Citric acid (CA) can be found naturally in fruits and vegetables, particularly citrus fruit. CA is widely used in many fields but its usage as a green modifying agent and binder for wood is barely addressed. Esterification is one of the most common chemical reactions applied in wood modification. CA contains three carboxyl groups, making it possible to attain at least two esterification reactions that are required for crosslinking when reacting with the hydroxyl groups of the cell wall polymers. In addition, the reaction could form ester linkages to bring adhesivity and good bonding characteristics, and therefore CA could be used as wood binder too. The environmental impacts and future outlook of CA-treated wood and bonded composite are considered.

- Citric acid

- wood modification

- wood adhesive

- esterification

1. Introduction

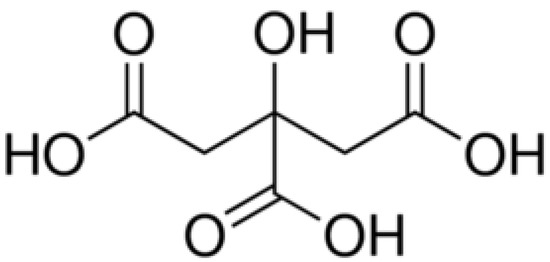

Citric acid (CA) is an organic acid with the formula C6H8O7, as shown in Figure 1. Owing to the fact that the anion can be stabilized by intramolecular hydrogen-bonding from other protic groups on CA, CA is a slightly stronger acid than typical carboxylic acids [1]. CA is also called different names, such as 2-hydroxy-1,2,3-propanetricarboxylic acid, β-hydroxytricarballyic acid, 3-carboxy-3-hydroxypentanedioic acid, and 3-carboxy-3-hydroxypentane-1,5-dioic acid [2]. CA could be found naturally from a variety of fruits and vegetables, particularly citrus fruits such as oranges, tangerines, lemons, limes, and pomelos. Penniston et al. [3] stated that lemons and limes are among the citrus fruits that contain a higher concentration of CA, which amount to 8% of the dry weight of the fruits.

Figure 1. Chemical structure of citric acid.

CA is odourless and exists in white coloured crystalline powder form at room temperature. Moreover, CA also exists in two other forms, namely anhydrous and monohydrate forms. The former is crystallized from hot water while the latter from cold water. Both forms have different molar masses, namely 192.123 g/mol and 210.14 g/mol, respectively. The density of CA in both forms are different too, whereas anhydrous has a density of 1.665 g/cm3, the density for monohydrate is 1.542 g/cm3. The melting point of CA is 156 °C. At 175 °C, CA starts to decompose through the loss of carbon dioxide and water.

The discovery of CA could be traced back to eighth century. Abu Musa Jabir ibn Hayyan, also known as Geber, was a renowned Islamist alchemist in the eighth century. He was credited for the first discovery of CA, the sour component of lemons and other unripe fruits [4]. In 1923, the Currie-Thom fermentation process discovered by food chemist James Currie and microbiologist Charles Thom was commercialized.

CA is widely used as a pharmaceutically active substance in pharmaceuticals, personal care, and cosmetic products, as an acidulant and pH stabilizer in beverages, blood anticoagulants, as well as diuretic and flavoring agents [5]. In recent years, many emerging uses of CA have also been identified, e.g., crosslinker, disinfectant, environmental remediation, and extracting agent [5]. However, despite the versatility of CA, the reports on its usage as a wood modifying agent and wood adhesive are relatively scarce. As a major aminoplastic resin that is prevalently used for the manufacturing of wood-based composites, urea formaldehyde (UF) resin is claimed as the main source of formaldehyde emitted indoors [6]. The continuous emission of formaldehyde will subsequently lead to a medical condition called sick house syndrome, whereby the occupant experiences various symptoms such as headache, nose and throat irritation, and fatigue [7]. Therefore, many countries have already imposed a more stringent rule in limiting the level of emissions. On account of that, the application of a non-formaldehyde-based resin or green binder such as CA could be a partial solution for the issue. In the recent years, there are many studies dealing with the synthesis of environmentally friendly wood adhesives in response to environmental protection. The green wood adhesives include glyoxalated corn stalk lignin-based wood adhesive [8], sucrose and ammonium dihydrogen phosphate (ADP) adhesive [9],[10], defatted soybean flour-based wood adhesive [11], tannin–sucrose adhesive [12], and many other types of wood adhesive.

2. Citric Acid for wood modification

Generally, the modification of wood using CA could result in several advantages and disadvantages to the treated wood. The advantages including reduction in water absorption (WA), improved resistance against termites and fungi, improved modulus of elasticity (MOE) and compression strength and better dimensional stability. Meanwhile, no improvement in weathering resistance, reduction in modulus of rupture (MOR), reduction in impact strength and yellowing of the treated wood are among the disadvantages of CA treatment. In wood modification, CA could be used alone or added with other reactants to enhance its effectiveness. The reactants employed include glycerol, glucose, and sorbitol.

3. Citric Acid as Main Bonding Component for Wood Composites

Declining use of non-renewable fossil resources is anticipated to restrict the usage of conventional synthetic resins in the near future. In addition, conventional synthetic resins such as UF resin release formaldehyde that are detrimental to human health. Several countries in the world have already imposed stringent regulation in limiting the formaldehyde emission from the wood-based panels. A non-formaldehyde-based resin or green binder are therefore in high demand. On account to that, CA, also called 2-hydroxy-1,2,3-propanetricarboxylic acid, is potentially to be applied as a green binding agent to produce particleboard with no formaldehyde emission.CA has been used as main bonding agent for four types of wood-based composites, namely wood-based molding, particleboard, fibreboard, and veneer-based panels (plywood and laminated veneer lumber). Among them, particleboard is the most extensively studied.

4. Environmental Impact and Future Outlook

4.1. Environmental Impact of CA-Treated Wood

Modifying wood with CA, a green renewable chemical, is expected to be able to enhance the performance of a product and reduce the final environmental footprint. Logically, modified wood is expected to possess longer service life expectancy compared to that of the untreated wood and subsequently lower maintenance requirements [13]. This is owing to the fact that modified wood is normally bestowed with enhanced technological performance [14], reduced hygroscopicity, and improved durability after treatment [14]. There is only one study regarding the environment impacts of CA-treated wood found. Essoua et al. [15] studied the environmental impacts of CA and glycerol treated Lodgepole pine wood siding and the damage impact categories was evaluated using life cycle assessment (LCA). After treatment with CA, the treated siding has 2.8 times longer life expectancy than the untreated ones. For land occupation and impact for respiratory organics categories, CA-modified siding exhibited 80% and 44% lower impact, respectively, compared to that of untreated siding. Overall, CA-treated wood siding gives more impact to the environment than the untreated siding.

When simplified into five simple stages, which is production, distribution, installation, maintenance and end of the life, the production stage of treated wood siding presented the most environmental impacts, followed by maintenance stage. The production and maintenance stage respectively contributed 88.2% and 11.8%. Energy and material consumed in the CA production is one of the important factors that contributing to this finding. On the contrary, 99.9% of the total resources impact in untreated wood siding are contributed by the production stage where 82.9% comes from timber processing including extraction, sawing, drying and planning. It should be noted that all of the assessment made is based on the scenario where both treated and untreated has a service life expectancy of 20 years. It is reported that CA-modified wood would become more ecofriendly than untreated wood siding only when the service life expectancy of the treated wood siding reaches 55 years, which is five times that of untreated wood siding [15]. Therefore, future study should be focused on identifying low environmental impact treatments.

4.2. Future Outlook

Due to the rapid growth of food additives in the processed food industry, in the year of 2014, the global market of CA has reached USD 2.6 billion. It is expected to achieve USD 3.6 billion by the year of 2020 with a projection compound annual growth rate (CAGR) rate of 5.5%. The largest share in the market are dominated by European region in the year of 2014 as a result of flourishing processed food and beverage market. Food industry is still the leading industry in the application of CA [16]. However, the application of CA in the wood-based industry is believed to be expanded in the near future had its potential been fully excavated. One of the driven factors is the environmental issue. Environmental awareness among the consumers increased continuously in the recent years as a response to the climate policy actions [17]. At the same time, industries have been urged for adapting a transformation from a waste intensive linear economy system toward a less waste-producing and longer lifetime production-consumption system due to the emergence of so-called circular economy policy [18],[19]. One of the corresponding strategies that needed to be taken by the industries is to produce products with longer durability and better recyclability [20]. Modified wood automatically becomes the target as it would influence the recyclability of the wood and subsequently its environmental footprint. Nevertheless, studies on the particular topic in assessing the possibilities and challenges in recycling of modified wood is relatively scarce.

Modified wood products have become popular since the 2000s. Criticism received for the toxicity nature of traditional preservative treatment in combination with the dwindling sources of naturally durable tropical hardwoods has diverted the world’s attention to modified wood. Up until now, the role of modified wood has been insignificant in the circular economy. However, Sommerhuber et al. [21] believed that its market share will be expanded. Subsequently, the needs for recycling modified wood will also increase. Therefore, the task in ensuring the recovered raw materials and subsequent products free from any toxic chemical are most vital. All of this favours the application of a green modifying agent such as CA.

4.3. Economic Perspective

From the aspect of green binder for wood composite, the application of CA is expected to face some challenges as CA is strongly dependent on its market price. The price of commercialized CA is ranging from USD 0.70 to USD 2.00 per kilogram [22]. CA production was once a lucrative sector. Unfortunately, the high cost of raw materials and energy has changed the scenario in the recent years. If this situation persisted, it will hinder the willingness of manufacturers to adopt CA as a replacement for conventional wood adhesive. Therefore, seeking a more economical substrate or processing pathway is an urgent priority in order to reduce the cost of production [23].

5. Conclusions

CA has been studied and recognized as an environmentally friendly compounds to improve some selected properties of the modified wood. Apart from that, CA has also been proven able to substitute synthetic resin as a binding agent for the manufacturing of wood-based panels. The application of CA as a modifying agent and binder for wood has been reviewed in this paper. The following summaries can be drawn based on the review of the present literatures and works:

-

Wood modified with CA displayed an improvement in MOE, compression strength and dimensional stability and biological resistance as well as reduced WA.

-

Glycerol, glucose, and sorbitol can be combined with CA to resulted in a better treatment.

-

Several factors have been identified as able to affect the effectiveness of CA treatment on wood, namely catalyst type, wood species, and curing temperature. Apart from SHP, chlorhydric acid (HCl) and para-toluenesulphonic acid (p-TSA) are also among the most effective catalyst. A temperature of at least 140 °C is required to ensure the polyesterification occurs to a greater extent.

-

In the fabrication of wood-based composites, CA alone could attain sufficient bonding properties for the resultant boards. However, sucrose and starch could be added to improve some selected properties of the boards.

-

For the manufacturing of particleboard, particleboard with the optimum properties could be attained when 20 wt % of CA/sucrose adhesive with ratio of 25/75 (CA/sucrose) was pressed at a temperature >180 °C for 10 min, with the condition that pre-drying treatment of 12 h at 80 °C was adopted.

-

Contrarily, bonding the flat surfaces involves a completely different application compared to particleboard and fiberboard. Therefore, to fabricate CA/sucrose-bonded plywood with acceptable performance, one has to: 1) synthesize the CA/sucrose adhesive with ratio of 75/25 (CA/sucrose) at 100 °C for 2 h, and 2) hot-press the plywood at 190 °C for 7 min using a glue spread rate of 140 g/m2.

-

One of the challenges faced by CA is that it requires a higher pressing temperature and longer pressing time. Further study should be conducted to match the industrial practice.

This entry is adapted from the peer-reviewed paper 10.3390/polym12081692

References

- Apelblat, A. Citric acid; Apelblat, A, Eds.; Springer: Cham, Switzerland, 2014; pp. 213-266.

- He, Z.; Umemura, K. Bio-based Wood Adhesives: Preparation, Characterization, and Testing; He, Z., Eds.; CRC Press: Boca Raton, Florida, 2017; pp. 221-238.

- Kristina L. Penniston; Stephen Y. Nakada; Ross P. Holmes; Dean G. Assimos; Quantitative Assessment of Citric Acid in Lemon Juice, Lime Juice, and Commercially-Available Fruit Juice Products. Journal of Endourology 2008, 22, 567-570, 10.1089/end.2007.0304.

- Jabir Ibn Haiyan (Geber) . MUSLIM SCIENTISTS, 700 - 1500 C.E.. Retrieved 2020-7-31

- Rosaria Ciriminna; Francesco Meneguzzo; Riccardo DeLisi; Mario Pagliaro; Citric acid: emerging applications of key biotechnology industrial product. Chemistry Central Journal 2017, 11, 22, 10.1186/s13065-017-0251-y.

- Aizat Ghani; Zaidon Ashaari; Paiman Bawon; Seng Hua Lee; Reducing formaldehyde emission of urea formaldehyde-bonded particleboard by addition of amines as formaldehyde scavenger. Building and Environment 2018, 142, 188-194, 10.1016/j.buildenv.2018.06.020.

- A. Kanazawa; I. Saito; A. Araki; M. Takeda; Mingyue Ma; Yasuaki Saijo; Reiko Kishi; Association between indoor exposure to semi-volatile organic compounds and building-related symptoms among the occupants of residential dwellings. Indoor Air 2010, 20, 72-84, 10.1111/j.1600-0668.2009.00629.x.

- Sen Wang; Yalan Yu; Mingwei Di; Green Modification of Corn Stalk Lignin and Preparation of Environmentally Friendly Lignin-Based Wood Adhesive.. Polymers 2018, 10, 631, 10.3390/polym10060631.

- Zhongyuan Zhao; Shijing Sun; Di Wu; Min Zhang; Caoxing Huang; Kenji Umemura; Qiang Yong; Zhao; Sun; Wu; et al. Synthesis and Characterization of Sucrose and Ammonium Dihydrogen Phosphate (SADP) Adhesive for Plywood. Polymers 2019, 11, 1909, 10.3390/polym11121909.

- Zhongyuan Zhao; Shin Hayashi; Wei Xu; Zhihui Wu; Soichi Tanaka; Shijing Sun; Min Zhang; Kozo Kanayama; Kenji Umemura; A Novel Eco-Friendly Wood Adhesive Composed by Sucrose and Ammonium Dihydrogen Phosphate.. Polymers 2018, 10, 1251, 10.3390/polym10111251.

- Binghan Zhang; Jin Li; Yufei Kan; Jianfang Gao; Yuehong Zhang; Zhenhua Gao; The Effect of Thermo-Chemical Treatment on the Water Resistance of Defatted Soybean Flour-Based Wood Adhesive.. Polymers 2018, 10, 955, 10.3390/polym10090955.

- Zhongyuan Zhao; Yanfeng Miao; Ziqian Yang; Hua Wang; Ruijuan Sang; Yanchun Fu; Caoxing Huang; Zhihui Wu; Min Zhang; Shijing Sun; et al. Effects of Sulfuric Acid on the Curing Behavior and Bonding Performance of Tannin⁻Sucrose Adhesive.. Polymers 2018, 10, 651, 10.3390/polym10060651.

- Hill, C.A.S; Wood modification: An update. BioResources 2011, 6, 918-919, .

- Gatien Geraud Essoua Essoua; Pierre Blanchet; Veronic Landry; Robert Beauregard; Pine Wood Treated with a Citric Acid and Glycerol Mixture: Biomaterial Performance Improved by a Bio-byproduct. BioResources 2016, 11, 3049-3072, 10.15376/biores.11.2.3049-3072.

- Essoua Gatien Geraud Essoua; Robert Beauregard; Ben Amor; Pierre Blanchet; Véronic Landry; Evaluation of environmental impacts of citric acid and glycerol outdoor softwood treatment: Case-study. Journal of Cleaner Production 2017, 164, 1507-1518, 10.1016/j.jclepro.2017.06.125.

- Citric acid market by form (anhydrous and liquid), application (food, pharmaceuticals, and cosmetics), function (acidulant, antioxidant, preservative, and sequestrant), and by region (north america, europe, asia-pacific, and row) - global forecast to 2020 . Citric acid market. Retrieved 2020-7-31

- David Lazarevic; Petrus Kautto; Riina Antikainen; Finland's wood-frame multi-storey construction innovation system: Analysing motors of creative destruction. Forest Policy and Economics 2020, 110, 101861, 10.1016/j.forpol.2019.01.006.

- Teresa Domenech; Bettina Bahn-Walkowiak; Transition Towards a Resource Efficient Circular Economy in Europe: Policy Lessons From the EU and the Member States. Ecological Economics 2019, 155, 7-19, 10.1016/j.ecolecon.2017.11.001.

- Henning Wilts; Meghan O’Brien; A Policy Mix for Resource Efficiency in the EU: Key Instruments, Challenges and Research Needs. Ecological Economics 2019, 155, 59-69, 10.1016/j.ecolecon.2018.05.004.

- Henrik Heräjärvi; Janni Kunttu; Elias Hurmekoski; Teppo Hujala; Outlook for modified wood use and regulations in circular economy. Holzforschung 2020, 74, 334-343, 10.1515/hf-2019-0053.

- Philipp F. Sommerhuber; Johannes Welling; Andreas Krause; Substitution potentials of recycled HDPE and wood particles from post-consumer packaging waste in Wood–Plastic Composites. Waste Management 2015, 46, 76-85, 10.1016/j.wasman.2015.09.011.

- Vandenberghe, L. P. S.; Rodrigues, C.; De Carvalho, J. C.; Medeiros, A. B. P.; Soccol, C. R. . Current Developments in Biotechnology and Bioengineering; Larroche, C., Sanroman, M, Dr, G., Pandey, A, Eds.; Elsevier: Amsterdam, Netherlands, 2017; pp. 557-575.

- Gurpreet Singh Dhillon; Surinder Kaur; Saurabh Jyoti Sarma; Satinder Kaur Brar; Integrated process for fungal citric acid fermentation using apple processing wastes and sequential extraction of chitosan from waste stream. Industrial Crops and Products 2013, 50, 346-351, 10.1016/j.indcrop.2013.08.010.