Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Subjects:

Engineering, Mechanical

Friction stir processing (FSP) is a material processing technique developed in 1999 derived from friction stir welding (FSW). Developed by Mishra et al., this process utilizes localized plastic deformation by rotating a specialized pin through the working piece.

- friction stir processing

- steel

- dynamic recrystallization

- wear

- corrosion

- erosion

1. Introduction

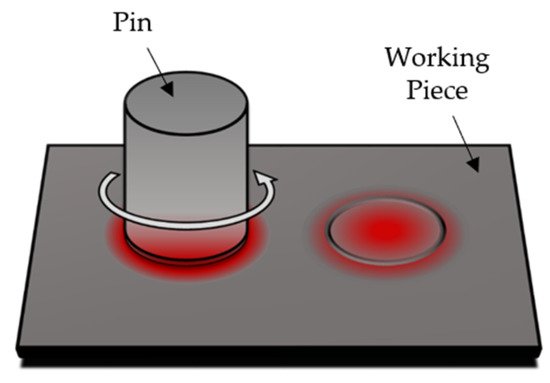

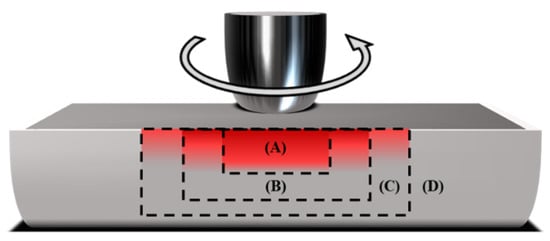

Friction stir processing (FSP) is a material processing technique developed in 1999 derived from friction stir welding (FSW). Developed by Mishra et al. [1,2], this process utilizes localized plastic deformation by rotating a specialized pin through the working piece [3], as shown in Figure 1. Typically, these specialized pins tend to vary in geometry depending on the experiment, whether optimizing material flow or increasing the frictional heat and plastic deformation along the processed region [4]. These pins are selected based on various characteristics, which can broadly impact the final surface finish [5,6]. When considering a pin, the selected material should have a suitable wear resistance against the working piece. For example, the suitable pin materials for FSP on steel are Tungsten and Molybdenum. This is crucial in order to sustain the long-term usage of the tooling piece. Of course, this implies that the tooling piece will have a combination of high toughness and strength for a variety of temperature ranges with the working temperature of the pin being within the range of 60–80% of the absolute melting temperature [7]. Considering these points, the thermal fatigue strength should be optimized while maintaining a low thermal expansion coefficient [5]. Nonetheless, the geometry of the tool tends to have largely impact the final metallurgical properties of the processed material which can dictate part performance [6,8]. As the pin is plunged into the substrate, the processed region experiences localized frictional heating, thus softening the material and refining various material properties, which is typically a consequence of the grain refinement from the plasticized metal [9,10].

Figure 1. A schematic of a performed FSP process. In this figure, the rotating pin is plunging into a singular area of the working piece.

Taking a macroscopic view of FSP, surface process techniques such as plasma spraying and high-velocity oxy-fuel coatings [11,12] tend to pale in comparison to this process due to various distinct advantages. These advantages span from its technical flexibility, energy efficiency, environmental impacts, and of course, its ability for metallurgical optimization [3,13]. The metallurgical benefits are primarily related to the grain refining nature of FSP, which acts as the primary studied mechanism of FSP [14]. However, it has been noted that the heating from the processed zone tends to densify the surface, which can enhance the mechanical, corrosive, and tribological properties of the substrate [15]. It is particularly beneficial for the components fabricated using additive manufacturing (AM) techniques which typically suffer from microscopic porosity [16]. Given the popularity in additive based technologies [17], the study of FSP on components by AM techniques such as selective laser melting (SLM) [18], cold-spraying (CS) [19], and electron beam melting (EBM) [20] has been progressively increasing throughout the years. In fact, this increase in popularity has inspired many to use FSP as an additive manufacturing technology itself, which is commonly referred to as friction stir additive manufacturing (FSAM) [21]. Although a relatively new field of research, FSAM is proposed to be a better alternative to other AM techniques due to its conservation in production cost while maximizing the scale of production and its structural performance [22]. In essence, this technique is relatively simple where plates are continually added on top of each other and lap welded [23]. Acting as a quick and easy technique, this sector of research is one of the upcoming topics that should be observed closely in the coming years.

On the same note, for non-additive based FSP, many utilize this technique due to its great repeatability and dimensional stability when used. With the process being a one-step technique, it allows for ease of automation [24]. There is a low energy consumption rate with this process as the material enhancing mechanisms are due to frictional and plastic deformation. Lastly, this process also yields the benefits of eliminating the use of solvents, noise reduction, and mitigating the by-product of fumes, opposed to other processing methods which enable it as an appropriate choice for a green and efficient process [13]. This is primarily related to its simple singular step process (Figure 1), which can be easily programmed and replicated. On an industrial scale, it is predicted that FSP can result up to 95% reduction of energy used in heat treatment processes by improving the mechanical, tribological, corrosion, erosion, and general surface properties [25]. By utilizing these advantages, FSP has gained much traction since its introduction in industries such as military, naval, aerospace, automotive, and computing [26].

From an application perspective, FSP can be very useful as a post-surface processing technique. For example, explosive welding (EW) is a widely used fusion technique where metal plates can be cladded together in one singular step via instantaneous explosions. Although useful from a time efficiency timepoint, the intense temperature and pressure shockwave from the explosion result with surface defects such as cracks, holes, and voids [27]. Considering that large scale vessels and offshore structures largely employ EW, the usefulness of FSP is evident as it can easily repair their surfaces multiple times throughout their lifetimes. Of course, other industries such as chemical processing equipment and refineries utilize also exhibit poor surface qualities from EW can also see benefits from FSP [28]. Considering the number of publications in this subject, there has been a drastic increase overtime with the number of publications increasing from 16,800 in 2010 to 93,800 in 2020 demonstrating the popularity of this processing technique [29].

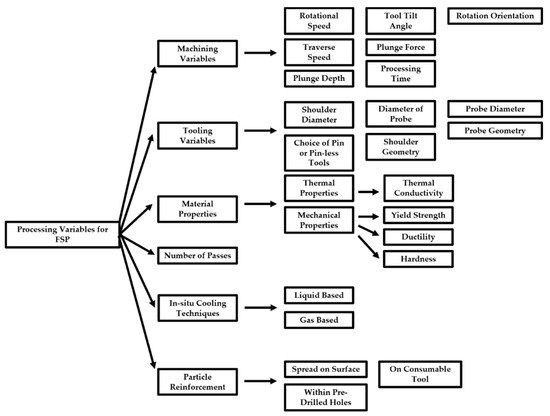

The most common practice to perform FSP is rotating the specialized tool and moving it along a single linear direction along the workpiece [30]. However, this method is one of many that scientists use to investigate FSP operations. When using this process, there are numerous variables (aside from path direction) the operator can manipulate in order to refine the material. Such variables can be categorized into six broad categories based on the current state of literature. These categories consist of (1) machine variables, (2) tool design variables, (3) material properties, (4) number of passes, (5) active cooling techniques, and (6) particle reinforcement, as shown in Figure 2 [1,10,31]. When considering machine variables, there are a total of 8 different parameters which are typically altered in FSP. In general, these machining variables tend to impact the material flow of the process as well as the heat distribution of the substrate. It can be generalized that for higher melting point materials, the heat input should be higher, which can be manipulated by variables such as greater rotational speeds or longer processing times. In contrast, lower melting point materials should have the opposite [32]. In addition, other variables come into play, such as tooling geometries, the number of passes, and cooling techniques, which can enable a greater strain rate due to super-plasticity [33].

Figure 2. A detailed depiction of the effects of different processing variables on FSP steels.

2. Microstructural Mechanisms of Friction Stir Processing

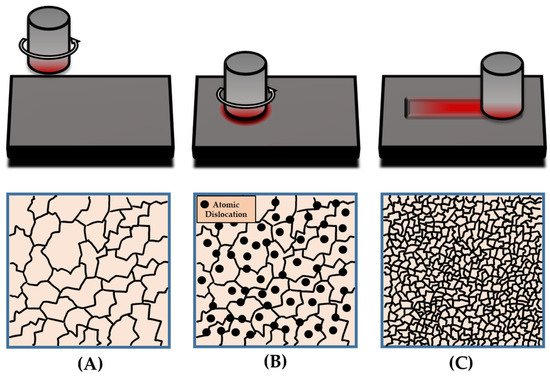

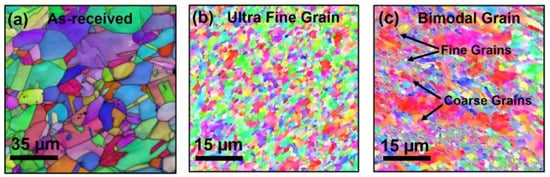

In a broad sense, the manipulation of the previously discussed variables tends to largely affect the mechanical, microstructural, corrosion, friction, and wear properties of various materials [10,34,35,36]. However, these properties are tailored by the refinement of the grain [37]. This is achieved by a microstructure altering mechanism called dynamic recrystallization (DRX). It should also be mentioned that DRX can be segmented into four distinct sub-mechanisms called continuous DRX (CDRX), discontinuous DRX (DDRX), twinning induced dynamic recrystallization (TDRX), and geometric dynamic recrystallization (GDRX), depending on the material type [38,39]. In order to induce DRX, a strain-induced deformation must occur to the working piece [40]. Depending on the amount of strain exhibit on the material, atoms within the working piece are dislocated, thus allowing for the nucleation of new grains [41]. As these grains become re-nucleated, finer grain sizes are created, thus enhancing the microstructural properties of the material [42]. The general concept of DRX via FSP processes is shown in Figure 3. Additionally, to better visual the microstructural changes from FSP, electron backscatter diffraction (EBSD) images of dual-phase bimodal steel are also provided in Figure 4 [43].

Figure 3. A schematic of the dynamic recrystallization process consisting of the (A) material in its base form, (B) the initial plunge into the working material, thus inducing severe atomic dislocations (shown by circles), (C) the reorientation of the atomic structure and the finalized grain structure.

Figure 4. A representation of the ultrafine microstructural refinement of dual-phase bimodal steel (a) before and (b–c) after FSP, reprinted with permission from Arora et al. [43], under CC BY 4.0; published by Scientific Reports, 2019.

Further exploring these mechanisms, CRDX is enabled by increasing dislocation slips due to thermal and strain-induced operations. As this happens, the lattice structure rotates with the sub-grain boundaries becoming high angled and, in consequence, more refined [44,45,46]. In contrast to this, DDRX is enabled by local elongation of the base grain or twin boundaries. During this migration, nucleation of the grain boundaries is initiated, thus resulting in grain refinement [39]. GDRX has been noted to occur during severe plastic deformation where grains impinge roughly two times the original grain size [47]. The most novel mechanism to date, however, is TDRX. Namely, this occurrence differs from the other stated mechanisms in the aspect that multiple processes can enable this recrystallization process. One process is related to the strain-induced transformation of high angle grain boundaries (HABG) from original twin boundaries (TB). In some instances, TBs will slip and migrate due to the annealing effect of frictional heating. This will result in the grains re-nucleating into equiaxed morphologies [45]. However, it should be noted that regardless of the mechanism, the grain size will be refined, thus improving the properties of the material.

Post FSP, the processed zone can be categorized into four distinct regions. These regions consist of the stir region (SR), thermo-mechanical affected zone (TMAZ), heat affected zone (HAZ), and the base material (BM) [7]. Figure 5 demonstrates this with respect to the utilized tool in-vivo. What differentiates these zones from each other is the general change of grain size away from the area of contact [44]. Through a direct impact of shear stress from the tool as well as the frictional heat, the area of contact is identified as the BM. This region will have the finest grain size in comparison to all of the other zones. Moving directly out of the HAZ is the TMAZ. This area is greatly impacted by processing, thus resulting in finer grains. Outside of this region then exists the HAZ, where the frictional heat still impacts the sample. As the grains begin to increase in size, the last region of the worked piece is identified as the base metal (BM) where its properties are unaffected by the FSP operation [48].

Figure 5. A depiction of the general processing zones derived from FSP. Zone A depicts the stir region (SR). Zone B is the thermomechanical affected region (TMAZ). Zone C is the heat affected zone (HAZ) and Zone D is the base material (BM).

Understanding the basics of FSP, a vast amount of literature focuses on the processing of soft-based metals due to their structural uses in industries such as aerospace and transportation [49]. Considering that softer metals such as aluminum or magnesium have a relatively low toughness high ductility, the high strain rate induced from processing can result with impactful improvements to their metallurgical properties [50]. In contrast to this, harder metals such as titanium, nickel, cobalt, and steel are often overlooked in research compared to softer metals due to their high melting points [51]. However, the growth of scientific knowledge in this topic has enabled new insights on how tougher materials can be improved from this refining process. In particular, steel is one of the most widely industrialized materials in this list being used in various industrial sectors such as transportation, aerospace, and medicine [52,53,54]. However, due to the intrinsic limitations of steel, there is an increasing need to enhance its metallurgical properties, thus expanding its long-term usability. Typically the primary concerns are found from excessive material degradation as well as corrosion over long periods of time [55]. In fact, several studies found that a total of $2.5 trillion is lost annually due to corrosion [56,57]. The primary industries which are affected can span from transportation, to infrastructure and manufacturing. Keeping this in mind, large sums of money can be lost overtime due to this which generates an increasing need for its optimization.

Understanding the economic impacts of excessive material degradation, this review will specifically focus on the advancements of knowledge of FSP for steel and how its tribological and corrosion-based properties are enhanced due to the microstructural refinement and material densification from FSP [58]. Although there exists a basic literature review regarding the impacts of FSW for steel [59], this review differs in the aspect that we will be focusing on the processing of steel rather than the joining of it. This, in turn, creates a larger discussion of tribological and corrosion responses from processing compared to the weld quality characteristics found from FSW. From this review, we hope to establish a valuable source for researchers in this field to refer to when pursuing this research with insightful discussions of the future developments and voids that should be addressed in this field of research [59].

This entry is adapted from the peer-reviewed paper 10.3390/jmmp5030097

This entry is offline, you can click here to edit this entry!