Frying is commonly used by consumers, restaurants, and industries around the globe to cook and process foods. Compared to other food processing methods, frying has several potential advantages, including reduced processing times and the creation of foods with desirable sensory attributes. Frying is often used to prepare starchy foods. After ingestion, the starch and fat in these foods are hydrolyzed by enzymes in the human digestive tract, thereby providing an important source of energy (glucose and fatty acids) for the human body. Conversely, overconsumption of fried starchy foods can induce overweight, obesity, and other chronic diseases. Moreover, frying can generate toxic reaction products that can damage people’s health. Consequently, there is interest in developing alternative frying technologies that reduce the levels of nutritionally undesirable components in fried foods, such as vacuum, microwave, air, and radiant frying methods.

- vacuum frying

- microwave vacuum frying

- air frying

- food quality

1. Introduction

|

Edible Oil |

Concn (g/100 g of Fat) |

Advantages |

Disadvantages |

Ref. |

|---|---|---|---|---|

|

Soybean oil |

C18:1, oleic acid: 25.76 ± 0.21 C18:2, linoleic acid: 51.04 ± 1.26 C16:0, palmitic acid: 11.02 ± 0.03 |

The content of vitamin E is rich; The output of the world is high and the price is cheap. |

The high content of polyunsaturated fatty acids makes it easy to oxidize, and regarding rancidity, it smells like fishy beans. |

[26] |

|

Rapeseed oil |

C18:1, oleic acid: 57.7 ± 0.10 C18:2, linoleic acid: 19.0 ± 0.03 C16:0, palmitic acid: 4.74 ± 0.01 |

It has high content of monounsaturated fatty acids. |

The price is relatively high. |

[27] |

|

Sunflower oil |

C18:1, oleic acid: 26.1 ± 0.06 C18:2, linoleic acid: 58.5 ± 0.10 C16:0, palmitic acid: 6.44 ± 0.03 |

It is rich in vitamin E and chlorogenic acid with antioxidant activity. |

The content of polyunsaturated fatty acids is high and it is easy to oxidize and deteriorate. |

[27] |

|

Peanut oil |

C18:1, oleic acid: 41.07 ± 0.43 C18:2, linoleic acid: 40.01 ± 0.62 C16:0, palmitic acid: 11.63 ± 0.03 |

It has unique peanut flavour and high thermal stability; It can be fried for a short time. |

There may be a small number of phospholipids, so frying makes it easy to foam, or even overflow the pan. |

[26] |

|

Peanut oil |

C18:1, oleic acid: 41.07 ± 0.43 C18:2, linoleic acid: 40.01 ± 0.62 C16:0, palmitic acid: 11.63 ± 0.03 |

It has unique peanut flavour and high thermal stability; It can be fried for a short time. |

There may be a small number of phospholipids, so frying makes it easy to foam, or even overflow the pan. |

|

Frying Techniques |

Characteristics |

Applications |

Ref. |

|---|---|---|---|

|

Vacuum frying (VF) |

Low fat content Smooth and uniform microstructure Longer frying time |

The efficiency of vacuum frying technology is not high, so microwave and ultrasonic assisted frying can greatly improve the frying efficiency, which is conducive to the expansion of industrial production. However, the equipment is expensive, and the operation and assembly are complex, so it is still difficult to carry out large-scale mass production. |

[40] |

|

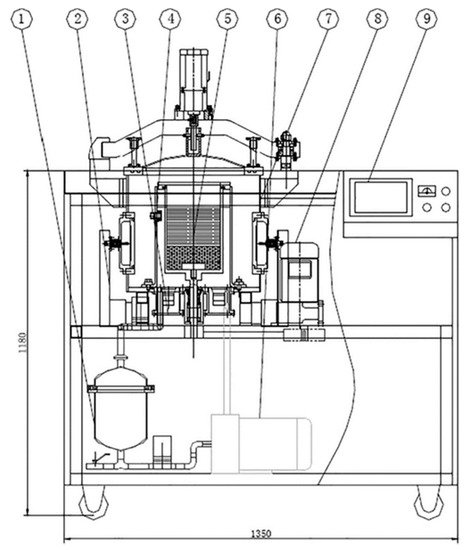

Microwave vacuum frying (MVF) |

Low moisture content Reducing the damage of food nutrients Similar taste of ordinary French fries |

||

|

Ultrasound combined microwave vacuum frying (UMVF) |

Increasing evaporation rate compared with VF and MVF Improving texture (crispness) and color, greatly shortening the frying time |

||

|

Air frying (AF) |

Reducing the amount of acrylamide and polar compounds Very low in fat Longer processing time Low degree of starch gelatinization Bad taste compared to traditional fried products |

There is no need to add extra oil when frying food, resulting in very low oil content in the final product. This makes it suitable for middle-aged and elderly people with cardiovascular and cerebrovascular diseases, such as hypertension or hyperlipidemia. The price is low and has entered thousands of households. However, its low frying efficiency is not suitable for industrial production. |

|

|

Oil-water mixed frying (OWF) |

Delaying the oxidation and polymerization degradation of oil No obvious change on the water content compared with conventional frying Similar in color, smell and flavor of conventional frying |

OWF has less decline in color, smell, flavor, and overall acceptability, which can produce healthier and better fried meat products. It is suggested that measures should be taken to slow down the hydrolysis rate of oil in the process of oil–water mixed frying in the future. |

[38] |

|

Spray frying |

Low fat content Better color of products (lighter) |

In order to improve the spray frying process, various parameters need to be optimized. |

[36] |

|

Radiant frying |

Lighter in color Less oil and more moisture than the immersion fried products |

Sensory evaluation personnel believe that the fried products taste no different from ordinary products, indicating that the fried products can be used as a feasible alternative to oil immersion frying. |

[47] |

|

Electric field frying (EFF) |

Delaying the oil degradation during frying Lower moisture content Smaller structural damage |

This technology can reduce the cost of industrial production, and future work will focus on the mechanism of electric field on fried products to improve the equipment. |

[39] |

2. Vacuum Frying

3. Microwave Vacuum Frying

4. Air Frying

5. Others

5.1. Water–Oil Mixed Frying

5.2. Spray Frying

5.3. Radiant Frying

5.4. Ultrasonic-Microwave-Assisted Vacuum Frying (UMVF)

5.5. Electric Field Frying (EFF)

This entry is adapted from the peer-reviewed paper 10.3390/foods10081852

References

- Saguy, I.; Dana, D. Integrated approach to deep fat frying: Engineering, nutrition, health and consumer aspects. J. Food Eng. 2003, 56, 143–152.

- Dana, D.; Saguy, I.S. Review: Mechanism of oil uptake during deep-fat frying and the surfactant effect-theory and myth. Adv. Colloid Interface Sci. 2006, 128–130, 267–272.

- Chen, L.; McClements, D.J.; Yang, T.; Ma, Y.; Ren, F.; Tian, Y.; Jin, Z. Effect of annealing and heat-moisture pretreatments on the oil absorption of normal maize starch during frying. Food Chem. 2021, 353, 129468.

- Tian, J.; Chen, J.; Ye, X.; Chen, S. Health benefits of the potato affected by domestic cooking: A review. Food Chem. 2016, 202, 165–175.

- Yates, R.A. Advances in deep-fat frying of foods. Int. News Fats Oils Relat. Mater. 2010, 21, 35.

- Wang, Y.; Chen, L.; Yang, T.; Ma, Y.; McClements, D.J.; Ren, F.; Tian, Y.; Jin, Z. A review of structural transformations and properties changes in starch during thermal processing of foods. Food Hydrocoll. 2021, 113, 106543.

- Chen, L.; Ma, R.; McClements, D.J.; Zhang, Z.; Jin, Z.; Tian, Y. Impact of granule size on microstructural changes and oil absorption of potato starch during frying. Food Hydrocoll. 2019, 94, 428–438.

- Chen, L.; Zhang, H.; McClements, D.J.; Zhang, Z.; Zhang, R.; Jin, Z.; Tian, Y. Effect of dietary fibers on the structure and digestibility of fried potato starch: A comparison of pullulan and pectin. Carbohydr. Polym. 2019, 215, 47–57.

- Jobling, S. Improving starch for food and industrial applications. Curr. Opin. Plant. Biol. 2004, 7, 210–218.

- Chen, L.; Tian, Y.; Sun, B.; Cai, C.; Ma, R.; Jin, Z. Measurement and characterization of external oil in the fried waxy maize starch granules using ATR-FTIR and XRD. Food Chem. 2018, 242, 131–138.

- Millin, T.M.; Medina-Meza, I.G.; Walters, B.C.; Huber, K.C.; Rasco, B.A.; Ganjyal, G.M. Frying oil temperature: Impact on physical and structural properties of french fries during the par and finish frying processes. Food Bioprocess. Technol. 2016, 9, 2080–2091.

- Chen, L.; Ma, R.; Zhang, Z.; McClements, D.J.; Qiu, L.; Jin, Z.; Tian, Y. Impact of frying conditions on hierarchical structures and oil absorption of normal maize starch. Food Hydrocoll. 2019, 97, 105231.

- Liberty, J.T.; Dehghannya, J.; Ngadi, M.O. Effective strategies for reduction of oil content in deep-fat fried foods: A review. Trends Food Sci. Technol. 2019, 92, 172–183.

- Chen, L.; McClements, D.; Zhang, Z.; Zhang, R.; Bian, X.; Jin, Z.; Tian, Y. Effect of pullulan on oil absorption and structural organization of native maize starch during frying. Food Chem. 2020, 309, 125681.

- Mestdagh, F.; De Wilde, T.; Fraselle, S.; Govaert, Y.; Ooghe, W.; Degroodt, J.-M.; Verhé, R.; Van Peteghem, C.; De Meulenaer, B. Optimization of the blanching process to reduce acrylamide in fried potatoes. LWT 2008, 41, 1648–1654.

- Hsu, H.-T.; Chen, M.-J.; Tseng, T.-P.; Cheng, L.-H.; Huang, L.-J.; Yeh, T.S. Kinetics for the distribution of acrylamide in French fries, fried oil and vapour during frying of potatoes. Food Chem. 2016, 211, 669–678.

- Aşkın, B.; Kaya, Y. Effect of deep frying process on the quality of the refined oleic/linoleic sunflower seed oil and olive oil. J. Food Sci. Technol. 2020, 57, 4716–4725.

- Cui, Y.; Hao, P.; Liu, B.; Meng, X. Effect of traditional Chinese cooking methods on fatty acid profiles of vegetable oils. Food Chem. 2017, 233, 77–84.

- Blasi, F.; Rocchetti, G.; Montesano, D.; Lucini, L.; Chiodelli, G.; Ghisoni, S.; Baccolo, G.; Simonetti, M.; Cossignani, L. Changes in extra-virgin olive oil added with Lycium barbarum L. carotenoids during frying: Chemical analyses and metabolomic approach. Food Res. Int. 2018, 105, 507–516.

- Napolitano, A.; Morales, F.; Sacchi, R.; Fogliano, V. Relationship between virgin olive oil phenolic compounds and acrylamide formation in fried crisps. J. Agric. Food Chem. 2008, 56, 2034–2040.

- Friedman, M.; Levin, C. Review of methods for the reduction of dietary content and toxicity of acrylamide. J. Agric. Food Chem. 2008, 56, 6113–6140.

- Zhang, Q.; Saleh, A.S.; Shen, Q. Monitoring of changes in composition of soybean oil during deep-fat frying with different food types. J. Am. Oil Chem. Soc. 2016, 93, 69–81.

- Liu, S.; Zhong, Y.; Shen, M.; Yan, Y.; Yu, Y.; Xie, J.; Nie, S.; Xie, M. Changes in fatty acids and formation of carbonyl compounds during frying of rice cakes and hairtails. J. Food Compos. Anal. 2021, 101, 103937.

- Gertz, C.; Klostermann, S. Analysis of acrylamide and mechanisms of its formation in deep-fried products. Eur. J. Lipid Sci. Technol. 2002, 104, 762–771.

- Becalski, A.; Lau, B.P.-Y.; Lewis, A.D.; Seaman, S.W. Acrylamide in Foods: Occurrence, Sources, and Modeling. J. Agric. Food Chem. 2003, 51, 802–808.

- Wang, Y.; Zhu, M.; Mei, J.; Luo, S.; Leng, T.; Chen, Y.; Nie, S.; Xie, M. Comparison of furans formation and volatile aldehydes profiles of four different vegetable oils during thermal oxidation. J. Food Sci. 2019, 84, 1966–1978.

- Multari, S.; Marsol-Vall, A.; Heponiemi, P.; Suomela, J.-P.; Yang, B. Changes in the volatile profile, fatty acid composition and other markers of lipid oxidation of six different vegetable oils during short-term deep-frying. Food Res. Int. 2019, 122, 318–329.

- Thürer, A.; Granvogl, M. Generation of desired aroma-active as well as undesired toxicologically relevant compounds during deep-frying of potatoes with different edible vegetable fats and oils. J. Agric. Food Chem. 2016, 64, 9107–9115.

- Zhu, F. Modifications of starch by electric field based techniques. Trends Food Sci. Technol. 2018, 75, 158–169.

- Zhang, X.; Zhang, M.; Adhikari, B. Recent developments in frying technologies applied to fresh foods. Trends Food Sci. Technol. 2020, 98, 68–81.

- Reyniers, S.; De Brier, N.; Ooms, N.; Matthijs, S.; Piovesan, A.; Verboven, P.; Brijs, K.; Gilbert, R.G.; Delcour, J.A. Amylose molecular fine structure dictates water–oil dynamics during deep-frying and the caloric density of potato crisps. Nat. Food 2020, 1, 736–745.

- Pankaj, S.K.; Keener, K.M. A review and research trends in alternate frying technologies. Curr. Opin. Food Sci. 2017, 16, 74–79.

- Fan, L.-P.; Zhang, M.; Mujumdar, A. Vacuum frying of carrot chips. Dry. Technol. 2005, 23, 645–656.

- Devi, S.; Zhang, M.; Mujumdar, A.S. Influence of ultrasound and microwave-assisted vacuum frying on quality parameters of fried product and the stability of frying oil. Dry. Technol. 2019, 39, 1–14.

- Zaghi, A.N.; Barbalho, S.M.; Guiguer, E.; Otoboni, A.M. Frying process: From conventional to air frying technology. Food Rev. Int. 2019, 35, 763–777.

- Udomkun, P.; Tangsanthatkun, J.; Innawong, B.; Tangsantaskul, J. Influence of process parameters on the physico-chemical and microstructural properties of rice crackers: A case study of novel spray-frying technique. Innov. Food Sci. Emerg. Technol. 2020, 59, 102271.

- Lloyd, B.J.; Farkas, B.E.; Keener, K.M. Quality comparison of french fry style potatoes produced by oven heating, immersion frying and controlled dynamic radiant heating. J. Food Process. Preserv. 2004, 28, 460–472.

- Ma, R.; Gao, T.; Song, L.; Zhang, L.; Jiang, Y.; Li, J.; Zhang, X.; Gao, F.; Zhou, G. Effects of oil-water mixed frying and pure-oil frying on the quality characteristics of soybean oil and chicken chop. Food Sci. Technol. 2016, 36, 329–336.

- Yang, D.; Wu, G.; Lu, Y.; Li, P.; Qi, X.; Zhang, H.; Wang, X.; Jin, Q. Comparative analysis of the effects of novel electric field frying and conventional frying on the quality of frying oil and oil absorption of fried shrimps. Food Control. 2021, 128, 108195.

- Fang, M.; Huang, G.-J.; Sung, W.-C. Mass transfer and texture characteristics of fish skin during deep-fat frying, electrostatic frying, air frying and vacuum frying. LWT 2021, 137, 110494.

- Su, Y.; Zhang, M.; Zhang, W.; Adhikari, B.; Yang, Z. Application of novel microwave-assisted vacuum frying to reduce the oil uptake and improve the quality of potato chips. LWT 2016, 73, 490–497.

- Sansano, M.; Reyes, R.D.L.; Andrés, A.M.; Heredia, A. Effect of microwave frying on acrylamide generation, mass transfer, color, and texture in french fries. Food Bioprocess. Technol. 2018, 11, 1934–1939.

- Parikh, A.; Takhar, P.S. Comparison of microwave and conventional frying on quality attributes and fat content of potatoes. J. Food Sci. 2016, 81, E2743–E2755.

- Su, Y.; Zhang, M.; Bhandari, B.; Zhang, W. Enhancement of water removing and the quality of fried purple-fleshed sweet potato in the vacuum frying by combined power ultrasound and microwave technology. Ultrason. Sonochem. 2018, 44, 368–379.

- Su, Y.; Zhang, M.; Adhikari, B.; Mujumdar, A.S.; Zhang, W. Improving the energy efficiency and the quality of fried products using a novel vacuum frying assisted by combined ultrasound and microwave technology. Innov. Food Sci. Emerg. Technol. 2018, 50, 148–159.

- Teruel, M.D.R.; Gordon, M.; Linares, M.B.; Garrido, M.D.; Ahromrit, A.; Niranjan, K. A Comparative study of the characteristics of french fries produced by deep fat frying and air frying. J. Food Sci. 2015, 80, E349–E358.

- Nelson, L.V.; Keener, K.M.; Kaczay, K.R.; Banerjee, P.; Jensen, J.L.; Liceaga, A. Comparison of the Fry Less 100 K radiant fryer to oil immersion frying. LWT 2013, 53, 473–479.

- Caro, C.A.D.; Sampayo, R.S.P.; Acevedo, C.D.; Montero, C.P.; Martelo, R.J. Mass transfer and colour analysis during vacuum frying of Colombian coastal carimañola. Int. J. Food Sci. 2020, 2020, 9816204.

- Granda, C.; Moreira, R.G.; Tichy, S.E. Reduction of acrylamide formation in potato chips by low-temperature vacuum frying. J. Food Sci. 2004, 69, E405–E411.

- Da Silva, P.F.; Moreira, R.G. Vacuum frying of high-quality fruit and vegetable-based snacks. LWT 2008, 41, 1758–1767.

- Andrés-Bello, A.; García-Segovia, P.; Martínez-Monzó, J. Vacuum frying: An alternative to obtain high-quality dried products. Food Eng. Rev. 2011, 3, 63–78.

- Albertos, I.; Martin-Diana, A.; Sanz, M.; Barat, J.; Diez, A.; Jaime, I.; Rico, D. Effect of high pressure processing or freezing technologies as pretreatment in vacuum fried carrot snacks. Innov. Food Sci. Emerg. Technol. 2016, 33, 115–122.

- Su, Y.; Zhang, M.; Zhang, W. Effect of low temperature on the microwave-assisted vacuum frying of potato chips. Dry. Technol. 2015, 34, 227–234.

- Quan, X.; Zhang, M.; Zhang, W.; Adhikari, B. Effect of microwave-assisted vacuum frying on the quality of potato chips. Dry. Technol. 2014, 32, 1812–1819.

- Yu, X.; Li, L.; Xue, J.; Wang, J.; Song, G.; Zhang, Y.; Shen, Q. Effect of air-frying conditions on the quality attributes and lipidomic characteristics of surimi during processing. Innov. Food Sci. Emerg. Technol. 2020, 60, 102305.

- Shuai, S.; Zhifang, L.; Taotao, C. Effect of oil-water mixed frying method on the quality characteristics of Taizhou dragon taro balls. Food Sci. Technol. 2020, 45, 168–173.

- Carcel, J.A.; Benedito, J.; Rosselló, C.; Mulet, A. Influence of ultrasound intensity on mass transfer in apple immersed in a sucrose solution. J. Food Eng. 2007, 78, 472–479.

- Al Faruq, A.; Zhang, M.; Fan, D. Modeling the dehydration and analysis of dielectric properties of ultrasound and microwave combined vacuum frying apple slices. Dry. Technol. 2018, 37, 409–423.

- Azam, S.M.R.; Ma, H.; Xu, B.; Devi, S.; Siddique, A.B.; Stanley, S.L.; Bhandari, B.; Zhu, J. Efficacy of ultrasound treatment in the removal of pesticide residues from fresh vegetables: A review. Trends Food Sci. Technol. 2020, 97, 417–432.

- Bouchon, P. Chapter 5 understanding oil absorption during deep-fat frying. Adv. Food Nutr. Res. 2009, 57, 209–234.