Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Subjects:

Education & Educational Research

Repair as a design practice means that repair ought to be part of design education, at the very least for those design curricula that cover product design.

- repair

- product design

- design education

- sustainable design

- circular economy

1. Introduction

The current paradigm of product design education often serves the linear system and perpetuates a throw-away mentality. As the linear economy has brought us to a global ecological crisis, alternative systems such as a circular economy are needed to overcome these problems [1][2][3][4]. Designers play a significant role in mitigating today’s environmental problems [5], and in the transition towards a circular economy [6]. Students, as the future designers, must be prepared for alternative scenarios and be equipped with the relevant knowledge to be able to deal with environmental issues. This need to solve this issue can be seen from the increasing calls for change in design education throughout the literature [5][6][7][8][9][10][11]. Many educational resources, courses, and projects exist that aim to incorporate sustainability and a circular economy into product design education [12][13][14][15]. However, there is an insufficient number of these courses, and few of them focus on repair and the competencies related to it. In fact, most product design programs solely offer industrial design, thus catering to mass production in a capitalistic economic setting. Inherent in such programs is the belief that there is a need for new products. If there are needs in the world, then newly designed, better-quality products will help to fulfil those needs. Not being asked to design new products may feel quite unsettling to a product designer, yet a system that is not based on new products still requires a wide range of designer skills.

As a field, design has a largely unquestioned underlying paradigm; that any problem requires a new design to be put into the world. Papanek [16] has already argued that many designers focus on designing the wrong products, developing things that are often unnecessary, and sometimes even dangerously unsafe, all in an effort to sell more products. He argues that designers bear the responsibility for which problems they choose to work on solving. Fundamentally, however, that leaves the notion that new designs are needed, untouched. This belief in ‘the new’ runs very deep. Edgerton [17] already argued that our narratives about ‘the new’ are too focused on just the stories of inventors, ignoring how long the alternative systems could last. Designers should reflect much more on what is already in the world and question whether a new design will truly create an improvement. We explore how focusing on repair might help challenge this underlying notion.

To be able to design repairable products, designers need a particular set of knowledge and skills. Existing research in this area is sparse and it primarily covers design for sustainability and the circular economy competencies [18][19]. For example, Sumter et al. [19] provides a coherent overview of the existing literature about the circular economy competencies for design and identifies seven competencies that designers need to be able to successfully design products and services for a circular economy. Two of these competencies are specifically related to designing repairable products: (1) Design for Recovery, (2) Design for Multiple Use Cycles. Design for recovery refers to the consideration of repair, refurbishment, remanufacturing, and other recovery strategies to regenerate the value of the products between use cycles and at the end of the product’s life [19]. Similarly, design for multiple use cycles is about implementing these recovery strategies in the design of the product, considering the effects of long-term use and multiple recoveries on the current design [19]. Similarly, Wiek et al. [20] explain “anticipatory competency” that is also required to design repairable products. The authors describe this competency as the ability to envision the scenarios and the problems that might occur in the future and having the knowledge to answer these problems by using sustainability principles. Designers need to anticipate the future usage scenarios of the products and establish their possible breakdown reasons to invent suitable design solutions for repairability.

2. Integrating Repair into Product Design Education: Insights on Repair, Design and Sustainability

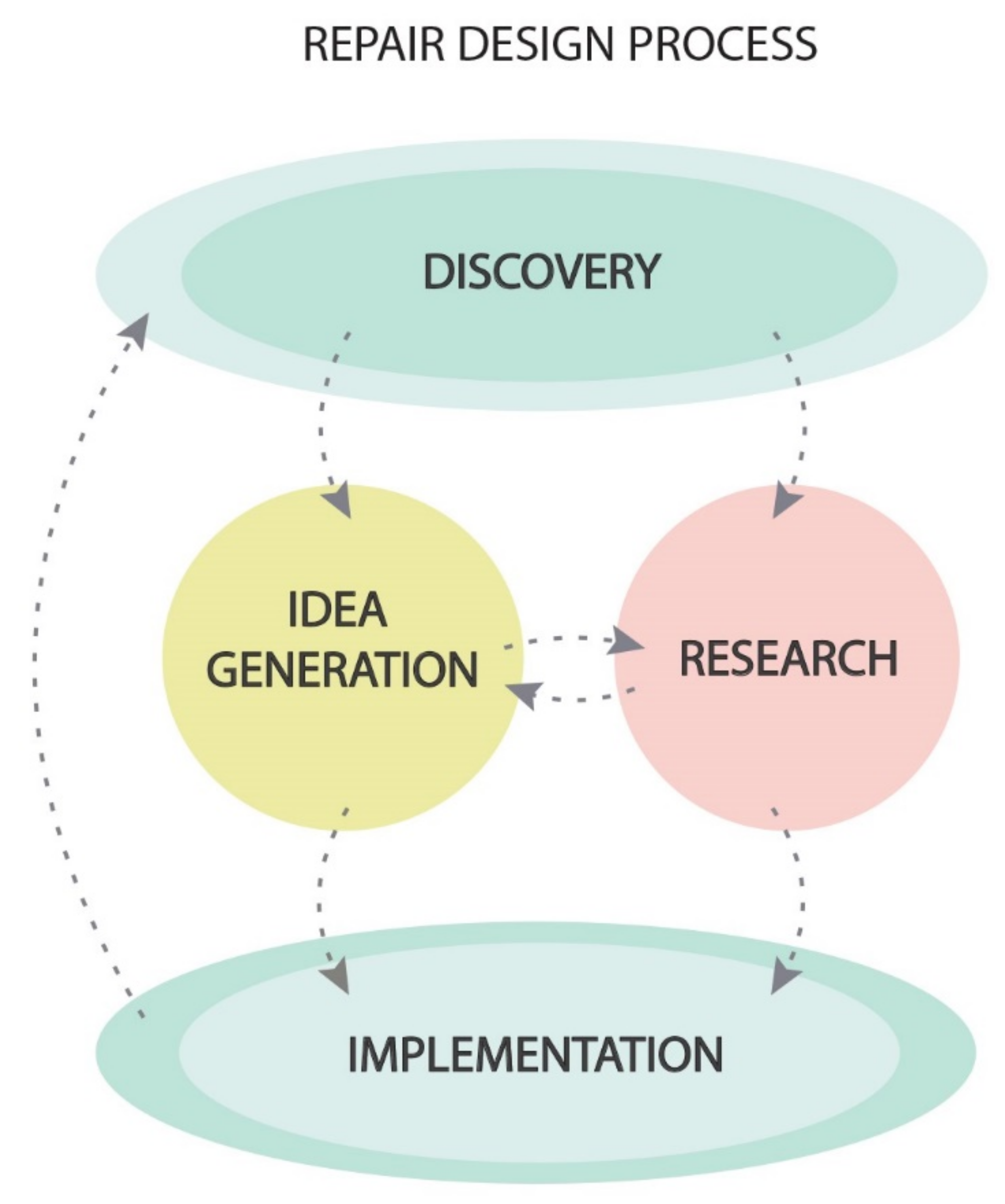

Repair has both advantages and disadvantages for incorporating it in the product design curriculum. Students learn that planning a repair has similarities to a design process, specifically for unique designs, such as craft objects. It also helps them reflect on the inherent notion in product design discipline that the solution is always a newly designed product. For teachers, the examples and perspectives can already serve as a basis for incorporating repair in a lecture format and inspiring adaptation in hands-on assignments. Additionally, it provides a hook for questioning the fundamentals of product design as a field. Another advantage of integrating repair into product design education is that it is a hands-on activity and an effective way to encourage students to work practically and create prototypes. However, it is important that instructors place emphasis on all stages of the repair process. Students need guidance on the three phases of a designed repair process: discovery, idea generation and implementation [21]. For example, Students 11 and 12 spent most of their time on the implementation phase and neglected the first two phases. Their final repair solutions would have been more creative and aesthetically pleasing if they had put more effort into the idea generation stage, especially via sketching and visual representation.

As a result, we want to present a more detailed version of the repair design process that Terzioğlu [21] explained in her paper. The repair design process includes discovery, idea generation, and implementation stages, and we identified the research stage as an addition to these three phases. The diagram in Figure 5 illustrates the different stages and the flow of the process between these stages. Discovery is the first phase of the repair design process, which includes two steps: inspection and determining the worth. At the inspection stage, the repairer inspects the problems and observes the features of the broken products through inspecting the damage, disassembling the product, analyzing its materials, and diagnosing the problem. Understanding how the product was used is also a significant step as it could help prevent the same damage from happening repeatedly. Traces on the object could be followed, such as the parts and surfaces that are worn down, to better understand the cause of the damage. The results of the discovery stage feed the decisions during the idea generation process. Idea generation involves creative thinking because, at this stage, the repairer starts to think about repair solutions for the damaged product. The repairer develops design ideas following the steps of making aesthetic and structural decisions, and considering the reproducibility of repair. To find successful solutions, the repairer can consider and research alternative methods and materials for the repair. The idea generation stage and the research stage are usually intertwined but they could be processed separately depending on the specific requirements of the repair process. Which materials, methods, and tools are needed to implement the repair are researched at the research stage. Amateur repairers can search for online repair videos or contact experts for more information. Lastly, the decisions made, and the solutions developed during the idea generation stage, are implemented at the implementation stage. Prototyping is an effective way to explore and observe whether the solutions work for the particular damage that the repairer is dealing with or not. This stage usually proceeds iteratively with the previous stages. If the identified repair solution fails, the repairer could go back to the discovery or idea generation stage to develop a better solution. The activities of the assignment were designed in a way to fit into this repair design process. Students were informed and directed about the different stages of the process during the studio discussions.

Figure 5. The repair design process includes discovery, idea generation, research, and implementation stages.

In this assignment students dealt with the real problems of repair, instead of imagining the breakdown reasons and possible problems that could occur with a newly designed product. In the case of the saucepan handle, Student 16 solved a couple of problems in a real-world context. For example, she needed to find the metal connection piece that connects the handle to the lid. Then, she designed a new longer-lasting handle to replace the broken one. As the connection piece was not available online or in any hardware store, she needed to contact the producer. This process showed the difficulties with repairing objects in the real world. Designing a new object was a design-focused activity whereas designing repair was a repair-focused activity where design was used as a means to reach the aim. When we reviewed the insights, we realised that dealing with product breakage provided different knowledge to students, compared to designing a new object and anticipating possible breakdown reasons.

Each year, analysis of the collected data resulted in different insights, but as it can be seen in Table 1, the third year’s research did not yield any new findings. The point of reaching data saturation is achieved when further data adds no new information to the research aim, and when there is enough information to replicate the study [22]. Data saturation was achieved in this research when the data became repetitive and did not necessarily add anything new to the aim of the research. In the third year, no additional data were found to develop new categories, so this research was concluded.

This entry is adapted from the peer-reviewed paper 10.3390/su131810067

References

- Ellen MacArthur Foundation. Towards the Circular Economy Vol. 1: An Economic and Business Rationale for an Accelerated Transition; Ellen MacArthur Foundation: Cowes, UK, 2012; Volume 1.

- Van den Berg, M.R.; Bakker, C.A. A product design framework for a circular economy. In Proceedings of the Product Lifetimes and the Environment Conference, Nottingham, UK, 17–19 June 2015; Cooper, T., Braithwaite, N., Moreno, M., Salvia, G., Eds.; Nottingham Trent University: Nottingham, UK, 2015.

- Bocken, N.M.; De Pauw, I.; Bakker, C.; Van der Grinten, B. Product design and business model strategies for a circular economy. J. Ind. Prod. Eng. 2016, 33, 308–320.

- Ghisellini, P.; Cialani, C.; Ulgiati, S. A review on circular economy: The expected transition to a balanced interplay of environmental and economic systems. J. Clean. Prod. 2016, 114, 11–32.

- Ramirez, M. Sustainability integration in industrial design education: A worldwide survey. In Proceedings of the Connected 2007 International Conference on Design Education, Sydney, Australia, 9–12 July 2007; The University of New South Wales: Sydney, Australia, 2007.

- Andrews, D. The circular economy, design thinking and education for sustainability. Local Econ. 2015, 30, 305–315.

- Findeli, A. Rethinking design education for the 21st century: Theoretical, methodological, and ethical discussion. Des. Issues 2001, 17, 5–17.

- Norman, D. Why Design Education Must Change. 2010. Available online: https://www.researchgate.net/profile/Donald_Norman/publication/235700801_Wir_brauchen_neue_Designer_Why_Design_Education_Must_Change/links/54a2b47e0cf256bf8bb0d448.pdf (accessed on 10 November 2018).

- Scheer, A.; Noweski, C.; Meinel, C. Transforming constructivist learning into action: Design thinking in education. Des. Technol. Educ. 2012, 17, 8–19.

- Meyer, M.W.; Norman, D. Changing Design Education for the 21st Century. She Ji J. Des. Econ. Innov. 2020, 6, 13–49.

- Wever, R.; Charnley, F.; Brass, C.; Harrison, L. Preparing designers for a circular economy goldrush; exploring the implications for education. In Proceedings of the Global Cleaner Production and Sustainable Consumption Conference, Barcelona, Spain, 1–4 November 2015.

- Ramirez, M. Sustainability in the education of industrial designers: The case for Australia. Int. J. Sustain. High. Educ. 2006, 7, 189–202.

- Lofthouse, V. Social issues: Making them relevant and appropriate to undergraduate student designers. Des. Technol. Educ. Int. J. 2013, 18, 8–23.

- Ellen MacArthur Foundation. Circular Economy and Curriculum Development in Higher Education. Available online: https://www.ellenmacarthurfoundation.org/assets/downloads/higher-education/EMF_HE-Curriculum-Brochure-17-JUNE_SINGLES.pdf (accessed on 10 January 2021).

- Lilley, D.; Lofthouse, V. Sustainable design education–considering design for behavioural change. Eng. Educ. 2009, 4, 29–41.

- Papanek, V.J. Design for the Real World: Human Ecology and Social Change; Thames and Hudson: London, UK, 1971.

- Edgerton, D. The Shock of the Old: Technology and Global History since 1900; Oxford University Press: Oxford, UK, 2007.

- De los Rios, I.C.; Charnley, F.J. Skills and capabilities for a sustainable and circular economy: The changing role of design. J. Clean. Prod. 2017, 160, 109–122.

- Sumter, D.; De Koning, J.; Bakker, C.; Balkenende, R. Circular economy competencies for design. Sustainability 2020, 12, 1561.

- Wiek, A.; Withycombe, L.; Redman, C.L. Key competencies in sustainability: A reference framework for academic program development. Sustain. Sci. 2011, 6, 203–218.

- Terzioglu, N. Do-fix workshops: Understanding users’ product repair experience. In Proceedings of the PLATE 2017 Conference, Delft, The Netherlands, 8–10 November 2017.

- Fusch, P.I.; Ness, L.R. Are we there yet? Data saturation in qualitative research. Qual. Rep. 2015, 20, 1408.

This entry is offline, you can click here to edit this entry!