Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Subjects:

Engineering, Biomedical

Graphene-based materials are found as excellent resources and employed as efficient anti-microbial agents, and they have been receiving significant attention from scientists and researchers in this regard.

- graphene

- antibacterial activity

- mechanism

- graphene-based materials

1. Introduction

Frequent increase in population leads to contamination of water and air in our day-to-day life. Consequently, infectious diseases and pathogens are developed worldwide. Over the past few years, drug resistance was developed in many pathogens because of the excessive utilization of antibiotics like β-lactam, chloramphenicol, carbapenem, etc. [1,2]. Therefore, multidrug resistance of pathogens affecting humans with various infections globally could be one of the crucial problems that needed to be resolved [3]. Several antimicrobial agents like carbon nanotubes, metal nanoparticles, and metal oxide nanoparticles have been discovered to address this problem. Graphene and its hybrid materials are currently recognized as efficient antimicrobial agents and have shown a deleterious effect on plant pathogens [4,5,6].

Graphene (GR) is a two-dimensional structure with hexagonal carbon arrangements in a honeycomb manner in which each carbon atom undergoes sp2 hybridization and contains one pure Pz electron. This is the reason for its exceptional electrical properties, and it is the thinnest material ever found on earth [7,8,9]. Graphene has grabbed much attention from researchers and scientists in several areas of nanotechnology owing to its distinctive physical, thermal, and electrical properties [10,11]. Graphene oxide is an oxidation form of graphene and having oxygen polarity groups on the planes of 2D structure, which is highly dispersible in water [5]. Graphene-based materials can hold biomolecules, particularly; graphene and graphene oxide nanomaterials could act as powerful bactericidal effects against all types of pathogenic microorganisms. This bactericidal mechanism is a complex structure and completely associated with the intrinsic properties of graphene-related materials. The parameters like the nature of the targeted microorganism, surface modification and composition, and the characteristics of the environment in which cell and graphene interaction take place are essential for efficient antibacterial activity. Current research unveiled that graphene oxide is a good candidate for antimicrobial applications, as it possesses polar oxygen groups. Thus, it can undergo oxidative stress. Several investigations have already reported that graphene, graphene oxide, and their hybrid materials could act efficiently against Gram-positive and Gram-negative bacteria [12,13,14]. Furthermore, graphene and graphene oxide could interact with bacterial cells either physically or chemically, responsible for their antimicrobial activity [15,16]. Physically, graphene may cause structural damage to the microorganism, capable of biologically isolating cells from their environment, ultimately leading to cell death. Furthermore, chemical interaction between graphene and microorganism releases toxic substances called reactive oxygen species (ROS). In addition, the electron transfer phenomenon could occur where electrons are progressively drained from the microbial’s outer surface, which further causes ROS-independent oxidative stress leading to biological death.

Currently, plenty of research is ongoing on graphene-based materials and their composites for their enormous diversifying implications. Although comprehensive research on graphene-based composites materials has already been established [17,18,19,20,21], exploration of graphene products commercialization is still under process. Such composites’ final performance entirely relies on the graphene dispersion and interfacial interactions associated with them. Graphene has already proved an excellent antimicrobial agent as a nano reinforcement in manufacturing hybrid composites, catalyst in catalysis, the sensor in solar cell applications, wastewater treatment, drug delivery, etc.

2. Preparation Methods of Graphene from Waste and Bioprecursors

The initial part of the present review emphasizes the preparation methods of graphene using waste and bio precursors. Due to the industrial revolution, waste generation and accumulation have become inevitable, so innovative approaches are required to utilize waste for valuable products. Converting this waste to use carbon materials like graphene is an appreciable approach. Graphene can be prepared by bio precursors like glucose, chitin, grape seed extract, alginate, etc. In this review, the preparation methods of graphene from different resources have been summarized, highlighting the merits and demerits. If graphene is economically produced using biomass or from waste, it can be utilized for various applications.

2.1. Significance of Preparation of Graphene from Bioresources

Inexpensive biosources have been identified from the available literature and discussed. This review intended to unveil the eco-friendly and straightforward preparation methods of graphene and augment the innovative approaches. In recent years, much research has been progressing to prepare graphene with good quality with high yield. This section will undoubtedly enable the readers to obtain valuable information over other sources and ultimately raise some challenges to the researchers to fabricate economically viable and quality graphene.

Manifold sustainable resources are essential for synthesizing graphene. This review highlights the use of various renewable bioresources such as glucose, rice husk, hemp, and disposable paper cups, and a detailed mechanism for synthesizing graphene and its applications.

2.2. Different Bioprecursors

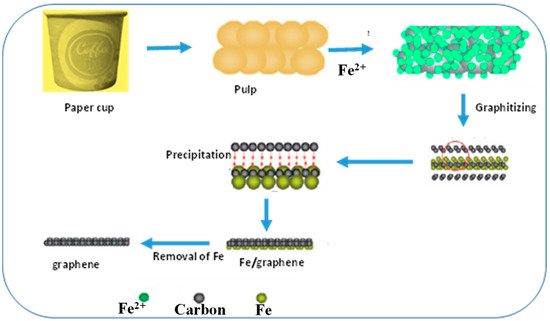

Generally, the paper cups are made of wood, containing cellulose and hemicellulose, an extraneous material. However, a research team perceived it differently to utilize them as a starting material for preparing graphene. Hong Zhao et al. had prepared graphene using disposable paper cups as a precursor in the presence of an iron catalyst [25]. They highlighted two great uses of this approach. One is preparing graphene from waste with high yield compared to other conventional methods, and the second one is the excellent quality of the product. The preparation mechanism involves the activation treatment of paper cups with the aid of K+ and KOH ions, and these ions are adsorbed on the structure of paper pulp. The addition of Fe catalyst results in the exchanging of ions Fe2+ with K+. In the end, the Fe3C layer could be formed when heated at higher temperatures, similar to the graphitization process. Carbon diffuses out to form multilayers of graphene over the Fe during the temperature reduction and thus resulting in the Fe/graphene composite. In the end, the etching process can be employed to eliminate Fe ions from the resultant graphene product. Besides, Pt/graphene can also be prepared [25] by exchanging Fe ions with Pt through galvanic displacement. The entire mechanism is summarized in Figure 1. This method is economically viable, quality graphene can be prepared from disposable paper cups, and it is a pioneering fabrication method that still requires optimization.

Figure 1. Formation mechanism of graphene sheets from paper cups [25].

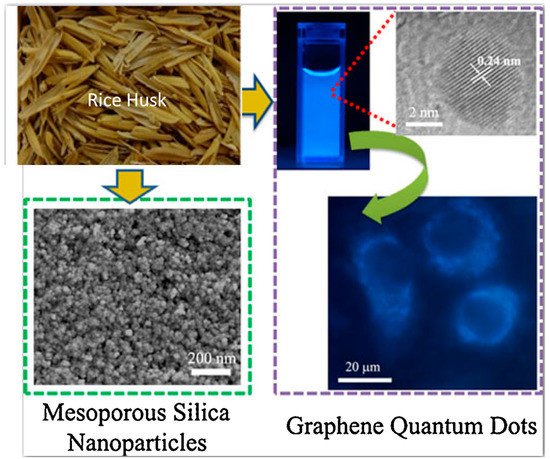

The rice husk covers rice kernels, and rice is produced annually in huge million tons. As a consequence, rice husk is being considered a substantial agricultural waste. The potential use of rice husk has been implemented for synthesizing graphene [26,27,28,29,30] (see Figure 2). However, it is also utilized to manufacture silica products [31,32] because it contains more amount Si concentration. Eliminating the Si from rice husk results in a large amount of organic carbon, which is being wasted [33]. Recently, research has been conducted on deriving nanocarbon materials from the same. Research reports have revealed that a biocompatible graphene quantum dot could be prepared from rice husk with a good yield of 15%. The biocompatibility of the obtained product was confirmed using a cell viability test. Besides, silicon nanoparticles with a vast surface area can also be prepared from the rice husk as they can be utilized for comprehensive purposes. In the past, Hiroyuki et al. revealed a new synthetic method for the preparation of graphene through activation of rice husk by activating it with KOH, and substantial heating at high temperatures was conducted at 1123 K [34]. Herein, KOH helps prepare high-quality graphene containing sharp edges and can induce porosity while eliminating Si impurities. Nevertheless, the research team failed to explain the mechanism of the formation of graphene. In another report, graphene was prepared using rice husk for high-energy storage applications [35] due to the rice husk’s inter-connected nanoporous structure. Therefore, quality-related issues should be thoroughly answered when utilizing rice husk to prepare graphene.

Figure 2. Utilization of rice husk for the preparation of graphene quantum dots Reprinted with permission from ref. [33] Copyright 2016 American Chemical Society.

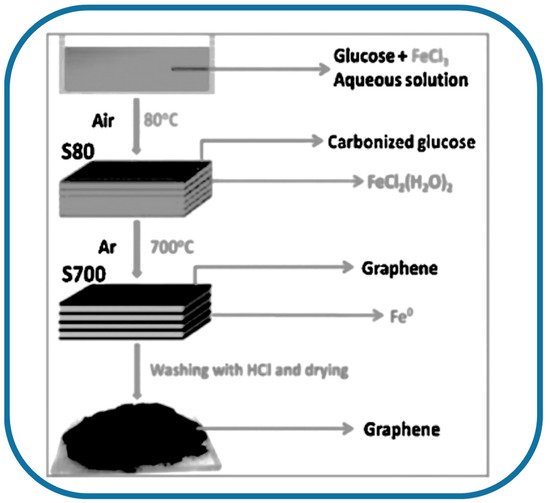

Glucose is a carbohydrate molecule having the structural formulae C6H12O6, and it is a renewable carbon resource. Many researchers utilize graphene and its derivatives to identify glucose non-invasively due to its sensitivity to environmental changes [36]. On the other side, glucose can be starting precursor for synthesizing graphene. Recently, a report revealed the preparation of graphene from glucose with the aid of ferric chloride [37]. In this preparation method, initially, glucose was dissolved with water in the presence of FeCl3. Then, the resultant mixture was heated to 80 °C, subsequent calcination at 700 °C with inert gas atmosphere results in the formation of graphene and Fe (0). In the end, Fe can be removed with the aid of HCl. Here, FeCl3 plays a crucial role in forming quality graphene because it acts as a catalyst. Therefore, this method can be easily adapted for the mass production of graphene. The schematic representation of the preparation method is given in Figure 3. Xin Hao Li and his group [38] also reported the preparation of graphene utilizing glucose and formed graphene named patched graphene. In this method, dicyandiamide (DCDA) was mixed with glucose in the presence of a nitrogen atmosphere to form the layered graphitic nitride (g-C3N4). Complete thermolysis of the developed g-C3N4 results in sheet-like graphene having high crystallinity with a pure atomic structure. This method is suitable for obtaining nitrogen-doped graphene because it can regulate nitrogen content. As in the Hummer method, graphene oxide (GO) substantially aggregates into thick flakes. In this approach, entangled graphene sheets can be produced without any separation or post-purification process.

Figure 3. Preparation of graphene from glucose with the help of ferric chloride [37].

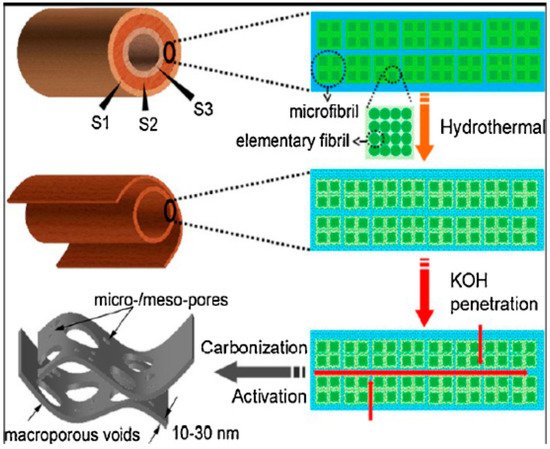

Hemp fiber is another type of bioresource that can be utilized for the preparation of graphene. It is derived from the cannabis plant known as bast. The fibrous part of this plant could be employed as clothing oil, rope, and plastics. Huanlei Wang and his coworkers synthesized nanographene from hemp fiber waste, an inexpensive starting material [39]. In another report, David Miltin revealed that Hemp bast is considered nanocomposite, which is made of hemicellulose, lignin, and crystalline cellulose [39]. The hydrothermal method was used to prepare nanocarbon material from Hemp fiber with the aid of KOH activation. Initially, the fibers were heated at 180 °C for 24 h to dissolve lignin and cellulose components. The following material was treated with KOH to prepare porous graphene (refer Figure 4). The prepared graphene can be used for energy and environmental applications.

Figure 4. Preparation of graphene from Hemp fiber Reprinted with permission from ref. [39] Copyright 2013 American Chemical Society.

This entry is adapted from the peer-reviewed paper 10.3390/coatings11101197

This entry is offline, you can click here to edit this entry!