 13, 1167, 10.3390/polym13071167.

- Zdeněk Starý; Magdalena Papp; Teodor Burghelea; Deformation regimes, failure and rupture of a low density polyethylene (LDPE) melt undergoing uniaxial extension. Journal of Non-Newtonian Fluid Mechanics 2015, 219, 35-49, 10.1016/j.jnnfm.2015.02.007.

- R. K. Bayer; H. G. Zachmann; W. Meins; Properties of elongational flow injection-molded polyethylene part 2: Influence of processing parameters. Polymer Engineering & Science 1989, 29, 193-201, 10.1002/pen.760290307.

- Tadmor, Z.; Molecular orientation in injection moldin. Journal of Applied Polymer Science 1974, 18, 1753, .

- Vivek Pandey; Hao Chen; Jiaxin Ma; João M. Maia; Extension‐dominated improved dispersive mixing in single‐screw extrusion. Part 2: Comparative analysis with twin‐screw extruder. Journal of Applied Polymer Science 2020, 138, 49765, 10.1002/app.49765.

- Zhongke Yuan; Xiaochuan Chen; Dingshan Yu; Recent Advances in Elongational Flow Dominated Polymer Processing Technologies. Polymers 2021, 13, 1792, 10.3390/polym13111792.

- Utracki, L.A.; Luciani, A.; Bourry, D.J.J. Extensional flow mixer (Canada Patent no. 2 304 668), 2004.

- Behzad Nazari; Hossein Nazockdast; Ali Asghar Katbab; The role of flow-induced microstructure in rheological behavior and nonisothermal crystallization kinetics of polyethylene/organoclay nanocomposites. Polymer Engineering & Science 2013, 54, 1839-1847, 10.1002/pen.23727.

- James L. White; Yoshiaki Ide; Instabilities and failure in elongational flow and melt spinning of fibers. Journal of Applied Polymer Science 1978, 22, 3057-3074, 10.1002/app.1978.070221102.

- K. Koyama; O. Ishizuka; Birefringence of polyethylene melt in transient elongational flow at constant strain rate. Journal of Polymer Science Part B: Polymer Physics 1989, 27, 297-306, 10.1002/polb.1989.090270206.

- 12. Ward, I.M.; Mechanical properties of oriented polymers. Polymer 1974, 15, 379, .

- Masami Okamoto; ‡ And Hiroshi Kubo; Tadao Kotaka; Elongational Flow-Induced Crystallization and Structure Development in Supercooled Poly(ethylene naphthalate). Macromolecules 1998, 31, 4223-4231, 10.1021/ma971713d.

- F. Oosterlinck; M. Mours; H. M. Laun; P. Moldenaers; Morphology development of a polystyrene/polymethylmethacrylate blend during start-up of uniaxial elongational flow. Journal of Rheology 2005, 49, 897, 10.1122/1.1940642.

- Zdeněk Starý; Martin Zatloukal; Morphology Development in Polymer Blends under Uniaxial Elongation. AIP Conference Proceedings 2009, 1152, 228-233, 10.1063/1.3203274.

- Jay Hoon Park; Yong Lak Joo; Tailoring nanorod alignment in a polymer matrix by elongational flow under confinement: simulation, experiments, and surface enhanced Raman scattering application. Soft Matter 2014, 10, 3494-3505, 10.1039/c4sm00096j.

- Nadka Tzankova Dintcheva; Rossella Arrigo; Giorgio Nasillo; Eugenio Caponetti; Francesco Paolo La Mantia; On the Role of Extensional Flow in Morphology and Property Modifications of MWCNT/Polyamide-Based Fibers. Macromolecular Materials and Engineering 2011, 296, 645-657, 10.1002/mame.201000355.

- Sheng Yang; Chao Luo; Hao Lin; Ping-Ping Xu; Ling Xu; Jun Lei; Gan-Ji Zhong; Zhong-Ming Li; Robust propylene-ethylene copolymer/polypropylene films: Extensional stress-induced orientation realized at low temperature processing. Polymer 2020, 206, 122848, 10.1016/j.polymer.2020.122848.

- Shikui Jia; Jinping Qu; Chengran Wu; Weifeng Liu; Rongyuan Chen; Shufeng Zhai; Zan Huang; Fuquan Chen; Novel Dynamic Elongational Flow Procedure for Reinforcing Strong, Tough, Thermally Stable Polypropylene/Thermoplastic Polyurethane Blends. Langmuir 2013, 29, 13509-13517, 10.1021/la4023079.

- Pietro Russo; Domenico Acierno; Giovanni Marletta; Giovanni Li Destri; Tensile properties, thermal and morphological analysis of thermoplastic polyurethane films reinforced with multiwalled carbon nanotubes. European Polymer Journal 2013, 49, 3155-3164, 10.1016/j.eurpolymj.2013.07.021.

- Seung Hwan Lee; Seong Yun Kim; Jae Ryoun Youn; Rheological behavior and theoretical modeling of uniaxial elongational flow properties of polypropylene/layered silicate nanocomposites. Polymer Composites 2008, 30, 1426-1436, 10.1002/pc.20707.

- F.P. La Mantia; A. Valenza; D. Acierno; Influence of the structure of linear density polyethylene on the rheological and mechanical properties of blends with low density polyethylene. European Polymer Journal 1986, 22, 647-652, 10.1016/0014-3057(86)90163-1.

- A. D. Gotsis; B. L. F. Zeevenhoven; A. H. Hogt; The effect of long chain branching on the processability of polypropylene in thermoforming. Polymer Engineering & Science 2004, 44, 973-982, 10.1002/pen.20089.

- Friedrich Wolff; Julia Antonia Resch; Joachim Kaschta; Helmut Münstedt; Comparison of viscous and elastic properties of polyolefin melts in shear and elongation. Rheologica Acta 2009, 49, 95-103, 10.1007/s00397-009-0396-2.

- F. P. La Mantia; A. Valenza; F. Scargiali; Nonisothermal elongational behavior of blends with liquid crystalline polymers. Polymer Engineering & Science 1994, 34, 799-803, 10.1002/pen.760341004.

- Kam Ho; Larry Kale; Scott Montgomery; Melt strength of linear low-density polyethylene/low-density polyethylene blends. Journal of Applied Polymer Science 2002, 85, 1408-1418, 10.1002/app.10677.

- Ji-Zhao Liang; Melt strength and drawability of HDPE, LDPE and HDPE/LDPE blends. Polymer Testing 2018, 73, 433-438, 10.1016/j.polymertesting.2018.12.007.

- Andreja Rudolf; Majda Sfiligoj Smole; Structure-properties relations of the drawn poly(ethylene terephthalate) filament sewing thread. Journal of Applied Polymer Science 2008, 110, 2641-2648, 10.1002/app.25008.

- Antonios K. Doufas; A microstructural flow-induced crystallization model for film blowing: validation with experimental data. Rheologica Acta 2014, 53, 269-293, 10.1007/s00397-013-0749-8.

- Koh-Hei Nitta; On the Orientation-Induced Crystallization of Polymers. Polymers 2016, 8, 229, 10.3390/polym8060229.

- B. Alcock; N.O. Cabrera; N.M. Barkoula; T. Peijs; The effect of processing conditions on the mechanical properties and thermal stability of highly oriented PP tapes. European Polymer Journal 2009, 45, 2878-2894, 10.1016/j.eurpolymj.2009.06.025.

- A. Peterlin; Drawing and extrusion of semi-crystalline polymers. Colloid & Polymer Science 1987, 265, 357-382, 10.1007/bf01412215.

- Peter A. Irvine; Paul Smith; Development of the axial Young's modulus with draw ratio of flexible-chain polymers. Macromolecules 1986, 19, 240-242, 10.1021/ma00155a038.

- Enrico Maria Troisi; Martin van Drongelen; H.J.M. Caelers; G. Portale; G.W.M. Peters; Structure evolution during film blowing: An experimental study using in-situ small angle X-ray scattering. European Polymer Journal 2016, 74, 190-208, 10.1016/j.eurpolymj.2015.11.022.

- La Mantia, F.P.; D’Amico, R.; Acierno, D.; Uniaxial hot stretching of polystyrene and mechanical properties of the oriented samples. Acta Polymerica 1979, 30, 685-688, .

- Yoshikazu Tanabe; Hisaaki Kanetsuna; Structure of oriented polystyrene monofilaments and its relationship to brittle-to-ductile transition. Journal of Applied Polymer Science 1978, 22, 1619-1630, 10.1002/app.1978.070220613.

- L. A. Utracki; On the viscosity‐concentration dependence of immiscible polymer blends. Journal of Rheology 1991, 35, 1615-1637, 10.1122/1.550248.

- Petra Pötschke; D. R. Paul; Formation of Co-continuous Structures in Melt-Mixed Immiscible Polymer Blends. Journal of Macromolecular Science, Part C: Polymer Reviews 2003, 43, 87-141, 10.1081/mc-120018022.

- Utracki, L.A.; Shi, Z.H.; Development of polymer blend morphology during compounding in a twin-screw extruder. Part I: Droplet dispersion and coalescence—a review. Polymer Engineering and Science 1992, 32, 1824-1833, .

- Harold P. Grace†; DISPERSION PHENOMENA IN HIGH VISCOSITY IMMISCIBLE FLUID SYSTEMS AND APPLICATION OF STATIC MIXERS AS DISPERSION DEVICES IN SUCH SYSTEMS. Chemical Engineering Communications 1982, 14, 225-277, 10.1080/00986448208911047.

- Utracki, L.A.; Sammut, P.; On the uniaxial elongational flow of PS/PE blends. Polymer Engineering and Science 1990, 30, 1019-1026, .

- Ivan Fortelný; Antonín Živný; Extensional flow induced coalescence in polymer blends. Rheologica Acta 2003, 42, 454-461, 10.1007/s00397-003-0300-4.

- Jinhai Yang; James L. White; Qibo Jiang; Phase morphology development in a low interfacial tension immiscible polyolefin blend during die extrusion and melt spinning. Polymer Engineering & Science 2010, 50, 1969-1977, 10.1002/pen.21726.

- F.P. La Mantia; M. Ceraulo; M.C. Mistretta; L. Botta; Effect of the elongational flow on morphology and properties of polypropylene/graphene nanoplatelets nanocomposites. Polymer Testing 2018, 71, 10-17, 10.1016/j.polymertesting.2018.08.016.

- Vishwa Pratap Singh; K. K. Vimal; G. S. Kapur; Shashikant Sharma; Veena Choudhary; High-density polyethylene/halloysite nanocomposites: morphology and rheological behaviour under extensional and shear flow. Journal of Polymer Research 2016, 23, 1-17, 10.1007/s10965-016-0937-1.

- Burak Kutlu; Juliane Meinl; Andreas Leuteritz; Harald Brünig; Gert Heinrich; Melt-spinning of LDH/HDPE nanocomposites. Polymer 2013, 54, 5712-5718, 10.1016/j.polymer.2013.08.015.

- Samaneh Abbasi; Pierre J. Carreau; Abdessalem Derdouri; Flow induced orientation of multiwalled carbon nanotubes in polycarbonate nanocomposites: Rheology, conductivity and mechanical properties. Polymer 2010, 51, 922-935, 10.1016/j.polymer.2009.12.041.

- Nadka T. Dintcheva; Rossella Arrigo; Giorgio Nasillo; Eugenio Caponetti; Francesco Paolo La Mantia; Effect of the nanotube aspect ratio and surface functionalization on the morphology and properties of multiwalled carbon nanotube polyamide-based fibers. Journal of Applied Polymer Science 2013, 129, 2479-2489, 10.1002/app.38898.

- Vanja Pasanovic-Zujo; Rahul Kumar Gupta; Satinath N. Bhattacharya; Effect of vinyl acetate content and silicate loading on EVA nanocomposites under shear and extensional flow. Rheologica Acta 2003, 43, 99-108, 10.1007/s00397-003-0324-9.

- Rahul K. Gupta; V. Pasanovic-Zujo; Sati Bhattacharya; Shear and extensional rheology of EVA/layered silicate-nanocomposites. Journal of Non-Newtonian Fluid Mechanics 2005, 128, 116-125, 10.1016/j.jnnfm.2005.05.002.

- F. P. La Mantia; M. Ceraulo; M. C. Mistretta; F. Sutera; L. Ascione; G. Nasillo; Effect of Elongational Flow and Polarity of Organomodified Clay on Morphology and Mechanical Properties of a PLA Based Nanobiocomposite. International Polymer Processing 2016, 31, 541-547, 10.3139/217.3224.

- David W. Litchfield; Donald G. Baird; The role of nanoclay in the generation of poly(ethylene terephthalate) fibers with improved modulus and tenacity. Polymer 2008, 49, 5027-5036, 10.1016/j.polymer.2008.08.064.

- Masami Okamoto; † Pham Hoai Nam; † Pralay Maiti; † Tadao Kotaka; ‡ And Naoki Hasegawa; Arimitsu Usuki‡; A House of Cards Structure in Polypropylene/Clay Nanocomposites under Elongational Flow. Nano Letters 2001, 1, 295-298, 10.1021/nl0100163.

- Francesco Paolo La Mantia; Nadka Tzankova Dintcheva; Roberto Scaffaro; Rosamaria Marino; Morphology and Properties of Polyethylene/Clay Nanocomposite Drawn Fibers. Macromolecular Materials and Engineering 2008, 293, 83-91, 10.1002/mame.200700204.

- Bartolomeo Coppola; Paola Scarfato; Loredana Incarnato; Luciano Di Maio; Morphology Development and Mechanical Properties Variation during Cold-Drawing of Polyethylene-Clay Nanocomposite Fibers. Polymers 2017, 9, 235, 10.3390/polym9060235.

- Garofalo, E.; Russo, G.M.; Scarfato, P.; Incarnato, L.; Nanostructural Modifications of Polyamide/MMT Hybrids Under Isothermal and Nonisothermal Elongational Flow. Journal of Polymer Science Part B: Polymer Physics 2009, 47, 981-993, .