Electroactive polymers (EAPs) are a versatile class of electrically deformable polymers. These polymers have the ability to deform when excited by electrical potentials due to their inherent electro-mechanical properties. The piezoelectric couplings in EAPs provide them with unique capabilities that are of significant interest in actuators and soft robotics.

- actuator

- electroactive

- ionic

- polymer

- tribology

1. Introduction

Electroactive polymers (EAPs) are a versatile class of electrically deformable polymers. These polymers have the ability to deform when excited by electrical potentials [1] due to their inherent electro-mechanical properties [2]. The piezoelectric couplings in EAPs provide them with unique capabilities that are of significant interest in actuators and soft robotics [3]. Additionally, their ability to transform an electrical stimulus into a mechanical response has the potential to develop biocompatible artificial muscles. Furthermore, EAPs have become an attractive material for wearable sensors and biomimetics. Due to their versatile applications, EAPs are of significant interest for research innovation in the mechano-electrical sector of late [4][5].

Electroactive polymers could be split between two major types depending on how they are produced: electronic EAPs and ionic EAPs. Electronic EAPs, such as dielectric elastomers, mechanically respond to the changes in electrical charge, typically by expansion. Similarly, ionic EAPs can be activated by an electric field that causes deformation due to ion movement. Comparatively, ionic EAPs require a lower voltage than electronic EAPs for activation and therefore have received repeated attention in the literature [6]. On the other hand, electronic EAPs have progressed significantly, and there are different types of electric EAPs already present in the market. Statistically, the overall market of the electroactive polymer was approximately $3.51 billion in 2017, which is projected to be 5.12 billion by 2022 [7].

One major advantage of EAP is that the amount of strain these materials may experience is much higher than what many conventional mechanical actuators would allow [8]. Therefore, EAPs have significant usage in the development of organic actuators, which are highly desirable in prosthetics. Due to their biocompatible makeup, flexibility, and light weight, EAPs are a potential candidate for artificial muscle [9]. Also, EAPs stand to benefit the field of soft robotics. The use of soft actuators eliminates some safety concerns that are present when traditional robots interact with humans or delicate tools. Since soft robots tend to be lighter and more compliant, they are less likely to apply crushing forces [10]. Beyond being able to control the movement of EAPs, their adaptability allows for novel robotic motions, such as a snake-shaped robot travelling in a serpentine path [11]. Dielectric elastomers, known for their high deformability and ease of production, could be useful in these types of robotic applications. Other types of applications, such as underwater or in corrosive environments, could benefit from the use of EAPs [12]. EAPs can be designed as a noiseless propulsion devise, which is beneficial to marine organisms that may be damaged by loud noises. Additionally, a soft robot made with EAPs would be less likely to cause catastrophic failure or corrosion in the event of a collision. Lastly, wearable electronics may have a variety of uses for EAPs. Wearable devices often require small electronics for nuanced applications, such as implanted or surface-mounted sensors [12]. EAPS could be used in such applications.

2. Different Types of EAPs

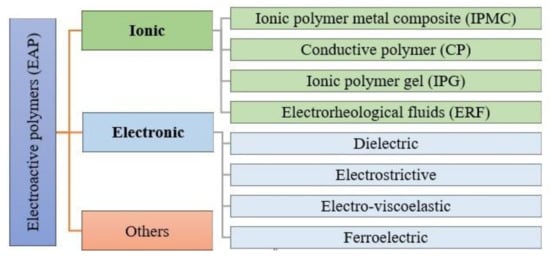

Electroactive polymers are typically divided into two categories. One is ionic EAPs, and the other one is electronic EAPs. Each of these divisions can be further sub-divided into multiple branches, as shown in Figure 1 . In this review, four types of popular subdivisions of each category are going to be discussed. Moreover, some EAPs have also been developed incorporating both ionic and electronic EAPs to obtain specific advantages. This review will present a brief overview of various EAPs, and discuss their properties, applications, and challenges. In the following subsections, the synthesis routes of different ionic EAPs are depicted with schematic illustrations.

There are multiple routes to produce ionic EAPs using different materials. Based on these routes, ionic EAPs could be subdivided into several categories, such as ionic polymer-metal composites (IPMCs), conductive polymers (CPs), ionic polymer gels (IPGs), and electrorheological fluids (ERFs) [13]. It is important to note that these categories are not rigid. Instead, they are often combined into new ionic EAPs as their properties are explored and understood. The following sections detail the synthesis steps of several ionic EAPs that fit into one or more of the above-mentioned categories.

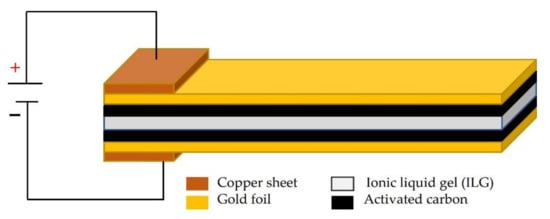

Conducting Polymers are often associated with ionic polymer gels since the same polymers used in CPs can be made into an ionic polymer gel. These gels consist of an ionic liquid in a solid matrix. They have gained attention since they do not include water, allowing them to function in the air better than other kinds of CPs. They are also similar in texture to biological muscles, making them potentially useful for biomedical purposes. Ionic polymer gel EAPs tend to follow a trilayer structure, with the gel forming the ion-exchange membrane; and a conductive material, such as metals or conducting polymers, as the electrodes. Also, some gel actuators include a layer of activated carbon between the membrane and the electrode, forming a 5-layer structure, as shown below in Figure 2 [14].

Electronic electroactive polymers have received significant research attention in the last few decades. In contrast with ionic EAPs, Electronic EAPs do not require any electrolyte medium or ion migration [15]. Therefore, the field of electronic EAPs is rapidly developing with the increased interest in lightweight materials that are biocompatible and simple to manufacture [16]. So far, different kinds of electronic EAPs have been developed for numerous applications. Dielectric, electrostrictive graft, electrostrictive paper, electro-viscoelastic, ferroelectric, and liquid crystal are some notable electric EAPs, widely discussed in the literature [16][17][18].

3. Properties of EAPs

EAPs are a robust family of materials with versatile mechanical, electrical, electro-mechanical, and tribological properties. Each of these properties plays a significant role in serving the intended purpose in actuator, coating, or soft electronics. By combining general polymer attributes and electro-mechanical properties, EAPs have become a material that attracts the attention of scientists and engineers [19]. In the following subsections, the mechanical, electroactive, and tribological properties of ionic EAPs will be covered.

Mechanical properties are important physical properties that a material exhibits against an applied force. Modulus of elasticity, fatigue limit, tensile strength, flexibility, and hardness are some of the mechanical properties of EAPs. These properties modulate the bending capability when the EAP is used in actuators.

In the performance of EAPs, electric properties play a significant role. These properties include, but are not limited to, electrostriction, dielectric constant, capacitance, impedance, and electrical conductivity [20]. Each of these properties has impact on the EAP’s mechanical and chemical properties. The impacts may vary across each respective EAP, but since EAPs are a family of polymers, there are a lot of similarities within the family.

Compared to ionic EAPs (<10 V), electronic EAPs are driven by larger electric fields (>100 MV/m) to achieve linear deformation between the 4 to 360% range [21]. Polyvinylidene fluoride (PVDF) is one of the most common EAPs with ferroelectric behavior [22]. PVDF has high stiffness, mechanical strength, toughness and creep and abrasion resistance, good chemical resistance, high dielectric strength, chemical inertness, low flammability, and low moisture absorption capabilities [23]. Dielectric elastomers (DEs) are capable of large strains and change their capacitance when a voltage is applied by compressing the thickness of the polymer and expanding its cross-section [24]. This type of EAPs typically requires a large voltage to generate a high electric field, but it consumes very little power [24]. PVDF, PVDF’s copolymer of trifluoroethylene (PVDF-TrFE), nylon-11 and polyuria are considered piezoelectric polymers [25]. PVDF and its copolymers constitute most polymer-based piezoelectric generators [26]. Piezoelectric polymers have a lower piezoelectric strain constant than ceramic materials [27]. However, piezoelectric polymers could help to develop much better sensors than ceramics due to higher piezoelectric stress constant [27]. Piezoelectric polymeric sensors and actuators have the advantage of processing flexibility being lightweight, tough, and amenable to be easily cut and formed into complex shapes [27].

4. Recent Advancements in the Applications of Electroactive Polymers

EAPs are notable for their ability to turn electrical energy into mechanical energy. In particular, EAPs are widely investigated for actuators. EAPs can be beneficial in circumstances where hard mechanical parts may be undesirable. Additionally, EAP actuators are a single component rather than a series of parts that may rub and produce wear. EAPs can operate with minimal noise, and their use could dramatically reduce wear and friction compared to traditional actuators [28][29]. Furthermore, their flexible nature helps them to alter their properties according to the situation for which they are needed [30]. These properties make EAP actuators useful for multiple applications where traditional actuators are not optimal. Also, in recent years, EAPs-based coating has become a viable option for improving product performance. There are a variety of advantages that becomes available by coating a substrate material with EAPs. Those advantages include: increasing electrochemical capacitance, reducing friction, wear, corrosion protection, reducing electric resistance, biomedical applications, and stabilization of oxide surfaces [31]. Therefore, EAPs have been successfully used in fields such as engineering and medicine to make numerous devices. Some of the interesting applications of EAPs are highlighted here.

In the field of robotics, soft robots using EAPs have significant potential. Soft actuators are able to deform while still being functional, making them safe for interaction with humans. Furthermore, their flexibility and adaptability allow for novel robotic motion, such as a snake-shaped robot capable of serpentine motion [32]. Their flexibility also allows for the development of nuanced structures, such as a simulated human fingertip. The potential for most EAPs to be made into actuation devices allows for virtually all EAPs to be used in robotics according to specific requirements. However, a few types stand out as the most widely applicable. Dielectric elastomers (DEAs) could be particularly useful in some robotic applications due to their large deformations, light weight, easy production, and adaptability [33]. CP actuators can also be useful, particularly in biomedical applications, because they are typically bio-compatible and can be manufactured at the micro and nano scales [34]. Various other types of EAPs are useful depending on the exact circumstances that the actuator is intended to be used.

Synthetic muscles, either for use as prosthetics or robotic components, represent another potential application for EAP actuators. The characteristics of EAPs, such as their large bending strain and similarity to natural muscles, would make them useful as synthetic muscles [35]. Furthermore, EAPs generally have inaudible actuation. This makes them viable for prosthetics since they would not audibly disrupt the user or others. Dielectric EAPs, in particular, have been investigated for their potential as synthetic muscles due to their quick response time, durability, and noiselessness [36]. Some EAP actuators have even proven useful in the field of acoustic engineering for sound dampening. EAP actuators have been used for devices, such as noise-cancelling headphones, transducers, and resonators [37][38][39]. However, the high activation voltage of electrical EAP actuators may be dangerous for users. Another challenge is handling the dielectric breakdown, which is not desirable in a synthetic muscle [40][41]. Some types of ionic EAPs may also be used to create synthetic muscles, as their bending deformation can be used to obtain linear motion with the appropriate techniques [42]. Regardless of the type of EAP that is used as synthetic muscles, tribological considerations are significant due to the damage and pain that friction can cause in the human body [43]. Also, electroactive polymer coating was found useful for developing flexible artificial muscles. Ebadi et al. [44] applied EAP coating to polyurethane nanofibers, and achieved an angular displacement between 48°–225°. This illustrates a clear benefit, especially when considering flexible bodies as muscles.

Wearable electronics is another sector in which EAP actuators are widely used. Since they are flexible, they can adapt to the shapes of human body parts. Additionally, they can be fabricated as very small devices, so that they can be used for nuanced applications. For instance, Ig Mo Koo et al. developed a tactile display for a human fingertip that consists of a series of tactile simulators made with dielectric elastomers [45]. It is even possible to create a fabric with EAPs that has the potential to change its density based on the activity for which it is needed [46]. Wearable EAPs could also be harnessed to harvest mechanical energy because they generate an electric charge when they are deformed. Electronic EAPs are the most common type of EAPs for these applications since they are easier to operate in the open air compared to ionic EAPs. However, ionic EAPs have the potential to be safer for human use because of their lower activation voltage. Polyvinylidene fluoride (PVDF) is a type of electrical EAPs that has gained attention for wearable technology due to its superior properties [12].

This entry is adapted from the peer-reviewed paper 10.3390/ceramics4030038

References

- Bar-Cohen, Y.; Anderson, I.A. Electroactive polymer (EAP) actuators—Background review. Mech. Soft Mater. 2019, 1, 5.

- Bar-Cohen, Y.; Zhang, Q. Electroactive Polymer Actuators and Sensors. MRS Bull. 2008, 33, 173–181.

- Hunt, A.; Chen, Z.; Tan, X.; Kruusmaa, M. An integrated electroactive polymer sensor–actuator: Design, model-based control, and performance characterization. Smart Mater. Struct. 2016, 25, 035016.

- Palza, H.; Zapata, P.A.; Angulo-Pineda, C. Electroactive Smart Polymers for Biomedical Applications. Materials 2019, 12, 277.

- Khuyen, N.Q.; Kiefer, R.; Elhi, F.; Anbarjafari, G.; Martinez, J.G.; Tamm, T. A biomimetic approach to increasing soft actuator performance by friction reduction. Polymers 2020, 12, 1120.

- Neuhaus, R.; Zahiri, N.; Petrs, J.; Tahouni, Y.; Siegert, J.; Kolaric, I.; Dahy, H.; Bauernhansl, T. Integrating ionic electroactive polymer actuators and sensors into adaptive building skins: Potentials and limitations. Front. Built Environ. 2020, 6, 95.

- Research and Markets. Electroactive Polymer Market by Type (Conductive Plastic, Inherently Conductive Polymer, Inherently Dissipative Polymer), Application (ESD Protection, EMI Shielding, Actuators, Capacitors, Batteries, Sensors), and Region—Global Forecast to 2022. Available online: https://www.researchandmarkets.com/reports/4460750/electroactive-polymer-market-by-type-conductive (accessed on 11 July 2021).

- Tagarielli, V.L.; Hildick-Smith, R.; Huber, J.E. Electro-mechanical properties and electrostriction response of a rubbery polymer for EAP applications. Int. J. Solids Struct. 2012, 49, 3409–3415.

- Põldsalu, I.; Johanson, U.; Tamm, T.; Punning, A.; Greco, F.; Peikolainen, A.-L.; Kiefer, R.; Aabloo, A. Mechanical and electro-mechanical properties of EAP actuators with inkjet printed electrodes. Synth. Met. 2018, 246, 122–127.

- Abidi, H.; Cianchetti, M. On intrinsic safety of soft robots. Front. Robot. AI 2017, 4, 5.

- Onal, C.D.; Rus, D. Autonomous undulatory serpentine locomotion utilizing body dynamics of a fluidic soft robot. Bioinspir. Biomim. 2013, 8, 026003.

- Forouharshad, M.; King, S.G.; Buxton, W.; Kunovski, P.; Stolojan, V. Textile-Compatible, Electroactive Polyvinylidene Fluoride Electrospun Mats for Energy Harvesting. Macromol. Chem. Phys. 2019, 220, 1900364.

- Kim, O.; Kim, S.J.; Park, M.J. Low-voltage-driven soft actuators. Chem. Commun. 2018, 54, 4895–4904.

- Zhang, C.; He, B.; Wang, Z.; Zhou, Y.; Ming, A. Application and Analysis of an Ionic Liquid Gel in a Soft Robot. Adv. Mater. Sci. Eng. 2019, 2019, 2857282.

- Wang, T.; Farajollahi, M.; Choi, Y.S.; Lin, I.T.; Marshall, J.E.; Thompson, N.M.; Kar-Narayan, S.; Madden, J.D.W.; Smoukov, S.K. Electroactive polymers for sensing. Interface Focus 2016, 6, 20160026.

- Araromi, O.A.; Conn, A.T.; Ling, C.S.; Burgess, S.C.; Vaidyanathan, R. A Novel Fabrication Set-up for the Flexible Production of Silicone Based EAP “Artificial Muscle” Actuators. Des. Nat. V 2010, 138, 289–300.

- Bar-Cohen, Y. Electroactive Polymer (EAP) Actuators as Artificial Muscles: Reality, Potential, and Challenges; SPIE Press: Bellingham, WA, USA, 2004; Volume 136.

- Pelrine, R.E.; Kornbluh, R.D.; Joseph, J.P. Electrostriction of polymer dielectrics with compliant electrodes as a means of actuation. Sens. Actuators A Phys. 1998, 64, 77–85.

- Shankar, R.; Ghosh, T.K.; Spontak, R.J. Mechanical and actuation behavior of electroactive nanostructured polymers. Sens. Actuators A Phys. 2009, 151, 46–52.

- Paul, B.K.; Kar, S.; Bandyopadhyay, P.; Basu, R.; Das, S.; Bhar, D.S.; Manchanda, R.K.; Khurana, A.; Nayak, D.; Nandy, P. Significant enhancement of dielectric and conducting properties of electroactive polymer polyvinylidene fluoride films: An innovative use of Ferrum metallicum at different concentrations. Indian J. Res. Homoeopath. 2016, 10, 52–58.

- Bar-Cohen, Y.; Sherrit, S.; Lih, S.-S. Characterization of the electromechanical properties of EAP materials. In Smart Structures and Materials 2001: Electroactive Polymer Actuators and Devices; International Society for Optics and Photonics: Bellingham, WA, USA, 2001; pp. 319–327.

- UKEssays. Classes of Electroactive Polymer Materials. Available online: https://www.ukessays.com/essays/chemistry/classes-of-electroactive-polymer-materials.php?vref=1 (accessed on 11 July 2021).

- Engineering & Manufacturing Services. Polyfluor: Breda, The Netherlands. Available online: https://www.polyfluor.nl/en/materials/pvdf/ (accessed on 10 September 2021).

- Brochu, P. Dielectric Elastomers for Actuation and Energy Harvesting; University of California: Los Angeles, CA, USA, 2012.

- Peng, H.; Sun, X.; Weng, W.; Fang, X. 5—Energy Harvesting Based on Polymer. In Polymer Materials for Energy and Electronic Applications; Peng, H., Sun, X., Weng, W., Fang, X., Eds.; Academic Press: Cambridge, MA, USA, 2017; pp. 151–196.

- Peng, H.; Sun, X.; Weng, W.; Fang, X. Polymer Materials for Energy and Electronic Applications; Academic Press: Cambridge, MA, USA, 2016.

- Boczkowska, A.; Leonowicz, M. Intelligent materials for intelligent textiles. Fibres Text. East. Eur. 2006, 14, 13–17.

- Punning, A.; Kim, K.J.; Palmre, V.; Vidal, F.; Plesse, C.; Festin, N.; Maziz, A.; Asaka, K.; Sugino, T.; Alici, G. Ionic electroactive polymer artificial muscles in space applications. Sci. Rep. 2014, 4, 6913.

- Tribology for Scientists and Engineers; Menezes, P.L.; Nosonovsky, M.; Ingole, S.P.; Kailas, S.V.; Lovell, M.R. (Eds.) Tribology for Scientists and Engineers; Springer: New York, NY, USA, 2013.

- Mun, S.; Yun, S.; Nam, S.; Park, S.K.; Park, S.; Park, B.J.; Lim, J.M.; Kyung, K.-U. Electro-active polymer based soft tactile interface for wearable devices. IEEE Trans. Haptics 2018, 11, 15–21.

- Lyons, M.E.G. Electroactive Polymer Electrochemistry: Part 1: Fundamentals; Springer Science & Business Media: Berlin, Germany, 2013.

- Ahmed, M.; Billah, M.M. Smart material-actuated flexible tendon-based snake robot. Int. J. Adv. Robot. Syst. 2016, 13, 89.

- Jung, K.; Koo, J.C.; Lee, Y.K.; Choi, H.R. Artificial annelid robot driven by soft actuators. Bioinspir. Biomim. 2007, 2, S42.

- Hines, L.; Petersen, K.; Lum, G.Z.; Sitti, M. Soft actuators for small-scale robotics. Adv. Mater. 2017, 29, 1603483.

- Bar-Cohen, Y. Bionic: Bionic humans using EAP as artificial muscles reality and challenges. Int. J. Adv. Robot. Syst. 2004, 1, 21.

- Biddiss, E.; Chau, T. Dielectric elastomers as actuators for upper limb prosthetics: Challenges and opportunities. Med. Eng. Phys. 2008, 30, 403–418.

- Hitchcock, R.N.; Humphreys, D.W.; Muir, A.H.; Zarrabi, A. Audio Devices with Electroactive Polymer Actuators Noise Cancellation. Google Patents W02014100573A2, 26 June 2014.

- Heydt, R.P.; Pelrine, R.E.; Kornbluh, R.D.; Bonwit, N.A.; Eckerle, J.S. Compliant electroactive polymer transducers for sonic applications. Acoust. Soc. Am. J. 2011, 130, 1078.

- Abbad, A.; Rabenorosoa, K.; Ouisse, M.; Atalla, N. Adaptive Helmholtz resonator based on electroactive polymers: Modeling, characterization, and control. Smart Mater. Struct. 2018, 27, 105029.

- Qiu, Y.; Zhang, E.; Plamthottam, R.; Pei, Q. Dielectric elastomer artificial muscle: Materials innovations and device explorations. Acc. Chem. Res. 2019, 52, 316–325.

- Palumbo, F.; Wen, C.; Lombardo, S.; Pazos, S.; Aguirre, F.; Eizenberg, M.; Hui, F.; Lanza, M. A review on dielectric breakdown in thin dielectrics: Silicon dioxide, high-k, and layered dielectrics. Adv. Funct. Mater. 2020, 30, 1900657.

- Fannir, A.; Temmer, R.; Nguyen, G.T.M.; Cadiergues, L.; Laurent, E.; Madden, J.D.W.; Vidal, F.; Plesse, C. Linear Artificial Muscle Based on Ionic Electroactive Polymer: A Rational Design for Open-Air and Vacuum Actuation. Adv. Mater. Technol. 2019, 4, 1800519.

- Klontzas, M.E.; Akoumianakis, I.D.; Vagios, I.; Karantanas, A.H. MR imaging findings of medial tibial crest friction. Eur. J. Radiol. 2013, 82, e703–e706.

- Ebadi, S.V.; Fashandi, H.; Semnani, D.; Rezaei, B.; Fakhrali, A. Electroactive actuator based on polyurethane nanofibers coated with polypyrrole through electrochemical polymerization: A competent method for developing artificial muscles. Smart Mater. Struct. 2020, 29, 045008.

- Koo, I.M.; Jung, K.; Koo, J.C.; Nam, J.-D.; Lee, Y.K.; Choi, H.R. Development of soft-actuator-based wearable tactile display. IEEE Trans. Robot. 2008, 24, 549–558.

- Rider, T.; Taite, S.; Intel Corp. Wearable adaptive electroactive polymer fabric. United States patent US 10,334,899, 2 July 2019.