Milk, alongside meat, is one of the basic animal materials of importance in food processing. Most of the world’s milk production is carried out in an intensive system focused on high productivity at the expense of quality. This system is dominant in highly developed countries, while milk production in developing and poorer countries is still carried out in a traditional manner, using silage.

- milk

- production system

- organic dairy products

- bioactive compounds

- mycotoxins

- technological parameters

1. Introduction

Global production of cow milk in 2019 amounted to almost 716 million tonnes and was 36 times higher than production of goat’s milk and nearly 68 times higher than production of sheep’s milk. Since 2000, global production of cow milk has increased by over 46%. Europe remains the largest producer of this raw material. However, its percentage in world production decreased by almost 11 p.p. to 31.5%, mainly due to a small increase in production (8.6%) compared to other parts of the world, such as Asia (133%). Due to the 12.5% increase in the production of cow milk in the EU28, milk production in these countries has increased its share of production in Europe (by 2.5 p.p. to 74.5%), while the role of the EU globally has decreased (by 7 p.p. to 23.5%) [8,9].

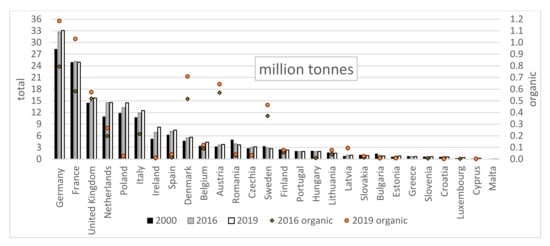

The largest producers of cow milk in the EU as of 2019 were Germany, France, the United Kingdom, the Netherlands, Poland, and Italy ( Figure 1 ), with a total share of 68.5% (115.29 million tonnes), which has remained practically unchanged since 2000. The volume of milk production increased in countries with high (Germany, The United Kingdom, The Netherlands, Poland, and Italy), medium (Belgium, Denmark, Ireland, Spain, Austria, Czech Republic), and low production (Estonia, Cyprus, Latvia, Luxembourg). Production of organic milk in the EU grew dynamically in recent years (126% since 2007) to 5.52 million tonnes in 2019 and was expected to exceed 6 million tonnes from 2020 [10]. Currently, nearly 3.3% of milk produced is organic, and this proportion is growing steadily (it has doubled since 2007). The largest producers of organic milk in the EU in 2029 were Germany (1.19 million tonnes in 2019), France (1.03 million tonnes), Denmark (0.71 million tonnes), Austria (0.64 million tonnes), The United Kingdom (0.57 million tonnes), and Sweden (0.46 million tonnes). This accounted for 83.4% of organic production in the EU. Organic milk production has been growing for several years, although total milk production in some of the countries (Sweden and France) is decreasing. Organic production in the EU is also becoming more concentrated, as the share of the six largest producers of organic raw milk is increasing (1.4% since 2016). The percentage of organic milk in total milk production in the EU is highest in countries with average or small milk production volume, i.e., Sweden (17.2%), Austria (17.0%), Denmark (12.6%), and Latvia (9.6%). In other countries with organic production, its proportion does not exceed 5%. A surprising phenomenon is the lack of growth of organic milk production in countries with high (Poland) or medium (Ireland, Spain) total milk production [8,11].

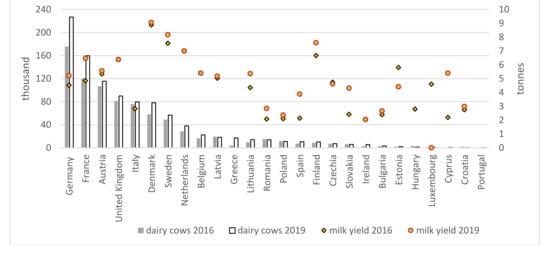

The high production volume of organic milk in some countries is mainly due to their large dairy cow populations (Germany, France, Austria, and The United Kingdom) and high milk yield in the case of Denmark and Sweden (over 8000 kg in 2019). In these countries, both the number of cows kept on organic farms and their productivity are increasing ( Figure 2 ). In Italy, despite the large cow population, milk production is low due to poor milk yield. In Poland, the milk yield of cows is improving steadily (34.5% to 2362.8 kg since 2012), but the number of cows continues to decline (by 45% to less than 11,000 in 2019), which has reduced milk production (by 26% to almost 26,000 kg) [8].

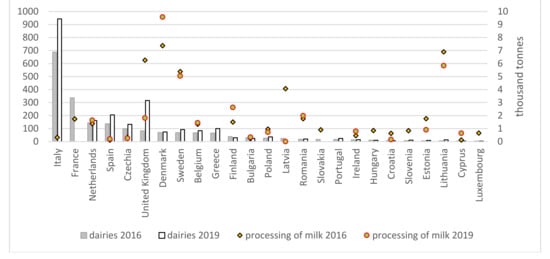

The technical efficiency of organic milk processing is highest in Denmark, Lithuania and Sweden (over 5000 tonnes of milk in 2019; Figure 3 ). These are countries with high milk production (Denmark and Sweden) or low production and few dairies (Lithuania). The most certified dairies are located in Italy, France, the Netherlands, Spain, the Czech Republic, and the United Kingdom. The United Kingdom is an interesting example of a lack of coordination between the rate of milk production and its processing, as the performance of dairy plants decreased by 71% within a few years due to the rapid increase in the number of dairies (from 83 to 316) accompanied by slower growth of organic milk production (by 10%). In Poland, the number of certified dairies has increased by almost 12% to 36 since 2012, which, given the decrease in the volume of raw milk produced (26%), resulted in a significant (65%) reduction in the technical efficiency of dairies to 721 tonnes [8].

2. Requirements for Processing Raw Milk

For processors, what is most important is the quality of the raw milk, which is verified when the milk is received by the plant. Pursuant to Commission Regulation (EC) No 1662/2006 of 6 November 2006 relating to the hygiene of food of animal origin [12], the total bacterial count (TBC) and somatic cell count (SCC) in raw cow milk may not exceed 100,000 cfu/mL and 400,000 somatic cells/mL, respectively. Total bacterial count (TBC) has become one of the criteria adopted for grading milk around the world [13,14]. High-quality raw milk has a low TBC [15,16,17]. In the United States, the Pasteurized Milk Ordinance requires that bacterial and somatic cell counts of Grade A raw milk do not exceed 100,000 standard plate count (SPC) and 750,000 SCC/mL, respectively [18]. Raw milk must also meet other quality standards. It should be free of drug residues, added water, sediment, contaminants, and other abnormalities. The overall condition and cleanliness of the dairy farm, determined in routine inspections, are considered as well. In China, the national standard requires raw milk to have a TBC of <2 × 10 6 cfu/mL [19]. Although regulatory requirements have been instrumental in ensuring the quality of raw milk, most segments of the dairy industry feel that more stringent standards should be maintained. Burke et al. [20] reports that in some US states an SPC of less than 10,000 cfu/mL is required for unpasteurized milk for direct consumption, which is regulated by state law [21]. In England and Wales, the SPC value must be lower than 20,000 cfu/mL in unpasteurized milk for direct consumption, while in Germany the limit for certified raw milk is 50,000 cfu/mL [21].

European law also regulates the temperature of milk. Directly after milking, milk must be cooled immediately to a temperature no higher than 8 °C in the case of daily collection or no more than 6 °C if it is not collected daily. Cooling conditions must also be maintained during transport; milk temperature must not exceed 10 °C on delivery to the plant [12]. Therefore, food business operators must implement procedures to ensure that raw milk meets these criteria. Additionally, there are specific national regulations in effect. In Poland, milk for processing must have an appropriate acidity, indicating its freshness, i.e., pH in the range of 6.6–6.8 and titratable acidity of 6.0–7.5 °SH [22]. The use of high-quality raw milk is a key factor determining the quality of dairy products. It is important to manufacturers because it ensures the desired taste and texture of the products as well as the efficiency of the physical processes the milk undergoes and its fermentation. This is especially important in cheese production [23].

The quality of raw milk, however, is determined by many genetic (species, breed, variety) and environmental factors (feeding system, production season, welfare, climate zone) [1,3,26,27,28]. It is generally believed that more than 50% of the variability in the content of nutrients is determined by genetic factors and about 40% by environmental factors. The productivity of cows and the quality of milk are mainly determined by their diet, which is closely linked to the production system, and this in turn is largely associated with the production season [2,25,29].

3. Milk Production System

Most of the world’s milk production is carried out in a conventional, usually intensive system, focused on high productivity. This system is dominant in highly developed countries, while milk production in developing and poorer countries is still carried out in a traditional (extensive) manner. The popularity of organic milk, whose production is certified, has been increasing in European countries since the 1990s.

Organic milk production may only be conducted on certified farms, supervised by a certification body. It must strictly comply with Council Regulation (EC) No 834/2007 [30] (detailed in Commission Regulation (EC) No 889/2008 [31]). The regulation remains in effect until the end of 2021, and from 1 January 2022 it will be replaced by Regulation (EU) 2018/848 of the European Parliament and of the Council of 30 May 2018 on organic production and labelling of organic products and repealing Council Regulation (EC) No 834/2007 [32]. Organic animal production combines the preservation of a high level of biodiversity, protection of natural resources, and high animal welfare standards. The specific rules in force on organic farms are conducive to the production of high-quality material. These include prioritization of native cattle breeds, animal nutrition based on on-farm feed from organically fertilized crops, prohibition of industrial concentrates, complete feeds, feed produced with GMOs, growth stimulants, synthetic amino acids and antibiotics, permanent access to outdoor areas, and stocking density adapted to the buildings and grassland areas [2,31,32]. According to the principles of organic production, animal feeding on organic farms is not aimed at intensive exploitation of cows, but at sustaining the balance of feed resources and utilizing them completely. Animals must be fed organic feed composed of ingredients obtained from organic agricultural production, but natural non-agricultural substances are also allowed. At least 60% of the feed must come from the same farm. Moreover, at least 60% of the dry matter in the feed ration should be roughage, green fodder, dried fodder, or silage. Pastures should be maximized accordingly to their availability in different seasons of the year [31,32,33]. The differences in non-conventional and organic feeding result mainly from the diversity of available vegetation in pastures, mainly in the spring and early summer. In summer, cows have ad libitum access to pasture vegetation, consisting mainly of low grasses (50%), tall grasses (30%), and legumes (10–20%). It should be emphasized that the pasture feeding period on organic farms often exceeds 180 days, while on traditional farms it usually lasts no longer than 140 days [34]. Organic pastures are distinguished by high sward biodiversity (numerous species of grasses, legumes, and herbs), which directly translates into the nutritional value and quality of fodder. This fodder is a source of numerous bioactive substances that enter the milk [2]. In the autumn and winter, cattle must be fed roughage, which includes silage based on mixtures of cereals and legumes or haylage. Beets or potatoes are added to the diet of cattle only in winter [35,36].

One of the most popular feeding systems for high-yield cows is a total mixed ration (TMR) administered using a feed truck. TMR is a mixture of roughage and concentrate feeds supplemented with vitamin and minerals. The key feature of this system is the stability of the food ration, as frequent modifications may affect digestion or the occurrence of metabolic diseases in animals [37]. This system is used in high-yield cows that require a complete diet satisfying the demand for all necessary nutrients, deficiencies of which may negatively affect the quality and quantity of the product [38]. The basic ingredients of concentrate feed include maize silage, grass silage, legume silage, alfalfa hay, barley, or beet molasses/pulp [2,3,39,40]. The TMR system requires the formation of several feeding groups or the use of one averaged food ration. However, the use of an averaged ration does not allow for full utilization of the capacity of the most productive cows, while at the same time costly concentrate feed is given to cows with lower production potential. An alternative is PMR (partial mixed ration), a system, of partially complete feed rations. The PMR system combines the advantages of TMR and the precision of feeding stations in the rationing of concentrate feed and vitamin and mineral supplements. Moreover, PMR does not require separate feeding groups, because all cows receive one basic TMR ration composed for a specific average milk yield, and only individual cows exceeding this yield are rewarded with concentrated feed and additives from the feeding station. This system reduces the consumption of concentrate feed and is better adjusted to the energy and protein requirements of individual cows, e.g., those in the first stage of lactation [37,39,41]. An increasing number of dairy cow farms have introduced intensive milk production systems (TMR or PMR) in the last 20 years. This is linked to the construction of new barns or modernization of old tie-stall barns in favour of free stalls, in which a uniform, complete-ration feeding system is used throughout the year [42].

The intensive milk production system is replacing the traditional system, which until recently was the most common, although the latter will continue to dominate for a long time in some parts of the world (especially in developing countries) [43,44,45,46]. On traditional farms, the cows are kept in tie-stall barns with or without litter. The diet is based mainly on roughage, usually administered ad libitum (without specialized equipment and calculation of feed rations). Grassland, both permanent and temporary, is an important source of fodder from spring to autumn in the traditional production system and is also the least expensive. The ration is not uniform in this feeding system. It is usually difficult to balance, and for this reason high milk yields are difficult to achieve. However, as a more natural system for cows, it is conducive to their welfare. The traditional and intensive systems collectively are referred to as the conventional milk production system. However, at the turn of the 21st century, their alternative, the organic system, has gained in popularity [47,48,49].

4. Milk Production System and the Quantity and Quality of Raw Milk and Manufactured Dairy Products

Luukkonen et al. [74] compared the chemical composition and hygienic quality of organic and conventional milk from 126 Finnish farms. Organic milk had a lower total bacterial count than conventional milk and a similar or higher somatic cell count. However, the authors noted that although the differences between organic and conventional milk were rather small, they were of economic significance in large-scale cheese manufacturing. Kapturowska et al. [75], in an assessment of the quality of raw milk in relation to the quality of ensiled roughage on selected organic farms, indicated a possible relationship between the quality of ensiled roughage and selected quality parameters of raw milk. In the milk from farms where cows were fed with experimental silage of high quality, including microbiological quality, no contamination or significantly less was detected, including microbiological contamination.

Many studies have assessed the basic nutritional value of organic and conventional milk. According to Nauta et al. [59], Dutch farmers who converted to organic farming during the late 1990s represented a specific group of farmers distinct from conventional farmers. This was reflected in lower milk yields and lower milk fat and protein percentage after conversion compared to conventional farms. During conversion, significant changes occurred in milk production and in protein and fat content. Luukkonen [74] demonstrated that Finnish organic milk contained significantly less fat (4.17%, p ≤ 0.01) and protein (3.30%, p < 0.001) than conventional milk (4.24% and 3.38%, respectively), while organic milk contained significantly more lactose (4.79% vs. 4.74%, p ≤ 0.01). Partially similar results were obtained by Toledo et al. [91] from 31 organic dairy farms in Sweden for raw milk samples collected once a month for one year. The authors obtained similar results for fat, as they observed a significantly lower fat content in milk from large organic farms (40–60 animals) than in milk from large conventional farms. However, no differences were noted between the protein content of organic and conventional milk. A Polish study [61] assessed raw milk from Simmental cows from organic and conventional farms (traditional and intensive). The authors reported that milk obtained from organic and traditional farms was a significantly ( p ≤ 0.01) poorer source of total protein (3.24% and 3.33%, respectively), including casein (2.47% and 2.53%, respectively), compared to the intensive system (PMR) (3.59% and 2.81%, respectively). Wójcik-Saganek [57] also found that the milk of Simmental cows kept on organic farms was a significantly ( p ≤ 0.01) poorer source of total protein (3.15%), including casein (2.46%), compared to cows of this breed from conventional farms (by 13% and 5%, respectively). Therefore, it can be assumed that the production system in organic and traditional farms did not fully satisfy the cows’ requirements for nutrients. Other authors have also demonstrated significantly lower content of protein, including casein, in organic milk compared to conventional milk [4,59,71,92]. According to Zagorska and Ciprovic [92], the lower protein content in organic milk was caused by the lower amount of starch in the feed, which was linked to the smaller proportion of concentrated feeds. According to Kruczyńska [93], the use of maize silage in cow diets promoted bacterial protein synthesis in the rumen and had a positive effect on its quantity in milk. These relationships corresponded with the results of our own research, in which higher protein content was obtained in milk produced in the intensive system, where cow feeding was based primarily on maize silage. Vicini et al. [94] noted an increase in protein content in organic milk compared to conventional milk. In contrast, Luukkonen et al. [74] observed no effect of the organic and conventional production systems on milk protein content. Stergadis et al. [95] showed that the amount of protein, including casein, was significantly higher in organic milk than in conventional milk.

The influence of pasture feeding on the mineral composition of milk is not clear. Kuczyńska [51], Wójcik-Saganek [57], Hermansen et al. [168], Gabryszuk et al. [169], and Koperska et al. [170] have demonstrated that organic milk is a poorer source of minerals than milk from conventional farms. The content of macro- and micronutrients in milk differed significantly statistically depending on the production system. Koperska et al. [170] reported that milk from organic farms had significantly ( p ≤ 0.05) lower content of most of the analysed elements (Ca, Mg, Zn, Mn, and Cu). Litwińczuk et al. [26] observed the highest levels of minerals in milk from farms where the cows were fed traditionally (extensively). Milk from the organic system contained the lowest amounts of Ca, Na, Mg, Zn and Fe. The values for copper were comparable. The highest potassium content was found in organic milk, which could be due to the relatively large amount of this element in fodder from grasslands. Concentrations of iodine and selenium were significantly lower in organic milk than in conventional milk from cows fed concentrate feed [26]. This difference was even more pronounced in the summer, due to the increase in the proportion of green pasture forage in the diet [169,171,172]. Walther et al. [173] also showed a significantly lower concentration of iodine in organic milk than in conventional milk. This was true not only of the raw milk, but also the drinking milk produced from it. Organic UHT milk contained on average 36% less iodine than traditional UHT milk. A similar relationship was found by Flachowsky et al. [174], who reported that organic UHT milk contained 30–42% less iodine than conventional UHT milk. Pilarczyk et al. [175] found that organic milk from cows whose diet was rich in hay and maize silage had significantly higher selenium content than conventional milk. On the other hand, Fall and Emanuelson [164] reported nearly identical levels of Se in organic and conventional milk, which the authors argued was due to similar diets.

Zwierzchowksi and Ametaj [176] compared levels of heavy metals As, Ni, Al, Cd and Pb in organic and conventional milk. Conventional milk proved to be more contaminated ( p < 0.05). The greatest differences were obtained for Al concentration, which was 6.5 times higher in conventional milk.

This entry is adapted from the peer-reviewed paper 10.3390/ani11102760