Exposure to mycotoxins is a worldwide concern as their occurrence is unavoidable and varies among geographical regions. Mycotoxins can affect the performance and quality of livestock production and act as carriers putting human health at risk. Feed can be contaminated by various fungal species, and mycotoxins co-occurrence, and modified and emerging mycotoxins are at the centre of modern mycotoxin research. Preventing mould and mycotoxin contamination is almost impossible; it is necessary for producers to implement a comprehensive mycotoxin management program to moderate these risks along the animal feed supply chain in an HACCP perspective.

1. Introduction

Animal feeds have an important role in the world food industry, empowering the safe production of animal-origin food across the globe. The feed industry is an integrated part of the food chain, and it generates income and economic sustainability. Feed safety is a precondition for food safety and human health [

1] as well as a requirement for animal welfare and health; it has been acknowledged as a shared value and responsibility among all production steps.

Mycotoxins are toxic compounds formed by the metabolism of specific fungi that affect crops and contaminate commodities consumed by humans and animals. Fungal growth rely on favourable environmental conditions [

2,

3,

4]. Exposure to mycotoxins is a worldwide concern [

5], and their occurrence is unavoidable and varies among geographical areas [

6]. With the globalization of feed ingredients, trade, and climate changes, the occurrence of mycotoxins becomes gradually difficult to predict [

7,

8]. Mycotoxins have been declared a high priority by the Food and Agriculture Organization of the United Nations (FAO) and by the World Health Organization (WHO) due to their toxicological impact on human and animal health. This has led to legislative limits for mycotoxins in about 100 countries, with regional harmonisation for the European Union (EU), Australia and New Zealand (AU & NZ), the Gulf Cooperation Council (GCC), and Mercado Común del Sur (MERCORSUR; Argentina, Brazil, Paraguay, Uruguay, and Venezuela). In the EU, maximum levels in feed are enforced for Aflatoxins (AFs), Deoxynivalenol (DON), Fumonisins (FUM), Ochratoxins (OT), Zearalenone (ZEA), and T-2 and HT-2 toxins. The legal limits have been stipulated for AFs, while for other toxins, there are national and international recommendations [

9,

10,

11,

12,

13]. Another topic of concern is the co-occurrence of mycotoxins [

14]. Feed may be contaminated by several fungal species and mycotoxins at the same time, and the toxicological effects can be different according to the type of mycotoxin interaction: less than additive, additive, synergistic, enhanced, or antagonistic [

15,

16,

17]. For these reasons, mycotoxin concentrations in feed should be continuously monitored to support risk assessment.

Although a number of methods can be used, it is almost impossible to prevent mould and mycotoxin contamination. It is widely recognised that mycotoxins are classified as chemical or biological hazards; therefore, effective quality control methods, such as HACCP and GMP, should be implemented including mycotoxin control [

18,

19,

20]. It is necessary for producers to enforce a comprehensive mycotoxin management program to minimize these risks along the whole animal feed supply chain [

18].

Mycotoxin management is systemic and includes all stages of the feed supply chain, starting from the production of raw materials to the feeding in the farm: crop phase (pre-harvest and harvest), transportation, storage, feed mill operations, and livestock production.

2. Mycotoxin Occurrence

Recently, surveys have been performed to assess the worldwide incidence of mycotoxin contamination in feed and raw feed materials, mainly grains and grain co-products (corn gluten meal, bran, and dried distillers’ grains) as well as other feed ingredients, although these are to a minor extent (e.g., soybean meal, cotton seed, sorghum, peanut, copra, cassava, etc.). These surveys state that AFs, DON, FUM, ochratoxin A (OTA), T-2 toxin, and ZEN are the principal contaminating mycotoxins in feed [

21,

22,

23,

24]. The results of the mycotoxin surveys highlighted two important issues of great concern for feed safety: mycotoxin co-occurrence, and modified and emerging mycotoxins [

25].

The world mycotoxin survey [

5] has been recently published, in which the European situation in 2020 has been analysed in comparison with the previous year: risk in Europe is high to severe. The most ubiquitous mycotoxin is DON, followed by ZEN and FUM. DON is the main hazard for livestock, with 70% of corn samples positive for this mycotoxin. Cereals were also a concern: DON reached a concentration of 11,875 ppb. ZEN increased its average contamination in corn to 171 ppb. Regarding AFs, their contamination is more prevalent in southern Europe, where they reached up to 20% of the positive cereals samples. This data have also been associated with climate change. For instance, Fusarium incidence was low or absent in the most southern regions of Italy and Spain until a few years ago; however, during the last years several northern regions of Italy, Spain, and Portugal as well as some southern regions of France and the Balkan Peninsula, Fusarium graminearum increased its occurrence in cereals at maturity, together with DON, inducing a high occurrence of this mycotoxin also in southern Europe. Regarding AFs, their contamination is growing in the Mediterranean area, where extreme changes in temperature, CO

2 levels, and rainfall patterns in combination with high heat and drought seems to compromise host plant resistance and therefor facilitates

A. flavus infection.

To obtain significant data regarding mycotoxin occurrence in feed and food, sampling and analysis are the critical points. The Commission Regulations [

10,

26] setting down the sampling and analysis methods for the official control of the levels of mycotoxins in feed and foodstuffs are in force.

2.1. Mycotoxin Co-Occurrence

The probability of finding only one mycotoxin contaminating raw materials or feed is extremely low. Worldwide, the incidence of co-contamination is high. The global monitoring reported that 72% of the samples of feed and raw materials were contaminated with more than one mycotoxin [

27]. The same authors [

28] detected 83 samples of feed and raw materials contaminated with 7 to 69 mycotoxins per sample, having analysed 169 different compounds.

The occurrence of mycotoxin co-contamination in Europe tends to follow the same pattern. Several studies have revealed the simultaneous presence of mycotoxin co-contamination in samples from European countries, finding a high percentage of feed samples contaminated with trichothecenes (DON, acetyldeoxynivalenol (AcDon), T2, and HT2) and FUM, as well as with ZEN [

29,

30,

31,

32,

33,

34,

35,

36]. In Germany, [

37] maize was found simultaneously contaminated with 14 Fusarium mycotoxins, such as DON and its acetylated forms, ZEN, Moniliformin (MON), Beauvericin (BEA), Nivalenol (NIV), Eniantins (ENNs), FBs, and HT-2 Toxin. Recently, data have been published regarding fodder mycotoxin co-contamination, which showed all silage samples positive for at least one mycotoxin, and 61% of samples contained five or more mycotoxins simultaneously. According to [

5], an average of 30 mycotoxins and their metabolites per sample were found and 87% of the samples have 10 or more mycotoxins or metabolites.

The most frequently detected toxins were DON, NIV, ZEA, enniatins, and BEA, although the levels of these toxins were relatively low [

38]. Co-contamination is a great concern, as it may exert adverse effects on animals due to the additive/synergistic interactions of the mycotoxins, the complexity of which varies according to the animal species, the level and type of mycotoxin contamination, the toxicity of the compound ingested, body weight, age and animal physiological condition, compound action mechanism, the presence of other mycotoxins, and the length of exposure. In general, in most cases, there are additive or synergic effects [

39,

40]. Many authors have highlighted this additivity, synergy, or enhancement. Although most results reveal the additive or synergic effects of mycotoxins, it should be noted that antagonistic effects could also be seen [

41,

42,

43]. The co-occurrence between regulated, modified, and emerging toxins and their interactions are still little known.

2.2. Modified Mycotoxins

The European Food Safety Authority (EFSA) refers to “modified mycotoxins” as all forms that have been structurally modified in relation to their “parental compound” or the free mycotoxins [

44,

45]. Plants and certain microorganisms, such as yeasts, filamentous fungi, and bacteria, are capable of transforming mycotoxins into conjugated forms (biologically modified mycotoxins), reducing their toxicity [

46]. In fact, plant metabolites have been identified for DON, NIV, fusarenon-X, T-2 toxin, HT-2 toxin, ZEN, OTA, destruxins, and fusaric acid, while modified fumonisins have been detected in cereal commodities, such as corn, wheat, and barley. Toxicological data on modified mycotoxins, including those of processing origin (chemically modified mycotoxins), are still limited [

47,

48]. However, recent advances in modified mycotoxin occurrence and toxicity have suggested that mycotoxins conjugates have a reduced toxicity potential due to the lower absorption in the gastrointestinal tract [

6]. These modified mycotoxins differ in their structure, solubility, polarity, and molecular mass; furthermore, they can be formed during the processing of foods from contaminated raw materials and can be reconverted to the original toxin during the human and animal metabolism [

49,

50,

51,

52]. Free mycotoxins co-occur with modified mycotoxins [

49,

50], and the modified mycotoxin concentration exceeds the level of free form. The possibility of modified mycotoxin conversion to its free form may involve risks for human and animal health. The conversion of modified to free form can result in increased bioavailability of mycotoxin [

53,

54]. It is necessary to set up and validate affordable methods for the detection of modified mycotoxin as well as to study their stability during the processing of feeds, their outcome in the animal digestive system, and their toxicokinetic and toxicodynamic properties [

55]. In addition, the knowledge of their formation process and their structure and molecular mass may resolve analytical and technological gaps [

56,

57].

2.3. Emerging Mycotoxins

Emerging mycotoxins became a major issue due to their high occurrence in cereals, feed, and food commodities [

58,

59,

60]. They are lesser-known or newer forms of mycotoxins that, by definition, are neither routinely determined nor legislatively regulated. The most prevalent emerging mycotoxins are

Fusarium toxins, such as ENNs, BEA, MON, fusaproliferin (FP), fusidic acid (FA), culmorin (CUL), and butenolide (BUT) [

61,

62]. The presence of emerging mycotoxins in feed and food commodities, such as

Aspergillus toxins (sterigmatocystin (STE) and emodin (EMO)),

Penicillium toxins (mycophenolic acid (MPA)),

Alternaria toxins (alternariol (AOH), monomethyl alternariol ether (AME), altenuene (ALT), altertoxin (ATX), and tenuazonic acid (TeA)), ergot alkaloids, and citrinin, is equally common [

58,

61,

62]. Research indicates that these emerging toxins are rapidly becoming prevalent co-contaminants in feed and food such as grains (corn, wheat, barley, etc.) showing greater occurrence when other

Fusarium mycotoxins are present. In an extensive review on co-occurrence of regulated, modified, and emerging mycotoxins in finished feed and maize, emerging mycotoxins, such as ENNs, MON, and BEA, were found to be ubiquitous in analysed samples [

48]. According to [

5], the raw materials most frequently presenting emerging toxins are maize and animal compound feed. In particular, corn presented 93% of MON and 83% of Aurofusarium, while the finished feed presented 97% and 93% for Bauvericin, and Enniantin B and B1.

However, these data have to be considered with caution. Indeed, although thanks to certain modern analytical methods we are able to detect hundreds of “new” different fungal metabolites in a variety of food and feed samples, we have to consider that many of these compounds are irrelevant in terms of food and feed safety [

62]. Their limited risk, however, can change in the future: climate change, commodities origin, and processing as well as several others environmental factors can alter both toxicity and occurrence of these compounds. Thus, for an adequate risk assessment and in order to prevent future food and feed safety crisis, it is also important to start collecting information (occurrence, acute vs. chronic toxicity, distribution, commodities, etc.) about these fungal metabolites.

3. Mycotoxin Risk in the Feed Supply Chain: Need for a Management Plan

Commodities can become contaminated with mycotoxins anytime in the production cycle, i.e., at each stage from the field through harvesting, processing, storage, and transportation [

72,

73]. A representation of the feed chain is shown in

Figure 1. Each of these phases are examined in

Section 5 and

Section 6.

Figure 1. Representation of the feed chain.

The feed chain is complex and articulated; the same applies to mycotoxin contamination. The demand for feed will increase by 2050 in support of animal product requests; in view of this growth, feed safety will become fundamental. There are steps in the feed process that can be updated through the experimentation of new technologies, some of which are designed to manage mycotoxin contamination.

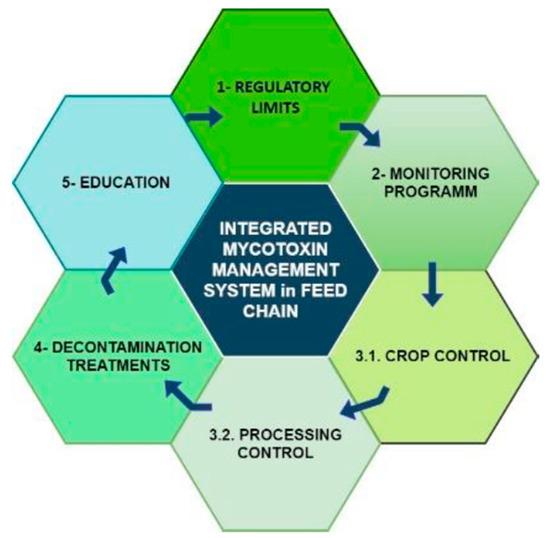

One possible approach for managing mycotoxin risks in the feed supply chain is the use of an integrated system [

74] (

Figure 2).

Figure 2. Integrated system phases for mycotoxin management (modified from FAO 1995).

An integrated system includes technical aspects such as fixing regulatory limits, programming a precise monitoring and control of cultivation, and production phases. In addition, it proposes solutions to non-conformities that may take place and, above all, for widespread training of all operators in the feed chain. An integrated system is therefore preventative, planning how to act in the case of system anomalies. It is a plan to avoid arriving unprepared in the case of contamination.

An integrated system is based on the synchronised use of prevention and control implements such as Good Agricultural Practices (GAP), Good Manufacturing Practices (GMP), Good Hygienic Practices (GHP), quality control, and Hazard Analysis and Critical Control Point (HACCP) at all stages of production from the field to the final consumer. The phases of an integrated mycotoxin management system as proposed by FAO in 1995 [

74] are reported in

Table 1. Although most of these actions (legal limits, control systems, alert systems, etc.) have been activated in different world regions by single countries or market/areas (e.g., EU), world harmonisation exists.

Table 1. Phases of an integrated mycotoxin management system (modified from FAO, 1995).

HACCP for Feed Mycotoxin Contamination

In an integrated management system, prevention is key; the risks related to mycotoxin hazards should be minimized at each production phase. Mycotoxin contamination is best dealt with in the pre-harvest phase, but when contamination occurs, the related dangers can be handled through post-harvest techniques, applying the corrective actions reported in the HACCP plan.

The HACCP system is designed to decrease the risk of feed safety exposure by identifying the hazards and by monitoring controls [

74,

75]; it provides a scientific quality control methodology. In addition, HACCP system can be designed and used in combination with other quality systems. The most crucial source of mycotoxin intake can be found in agro-commodities (FAO/WHO 2014); for this reason, an effective preventative strategy could be represented by an approach spanning the entirety of the commodity supply chain. The application of an HACCP system aimed at improving food safety, from the fields to farm animals, can control mycotoxin contamination of raw material [

76,

77]. To ensure that the product has acceptable mycotoxin levels, an integrated HACCP approach in the pre-harvest stage can be used. Effective integrated management programmes cover agro-products mycotoxin prevention/detoxification as well as routine surveillance, updating national and international regulatory measures, information, education, and communication activities.

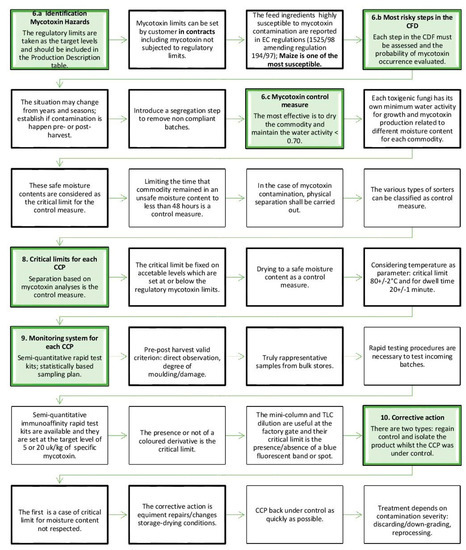

The key points for an effective HACCP plan are hazard identification and analysis and the record keeping procedures [

78,

79,

80]. The text “Manual on the application of the HACCP system in mycotoxin prevention and control” was published [

77] and is a reference for the HACPP plan drafting, but there is a lack of HACCP plans specific for the feed chain in this text. The most crucial points of HACCP for mycotoxin control in the feed chain are reported in

Figure 3.

Figure 3. Crucial HACCP tasks for mycotoxin control in the feed chain (modified from FAO, 2001).

In order to deal with the preliminary stages in commodity flow, an effective team, made of microbiologist; mycologist; and experts in farming, storage, distribution, and trading should be formed. In a holistic approach to mycotoxin control, there is a need for a commodity flow diagram (CFD), which includes all aspects of primary production, drying, storage, transport, and final processing steps (Figure 1). The modern commodity supply chain complicates the creation of this document due to the fact that products move between several owner groups (farmers, traders, transporter, and processors). The commodity and the final product type, climatic zone, and production country will affect the drafting of this report.

Control parameters for the manufacturing of mycotoxin susceptible commodities involve harvesting time, temperature, storage and transportation moisture level, selection prior to processing of agricultural feedstuffs, decontamination environments, and final product storage and transportation [

81].

An HACCP plan to manage mycotoxin hazard in feed chain would guide experts at every stage of the supply chain, for which a guide model for the feed chain is reported in Table 2. It is paramount to define critical the control points, hazards, control limits, preventive actions, monitoring strategies (measurable parameters, methods, control frequency, and responsible figure), corrective actions, records, and finally the verifications for each feed chain step. These parameters are certainly specific for each operation and depend on the kind of risk involved.

Table 2. Managing mycotoxins in the feed chain: guide model of a HACCP plan.

| CCP |

Hazard |

Critical Limit |

Preventive Action |

Monitoring |

Corrective Action |

Records |

Verification |

| |

|

|

|

Parameter |

Method |

Frequency |

Responsable |

|

|

|

| Pre-harvest |

Low soil moisture/plant stress |

Lower limit of critical Aw |

Irrigate |

Soil moisture value |

|

Weekly on Tuesday morning |

Agronomist |

Supplementary irrigation |

Soil moisture |

State of plants |

| |

Insufficient soil nutrients |

N,P,K applications |

Fertilise |

Fertilizer application |

|

As recommended for hybrid |

Agronomist |

Additional fertilizer |

Amounts and type of fertilize |

State of plants |

| |

Insect attack |

Insect population within accettable limits |

Integrated pest management plan |

Visual inspection and sample |

|

Weekly |

Agronomist |

Apply pestice in accordance with IPM plan |

Results of the monitoring |

State of plants |

| Harvest |

Damage kernel |

Moisture content <14% |

Harvest when kernels are dry |

Measure grain moisture |

|

Prior to harvest |

Farmer/

Agro-mechanical |

Postpone harvest till kernels properly dried |

Grain moisture |

Visual inspection/analyses of raw materials |

| Storage |

Excessive moisture content |

Moisture content <14% |

Do not store until kernels dry |

Measure grain moisture |

|

Immediately prior to storage |

Commodity quality assistant |

Dry mechanically |

Grain moisture |

Analysis |

| |

Insect attack |

Inspection protocols show no evidence of insect or rodent infestation |

IPM plan |

Visual inspection |

|

Weekly |

Mill operators |

Follow IPM plan for pest control method |

Visual inspection |

Analysis results |

| |

High humidity and temperature |

Temperature and humidity within limits recommended in industry literature |

Aerate grain to control temperature and humidity |

Measure humidity, temperature and airflow |

|

Daily during storage |

Mill operators |

Adjust aeration- time, or airflow to achieve desidered temperature and humidity |

Humidity, temeperature and airflow |

Authomatic monitoring systems |

| Feed mill |

Increase of myctoxin levels in mixer phase |

mixer cleaning mycotoxin levels |

Controlling mixer cleaning and way of frequency |

ppb |

ELISA and UV |

Before every mixing process |

Feed quality assistant |

Changing the time and method of cleaning |

Cleaning and disinfection register form |

Cleaning, analysis results |

| |

Increased myctoxin levels in Cooler |

The heat of feed should be at most 5 °C more than environment heat |

Increasing empting time of the cooler; decreasing the capacity of pellet; controlling the heat levels of the cooler |

°C |

Thermometer |

Daily |

Foremen |

Mixing with cold feed, keeping a backup cooler |

Cooler heat follow form |

Measuring heat during cooling process |

| Livestock production |

Increase of mycotoxins levels |

Temperature, cleaning |

Feeding silo cleaning, climate and insect/rodent control |

°C, ppb |

Thermometer, ELISA |

Before every entering livestock, daily, weekly |

Farmers, Livestock keeper |

Dietary manipulation, on-farm management strategies, use of binding agents |

Live activity form |

Cleaning and disinfection results, analises of animal products |

This entry is adapted from the peer-reviewed paper 10.3390/toxins13080572