Rice (Oryza sativa L. genus) is the primary source of daily food intake and has become the world’s second most important cereal crop sector due to the demand of billions of human beings. Rice husk (RH) should never be burned, due to various reasons, such as the ashes, harmful gases, and fumes that contribute to air pollution. Typically, the RH can be used as biochar, extracted silica, or husk itself. In general, RH is a hull to protect seeds or grains. It is formed from rigid materials, is water-insoluble, and is abrasive, with a high level of cellulose–silica structures. The exterior of the hulls consists of silica covered with a cuticle, with a small amount of silica content at the innermost epidermis. The exploitation of RH residues in biocomposites offers multiple advantages, for example, reducing the relative amount of constituents derived from synthetic polymers, such as resin polymers and some additives. The tensile strength is mainly used to evaluate the strength behavior of a composite material.

- natural fiber

- rice husk

- biocomposites

- physicomechanical

1. Tensile Strength of RH Composites

The behavior of composites is dependent upon the filler type, matrix material, concentration, size, dispersion, and the adhesion between the filler and the matrix material. Various studies have been conducted on the variation of tensile properties of RH-reinforced composites at different filler loadings using different types of matrix materials as polymer matrices, as tabulated in Table 1. However, they can be classified into four groups: matrix modification, filler treatment/modification, and hybridization.

Table 1. Reported studies of the mechanical properties of RH reinforced polymers.

| Matrix | Parametric Study | Tensile Strength (MPa) | Flexural (MPa) | Impact Strength (kJ/m2) | References |

|---|---|---|---|---|---|

| HDPE | Matrix modification | 22.5 ± 0.5 | 49.6 ± 1.2 | Abdulkarem et al. [1] | |

| PP | Filler loading | 19.7 | 39.2 | Zafar et al. [2] | |

| HDPE | Filler modification | 20 | 53.7 | 13 | Zhang et al. [3] |

| HDPE | Hybrid | 15.8 | 25.7 | 15.2 | Zhang et al. [4] |

| Natural rubber | Filler modification | 21.3 ± 0.7 | Xue et al. [5] | ||

| Epoxy | Filler modification | 120 | Fernandes et al. [6] | ||

| Epoxidized natural rubber | Filler modification | 18.5 ± 0.5 | Pongdong et al. [7] | ||

| HDPE/PET | Matrix modification | 22.2 ± 0.1 | 48 ± 2 | 3 ± 0.1 | Chen et al. [8] |

| Epoxidized natural rubber | Matrix modification | 35 | 45 | 22 | Raghu et al. [9] |

| rHDPE | Filler treatment | 18.37 | Rajendran et al. [10] | ||

| Epoxy | Filler treatment | 46 ± 1 | 87 ± 2 | 2.7 ± 0.1 | Bisht et al. [11] |

| rABS/PP | Matrix modification | 21 ± 1 | Santiago et al. [12] | ||

| HDPE | Filler treatment | 26.3 ± 0.50 | Zhang et al. [13] | ||

| rPP | Filler treatment | 28 ± 0.25 | 3.0 ± 0.5 | Moreno et al. [14] | |

| TPS | Filler treatment | 2.43 ± 0.25 | Boonsuk et al. [15] | ||

| PU | Filler treatment | 0.25 ± 0.11 | Olcay et al. [16] | ||

| Epoxy | Hybrid | 43 | Shubbar [17] | ||

| PP | Hybrid | 40 ± 2 | Awang et al. [18] | ||

| Epoxy | Hybrid | 30 ± 2 | 25 ± 2 | Kumar et al. [19] | |

| PP | Filler loading | 33.2 ± 0.5 | 39.8 ± 0.3 | Hidalgo-Salazar et al. [20] | |

| Corn starch | Hybrid | 10.7 | 19.6 | Singh et al. [21] | |

| HDPE | Matrix modification | 30 ± 2 | Sun et al. [22] | ||

| PLA | Matrix modification | 5254 ± 25 | Běhálek et al. [23] | ||

| PP | Hybrid | 15.6 ± 0.25 | 37.6 ± 1.88 | Guna et al. [24] | |

| PVC | Matrix modification | 51.9 ± 2.54 | 74.9 ± 5.81 | Petchwattana et al. [25] | |

| PVC | Hybrid | 5.5 ± 0.80 | Jiang et al. [26] | ||

| Cassava starch | Filler modification | 3.3 ± 0.5 | Kargarzadeh et al. [27] | ||

| Corn starch | Matrix modification | 14.3 ± 1.13 | Yap et al. [28] | ||

| PLA and PBAT | Matrix modification | 10.0 ± 1.0 | Spada et al. [29] |

Using RH as a reinforcement has offered significant enhancements to the tensile properties of composites, as reported by Abdulkareem et al. [1]. They clarified that the Young’s modulus of RH/waste polystyrene (PS) composite increased with increasing the RH content; up to 40 wt % compared to pure PS. A similar improvement in strength was also discovered by Zafar et al. [2] when studying an RH reinforced polypropylene (PP) matrix composite. The maximum tensile strength was achieved at 5 wt % of RH loading, with the size of the RH filler being 355–500 micron. In contrast, this contradicted the findings mentioned by Zhang et al. [3], where increasing the RH filler to 70 wt % decreased the tensile properties due to fiber agglomeration in the matrix. Zhang et al. [4] also studied the tensile strength of RH in a high-density polyethene (HDPE) matrix for different RH loadings, and the best level of tensile strength was attained at 40 wt % loadings. This was the result of the uniform distribution of RH in the matrix, making the matrix tightly wrap the RH, and thus improving the interface bonding. In another study, a unique type of RH, called hydrochar, was reinforced with polylactic acid (PLA) as the matrix, and it was observed that the tensile modulus improved from 2.63 GPa in virgin PLA to 4.24 GPa after blending with hydrochar. Xue et al. [5] used the ball milling technique to enhance the filler–matrix interaction by refining the particle size. They found that the tensile strength increased 44% compared to unmilled RH.

While studying the performance between unfilled and filled epoxidized natural rubber (ENR) with RH ash, it was shown that the filled ENR provided a higher tensile strength than the unfilled ENR. A study of the differences in mechanical properties between RH ash filler and high-purity silica in an epoxy matrix composite by Fernandes et al. [6] found that similar characteristics were observed. They claimed that RH ash could replace silica with little loss of desirable properties. Pongdong et al. [7] indicated a similar conclusion, whereby they found that RH ash filler exhibited a similar reinforcement compared to conventional siliceous earth for epoxidized natural rubber matrix composites.

In order to reduce the level of alkalinity of the pore water in a synthetic polymer, matrix modification has been promoted. This method can typically enhance the durability of the fiber–matrix interaction by using cementitious materials. The tensile strength of the RH reinforced hybrid recycled HDPE/polyethylene terephthalate (PET) composites was optimum at 70 wt % of filler loading, as reported by Chen et al. [8]. In a similar study, Raghu et al. [9] used maleic anhydride grafted polypropylene (MAPP) and m-isopropenyl α–α-dimethylbenzyl-isocyanate grafted polypropylene (m-TMI-g-PP) as coupling agents. They found that the tensile properties of the RH/PP composites were better than the control samples. They observed that at 50 wt % RH loading, the tensile strength increased by 52% as compared with another type of filler, which were encouraging results.

Several researchers evaluated the improved tensile strength properties between RH and the matrix resin using surface modification techniques such as esterification, silane treatment, fiber mercerization, or fiber surface modification. For example, Rajendran et al. [10] treated RH with ultraviolet-ozonolysis and found that the treated RH composites improved the tensile strength by 5% compared to the composite with untreated RH. Bisht et al. [11] used a mercerization treatment on RH flour and studied the effect on the tensile strength of RH/epoxy composites. The tensile strength of the composite improved by 36% with treated sodium hydroxide (NaOH) solution, by up to 8%. Santiago et al. [12] compared the tensile strength of RH powder in a recycled acrylonitrile butadiene rubber/PP hybrid matrix between a silane treatment and anhydride (AC) treatment of the fillers. Again, the AC treatment exhibited better tensile strength compared to the silane treatment.

Zhang et al. [13] analyzed an extracted RH biochar reinforced HDPE composite at different pyrolysis temperatures using injection moulding. The best tensile properties of the composites were obtained in the temperature range of 500–600 °C, due to their outstanding physical interlocking structures. A similar pyrolysis of RH work was conducted by Moreno et al. [14]. It was shown that the increased RH content in the PP matrix led to a proportional decrease in the tensile strength. However, the decrease in tensile strength was less significant for the pyrolysis composites, as verified by the fracture surface.

In addition, Boonsuk et al. [15] mentioned that an alkaline treatment with 11% w/v of NaOH removed the hemicellulose layer of RH and offered an outstanding tensile strength improvement, by a factor of 220%, compared to the neat thermoplastic starch. It improved the matrix-filler load transfer capabilities due to the loss of hemicellulose and the rougher outer surfaces after alkaline treatment. By contrast, the combination between untreated and 5% RH loading in a flexible polyurethane (PU) was found to have the best tensile performance of the composites [16]. The treated RH with 10% w/v NaOH adversely affected the surface of the filler and decreased the tensile behavior.

Some researchers fabricated hybrid RH composites by combining two or more different types of fillers within a common matrix. For example, Shubbar [17] evaluated the tensile properties of RH combined with fumed silica nanopowder in an epoxy matrix. The tensile properties increased by 50%, just by adding 5 wt % RH, compared to the sample with pure resin. Furthermore, Awang et al. [18] evaluated RH combined with titanium oxide (TiO2) and zirconium oxide (ZnO) in the PP matrix and proposed that the addition of TiO2 gave a higher tensile strength and Young’s modulus compared to the addition of ZnO. From the scanning electron microscope (SEM) images, they concluded that this higher tensile strength was due to a better interaction between the matrix and the RH particles. Additionally, Kumar et al. [19] assessed a combination of RH/bauhinia-vahilii-weight/sisal filler with epoxy as the matrix and concluded that the addition of RH improved the tensile strength by 34.42% compared to not using the RH filler loading.

The application of RH as a filler in polymer matrix composites increased the tensile strength in all the research that was reviewed in this paper. RH could replace silica and other fillers; however, some of the research showed that the tensile strength increment had a maximum point after a certain amount of RH loading. Some researchers conducted additional studies on the improvement of the interface properties of the filler–matrix, either by surface modification of RH or to the matrix formulation. It is believed that this is the way forward for increasing the usage of RH in polymer matrix composites.

2. Flexural Strength of RH Composites

In order to characterise the bending properties of the composite material, the most classical test used to characterize this behaviour is the flexural test (three or four points). A study by Zhang et al. [3] reported that the bending strength of a RH biochar/HDPE composite reached 53.7 MPa, which was far beyond wood–plastic composites. It was indicated that the biochar behaved as a rigid grain and locked the movement of a particle in the polymer chains. Hidalgo-Salazar et al. [20] analyzed a RH-reinforced PP composite and recorded an increase of 75% in flexural strength for the RH/PP composite compared with neat PP. They attributed the increase in bending properties to the stiffening effect of RH in the PP matrix. Singh et al. [21] also measured the flexural strength of a fully recycled RH-reinforced corn starch matrix composite and mentioned that the maximum flexural strength was 19.60 MPa for a RH/corn starch composite with 15 wt % RH content.

Flexural modulus is a material characteristic that is significantly influenced by the morphology and crystallinity of polymers. In particular, the heterogeneous structure of the surface layers is important for high values of flexural modulus. Using a compatibilizer, Chen et al. [8] used an ethylene-glycidyl methacrylate (E-GMA) copolymer as a compatibilizer between recycled HDPE and recycled PET, and maleic anhydride polyethene (MAPE) as a coupling agent between the filler and matrix. They reported an increase in flexural strength of 62% with the increase of RH concentration in the polymer blends of recycled HDPE and recycled PET. It was discovered that the use of a compatibilizer increased the strength of the RH composite with the matrix blend. The coupling agent also improved the flexural strength of the RH/PP composites, and an increase of 46% was reported by Raghu et al. [9]. Moreover, when comparing the effect of silane coupling and compatibilizer MAPE on interfacial adhesion properties in RH/HDPE composites, Sun et al. [22] found that the bending strength and flexural strength were improved by 11.5% and 40.7%, respectively. It was observed that the flexural modulus increased with the increase in RH and the technical cellulose fiber amount. It was obvious that the flexural modulus reached higher values at higher quantities of cellulose fibers (20–30 mass%). Furthermore, there was no positive effect on the flexural modulus with a variety of plasma surface treatments of technical cellulose fibers or grafted maleic anhydride (PLA-g-MAH/PLA/30CeF). The smallest effect on the flexural modulus was noted for ozone-treated fillers [23].

Kumar et al. [19] reported an increase of 33% in the flexural strength for RH/bauhinia-vahilii-weight/sisal epoxy composites compared to unfilled composites at all filler loadings. The effects of hybridized RH with groundnut shell (GNS) reinforced with PP were obtained by Guna et al. [24]. The maximum flexural strength of the hybrid composites was obtained with a 20/60/20 GNS/RH/PP ratio, which was 40% higher than the non-hybrid composites. This could suggest that a higher loading of small fillers was inclined to extensive delamination, and the misalignment of the filler in the matrix thus decreased the strength properties.

3. Impact Strength of RH Composites

Singh [21] reported that the impact energy of RH/corn starch composites increased with the increase of the amount of RH content. The impact strength reached 0.362 J for composites with 15 wt % RH content.

The mercerization of fibers improved the impact strength, and Bisht et al. [11] reported that the impact strength of RH flour–epoxy composites were highest at 8% NaOH concentration. The reason for the increase of the impact strength was due to the mercerisation treatment, which improved the adhesion between the matrix and fiber by way of removing the voids on the surface of the untreated RHs. Surface modification by silane treatment of a PVC matrix in RH–PVC composites also increased the impact strength to 44%, as reported by Petchwattan et al. [25].

The use of coupling agents, as studied by Raghu [9], showed that the impact strength of RH–PP composites decreased with increasing filler loadings. Jiang et al. [26] explored the possibility of reinforcing RH–PVC composites with basalt fibers (BF) and found a noticeably increase in impact strength, whereby the BF acted as a reinforcing agent and strengthened the mobility of the matrix chains. Additionally, the aspect ratio of BF was higher than RH, thus the shift of the stress from the matrix to the fiber was more effective.

4. Water Diffusion Behavior of RH Composites

The water diffusion behavior of fiber-reinforced composites is dependent on the relative mobility of penetrants between the water molecules and polymer parts. In general, this obeys Fick’s diffusion theory, and three classes of diffusion can be determined [30][31]. The measurement of the kinetic diffusion mechanism was evaluated based on Fick’s theory and the fitting of experimental values, as follows:

where Mt and M∞ are the water absorption at time t and the saturation point, respectively. k and n are constants.

The diffusion mechanism is reflected in the value of n. When the rate of diffusion of the infiltrate is less than the polymer part, Case I of the Fickian diffusion mechanism is obtained. For this case, the value of n = 0.5, where the saturated condition corresponding to a time is rapidly gained and conserved inside the composite [32]. However, when n = 1.0, this indicates that the diffusion activity is faster than the relaxation process [33]. The mechanism is distinguished by the progressive barrier between the bulging outer part and the inner glassy part of the synthetic polymer. In Case II, an equilibrium penetration diffusion is reached at a constant velocity. The non-Fickian is justified at a 0.5 < n < 1.0 diffusion mechanism and does not obey the Fickian laws. At this condition, Melo et al. [34] used a Langmuir-type model to closely interpret the physical phenomenon of water absorption relaxation of natural fibre composites. In some cases, when n is larger than 1, it is known as Super Case II kinetics [35]; however, when n < 0.5, this can be classified as ‘Less Fickian’ behaviour.

Table 2 summarises the water absorption kinetics of an RH-reinforced synthetic polymer. Chen and Ahmad [36] reported that the water absorption and swelling showed a linear increase with the increase of RH content. The higher water absorption and swelling with higher RH fiber content were due to the hydrophilicity of RH. This finding agreed with the finding of Abdulkareem et al. [1], where it was observed that the percentage of water absorbed increased with the addition of RH. Abdulkareem et al. [1] attributed the increase in water absorption to the pores and gaps in the RH structure. A different mechanism was observed in the epoxy matrix by Shubbar [17], whereby it was reported that due to the swelling of the composite as a result of water absorption, the epoxy matrix cracked, which in turn generated a capillary effect and caused further water absorption.

Table 2. Reported studies of moisture absorption kinetics of RH-reinforced polymers.

| Matrix | Parametric Study | M∞(%) | Thickness Swelling (%) | Diffusion Coefficients (D × 10–5 mm2/s) |

References |

|---|---|---|---|---|---|

| rHDPE | Hybrid | 1.8–4.0 | 4.8–6.8 | Chen and Ahmad [36] | |

| HDPE | Filler content | 12.0–13.0 | 8.5–10.0 | Sheykh et al. [37] | |

| PE | Filler treatment | 3.0–7.0 | Nabinejad et al. 2017 | ||

| Cassava starch | Hybrid | 0.5–2.7 | Huner [38] | ||

| PVC | Coupling agent | 0.4–2.4 | Saidi et al. [39] | ||

| PE | Hybrid | 2.5–13.0 | Mohamed et al. [40] | ||

| Corn starch | Filler content | 5.1–11.9 | Battegazzore et al. [41] | ||

| PVC | Coupling agent | 4.2–6.3 | Petchwattana et al. [25] | ||

| Epoxy | Hybrid | 1.2–2.4 | Shubbar [17] | ||

| rHDPE | Filler treatment | 1.7–4.0 | Rajendran et al. [10] | ||

| rPE | Filler content | 2.8–1.6 | Abdulkareem et al. [1] | ||

| rHDPE/rPET | Hybrid | 3.0–9.5 | 4.0–8.8 | Chen et al. [8] | |

| Epoxy | Filler content | 0.06–0.17 | Fernandes et al. [6] | ||

| PLA | Filler treatment | 2.5–3.5 | Prappuddivongs et al. [42] | ||

| PLA/PLB | Blending effect | 0.8–5.2 | Akindoyo et al. [43] | ||

| HDPE | Filler content | 0.12–0.28 | Daramola [44] | ||

| Epoxy | Filler content | 0.08–0.13 | Hamid et al. [45] | ||

| Soy bean | Coating | 4.0–11.0 | 3.2–15.9 | Chalapud et al. [46] | |

| ABS | Hybrid | 6.9–9.1 | 1.1–1.4 | Norhasnan et al. [47] | |

| rHDPE | Filler treatment | 3.7–26.6 | 0.63 | Chen et al. [48] |

The RH was found to be better in terms of its water absorption properties when it was compared with other types of fillers. Muthuraj et al. [49] found that composites containing RH showed lower water absorption compared to other types of fillers, such as wheat husk, wood fibers, and textile waste. This observation was explained by the higher hydrophobicity of RH compared to other fillers. Yusuf et al. [50] compared composites containing RH with composites containing bamboo stem fiber. They found that composites with RH were better in terms of their lower water absorption and swelling thickness due to the lower affinity of RH to water. Sheykh et al. [37] compared RH and bagasse ash in an HDPE composite. The RH–HDPE composite was found to have lower water absorption and thickness swelling properties. This was due to the lower accessible -OH group on the surface of RH compared to bagasse fibers. Mohamed et al. [40] compared the water absorption properties of different contents of hybrid kenaf–RH in a polypropylene composite. Similarly, other researchers found that a higher RH content exhibited lower water absorption properties. This is because kenaf has larger voids and has more hydroxyl groups that can interact with water.

Antunes et al. [51] studied the ability of RH panels (to be used as wall panels) to absorb and desorb moisture using the moisture buffer value test. They found that the higher RH content panels had a better ability for absorbing and desorbing moisture compared to panels with a lower content of RH, which makes them excellent for high humidity applications.

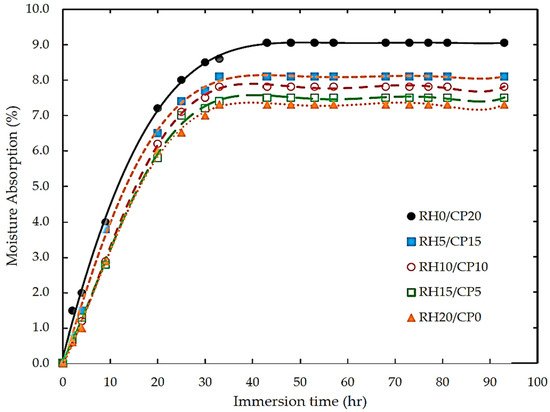

Akindoyo et al. [43] presented that all composite structures massively absorbed more water than neat PLA due to a natural fiber composite, which contained a higher abundance hydroxyl groups and easily interacted with water molecules. The increase in water absorption was higher in the reinforced blends, which could be credited to the water uptake properties of natural fibers. In general, all the composites conformed with Fickian’s law, where there was an initial rapid water uptake before reaching a saturation plateau region, with further increases in the soaking period. The effect of nano-silica particles extracted from RH on the water absorption characteristics was evaluated by Daramola [44]. An enhancement of the moisture absorption resistance of a nano silica-reinforced HDPE composite was observed at a lower particle weight fraction. However, increasing the filler loading resulted in an increase in the void content, interfacial bonding, and exposure surface between the filler and blend. Similar work was also reported by Hamid et al. [45]. In contrast, they reported that the silica concentration had no significant effect on the water moisture kinetic. Additionally, a nano-silica crystalline composite offered a higher water resistance than a nano-silica amorphous coupon. Both composites had a more hydrophobic resistance compared to epoxy resin. Furthermore, Norhasnan et al. [47] evaluated a hybridized RH/coco peat reinforced ABS, which showed reduced water-resistance biocomposite structures. Figure 1 shows the moisture absorption behaviour of the RH/CP reinforced ABS, and a maximum water kinetic behaviour for 20 wt % of coco peat composite composition was found, due to the higher hydrophilicity of the coco peat particle.

Figure 1. Typical of water absorption plots of RH and cocopeat ABS polymer blend composites.

Fiber surface treatment and matrix modification improves the water absorption properties of RH composites. This was confirmed by several kinds of research that used NaOH and silane treatments on RH and coupling agents on the matrix. Huner [38] used 10% NaOH, while Nabinejad et al. [52] used 5% NaOH. Both found that NaOH decreased the water absorption of the RH–PP composite. NaOH treatment caused the surface of the RH to be polar. The same result was also produced by silane treatment of RH. Water absorption decreased by up to 38%, as reported by Petchwattana et al. [25], due to the silane reacting with free OH groups and due to the elimination of voids. Huner [38] reported that the tendency for reaction was lower than NaOH, causing the water absorption rate for silane treated composite to be lower. The use of MAPP decreased the water absorption rate due to the decrease of micro gaps in the interface, as a result of enhanced bonding between the filler and matrix [38]. The comparison between NaOH treatment and UV/O2 treatment by Rajendran Royan et al. [10] showed that the NaOH-treated RH exhibited higher water absorption properties. The reason for this was due to the dry treatment with UV/O2, where the RH was not soaked in any liquid and as a result, there was no fiber swelling that could give access to water in the reactive region. Saidi et al. [39] used a titanate coupling agent for a RH–PVC composite. Titanate coupling improved the interfacial adhesion between the RH and PVC matrix, preventing the diffusion of water molecules. As a result, the water absorption was reduced by 26%.

Researchers have also used hydrophobic materials to increase the water resistance of the composite structure. As an example, Chalapud et al. [46] used a tung oil in RH that was adhesively bonded by a soy protein composite to improve the moisture resistance of particleboard. The impregnation of the composite panel with tung oil decreased its moisture absorption capacity and reduced the volume of voids, as obtained by surface microscopy. Since the oil was hydrophobic, a longer time period was required to reach saturation conditions, and this reduced the water kinetic mechanism, diffusing inside the hydroxyl groups of the RH and matrix to form hydrogen bonding. Moreover, a gamma radiation post-treatment was also employed by Chen et al. [48] and proved that the irradiation process increased the moisture kinetics and swelling effect on the composites. However, increasing the filler content after post-treatment also increased the moisture absorption, due to a huge quantity of carbonyl and hydroxyl groups in the composite, which allowed more molecule water to be diffused via the capillary effect.

This entry is adapted from the peer-reviewed paper 10.3390/polym13152391

References

- Abdulkareem, S.A.; Adeniyi, A.G. Tensile and water absorbing properties of natural fibre reinforced plastic composites from waste polystyrene and rice husk. J. Eng. Res. Dev. 2018, 1, 199–204.

- Zafar, M.F.; Siddiqui, M.A. Raw natural fiber reinforced polystyrene composites: Effect of fiber size and loading. Mater. Today Proc. 2018, 5, 5908–5917.

- Zhang, Q.; Yi, W.; Li, Z.; Wang, L.; Cai, H. Mechanical Properties of Rice Husk Biochar Reinforced High Density Polyethylene Composites. Polymers 2018, 10, 286.

- Zhang, Q.; Li, Y.; Cai, H.; Lin, X.; Yi, W.; Zhang, J. Properties comparison of high density polyethylene composites filled with three kinds of shell fibers. Results Phys. 2019, 12, 1542–1546.

- Xue, B.; Wang, X.; Sui, J.; Xu, D.; Zhu, Y.; Liu, X. A facile ball milling method to produce sustainable pyrolytic rice husk bio-filler for reinforcement of rubber mechanical property. Ind. Crops Prod. 2019, 141, 111791.

- Fernandes, I.J.; Santos, R.V.; Santos, E.C.A.d.; Rocha, T.L.A.C.; Domingues, N.S., Jr.; Moraes, C.A.M. Replacement of commercial silica by rice husk ash in epoxy composites: A comparative analysis. Mater. Res. 2018, 21.

- Pongdong, W.; Kummerlöwe, C.; Vennemann, N.; Thitithammawong, A.; Nakason, C. A comparative investigation of rice husk ash and siliceous earth as reinforcing fillers in dynamically cured blends of epoxidized natural rubber (ENR) and thermoplastic polyurethane (TPU). J. Polym. Environ. 2018, 26, 1145–1159.

- Chen, R.S.; Ahmad, S.; Gan, S. Rice husk bio-filler reinforced polymer blends of recycled HDPE/PET: Three-dimensional stability under water immersion and mechanical performance. Polym. Compos. 2018, 39, 2695–2704.

- Raghu, N.; Kale, A.; Chauhan, S.; Aggarwal, P.K. Rice husk reinforced polypropylene composites: Mechanical, morphological and thermal properties. J. Indian Acad. Wood Sci. 2018, 15, 96–104.

- Rajendran Royan, N.R.; Sulong, A.B.; Yuhana, N.Y.; Chen, R.S.; Ab Ghani, M.H.; Ahmad, S. UV/O3 treatment as a surface modification of rice husk towards preparation of novel biocomposites. PLoS ONE 2018, 13, e0197345.

- Bisht, N.; Gope, P. Effect of alkali treatment on mechanical properties of rice husk flour reinforced epoxy bio-Composite. Mater. Today Proc. 2018, 5, 24330–24338.

- Santiagoo, R.; Ismail, H.; Suharty, N. Comparison of processing and mechanical properties of polypropylene/recycled acrylonitrile butadiene rubber/rice husk powder composites modified with silane and acetic anhydride compound. In Natural Fibre Reinforced Vinyl Ester and Vinyl Polymer Composites; Elsevier: Amsterdam, The Netherlands, 2018; pp. 333–347.

- Zhang, Q.; Zhang, D.; Lu, W.; Khan, M.U.; Xu, H.; Yi, W.; Lei, H.; Huo, E.; Qian, M.; Zhao, Y. Production of high-density polyethylene biocomposites from rice husk biochar: Effects of varying pyrolysis temperature. Sci. Total Environ. 2020, 738, 139910.

- Moreno, D.D.P.; de Camargo, R.V.; dos Santos Luiz, D.; Branco, L.T.P.; Grillo, C.C.; Saron, C. Composites of recycled polypropylene from cotton swab waste with pyrolyzed rice husk. J. Polym. Environ. 2021, 29, 350–362.

- Boonsuk, P.; Sukolrat, A.; Bourkaew, S.; Kaewtatip, K.; Chantarak, S.; Kelarakis, A.; Chaibundit, C. Structure-properties relationships in alkaline treated rice husk reinforced thermoplastic cassava starch biocomposites. Int. J. Biol. Macromol. 2021, 167, 130–140.

- Olcay, H.; Kocak, E.D. Rice plant waste reinforced polyurethane composites for use as the acoustic absorption material. Appl. Acoust. 2021, 173, 107733.

- Shubbar, S.D.A. Experimental investigation of rice husk particles as filler in hybrid composites. J. Univ. Babylon Eng. Sci. 2018, 26, 307–315.

- Awang, M.; Mohd, W.W. Comparative studies of Titanium Dioxide and Zinc Oxide as a potential filler in Polypropylene reinforced rice husk composite. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Pekan, Malayzia, 1–2 March 2018; p. 012046.

- Kumar, S.; Mer, K.K.S.; Gangil, B.; Patel, V.K. Synergy of rice-husk filler on physico-mechanical and tribological properties of hybrid Bauhinia-vahlii/sisal fiber reinforced epoxy composites. J. Mater. Res. Technol. 2019, 8, 2070–2082.

- Hidalgo-Salazar, M.A.; Salinas, E. Mechanical, thermal, viscoelastic performance and product application of PP-rice husk Colombian biocomposites. Compos. Part. B Eng. 2019, 176, 107135.

- Singh, T.; Gangil, B.; Patnaik, A.; Biswas, D.; Fekete, G. Agriculture waste reinforced corn starch-based biocomposites: Effect of rice husk/walnut shell on physicomechanical, biodegradable and thermal properties. Mater. Res. Express 2019, 6, 045702.

- Sun, J.; Pang, Y.; Yang, Y.; Zhao, J.; Xia, R.; Li, Y.; Liu, Y.; Guo, H. Improvement of rice husk/HDPE bio-composites interfacial properties by silane coupling agent and compatibilizer complementary modification. Polymers 2019, 11, 1928.

- Běhálek, L.; Borůvka, M.; Brdlík, P.; Habr, J.; Lenfeld, P.; Kroisová, D.; Veselka, F.; Novák, J. Thermal properties and non-isothermal crystallization kinetics of biocomposites based on poly (lactic acid), rice husks and cellulose fibres. J. Therm. Anal. Calorim. 2020, 142, 629–649.

- Guna, V.; Ilangovan, M.; Rather, M.H.; Giridharan, B.; Prajwal, B.; Krishna, K.V.; Venkatesh, K.; Reddy, N. Groundnut shell/rice husk agro-waste reinforced polypropylene hybrid biocomposites. J. Build. Eng. 2020, 27, 100991.

- Petchwattana, N.; Sanetuntikul, J. Static and Dynamic Mechanical Properties of Poly (vinyl chloride) and Waste Rice Husk Ash Composites Compatibilized with γ-aminopropyltrimethoxysilane. Silicon 2018, 10, 287–292.

- Jiang, L.; Fu, J.; Liu, L.; Du, P. Wear and thermal behavior of basalt fiber reinforced rice husk/polyvinyl chloride composites. J. Appl. Polym. Sci. 2021, 138, 50094.

- Kargarzadeh, H.; Johar, N.; Ahmad, I. Starch biocomposite film reinforced by multiscale rice husk fiber. Compos. Sci. Technol. 2017, 151, 147–155.

- Yap, S.Y.; Sreekantan, S.; Hassan, M.; Sudesh, K.; Ong, M.T. Characterization and Biodegradability of Rice Husk-Filled Polymer Composites. Polymers 2021, 13, 104.

- Spada, J.C.; Seibert, S.F.; Tessaro, I.C. Impact of PLA Poly (Lactic Acid) and PBAT Poly (butylene adipate-co-terephthalate) coating on the properties of composites with high content of rice husk. J. Polym. Environ. 2021, 29, 1324–1331.

- Deo, C.; Acharya, S. Effect of moisture absorption on mechanical properties of chopped natural fiber reinforced epoxy composite. J. Reinf. Plast. Compos. 2010, 29, 2513–2521.

- Shakeri, A.; Ghasemian, A. Water absorption and thickness swelling behavior of polypropylene reinforced with hybrid recycled newspaper and glass fiber. Appl. Compos. Mater. 2010, 17, 183–193.

- Miao, J.; Tsige, M.; Taylor, P.L. Generalized model for the diffusion of solvents in glassy polymers: From fickian to super case II. J. Chem. Phys. 2017, 147, 044904.

- Siriwardena, S.; Ismail, H.; Ishiaku, U. A comparison of the mechanical properties and water absorption behavior of white rice husk ash and silica filled polypropylene composites. J. Reinf. Plast. Compos. 2003, 22, 1645–1666.

- Melo, R.Q.; Lia Fook, M.V.; de Lima, A.G. Non-Fickian Moisture Transport in Vegetable-Fiber-Reinforced Polymer Composites Using a Langmuir-Type Model. Polymers 2020, 12, 2503.

- Lee, S.-H.; Ohkita, T.; Kitagawa, K. Eco-composite from poly (lactic acid) and bamboo fiber. Walter de Gruyter 2004, 58, 529–536.

- Chen, R.S.; Ahmad, S. Mechanical performance and flame retardancy of rice husk/organoclay-reinforced blend of recycled plastics. Mater. Chem. Phys. 2017, 198, 57–65.

- Sheykh, M.J.; Tarmian, A.; Doosthoseini, K. Wear resistance and friction coefficient of nano-SiO2 and ash-filled HDPE/lignocellulosic fiber composites. Polym. Bull. 2017, 74, 4537–4547.

- Huner, U. Effect of chemical treatment and maleic anhydride grafted polypropylene coupling agent on rice husk and rice husk reinforced composite. Mater. Express 2017, 7, 134–144.

- Saidi, M.A.; Ahmad, M.; Arjmandi, R.; Hassan, A.; Rahmat, A.R. The effect of titanate coupling agent on water absorption and mechanical properties of rice husk filled poly (vinyl chloride) composites. In Natural Fibre Reinforced Vinyl Ester and Vinyl Polymer Composites; Elsevier: Amsterdam, The Netherlands, 2018; pp. 197–210.

- Mohamed, R.; Mohamed, M.M.F.; Norizan, M.N.; Mohamed, R.R.R. Physical and morphological properties of filled calcium carbonate/kenaf fibre/rice husk polypropylene hybrid composite. In Proceedings of the AIP Conference Proceedings, Selangor, Malaysia, 21–22 October 2017; p. 050003.

- Battegazzore, D.; Alongi, J.; Frache, A.; Wågberg, L.; Carosio, F. Layer by Layer-functionalized rice husk particles: A novel and sustainable solution for particleboard production. Mater. Today Commun. 2017, 13, 92–101.

- Prapruddivongs, C.; Apichartsitporn, M.; Wongpreedee, T. Effect of silica resources on the biodegradation behavior of poly (lactic acid) and chemical crosslinked poly (lactic acid) composites. Polym. Test. 2018, 71, 87–94.

- Akindoyo, J.O.; Husney, N.A.A.b.; Ismail, N.H.; Mariatti, M. Structure and performance of poly (lactic acid)/poly (butylene succinate-co-L-lactate) blend reinforced with rice husk and coconut shell filler. Polym. Polym. Compos. 2020, 0967391120954047.

- Daramola, O.O. Flesural properties and water absorotion characteristics of high density polyethylene-based siliceous composites. Acta Tech. Corviniensis-Bull. Eng. 2019, 12, 57–62.

- Hamid, N.H.; Hisan, W.S.I.W.B.; Abdullah, U.H.; Azim, A.A.A.; Tahir, P.M. Mechanical properties and moisture absorption of epoxy composites mixed with amorphous and crystalline silica from rice husk. BioResources 2019, 14, 7363–7374.

- Chalapud, M.C.; Herdt, M.; Nicolao, E.S.; Ruseckaite, R.A.; Ciannamea, E.M.; Stefani, P.M. Biobased particleboards based on rice husk and soy proteins: Effect of the impregnation with tung oil on the physical and mechanical behavior. Constr. Build. Mater. 2020, 230, 116996.

- Norhasnan, N.H.A.; Hassan, M.Z.; Nor, A.F.M.; Zaki, S.; Dolah, R.; Jamaludin, K.R.; Aziz, S.A.A. Physicomechanical properties of rice husk/coco peat reinforced acrylonitrile butadiene styrene blend composites. Polymers 2021, 13, 1171.

- Chen, R.S.; Ab Ghani, M.H.; Ahmad, S.; Mou’ad, A.T.; Gan, S. Tensile, thermal degradation and water diffusion behaviour of gamma-radiation induced recycled polymer blend/rice husk composites: Experimental and statistical analysis. Compos. Sci. Technol. 2021, 207, 108748.

- Muthuraj, R.; Lacoste, C.; Lacroix, P.; Bergeret, A. Sustainable thermal insulation biocomposites from rice husk, wheat husk, wood fibers and textile waste fibers: Elaboration and performances evaluation. Ind. Crops Prod. 2019, 135, 238–245.

- Yusuf, T.A. Characterization of selected properties of composites of waste paper with untreated bamboo stem fibre and rice husk. Acta Polytech. 2017, 57, 295–303.

- Antunes, A.; Faria, P.; Silva, V.; Brás, A. Rice husk-earth based composites: A novel bio-based panel for buildings refurbishment. Constr. Build. Mater. 2019, 221, 99–108.

- Nabinejad, O.; Debnath, S.; Ying, T.J.; Liew, W.Y.; Davies, I.J. Influence of alkali treatment and nanoclay content on the properties of rice husk filled polyester composites. Mater. Sci. Forum 2017, 882, 89–100.