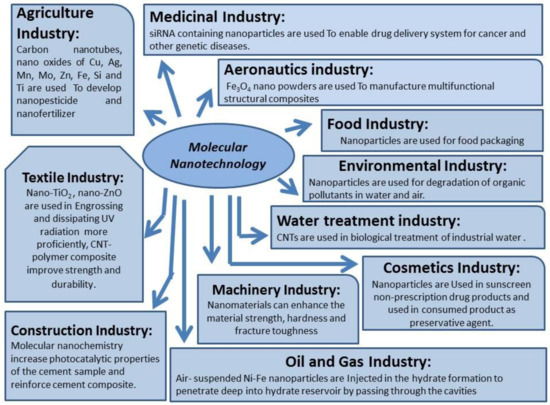

Nanomaterials have not only become one of the ‘hottest’ areas in research and development all over the world but also attracted numerous considerations in the industrial sectors. This technology can be primarily defined by their functional properties which determine how they interact with other disciplines. Recently, it becomes an evolving field in material science, materials processing technology, mechanics, electronics, optics, medicine, energy and aerospace, plastics and textiles etc. This technology not only establishes an interdisciplinary and emerging domain that embraces physics, chemistry, engineering but also contributes to detection of diseases, better therapy options, and remarkable reduced health-care expenses. Molecular nanomaterials can also be applied in manufacturing through ultra-precision, development of nano-metric microscopic devices, biological structures, nano robots, super computers, industries and genetics etc. All materials or devices which are nanometer scale (dimensions of roughly 1 to 100 nm) structured are included in nanomaterials.

- molecular nanomaterials

- industrial applications

- manufacturing

1. Introduction

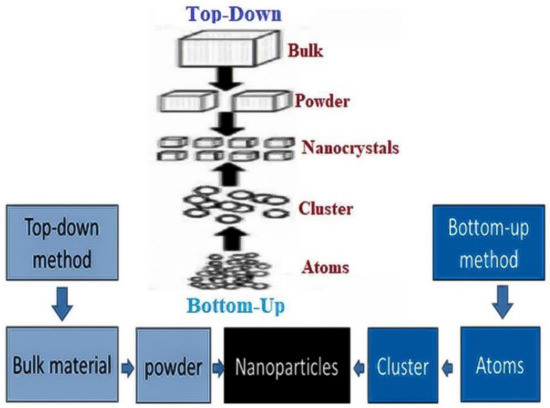

2. Fabrication and Characterization of Molecular Nanomaterials

3. Industrial Applications

3.1. Construction Industry

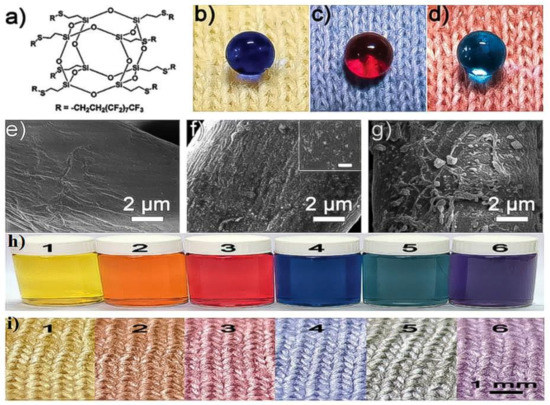

3.2. Textile Industry

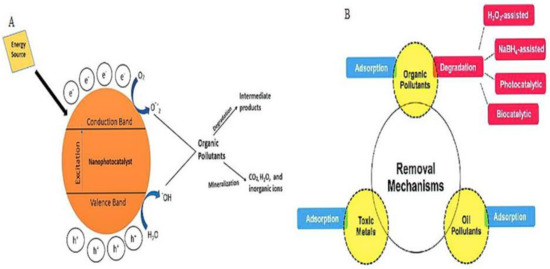

3.3. Water Treatment Industry

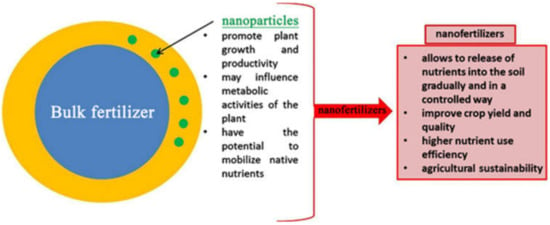

3.4. Agriculture Industry

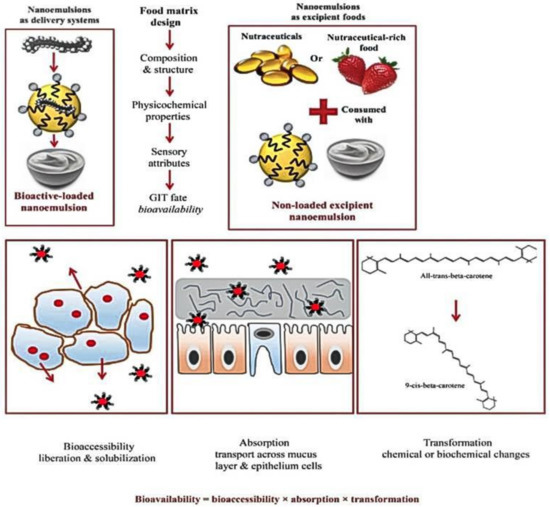

3.5. Food Industry

3.6. Aeronautics Industry

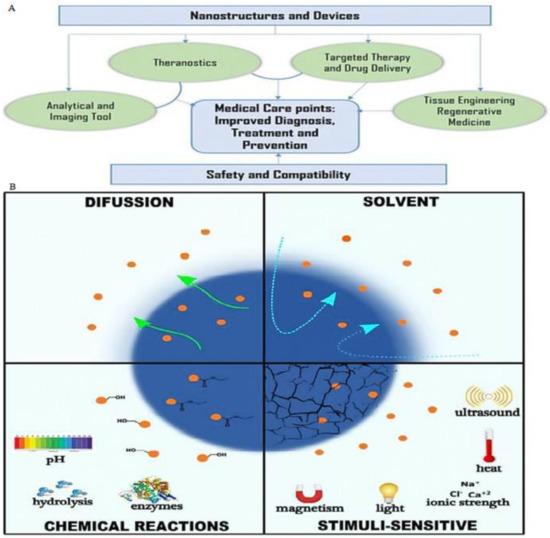

3.7. Medicinal Industry

3.8. Environmental Industry

3.9. Cosmetics Industry

3.10. Machinery Industry

3.11. Oil and Gas Industry

3.12. Computer Industry

3.13. Miscellaneous Applications of Molecular Nanomaterials

This entry is adapted from the peer-reviewed paper 10.3390/nanomanufacturing1020008

References

- Tamirat, Y. The Role of Nanotechnology in Semiconductor Industry: Review Article. J. Mater. Sci. Nanotechnol. 2017, 5, 202.

- Sobolev, K.; Gutierrez, M.F. How Nanotechnology Can Change the Concrete World Successfully mimicking nature’s bottom-up construction processes is one of the most promising directions. Am. Ceram. Soc. Bull. 2021, 84, 15–17.

- Zhu, W.; Bartos, P.; Porro, A. Application of nanotechnology in construction. Mater. Struct. 2004, 37, 649–658.

- Havancsák, K. Nanotechnology at Present and its Promise for the Future. Mater. Sci. Forum 2003, 414, 85–94.

- Silva, G. Neuroscience nanotechnology: Progress, opportunities and challenges. Nat. Rev. Neurosci. 2006, 7, 65–74.

- Asif, A.K.M.A.H.; Hasan, M.Z. Application of Nanotechnology in Modern Textiles: A Review. Int. J. Curr. Eng. Technol. 2018, 8, 227–231.

- Muñoz-Écija, T.; Vargas-Quesada, B.; Chinchilla Rodríguez, Z. Coping with methods for delineating emerging fields: Nanoscience and nanotechnology as a case study. J. Inf. 2019, 13, 100976.

- Satalkar, P.; Elger, B.; Shaw, D. Defining Nano, Nanotechnology and Nanomedicine: Why Should It Matter? Sci. Eng. Ethics 2015, 22, 1255–1276.

- Bale, A.S.; Aditya Khatokar, J.A.; Singh, S.; Bharath, G.; Kiran Mohan, M.K.; Reddy, S.V.; Satheesha, T.; Huddar, S.A. Nanosciences fostering cross domain engineering applications. Mater. Today Proc. 2021, 43, 3428–3431.

- Sawhney, A.P.S.; Condon, B.; Singh, K.V.; Pang, S.S.; Li, G.; Hui, D. Modern Applications of Nanotechnology in Textiles. Text. Res. J. 2008, 78, 731–739.

- Nigam Joshi, P. Green Chemistry for Nanotechnology: Opportunities and Future Challenges. Res. Rev. J. Chem. 2016, 5, 3–4.

- Grieneisen, M.; Zhang, M. Nanoscience and Nanotechnology: Evolving Definitions and Growing Footprint on the Scientific Landscape. Small 2011, 7, 2836–2839.

- Mulvaney, P.; Weiss, P. Have Nanoscience and Nanotechnology Delivered? ACS Nano 2016, 10, 7225–7226.

- Deng, L.; Hu, W.; Deng, H.; Xiao, S. Surface Segregation and Structural Features of Bimetallic Au−Pt Nanoparticles. J. Phys. Chem. C 2010, 114, 11026–11032.

- Saratale, R.G.; Shin, H.S.; Kumar, G.; Benelli, G.; Ghodake, G.S.; Jiang, Y.Y.; Kim, D.S.; Saratale, G.D. Exploiting fruit byproducts for eco-friendly nanosynthesis: Citrus × clementina peel extract mediated fabrication of silver nanoparticles with high efficacy against microbial pathogens and rat glial tumor C6 cells. Environ. Sci. Pollut. Res. 2018, 25, 10250–10263.

- Kolahalam, L.A.; Kasi Viswanath, I.V.; Diwakar, B.S.; Govindh, B.; Reddy, V.; Murthy, Y.L.N. Review on nanomaterials: Synthesis and applications. Mater. Today Proc. 2019, 18, 2182–2190.

- Kashef, M.; Sabouni, A.R. Nanotechnology and the building industry. In Proceedings of the International Conference on Nanotechnology: Fundamentals and Applications, Ottawa, ON, Canada, 4–6 August 2010; pp. 550–558.

- Du, S.; Wu, J.; Alshareedah, O.; Shi, X. Nanotechnology in cement-based materials: A review of durability, modeling, and advanced characterization. Nanomaterials 2019, 9, 1213.

- Eftekhari, M.; Mohammadi, S.; Khanmohammadi, M. A hierarchical nano to macro multiscale analysis of monotonic behavior of concrete columns made of CNT-reinforced cement composite. Constr. Build. Mater. 2018, 175, 134–143.

- Choi, Y.C. Cyclic heating and mechanical properties of CNT reinforced cement composite. Compos. Struct. 2021, 256, 113104.

- Jayapalan, A.R.; Lee, B.Y.; Kurtis, K.E. Effect of Nano-sized Titanium Dioxide on Early Age Hydration of Portland Cement. In Nanotechnology in Construction 3; Springer: Berlin/Heidelberg, Germany, 2009; pp. 267–273.

- Meng, T.; Yu, Y.; Qian, X.; Zhan, S.; Qian, K. Effect of nano-TiO2 on the mechanical properties of cement mortar. Constr. Build. Mater. 2012, 29, 241–245.

- Santos, C.; Gabriel, B.; Blanchy, M.; Neto, V.; Santos, C.S.C.; Menes, O.; Arconada, N. Industrial Applications of Nanoparticles—A Prospective Overview. Mater. Today Proc. 2014, 2, 456–465.

- Wu, M.; Ma, B.; Pan, T.; Chen, S.; Sun, J. Silver-Nanoparticle-Colored Cotton Fabrics with Tunable Colors and Durable Antibacterial and Self-Healing Superhydrophobic Properties. Adv. Funct. Mater. 2016, 26, 569–576.

- Yaqoob, A.A.; Parveen, T.; Umar, K.; Mohamad Ibrahim, M.N. Role of Nanomaterials in the Treatment of Wastewater: A Review. Water 2020, 12, 495.

- Alvarez, P.J.J.; Chan, C.K.; Elimelech, M.; Halas, N.J.; Villagrán, D. Emerging opportunities for nanotechnology to enhance water security. Nat. Nanotechnol. 2018, 13, 634–641.

- Wang, Z.; Wang, Z.; Lin, S.; Jin, H.; Gao, S.; Zhu, Y.; Jin, J. Nanoparticle-templated nanofiltration membranes for ultrahigh performance desalination. Nat. Commun. 2018, 9, 2004.

- Jassby, D.; Cath, T.Y.; Buisson, H. The role of nanotechnology in industrial water treatment. Nat. Nanotechnol. 2018, 13, 670–672.

- Danwittayakula, S.; Jaisaib, M.; Duttab, J. Efficient solar photocatalytic degradation of textile wastewater usingZnO/ZTO composites. Appl. Catal. B Environ. 2015, 163, 1–8.

- Qian, C.; Yin, J.; Zhao, J.; Li, X.; Wang, S.; Bai, Z.; Jiao, T. Facile preparation and highly efficient photodegradation performances of self-assembled Artemia eggshell-ZnO nanocomposites for wastewater treatment. Colloids Surf. A Physicochem. Eng. Asp. 2021, 610, 125752.

- Handford, C.E.; Dean, M.; Henchion, M.; Spence, M.; Elliott, C.T.; Campbell, K. Implications of nanotechnology for the agri-food industry: Opportunities, benefits and risks. Trends Food Sci. Technol. 2014, 40, 226–241.

- Ndlovu, N.; Mayaya, T.; Muitire, C.; Munyengwa, N. Nanotechnology Applications in Crop Production and Food Systems. Int. J. Plant Breed. 2020, 7, 624–634.

- Bratovcic, A.; Hikal, W.; Said-Al Ahl, H.; Tkachenko, K.; Baeshen, R.; Sabra, A.; Sany, H. Nanopesticides and Nanofertilizers and Agricultural Development: Scopes, Advances and Applications. Open J. Ecol. 2021, 11, 301–316.

- Raliya, R.; Saharan, V.; Dimkpa, C.; Biswas, P. Nanofertilizer for Precision and Sustainable Agriculture: Current State and Future Perspectives. J. Agric. Food Chem. 2018, 66, 6487–6503.

- Chhipa, H. Nanofertilizers and nanopesticides for agriculture. Environ. Chem. Lett. 2017, 15, 15–22.

- Dimkpa, C.O.; Bindraban, P.S. Nanofertilizers: New Products for the Industry? J. Agric. Food Chem. 2018, 66, 6462–6473.

- He, X.; Hwang, H.M. Nanotechnology in food science: Functionality, applicability, and safety assessment. J. Food Drug Anal. 2016, 24, 671–681.

- Li, W.L.; Li, X.H.; Zhang, P.P.; Xing, Y.G. Development of nano-ZnO coated food packaging film and its inhibitory effect on Escherichia coli in vitro and in actual tests. Adv. Mater. Res. 2010, 152, 489–492.

- Eljeeva Emerald, F.M.; Pushpadass, H.A.; Joseph, D.; Jaya, S.V. Impact of Nanotechnology in Beverage Processing. In Innovative Food Processing Technologies, 1st ed.; Muthukumarappan, K., Knoerzer, K., Eds.; Elsevier E-book: Amsterdam, The Netherlands, 2021; pp. 688–700.

- Othman, S.H.; Abd Salam, N.R.; Zainal, N.; Kadir Basha, R.; Talib, R.A. Antimicrobial activity of TiO2 nanoparticle-coated film for potential food packaging applications. Int. J. Photoenergy 2014, 2014, 1–6.

- Ferreira, L.M.P.; Bayraktar, E.; Miskioglu, I.; Robert, M.H. Design and physical properties of multifunctional structural composites reinforced with nanoparticles for aeronautical applications. Adv. Mater. Process. Technol. 2017, 3, 33–44.

- Luna-Ochoa, S.; Robles-Belmont, E.; Suaste-Gomez, E. A profile of Mexico’s technological agglomerations: The case of the aerospace and nanotechnology industry in Querétaro and Monterrey. Technol. Soc. 2016, 46, 120–125.

- Viscardi, M.; Arena, M.; Guadagno, L.; Vertuccio, L.; Barra, G. Multi-functional nanotechnology integration for aeronautical structures performance enhancement. Int. J. Struct. Integr. 2018, 9, 737–752.

- Bazile, D.V. Nanotechnologies in drug delivery—An industrial perspective. J. Drug Deli. Sci. Technol. 2014, 24, 12–21.

- Namita Ashish, S. Nanotechnology definitions, research, industry and property rights. In Nanoscience in Food and Agriculture 1, Sustainable Agriculture Reviews 20; Ranjan, S., Dasgupta, N., Lichtfouse, E., Eds.; Springer International Publishing: Basel, Switzerland, 2016; pp. 43–64.

- Palit, S.; Hussain, C.M. Nanodevices applications and recent advancements in nanotechnology and the global pharmaceutical industry. In Nanomaterials in Diagnostic Tools and Devices; Kanchi, S., Sharma, D., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 395–415.

- Patra, J.K.; Das, G.; Fraceto, L.F.; Campos, E.V.R.; del Pilar Rodriguez-Torres, M.; Acosta-Torres, L.S.; Diaz-Torres, L.A.; Grillo, R.; Swamy, M.K.; Sharma, S.; et al. Nano based drug delivery systems: Recent developments and future prospects. J. Nanobiotechnol. 2018, 16, 71.

- Pathakoti, K.; Manubolu, M.; Hwang, H.M. Nanotechnology applications for environmental industry. In Handbook of Nanomaterials for Industrial Applications; Chaudhery, M.H., Ed.; Elsevier: Amsterdam, The Netherlands, 2018; pp. 894–907.

- Katz, L.; Dewan, K.; Bronaugh, R. Nanotechnology in cosmetics. Food Chem. Toxicol. 2015, 85, 127–137.

- Jaroenworaluck, A.; Sunsaneeyametha, W.; Kosachan, N.; Stevens, R. Characteristics of silica-coated TiO2 and its UV absorption for sunscreen cosmetic applications. Surf. Interface Anal. 2006, 38, 473–477.

- Leong, H.J.; Jang, I.; Hyun, K.S.; Jung, S.K.; Hong, G.H.; Jeong, H.A.; Oh, S.G. Preparation of alpha-bisabolol and phenylethyl resorcinol/TiO2 hybrid composites for potential applications in cosmetics. Int. J. Cosmet. Sci. 2016, 38, 524–534.

- García-Mesa, J.C.; Montoro-Leal, P.; Rodríguez-Moreno, A.; López Guerrero, M.M.; Vereda Alonso, E.I. Direct solid sampling for speciation of Zn2+ and ZnO nanoparticles in cosmetics by graphite furnace atomic absorption spectrometry. Talanta 2021, 223, 121795.

- Nia, S.; Hanb, F.; Wanga, W.; Hana, D.; Baoa, Y.; Hana, D.; Wanga, H.; Niua, L. Innovations upon antioxidant capacityevaluation for cosmetics: Aphotoelectrochemical sensor exploitation based on N-dopedgraphene/TiO2 nanocomposite. Sens. Actuators B 2018, 259, 963–971.

- Feng, X.; Liu, A.; Cheng, J. Applications and development of nanotechnology in machinery industry. Adv. Mater. Res. 2010, 121, 5–10.

- Hernández Battez, A.; Viesca, J.L.; González, R.; Blanco, D.; Asedegbega, E.; Osorio, A. Friction reduction properties of a CuO nanolubricant used as lubricant for a NiCrBSi coating. Wear 2010, 268, 325–328.

- Esmaeili, A. Applications of Nanotechnology in Oil and Gas Industry. In Proceedings of the Petrotech Conference, PETROTECH–2009, P09–076, New Delhi, India, 11–15 January 2009.

- Nabhani, N.; Emami, M.; Moghadam, A.B.T. Application of nanotechnology and nanomaterials in oil and gas industry. AIP Conf. Proc. 2011, 1415, 128–131.

- Ponmani, S.; Nagarajan, R.; Sangwai, J. Applications of nanotechnology for upstream oil and gas industry. J. Nano Res. 2013, 24, 7–15.

- Singh, N.A. Nanotechnology innovations, industrial applications and patents. Environ. Chem. Lett. 2017, 15, 185–191.

- Saththasivam, J.; Yiming, W.; Wang, K.; Jin, J.; Liu, Z. A Novel Architecture for Carbon Nanotube Membranes towards Fast and Efficient Oil/water Separation. Sci. Rep. 2018, 8, 7418.

- Mamalis, A.G. Recent advances in nanotechnology. J. Mater. Process. Technol. 2007, 181, 52–58.

- Jadhav, S.S.; Jadhav, S.V. Application of Nanotechnology in Modern Computers. In Proceedings of the 2018 International Conference on Circuits and Systems in Digital Enterprise Technology (ICCSDET), Kottayam, India, 21–22 December 2018.

- Mitchell, S.; Qin, R.; Zheng, N.; Pérez-Ramírez, J. Nanoscale engineering of catalytic materials for sustainable technologies. Nat. Nanotechnol. 2021, 16, 129–139.

- Malani, A.S.; Chudhari, A.D.; Sambje, R.U. A Review on Applications of Nanotechnology in Automotive Industry. Int. J. Mech. Mechatron. Eng. 2016, 10, 36–40.