An effective battery management system (BMS) is indispensable for any lithium-ion battery (LIB) powered systems such as electric vehicles (EVs) and stationary grid-tied energy storage systems. Massive wire harness, scalability issue, physical failure of wiring, and high implementation cost and weight are some of the major issues in conventional wired-BMS. One of the promising solutions researchers have come up with is the wireless BMS (WBMS) architecture. Despite research and development on WBMS getting momentum more than a decade ago, it is still in a preliminary stage. Significant further upgradation is required towards developing an industry-ready WBMS, especially for high-power LIB packs.

1. Introduction

Lithium-ion batteries (LIBs) are extensively used as a primary battery energy storage system in high power battery packs typically used in electric vehicles (EVs) and stationary grid-tied energy storage stations. However, the narrow safe operating area necessitates an effective battery management system (BMS) for almost all practical purposes

[1][2][3]. Some of the common functionalities of a BMS includes state of charge (SOC) estimation

[4][5] and state of health (SOH) estimation

[6][7], temperature measurement/estimation

[8], cell balancing

[9], fault detection/diagnosis

[10] and thermal management

[11]. BMS consists of several hardware components such as sensors, microcontrollers and software to perform all these functionalities. Therefore, a suitable communication architecture is essential for establishing data communication inside the BMS among internal sensors and controllers alongside communication with external devices for data storage, display and external control.

Traditionally wired-BMS are widely used in battery-powered systems where Controller Area Network (CAN)-bus, and I2C/SPI communication protocols are generally employed. CAN-bus communication requires a massive wire mesh to collect sensor data and transmit it to the master controller of BMS leading to very high implementation cost, weight, design complexity and the galvanic isolation of the cells. Placement of sophisticated controllers of BMS at a safe distance from the battery pack is also challenging due to extended wiring requirements. Wired-BMS can face physical connection failure due to the vibratory working condition of EVs leading to low reliability of the BMS. Troubleshooting in wired-BMS is also difficult due to massive wirings. These issues of wired-BMS started becoming more and more challenging with the increasing application of high-capacity LIB packs consisting of thousands of individual cells. Therefore, researchers started developing wireless topologies suitable for transmitting information and control commands among sensors and controllers. Wireless BMS (WBMS) offers improved system reliability, lower weight and cost due to reduced wiring complexity, elimination of the requirement of galvanic isolations and physical connectors, especially for high capacity multicell battery packs

[12]. WBMS also increases the flexibility of sensor placement inside the BMS and the placement of the BMS module itself inside the powertrain. The WBMS has high fault tolerance and adequate scalability when compared to conventional modularized BMS. Moreover, WBMS also enables the replacement of individual components without reconstructing the entire system. Few proposed architectures also employed memory units in each sensor node. Possessing in-node memory allows the system to recover data once the connection is restored after a temporary connection failure, resulting in enhanced data integrity and system reliability

[13].

Researchers have already proposed different kinds of WBMS architecture and some of them have also demonstrated satisfactory performance in real-world application in the last few years. However, in general, the research on WBMS is still in its preliminary stage. Significant further research and development are required to achieve an industry-ready WBMS with optimum wire harness and weight, low cost, easy implementation, adequate data transfer rate, reliable and equipped with necessary functionalities. Therefore, realizing the promising prospects of WBMS in LIB-powered systems, a detailed survey of existing WBMS architectures is presented in this article. To the best of the authors’ knowledge, an in-depth survey exclusively on WBMS has not yet been presented. The aim is to provide a complete summary of all recent and prominent developments, research trends and major challenges to provide a useful guideline to the research community for future developments, more so to enthuse them to provide more research efforts towards developing an industry-ready WBMS.

The remaining portion of the review article is organized as follows. Generic WBMS architecture is presented in

Section 2 and the classification of WBMS is discussed in

Section 3.

Section 4 is the prime section of this review article as it provides a comprehensive survey of existing WBMS architectures reported in the literature.

Section 5 summarizes the trends in WBMS research, current issues, challenges and future research scopes. Finally, concluding remarks are presented in

Section 6.

2. Generic WBMS Architecture

The basic architecture of WBMS and traditional wired-BMS

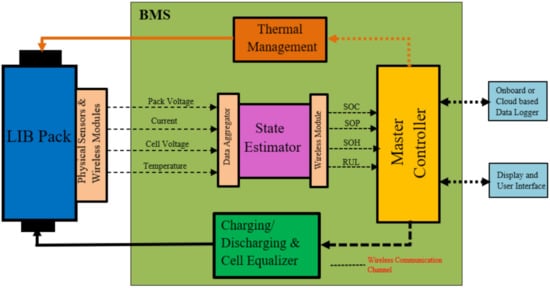

[14] are almost similar. All functionalities are also common in both architectures. The only major difference is in the internal and external communication channels. Information from each cell such as voltage, current, and temperature is required for the estimation of different states and to realize the control and management action by the centralized master controller of the BMS. Now, in the case of WBMS, all these information exchanges among each sensor node, master controller, onboard display unit, data storage unit and other control and management unit are realized by a wireless communication channel instead of wired communication as in the case of wired BMS. Recently developed, cloud-based BMS also uses wireless internet communication for bi-directional communication between onboard BMS and cloud BMS. The schematic layout of a generic WBMS is depicted in

Figure 1.

Figure 1. Schematic layout of a generic WBMS.

3. Comprehensive Review of the Wireless BMS Topologies

3.1. Bluetooth-Based WBMS

The safe operating area of LIB is very narrow; therefore, crucial battery parameters such as voltage, current and temperature need to be closely monitored during the charging and discharging period. Traditional wired BMS controls the charging/discharging current based on the feedback received from the wired sensors at each cell to collect voltage and current data. The high-capacity LIB-pack consists of thousands of LIB cells; therefore, it requires several thousands of wire terminals to mount sensors on cells. Therefore, wired BMS is susceptible to physical connection failure. Moreover, rebuilding, modification and scaling are highly challenging due to physical connections. Repair, modification and scaling often require rebuilding the entire BMS and the battery pack. In search of solutions, Shell et al.

[13] proposed a Bluetooth communication-based WBMS where wireless communication was used between cell sensors (voltage and current) and central controller instead of physical wired connections to minimize some of these challenges associated with the wired BMS. The scheme used a memory buffer in between the communication channel to enhance data integrity even if temporary failure of communication links. Despite its comparable performance with the wired BMS, the architecture could face the typical limitations of Bluetooth-based communication channels such as low data transfer rate, being prone to communication failure and low range. Further to this study, Bluetooth 4.0-based wireless sensors specially designed for WBMS were employed by Farmer et al.

[15] to monitor temperature information in addition to the voltage and current data during the charging/discharging cycle of a high capacity battery pack. Moreover, a wireless strain gauge at each cell was used to follow individual battery swelling. Small Bluetooth receivers compatible with USB ports and a custom-made software tool were used for data logging and visualization. The scheme was practically implemented for a 2.5 kWh LIB-pack for NASA’s Mars Science Laboratory

[15]. In both the schemes, the implemented WBMS used Bluetooth-based communication between each cell and central controller to collect battery parameters which are more of a battery monitoring system rather than a complete BMS.

Hardware implementation of BWBMS was demonstrated by Jamaluddin et al.

[16]. Voltage, current and temperature data were measured by the respective sensor, then Arduino UNO microcontroller and Bluetooth communication channel were used to transmit battery information to a personal computer and mobile device for data visualization. The scheme is not suitable for large capacity battery packs with a large number of individual cell and also encompasses typical limitations of Bluetooth-based communication. Chetan and Hiremath

[17] demonstrated the effectiveness of WBMS in automatic health report generation through a simulation study. A practical hardware-based scheme needs to be developed and tested to assess the suitability of the scheme in a real-world application. Luo et al.

[18] introduced a General Packet Radio Service (GPRS)-based online battery parameter monitoring scheme to determine important battery states, fault diagnosis and to facilitate data storage for future requirements such as SOH estimation. Although the GPRS communication protocol is still in use, currently, several advanced high-speed data communication standards have already been developed and extensively used for high speed and a large volume of data transmission. Moreover, the scheme is a battery monitoring system rather than a complete BMS. Following the above discussion, it could be highlighted that BWBMS is suitable for low-capacity LIB-packs and low-cost solutions. The power consumption of Bluetooth communication is very low, making it suitable for the battery-powered system. However, Bluetooth communication is not adequate for the BMS of large capacity LIB pack as it requires high volume and high-speed data transfer to ensure safe and reliable battery management.

3.2. Zigbee-Based WBMS

The Zigbee (IEEE 802.15.4)-based battery parameter monitoring scheme was introduced by Wu et al.

[19]. Individual voltage and temperature sensors along with a Zigbee module were attached to each cell to measure voltage and temperature information, thereafter sensing the data to a battery management unit (BMU) for data acquisition, analyzing and displaying the statistics. In this topology, wireless communication was only used between individual cells and BMU. CAN-bus was still employed for communication between BMU and vehicle controller for information and command transmission. Therefore, the reduction in wire mesh was minimum. Further to this study, a complete wireless communication scheme was employed by Otto et al.

[20]. The electromagnetic interference (EMI) has been reduced by several extents by eliminating the physical wires. However, the scheme suffers from similar drawbacks as in ref.

[19]. Schneider et al.

[21] suggested that a wireless Ultra High Frequency (UHF) sensor with an active downlink could be implemented for transmitting individual cell voltage, current information to the central battery control (CBC) unit wirelessly for estimating SOC and SOH. The primary intention of the study was to propose a wireless sensor based on the IEEE 802.15.4 communication protocol. They have also demonstrated that the battery electronic control unit (ECU) could be used to send addressed commands and multicast/broadcast commands to the sensors for monitoring and control of signal flow. The few major limitations include the high cost of implementation and micro-electronic implementation of such a sensor, especially for high current and voltage application, being challenging, which need further research. Furthermore, the scheme was tested for lead–acid batteries; therefore, it needs to be tested for other popular batteries such as LIBs. Further, Mathew et al.

[22] proposed an IEEE 802.15.4 protocol-based wireless communication architecture for monitoring LIB cells. The condition of a group of cells based on sensor data is communicated through a bidirectional wireless communication channel (2.4 GHz) to a local controller termed a Base Controller Module (BCM). Radio frequency (RF)-modem with antenna was used for wireless communication. Furthermore, fault conditions from BCM to the main Electronic Control Unit (ECU) were communicated through CAN-bus communication. Therefore, wiring requirement is still significant due to the partial use of CAN-bus communication.

Rahman et al.

[23] developed a cost-effective WBMS employing the Zigbee communication protocol and point-to-point wireless topology. The BMS was primarily developed for thermal management of a LIB pack with a large number of series and parallelly connected LIB cells. The wireless communication was mainly used for transmitting voltage, current, temperature and SOC information to the central processor and display unit. The scheme was highly effective in reducing massive wiring issues. However, a major focus was given on the double-tier switched-capacitor converter and resonant switched-capacitor converter-based cell balancing and thermal management schemes. The proposed WBMS demonstrated enhanced performance in cell balancing; however, no satisfactory results were shown in the thermal management of LIB cells. Despite the low cost, low power and easy to implement communication protocol, there are several limitations of Zigbee-based communication especially for highly sophisticated and large LIB packs from a safety and reliability point of view. In addition, limited data transfer rate and low-security issues are also some of the major limitations. IEEE 802.15.4 is suitable for low data rate application, advanced BMS requires very high-resolution data for better safety, operational control and management. Moreover, none of the studies covered an in-depth discussion on Zigbee-based WBMS. Most of the studies provided an overview that is not sufficient for real-world implementation and further development.

3.3. Wi-Fi-Based WBMS

The conventional distinct architecture of EV power train uses separate modules for BMS and charger controller resulting in hardware complexity, larger size and eventually, high implementation cost. Moreover, poor generalization and scalability issues are also very prominent. To reduce the dependence on discrete specialized components, Field Programmable Gate Array (FPGA), a generalized hybrid system, was used by Gherman et al.

[24] to develop a single chip for WBMS and charge controller for EVs. The proposed system used Wi-Fi as a wireless communication channel. The WBMS is capable to estimate SOC based on the measured battery parameters and facilitate SOC-based cell balancing both during the charging and discharging period. FPGA can facilitate both software and hardware updates without replacing the existing PCB. Despite the scheme having a dual-core processor, it has limited capability to handle a large volume of data. Thus, its application in state predictions that require a large volume of historical data such as SOH is challenging. Moreover, using a single chip for BMS and charge controller limits its application for large capacity LIB packs due to voltage and current handling limitations. The topology proposed by Gherman et al.

[24] uses a Cell Sensor Unit (CSU) that measures and transmits measured parameters from each cell to BMS. One Wi-Fi module is installed on each CSU, making the topology practically challenging especially for a large capacity LIB pack having thousands of individual cells.

WBMS for the smart cell was proposed by Huang et al.

[25]. A smart cell consists of a LIB cell, a cell bypass device and a slave controller. All such smart cells are controlled by a master controller termed a smart battery management system (SBMS). The primary intention was to develop a cell balancing scheme based on cell SOC and SOH where each slave associated with each cell was responsible for measuring cell voltage, current and temperature to estimate SOC and SOH. Finally, transmit this information to the master controller, that is, SBMS over a wireless Wi-Fi channel to control the cell balancing operation. SBMS also transmits the command signal to each slave over the same wireless channel. This scheme not only improved the fault tolerance by reducing the exclusive dependence on the master controller employing individual slave controllers at each cell but at the same time reducing the clutter caused by communication wires, thereby reducing the size and weight of the system. The study mainly focused on cell balancing, with no significant contribution to the wireless data collection and control part of BMS. Despite the promising performance, using smart cells in a high capacity LIB pack is impractical from a system cost and manufacturing complexity point of view. One of the major advantages of the WBMS based cell balancing is the ease of scalability due to reduced new wiring requirements.

3.4. Internet of Things (IoT)-Based WBMS

Friansa et al.

[26] proposed an IoT-based battery monitoring system for stationary battery energy storage system (BESS) used in microgrid systems. The centralized master-module-based BMS suffers from reliability issues due to the engagement of a single master BMS. Failure of communication between individual cell control module, sensors and master-module results in malfunctioning of BMS and even catastrophic failure of the battery system. Therefore, Faika et al.

[27] proposed an IoT-based dispersed and decentralized WBMS for reliable battery management. The IoT-WBMS network incorporated a message queuing telemetry transport (MQTT) protocol. The effective leader election algorithm, MQTT and cloud support provided a dispersed, scalable, reliable and cost-effective WBMS solution with powerful computation and reduced transmission power losses and interferences. Prime advantages of WBMS supported by IoT and cloud/edge computing technologies includes powerful computing and unlimited cloud support that results in rapid development, extended scalability and greater visibility. However, the employment of a cyber-physical system leads to cyber-attack, as the system is always connected to the network. Moreover, it also increases the implementation and maintenance cost. Therefore, Faika et al. extended their study presented in ref.

[27] to develop a cloud-supported IoT-enabled WBMS

[28]. The intention was to enhance the communication and data security of an IoT-enabled WBMS from malicious cyber-attacks by integrating blockchain technology. The security-enhanced WBMS was employed to develop a real-time health monitoring system for LIB cell and pack as well. The blockchain-IoT enabled BMS network can use a private channel with access control to facilitate module-to-module communication as well as communication with the external devices for decentralized BMS control securely. The system also utilizes cloud storage and secure data exchange primarily for the real-time health monitoring. The leader election algorithm was tolerant to the failure of either the wireless nodes or the controllers in the WMMSs that eventually enhanced the reliability of BMS compared to single centralized master-based BMS architecture. The practical feasibility of the scheme was also demonstrated by the authors by developing a prototype using five Raspberry pi, three IoT boards and a smart contract with the help of the Hyperledger Fabric blockchain platform

[29]. The study provided only an overview and technologies available for developing cloud supported blockchain-IoT enabled BMS. In-depth technical details and the mechanism behind the blockchain-based scheme to improve the security of BMS are missing. The cyber security of the cyber-physical WBMS was also not covered in these studies.

3.5. Cloud-Based WBMS

A cloud-based battery monitoring and information management scheme for EVs was proposed by Tanizawa et al.

[30]. Kim et al.

[31] introduced the CWBMS for condition monitoring and fault diagnosis for large-scale stationary BESS. The existing studies lack in providing the technical details of both software and hardware design for the CWBMS. Moreover, the performance and functionalities of the system have not been tested and validated with real-world operational data. Advanced functionalities of BMS, such as ageing prognostics and strategy optimization, are highly dependent on the longtime historical data. Therefore, incorporating these functionalities in onboard BMS with low computational power is not feasible. Therefore, to enhance the computational power and data storage of BMS, Li et al.

[32] presented a CWBMS that uses IoT for transmitting all relevant data from battery packs to the cloud platform. A digital twin of the LIB system was developed on the cloud platform that uses measured data and the equivalent circuit model of battery for SOC and SOH estimation powered by an adaptive extended H-infinity filter and particle swarm optimization, respectively. Compared to the on-board BMS, digital-twin-based WBMS facilitates continuous and accurate monitoring of parameters, online state estimation, fault prognosis/diagnosis. Despite the performance of the scheme being experimentally validated by developing a prototype, the primary impression of the paper was on SOC and SOH estimation. While an overview of the WBMS was presented, the basic topology was still IoT-based; no such improvement in topology or protocol was reported.

3.6. Other Relevant Studies on WBMS

Irrespective of types of WBMS, establishing an effective communication channel for wireless data transmission inside the battery pack is a prime challenge; while at the same time, the existing wireless topology for BMS, such as IEEE 802.15.4 in the 2.4 GHz band, suffers from low data transfer speed (maximum 250 kbps). Therefore, Alonso et al.

[33] conducted a study focusing on the wireless channel properties inside the battery pack, and the data rates. They have analyzed and measured the transmission capabilities of several antenna types and frequency ranges to provide a guideline for selecting a suitable antenna for data transmission inside a battery pack. They have also demonstrated that PIFA (Planar Inverted-F- Antenna) having the frequency band 2200 MHz–2600 MHz can have a data transfer rate of up to 2 Mbps, which is twice compared to CAN-bus communication. The results obtained by the authors were based on the simulation study; no real battery-based test was conducted in

[33]. Therefore, the authors extended their research by developing a prototype of the communication system, particularly for the physical and MAC layers. They have implemented the master and the slave nodes of the communication network with software-defined radio (SDR) platforms. Differential encoding (DQPSK) modulation and Time Division Multiple Access (TDMA) protocols were used by them for the physical layer and MAC layer, respectively. Despite an effort towards developing a communication protocol for WBMS, the proposed platform produces an inaccurate result in battery tag position propagation and the TDMA protocol was inappropriate in handling noise in the measured signals.

Lee et al.

[12] developed a WBMS architecture using energy-autonomous micro-sensors mounted on each battery cell, and a master module for centralized data processing. A Proprietary Wireless Battery Area Network (WiBaAN

TM) protocol that uses a 900 MHz unlicensed frequency band (ISM) was used for wireless data communication inside the BMS. Although the architecture can provide better scalability, data transfer rate, perfect isolation of high voltage and eliminate wired connection failure due to the harshly vibratory operating environment of EVs, the proprietary communication protocol can accommodate only 780 numbers battery cells under the condition of a 100 ms data update rate. Moreover, centralized data processing leads to reliability issues due to the failure of a single master processor. Installing one slave BMS consisting of one build-in current sensor, voltage sensor, temperature sensor and flash memory not only complicates the integration but also increases the scalability issue and cost of implementation. In addition, replacing each faulty cell with a new one is challenging as it requires several parameter matchings. Although, Kumtachi et al.

[34] has not proposed a WBMS scheme directly, however, they have developed an enhanced reliable multi-hop wireless communication protocol for EVs. According to the protocol, the system sends overheard packets without selecting the most suitable route to reduce communication latency. The performance was evaluated by computer simulation. It could be used for future generation smart fast-acting WBMS with a high degree of reliability. Wang et al.

[35] developed a very basic charging control scheme using a microcontroller, where wireless communication was only used for battery status monitoring. The charging current was controlled by varying the PWM using an ATMega32 microcontroller. Wireless topologies used in this scheme were not mentioned in the article.

With the increasing application of cyber-physical BMS, the cybersecurity aspect of BMS has become highly important. The hardware and cybersecurity of BMS have long been overlooked; however, these may lead to a catastrophic disaster. While several commercial solutions are available, they do not provide a scalable solution and typically can accommodate only very few numbers of cells. Moreover, a physical contact-based security scheme requires extra wiring, resulting in additional design and manufacturing complexity and cost for battery packs with a large number of cells. Therefore, Al Khas and Cicek

[36] designed and demonstrated a wireless cell authentication and remote health monitoring scheme. A low-power CMOS-RF integrated circuit was combined with cryptographic IP cores and low power synthesizable soft CPUs to form an integrated circuit and was attached to each cell and a Secure Hash Algorithm 2 (SHA-512) based wireless authentication scheme for use in remote monitoring of a battery pack. They have also demonstrated the effectiveness of the scheme by developing a hardware prototype using FPGA devices where a Wi-Fi module was employed to emulate wireless communication. Linear Technology (LT)

[37] developed an industry-first WBMS using a smart mesh embedded wireless network for EVs. In the mesh network topology, all nodes are interconnected to each other through a wireless channel and each node can send or receive data to and from the master node. However, such a centralized BMS network leads to an extra burden on the master node resulting in communication latency and sometimes connection failure. Failure of the single leader node eventually leads to the failure of the entire system and may even lead to catastrophic failure and accidents. Recently, research on smart cell and battery is getting momentum. Smart cell integrates multi-dimensional sensing and self-healing functions into each single cell. Then, the sensor data can be transmitted to BMS through a wireless channel or through wired connections. Regarding this, a detailed discussion on smart cell and battery management system was presented by Wei et al.

[38] through a review study.

This entry is adapted from the peer-reviewed paper 10.3390/electronics10182193