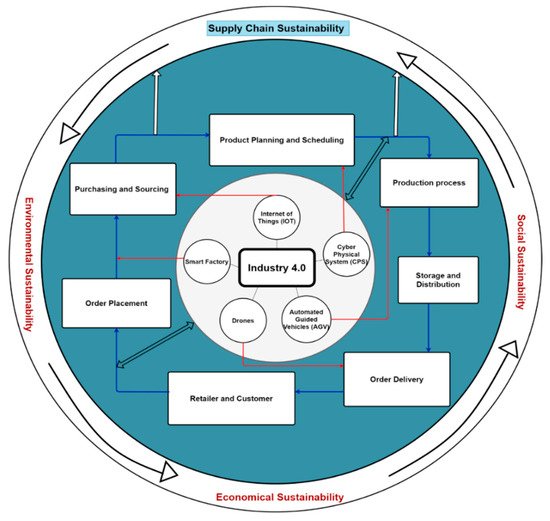

2.2. Taxonomy

This work studied two terms, namely Industry 4.0 and SCS. For Industry 4.0, we alienated Industry 4.0 into five technologies that are AGV, the IoT, the CPS, drones, and SF. Moreover, supply chain 4.0 includes SCS. In Table 3, the detailed comparison of each research article has been done according to their research focus, research methods, and results.

Table 3. Comparison of classified articles based on their focus, methods, and results.

Duarte et al. [

1] explained the relationship between lean and GSCM to smoothen the physical production process. For the virtual flow of information and data, they linked lean and GSCM with Industry 4.0, and companies can achieve a competitive advantage if they understand their characteristics. Further research can also be done to check which characteristics have more influence to achieve sustainability in the supply chain. Legenvre et al. [

2] proposed a framework by using a systematic inductive research approach to remove the issues that are associated with purchasing and the supply chain management function while installing IoT systems. They concluded that the adoption of IoT facilities in the company is the more productive approach. Matana et al. [

3] presented the model that helps to explain the association of internal logistics activities with the CPS system. Gupta et al. [

4] introduced the countermeasures and blockchain-based integrated AV architecture that helps to prevent cyberattacks and threats associated with AGV in Industry 4.0. Osterrieder et al. [

6] found eight distinct viewpoints within the concept of the smart factory based on currently available literature. Bag et al. [

8] identified 13 key enablers of Industry 4.0 that can be used to achieve sustainability in the supply chain system. Chalmeta et al. [

10] expanded the understanding of Industry 4.0 and big data in the development of a sustainable supply chain based on a literature review. They also defined six research directions for future studies. Bezai et al. [

13] presented a detailed review of automatic guided vehicles and combined the obstacles related to AV in one framework. Tang et al. [

15] examined the uses and applications of Industry 4.0 technologies. They also examined the role of logistics functions to achieve sustainability in the presence of these technologies. Yavas et al. [

16] conducted a comparison of traditional logistics centers with transformed logistics centers in Industry 4.0. Furthermore, they defined the criteria for the successful installation of smart logistics centers. Dalenogare et al proved that not all the Industry 4.0 technologies are beneficial for industrial performance and that some of the technologies can meet the expectations of industries while others are still in the adoption stage. Goodchild and Toy [

18] explained that drone delivery service is the more profitable approach for companies in the future. It also protects the environment from carbon emissions (CO

2). Moreover, they compared and explained the pons and cons of both traditional truck and drone delivery options. Wang et al. [

19] introduced an integrated IoT-based logistics system (combining the robotics and human coordination) to optimize the dispatching operations. Jeong et al. [

20] presented the idea of a humanitarian flying warehouse (HFW) that can be used for parcel delivery. Their goal was to overcome the risks and issues of ground vehicle delivery. Figliozzi [

22] compared the efficiency of both AV and ground vehicles used for last-mile delivery. Efficiency was measured in terms of vehicle capacity, range, and CO

2 emission. They found that sustainability in the supply chain can only be achieved if they adopt AV for last-mile delivery; however, this delivery system also has some disadvantages. Kirschstein [

23] summarized that drone delivery utilizes more energy than the normal conventional electric or diesel ground vehicles.

Manavalan et al. [

24] from the literature review proposed a framework that explains the adoption process and benefits of IoT-based systems in the company that led to achieving supply chain sustainability. Yadav et al. [

26] developed a framework that provides 22 ways to resolve different challenges SSC faced during the adoption of Industry 4.0. Ojo et al. [

27] emphasized that optimization of all the operations in the supply chain is essential to achieve sustainability. For this reason, they bring Industry 4.0 to the food industry. Moreover, You and Feng [

28] developed the CPS system to integrate Industry 4.0 technologies with the construction industry to flatter all the processes and pave the path for intelligent construction.

For challenges related to Industry 4.0 and supply chain sustainability, Furstenau et al. [

29] provided a literature review about Industry 4.0 and sustainability. They also point out the challenges and issues related to Industry 4.0 implementation in the industry. Chen et al. [

30] created the idea of a smart factory in the digital business era. They found core technologies that are required to build the structure of a smart factory for the purpose of increasing efficiency. Meneghello et al. [

31] examined the threats associated with IoT-based products and provided their countermeasures to overcome security risks. Xu et al. [

32] provided the gathered understanding of current IoT-based systems based on three system aspects which are control, networking, and computing. Weking et al. [

33] developed an innovative business model with the integration of Industry 4.0 technologies. They proved that this integrated BM enhances the coordination of all members in the supply chain and led the business to achieve sustainability. Palmaccio et al. [

35] found changes in the business process due to the adoption of IoT-based systems. Echchakoui and Barka [

36] found that the implementation and installation of Industry 4.0 in the plastic industry is still at the early adoption stage. They also highlighted the issues and obstacles that occur during the adoption of Industry 4.0. Zarzuelo et al. [

38] studied the effects of Industry 4.0 technologies on the maritime industry. They concluded that each technology in Industry 4.0 has its benefits and drawbacks; companies should adopt these technologies after analyzing their aftereffects. Li et al. [

37] explained the benefits of the digital supply chain on economic and environmental performance to accomplish sustainability in SC. Rosit et al. [

39] introduced the CPS-based integrated scheduling system in the company that uses real-time information to enhance the decision-making process and schedule the tasks effectively. Culot et al. [

41] through a systematic literature review, compared the different fragmented definitions of Industry 4.0 and creates a more specific definition of Industry 4.0. Reinhardt et al. [

42] identified the knowledge of Industry 4.0 in pharmaceutical companies and found that more experienced employees have more knowledge about Industry 4.0; thus, for a better understanding of Industry 4.0, there is a need for training required of all workers and employees in pharmaceutical companies in Ireland. Raj et al. [

44] identified 15 barriers in implementing Industry 4.0 in the manufacturing sector. They found that through involvement of company’s peers government bodies, and proper education of these technologies, these barriers can removed.

Lu [

47] provided detailed insights of Industry 4.0 applications on industrial sectors to achieve sustainability and achieve a competitive advantage. Choi et al. [

48] explained the involvement of Industry 4.0 technologies in the fashion industry that converts it into a sustainable fashion industry. For this, they proposed a framework that explains how sustainability can be achieved in the fashion supply chain. Liotta et al. [

49] established the framework that integrates the production and transportation process, which led the company to achieve sustainability in the supply chain. Dossou [

50] proposed a new framework that considers sustainability as a key benefit for future factories and integrates sustainability with Industry 4.0. Bai et al. [

51] explained that Industry 4.0 technologies have a positive impact on social sustainability. However, each technology should be examined carefully before implementation. Govindan et al. [

53] studied sustainability in terms of social, economic, and environmental sustainability. They found that social and environmental sustainability practices have positive impacts on firm operational and financial performance in all industrial sectors. Cole and Aitken [

54] identified that intermediates play an important role in building a strong relationship between suppliers and buyers, and led them to attain sustainability in which there is weak sustainability knowledge. Vaio et al. [

56] through a literature review, proposed a framework that explains how computer-based technologies (AI) help to achieve SCS.