Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Subjects:

Engineering, Electrical & Electronic

Solar Photovoltaic (PV) energy is a clean, attractive, and secure source of electricity generation. Due to its expanse usage around the globe, the development of an advanced monitoring method is crucial. PV performance can be affected by various environmental factors such as soiling, temperature, irradiance etc., Thus, solar PV accuracy and performance can be improved by employing an efficient solar PV real-time monitoring system.

- solar PV

- wireless monitoring system

- sensors

- data processing board

- data transmission protocols

- data acquisition

Introduction

The depletion of fossil fuels and carbon emission issues have transformed power systems from conventional systems to renewable systems [1,2,3]. Moreover, the need for energy security and economic stability has increased, and hence more and more emphasis is now being given to the generation of renewable energy [4,5]. Among the renewable energy sources, solar energy is attractive and sustainable [6]. Solar Photovoltaic (PV) energy is considered a clean, attractive, and secure source of electricity generation [7,8]. The solar PV system promises a great future and is increasingly popular due to its simple installation, low maintenance cost, robustness, and zero fuel cost [9,10]. Solar power is abundant; thus, it could play a crucial role in fulfilling global energy requirements including heating, ventilation, and air-conditioning (HVAC) systems, domestic lighting, hot water systems, and other key applications [11]. The cost reduction in solar PV installation is due to several factors such as improved technology, economies of scale, supply chain competitiveness, and the growing experience of developers [12,13]. At present, solar PV energy is the third-largest renewable source of energy generation after wind and hydro [14]. In the last two decades, the solar PV system has become one of the main sources for power generation [15,16]. In 2018, a unique milestone in the field of solar PV systems was achieved i.e., the 100 GW threshold of annual installations was crossed [17]. According to the Renewable Energy Market Report 2018 by the International Energy Agency (IEA), there will be a comprehensive growth in the generating capacity of solar PV systems from 572 GW to 720 GW between 2018 and 2023 [18]. Further, the global solar PV power capacity is expected to increase to more than 2840 GW by 2030, and to 8519 GW by 2050 [12].

Since the need for solar energy has risen around the globe, the development of an advanced monitoring method has become an urgent necessity. Due to various environmental factors such as soiling, temperature, irradiance etc., the operation and functionality of solar PV systems can be affected. Thus, the accuracy and performance of the solar PV system can be improved by employing an efficient solar PV monitoring system [19]. Monitoring is the process of observing and recording the parameters from the solar PV power plant in real-time. An efficient monitoring technology of the solar PV system improves the performance efficiency as it provides updated information and executes the preventive measures if any flaws are found. The monitoring method also notifies the users by an alert signal when unexpected events occur in a solar PV system [20]. The monitoring of the solar PV power plant is performed either at the module, string, or system level. The monitoring of the solar PV at the system level provides information about the system exclusively. The monitoring technology related to panels and strings helps in identifying the root cause of the problem precisely. Every panel and string needs to be monitored for the overall efficiency improvement of a solar PV power plant, as even a change in the output from a single panel can affect the efficiency of the entire system. Henceforth, numerous monitoring methods have been introduced in recent decades. There has been a change of trend from wired to wireless monitoring systems in the past decade [21].

In the past, the wired monitoring system was commonly used for transferring data through an RS232 cable or an RS485 cable [22,23] However, as the solar PV system has expanded, real-time monitoring using conventional wired cables has resulted in additional significant costs. Moreover, the cables carrying the data are exposed to environmental conditions such as rain, humidity, temperature, etc. In contrast, the wireless monitoring system is less prone to environmental conditions compared to the wired monitoring system and can deliver faster decision-making in real-time. This is due to the exposure of sensors and nodes to the open environment installed for data acquisition and transmission. Furthermore, wireless monitoring technologies not only increase mobility and network security by implementing associated security protocols, but they also have a longer range, a high response time, and low maintenance costs. Nevertheless, various factors can cause a change in the output of the system, including a change from a sunny sky to a cloudy sky, the temperature of the panel, humidity, irradiance, the mounting angle, and the mismatch between the specification from the manufacturers and the actual PV output [24]. Therefore, further exploration is required to design an effective solar PV monitoring technology before the system can be implemented, considering the number of anticipated challenges.

Very few notable review articles have been published on solar PV monitoring technologies. Shariff et al. [25] emphasized different designs and topologies of solar PV monitoring systems. The different monitoring characteristics such as sampling time, mechanisms for data transfer, associated software etc., were highlighted in the work but the works did not outline the current progress in the field of monitoring with regards to module-based technology. Madeti and Singh [26] focused on examining solar PV systems in terms of the sensors employed, the controllers used, and data transmission techniques. Rahman et al. [27] discussed the architecture and features of various monitoring systems for solar PV power plants. Triki-Lahiani et al. [28] explained the various monitoring systems and concentrated on addressing the major failures in solar PV systems. All the above-highlighted reviews do not consider the insights of the technological implementation of data transmission and data processing modules in the field of solar PV wireless monitoring systems in a comprehensive manner.

To bridge the existing research gaps, this review unveils new contributions with a detailed investigation of the monitoring technologies of the solar PV system. The review offers the following contributions:

-

A comprehensive explanation of various data processing modules for solar PV monitoring systems is presented in terms of categories, specifications, design implementation, software platforms, results, and limitations.

-

The categories of the various data transmission modules for wireless communication in solar PV monitoring systems are reported, highlighting topology, data transmission rage, sampling rate, power consumption, and range.

-

The existing issues and challenges for the monitoring technologies of solar PV applications are covered, emphasizing data handling, security, signal interference, energy efficiency, etc.

-

Some constructive future recommendations are presented toward the development of an efficient and reliable solar PV monitoring system.

2. Survey Methodology

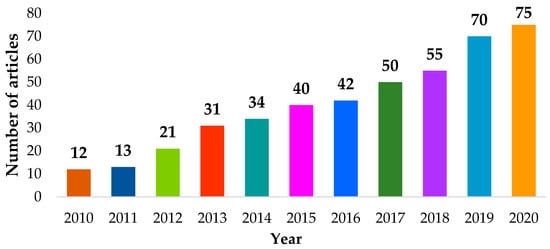

There has been a growing interest among researchers to enhance the performance of solar PV monitoring systems using various technologies. In line with this matter, various data processing modules and data transmission protocols have been introduced in the last decade. Figure 1 denotes the number of papers published between 2010 and 2020. A sharp upward trend is visible in the number of articles accepted from 2010 to 2020 which implies the importance and potential deployment of various modules and communication protocols in solar PV applications. A total of 443 papers were published between 2010 and 2020. Among the total number of manuscripts, 43.57% of the articles were published in the first seven years (2010–2016). However, the number of articles published in the next four years (2017–2020) increased at a greater rate. In this period, 56.43% of the articles were published which is 12.86% higher than the previous seven years.

Figure 1. Research trend of solar PV monitoring systems from 2010 to 2020.

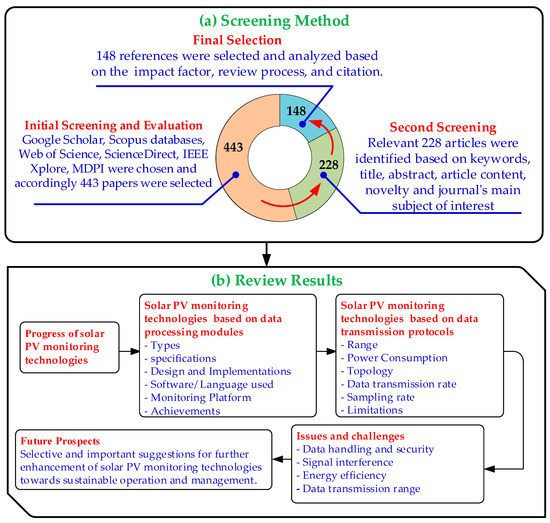

The goal of this review is to gather all the recent information, conduct an analysis, and provide a critical discussion of the monitoring technologies for solar PV systems. Firstly, Google scholar, IEEEXplore, MDPI, and ScienceDirect databases were utilized to explore the related work for this paper. Secondly, keywords, abstract, paper content, novelty, and the main topic of interest of the journal were applied to search for the relevant publications within the scope of this paper including solar PV, wireless monitoring systems, sensors, data processing board, and data transmission protocols. The final suitable works were investigated by assessing the impact factors, the review process, and the citations.

The outcome of the screening process can be categorized into four sections. Firstly, the review of solar PV monitoring systems based on data processing modules with its design features, implementation, comments or suggestions, and limitations is presented. Secondly, various data transmission protocols are studied for solar PV monitoring systems. Thirdly, the review investigates various issues and shortcomings of the monitoring technology for solar PV systems. Finally, the review delivers some selective future prospects for the further enhancement of solar PV monitoring systems. The review process can be divided into two phases as shown in Figure 2 and summarized as follows:

Figure 2. Schematic diagram of the survey methodology.

2.1. Selection Process

-

In the first search results, a total of 443 articles were found using various platforms including Google scholar, IEEEXplore, MDPI, and the ScienceDirect databases.

-

In the second screening results, a total of 228 articles were selected based on the appropriate title, keywords, abstract, and content of the paper.

-

In the third assessment results, the articles were analyzed based on impact factor, review process, and citation. Accordingly, a total of 148 references were finalized for the review paper consisting of journals, conferences proceedings, and recognized webpages.

2.2. Review Results

-

Monitoring technologies for solar PV systems based on data processing modules were explained.

-

Further, the monitoring technologies considering various data transmission protocols for solar PV application were discussed.

-

Key issues and limitations of the solar PV monitoring system based on the presented technology were explored.

-

Recommendations and future directions for the further improvement of the monitoring technology for solar PV systems were presented.

3. Overview and Taxonomy of Solar PV Monitoring System

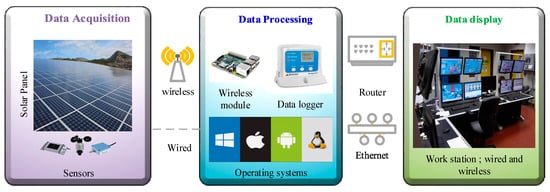

The architecture of the solar PV monitoring system can be divided into three levels, namely, the data acquisition level, the data processing level, and the data display and storage level, as illustrated in Figure 3 [27]. In the data acquisition level, the data are collected from the various sensors such as voltage, current, temperature, humidity, irradiance, etc., and are then sent to the next stage using either the wired or the wireless system. In the next level, the data are stored temporarily in auxiliary devices such data loggers, processed, and sent to the last stage for the display of the results. In the last level, the data are received by the workstation and then the required actions are taken by the system to be configured accordingly. These data can be accessed from anywhere at any time via the internet.

Figure 3. The basic architecture of a solar PV monitoring system.

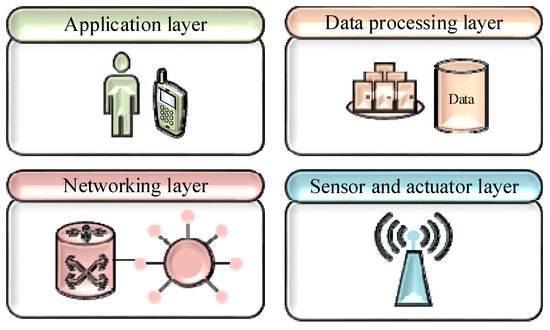

A comprehensive review of solar PV monitoring system-based data processing modules and data transmission protocols has been carried out. The data transmission modules allow the acquisition, control, and management of connected devices and networks in a real-time environment. Furthermore, they act as middleware that connects with different devices through cloud computing technology. The solar-based monitoring system is comprised of a four-layer structure which consists of sensors (electrical and environmental) for gathering data such as panel voltage, current, temperature, humidity (small scale) etc., a network layer for the transmission of the data by utilizing various transmission protocols such as ZigBee, Wi-Fi, Bluetooth, LoRa etc., a data processing layer for processing necessary data through various data processing modules such as Raspberry Pi and Arduino, and lastly, an application layer which acts as an interface between end devices and the network as depicted in Figure 4. Further, Fernandez et al. [29] explored the functionality of the various layers such as the sensor, transmission, data processing, and application layers. The authors revealed that the change in the execution of various layers is based on applications such as small scale or large-scale monitoring, and software-based or cloud-based monitoring. The classification of various electrical and environmental parameters based on large-scale and small-scale solar PV systems is presented in Table 1. Platforms such as BeagleBone, Arduino, Raspberry Pi, PLC, and the microcontroller chip have been reviewed in relation to the application of data transmission protocols, the parameters measured, the software used, the monitoring platform, and the related results. In addition, the monitoring system consists of several network protocols for communication to ensure the protection of data during transmission between connected devices [30] Furthermore, issues relating to low range, low computational speed, low storage memory etc., motivates the requirement of the communication protocol for the monitoring system [31]. In this regard, communication protocols utilizing various wireless communication modules such as ZigBee, Wi-Fi (ESP8266 module), Bluetooth, GSM, and the LoRa module have been reviewed for monitoring solar PV systems.

Figure 4. Primary layers for the development of a solar-based monitoring system.

Table 1. Classification of various electrical and environmental parameters monitored under large-scale and small-scale solar PV systems.

| Solar PV System | Parameters | |

|---|---|---|

| Environmental | Electrical | |

| Large scale | Irradiance | Array output voltage |

| Array Temperature | Array output current | |

| Speed of wind | Grid voltage | |

| Humidity | Current to and from grid | |

| Air pressure | Grid impedance | |

| Small scale | Panel output voltage | |

| Irradiance | Panel output current | |

| Panel Temperature | Inverter output voltage | |

| Humidity | Inverter output current | |

| Load output voltage | ||

| Load output current | ||

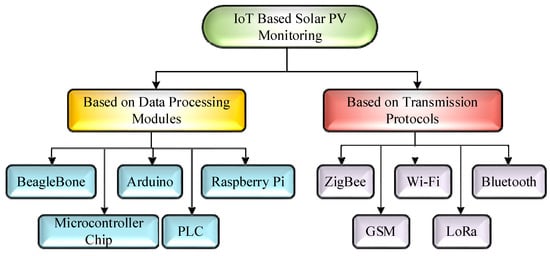

Various state-of-the-art monitoring technologies for solar PV applications have been comprehensively studied based on the application of electronics modules required for data processing, data transmission protocols, and Artificial Intelligence (AI) techniques. Monitoring technology depending on various data processing boards has been explored. The advancements in solar PV monitoring systems in relation to BeagleBone [32], Arduino [33,34] Raspberry Pi [35,36], PLC [37], and microcontroller chips such as ATMEGA8 and ATMEGA16 [38] have been explained along with their limitations. Data transmission protocols such as ZigBee [39,40], GSM [41], Wi-Fi [42], Bluetooth [43], and LoRa [44] have also been studied with regard to the various aspects such as range, parameters to be monitored, program language, sampling time etc. The review of the monitoring technologies based on two distinct classes is presented in Figure 5.

Figure 5. Classification of data processing technology and data transmission protocols for a solar PV monitoring system.

4. Progress of Data Processing Modules for Solar PV Monitoring System

A comprehensive review of various data processing modules for a solar PV monitoring system has been performed which gives an insight into its implementation, design, specifications, used software, and limitations.

4.1. BeagleBone-Based Module

The BeagleBone module is an open-source Linux platform and is also considered as microcomputer which was developed by Texas Instruments, digi-Key, and Newark element 14 in 2008 [45]. The board consists of several busses such as Serial Peripheral Interface (SPI), 12C and Control Area Network (CAN), analog inputs, general-purpose input-output pins, serial ports etc. [46]. It was developed to assist young students learning about open-source hardware and software. Furthermore, it is widely accepted worldwide due to various factors such as its network capabilities, remote control, time management, etc.

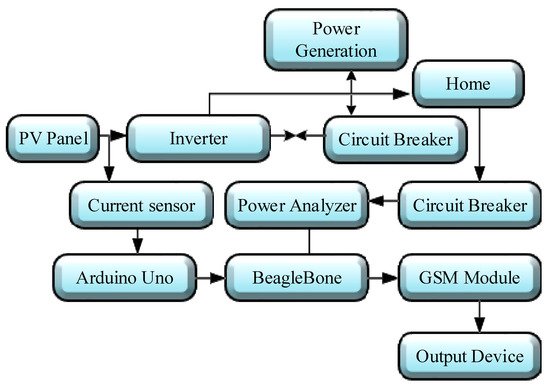

Ngo and Floriza proposed a BeagleBone module-based solar PV monitoring system for computing the energy generated as shown in Figure 6 [32]. The proposed system not only computes the energy generated from the solar PV system, but it also monitors its consumption by the respective households. In addition, the designed system was equipped with a web-based mobile application for analyzing the data in real-time. An algorithm was developed with a web-based application for calculating the monthly household energy consumption charge as well as the energy generated by the system. Furthermore, after analyzing the information provided by the web-based application software, it was easier to take the necessary steps to limit the consumption of energy and hence limiting the electricity cost. Solar PV in a household system was analyzed by the proposed design and several electricity parameters such as voltage, current, output power, and energy were calculated. The extracted electrical parameters were transmitted by the sensors to the server and further to mobiles via the Short Messaging Service (SMS). The presented design consisted of sensors such as INA219 for measuring DC power and the CS5463 sensor for the measurement of AC power, the BeagleBone Black module, and the GSM module for the transmission of data to the server. A python script was scripted in BeagleBone Black module to communicate with different sensors. It was realized that the proposed model could be enhanced comprehensively by employing sophisticated data processing modules for handling complex data in the calculation of the energy tariff for different household utilities. Moreover, Okhorzina et al. [47] proposed a low range monitoring and control system by utilizing the BeagleBone module. The paper proposed a tracking and cooling system to eliminate the problem of the heating of solar panels. The designed system is comprised of a BeagleBone module which controls the overall working of the system in conjunction with the temperature sensors. An algorithm was prepared to control and monitor the heat of the solar PV system by utilizing a liquid cooling mechanism. It was observed that the algorithm proposed by the author needs more attention to control the cooling of the PV station as well as the functionality of the station which could enhance the performance of the system.

Figure 6. BeagleBone-based monitoring of solar PV systems.

Although the BeagleBone modules have various advantages such as compact size, low power consumption of up to 2 W, high processing power, open-source platform to play etc., their usage is limited by factors such as low numbers of Universal Serial Bus (USB) ports for connecting external devices, expensive cost, the lack of extensive community support, limited connectivity to Wi-Fi, Bluetooth, and lastly, limited color in HDMI resolutions [48].

4.2. Arduino Based Module

The Ivrea Interaction Design Institute invented Arduino technology which was intended for students with no background in the field of electronics hardware as well as programming [49]. Due to the easy availability of hardware design and software programming codes, Arduino is currently one of the most influential open-source hardwares to work with. Arduino IDE is used to program an Arduino board which is a simplified version for C++. Furthermore, Arduino boards can read input from several sources as well as publish the output in various forms such as the switching on/off of the motor, writing a text online, and controlling light [50].

Allafi et al. [34] designed a monitoring system for standalone PV systems by utilizing low-cost Supervisory Control And Data Acquisition (SCADA) with Arduino Uno. The data was extracted by the current sensor ACS712 and a voltage sensor and sent to the Arduino Uno microcontroller which was further transmitted to the computer through a USB cable. Furthermore, the Modbus library was installed on Arduino to set up the communication between Arduino and SCADA. The main aim of the proposed system was to determine the MPPT efficiency of the system from the data extracted by the sensors. In addition to the proposed system, more functionality in terms of observing electrical as well as environmental parameters such as panel voltage, panel current, temperature, and humidity could be implemented for future research works. Furthermore, Vargas et al. [51] developed a low-cost data logger system for monitoring remote PV systems through Arduino Uno. The proposed design meets the necessary requirements laid down by the International Electro-Technical Commission (IEC). The low-cost data logger utilizing Arduino was capable of operating in remote locations with less network coverage and with minimum maintenance costs. To overcome the limitations of Arduino Uno, the author suggested improvements such as integrating the 12C bus with PCB, a Real-Time Clock (RTC), two external ADCs, SD flash memory, a visual interface, and a power consumption module to make the system compatible according to IEC standards. The temperature sensor DS18B20 along with the current sensor and voltage sensor were placed to extract the data and to send it to an improved data logger. The algorithm to operate Arduino was written in C/C++ with Arduino IDE. The test on the improved data logger was held for one month to test the efficiency in compliance with IEC standards. For further upgradation, the suggested model could be developed for a large coverage area with more data handling capabilities, and the complexity of the model could be reduced by using an easy programming language. Recently, Jamil et al. [52] presented an Arduino-based performance monitoring system for floating solar PV systems. In this approach, the main controller was regarded as Arduino Nano. Furthermore, electrical parameters such as voltage, current, and output power of solar PV modules of 10 W were monitored. Moreover, the monitoring of the module was performed on both the floating system as well as a land system. It was concluded that power output and efficiency were higher in the floating system compared to the land system. The presented system is simpler in implementation; hence, the system can be developed with high wattage monitoring capabilities. Gonzalen and Calderón [53] introduced a hybrid approach with PLC and Arduino to monitor the temperature of solar panels in Smart Grids/Micro-Grids applications. The acquisition and display of data were performed in combination with PLC and SCADA while the extraction and transmission of data were completed by the Arduino MEGA 2560 R3 platform. Although the extensive extraction of temperature was executed, the utilization of various other sensors for the extraction of electrical and environmental parameters could be considered in future works.

Although the technology of Arduino boards possesses several advantages such as low cost, adaptability to various operating systems such as Linux, Windows and Macintosh, easy and flexible programming environment, etc., it suffers from various limitations too. Firstly, it suffers from a limited bit resolution of up to 10 bits. Secondly, for complex and advanced research, more sophisticated platforms are chosen over Arduino boards as the latter is not capable of handling complex data consisting of several processes at once [54].

4.3. Raspberry Pi-Based Module

The Raspberry Pi module is a single-board computer with a low-cost package [33,55]. It is a device similar to a fully functional computer manufactured on a single printed circuit board. The size of Raspberry Pi is as small as a credit card but it has the capability of performing a task similar to a computer [56]. The Linux operating system is used to operate Raspberry Pi [57]. The ARM-based CPU embedded in Raspberry Pi draws less power which eliminates the need for a heat sink [58]. The easy-to-use module of Raspberry Pi can be utilized for enabling wireless technology [59] and Arduino interaction [60]. Moreover, many variants of the operating system are supported by Raspberry Pi which only requires power to boot [61]. Due to its numerous advantages stated above, Raspberry Pi modules are now used in real-time monitoring schemes.

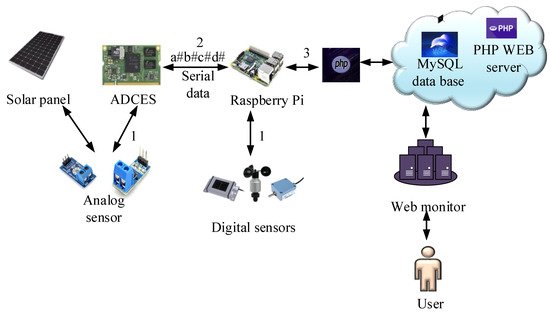

Pereira et al. developed a multi-user remote system-based Renewable Energy Monitoring System (REMS) using Raspberry Pi and the internet of things (IoT) concept as depicted in Figure 7 [62]. The REMS was updated by the Analogue Digital Converter Embedded System (ADCES) and the communication was established in Linux and cloud server profiles. The REMS server and online server database had a storage capacity of 84.44 MB and 2 GB, respectively. The data was stored at 1 sample/minute with the size of 150 bytes for 391 days. The experiment was performed on a 50 W load with the following specifications: model YL95P-17b 2/3, a maximum power of 95 Wp, 14.3% efficiency, an open-circuit voltage (Voc) of 22.5 V, and a short circuit current (Isc) of 5.59 A. The developed architecture did not have to unlock ports and/or firewall when using the multi-user cloud service. It was proposed that cryptography to secure data storage and database confidentiality should be implemented. The proposed model could be modified to record data from other types of analog or digital sensors as well as for other types of applications using renewable sources. In addition, the utilization of programming languages such as Basic C language and Linux is preferred.

Figure 7. The block diagram of Raspberry Pi and IoT-based REMS.

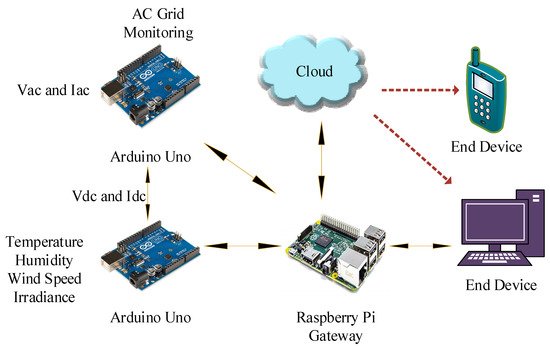

The work by the authors in [35] proposed a Raspberry Pi-based solar PV monitoring system at the module level using the IEC 61724 standard as presented in Figure 8 [35]. The monitoring was performed at the module level which gave detailed information about the solar PV plant performance. The system not only monitors the electrical and environmental data, but it also evaluates PV module performance and identifies any abnormal behaviors. The variable parameters of the solar PV were monitored under the environment of LABVIEW. The design was implemented with a 5 kWp solar PV consisting of 18 PV modules where each module had a capacity of 310 Wp. The results showed that the error rate was estimated to be less than 2%. The introduced design could be altered to store the data on the cloud/internet for future reference so it can be accessed easily.

Figure 8. Presented diagram for a Raspberry Pi-based monitoring system.

Ranjit and Abbod [63] designed a cloud-based Raspberry Pi system for solar PV monitoring consisting of four thermocouples connected to the ADAFRUIT MAX31855 processor. Data recorded by the Raspberry Pi were transferred to the cloud system. It was proposed that technological implementation can assist in lowering the fatigue at the panels which could be easily detectable when any fatigue condition occurs. The methodology could be improved by the inclusion of a cryptographic method to secure the data comprehensively. Bikrat et al. [64] established a system with a Raspberry Pi3 card for the monitoring of a remote solar PV system using Bluetooth and Wi-Fi modules. Bluetooth protocol was implemented by transferring the data from the sensors to the Raspberry Pi module. Wi-Fi protocol was used to transfer data from the gateway to the supervision machine/cloud. The comparative analysis among different Raspberry Pi modules confirmed the superiority of the Raspberry Pi3 module over other modules. Further modifications such as flexibility in the operating system as well as the processing application could lead to future expansion.

Raspberry Pi is one of the most effective data processing modules in the field of monitoring systems. However, it does have some technical drawbacks such as, it does not have a Real-Time Clock (RTC) with a backup battery, and it has a high power consumption and weight [65]. Moreover, it lacks a Basic Input Output System (BIOS), and thus it always boots from an SD card. Besides, it does not have a built-in Analog to Digital (AD) converter and hence, an external component must be used for AD conversion [66].

4.4. PLC-Based Module

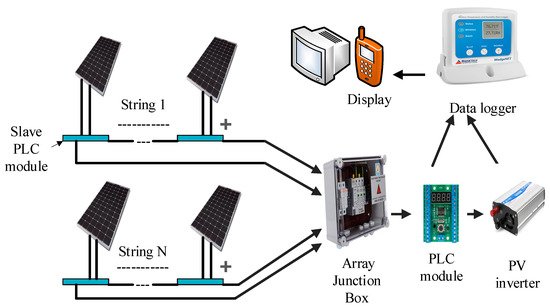

A programmable logic controller (PLC) or a programmable controller is part of a computer family applied in commercial and industrial applications [67,68]. PLC exhibits robust construction and operational features such as sequential control, ease of programming, timers and counters, easy-to-use hardware, and reliable controlling capabilities which are essential in automation and monitoring applications. PLC modules are reliable and efficient in the synchronization of methods, control applications, and automated systems. Furthermore, it observes the state of processes such as monitoring and relates the data acquired from various sensors [69]. The main operation of the PLC is to monitor and make a decision based on how the system is programmed and how the output is controlled. Moreover, a PLC-based system is implemented in various fields such as monitoring, control, and PV applications [70,71]. The basic PLC monitoring system is displayed in Figure 9 [66].

Figure 9. Configuration of a solar PV monitoring system implementing the PLC module.

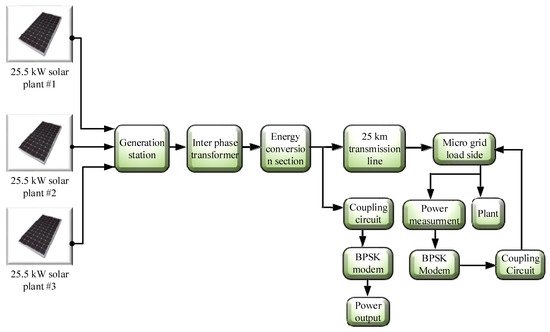

Han et al. [72] proposed a PLC-based monitoring system to record each solar PV module parameter. The low-cost PLC module was applied on the 16-bit microcontroller unit MCU) which generated a 100 kHz carrier. A 6.4 kW solar V plant consisting of 16 panels and an inverter rated at 10 kW were employed. The system operated at 49.4 V, 8.1 A, and 400 W of maximum power. Communication modules were not utilized in the proposed topology resulting in cost reductions in the system. The proposed monitoring system was integrated with the home network consisting of the home plug. Another concept in the field of the solar PV power plant is string monitoring with PLC which was proposed by Goto et al. [73]. The monitoring of each string in a solar PV plant consisted of 10–20 panels. The need for string monitoring was implemented due to factors such as aging solar panels and initial failure which degrades the output power of the solar power plant. The authors monitored 30 power stations with capacities ranging from 1 to 15 MW. A case study of a 1 MW solar plant consisting of 314 strings was investigated for 13 months from January 2015 to January 2016. It was observed that the proposed methodology for monitoring primarily focused on string monitoring. Hence, the methodology could be improved by incorporating the monitoring technique at array and module-level for low power generation applications. Mao et al. [69] introduced an intelligent solar PV module monitoring scheme based on a parallel resonant coupling unit. The proposed design used a DC bus and a communication channel to modulate the data into high frequencies for carrier communication. The presented scheme delivered high transmission efficiency and strong anti-interference ability with low costs. Kabalci and Kabalci [74] suggested a PLC-based solar PV monitoring method to develop a micro grid model on the MATLAB/Simulink environment. The system was designed using a DC-AC converter, three solar power plants with a maximum power point tracking (MPPT) system, a multilevel inverter for three-phase AC line voltage, with a 25 km transmission line and a PLC modem. It was stated that the proposed technique eliminated the need for additional monitoring costs since power lines carried the generated voltage as well as transferred the power drawn from the loads. The proposed block diagram of the PLC-based monitoring method is presented in Figure 10 [74]. The methodology of the proposed monitoring system could be further enhanced by simplifying the utilization of technology at the distribution level as well as the sub-distribution level too.

Figure 10. Proposed block diagram for a solar PV monitoring system implementing the PLC module.

PLC exhibits strong points in the progress of solar PV monitoring systems as it can deliver a better performance than other monitoring methods in terms of controlling outputs. In addition, PLC can last for 5–10 years and has low cooling costs since it does not generate much heat [75]. However, the outcome of PLC is not good enough when handling a large amount of data or complex data. Furthermore, the Pentium system, which is widely available today, outperforms even the fastest PLC. Moreover, debugging in PLC may become tedious as finding the fault is not very easy [76].

4.5. Microcontroller-Based Module

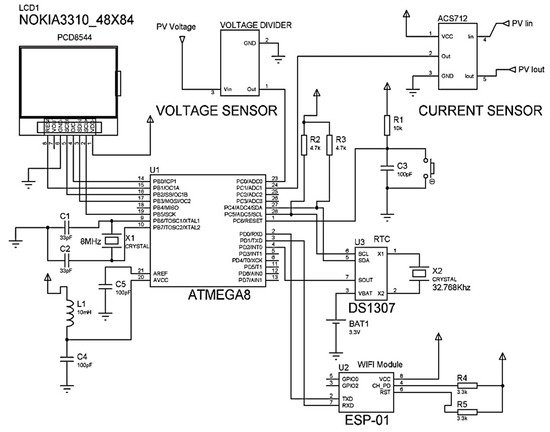

The microcontroller is an embedded computer system that has transformed the IoT [58,77,78]. Today, microcontrollers are extensively used in various fields [79] both in scientific research and industrial use [80]. The microcontroller module along with different interfaces is designed to monitor different parameters of solar PV power plants. The schematic circuit of a solar PV monitoring system with ATMEGA8 microcontroller is depicted in Figure 11.

Figure 11. Circuit diagram of a Microcontroller-based monitoring method for a solar PV system.

Suryavanshi et al. [81] proposed a solar PV monitoring system based on AVR microcontroller ATMEGA16. The load and battery were connected to the solar panel through a relay. The microcontroller sensed the power requirement of the load and accordingly managed two PV cells to connect to the load. The relay system was employed to manage the direction of the power from the solar panel either to the load or to the battery. Further improvements with regard to the maintenance of the solar panels by monitoring the environmental parameters could be assessed to develop a more reliable wireless solar PV monitoring system. A sensor network for monitoring solar PV with microcontroller PIC181F4620 was designed by Ayesh et al. [82]. Microchip MiWi protocol was used to monitor individual panels. The proposed structure was built to monitor open-circuit voltage (Voc), and short circuit currents (Isc) under various conditions such as dust accumulation, cracks in the string, shading, and MPPT. It was claimed that the monitoring of other electrical parameters such as Vpv and Ipv must be observed to effectively measure the power generated by the PV system under various conditions. Harmini and Nurhayati [83] developed a monitoring system for a standalone PV plant using an ATMEGA8 microcontroller through the ethernet. The accuracy of the panel output was determined by a voltage sensor and current sensor readings. It was concluded that the voltage sensors had an accuracy of about 99.3% and 95% for current sensors. Although the author implemented a real-time monitoring system by utilizing a visual basic system, it is necessary to integrate the technique with cloud-based monitoring to effectively utilize the monitored data for future reference.

Although the microprocessor is considered as the basic building block in many fields, it has some drawbacks, such as a lack of memory isolation and real-time performance. Moreover, the power consumption of the system on the chip increases due to the high-density integration of the embedded components [79]. The microcontroller is prone to unlimited physical access from attackers investigating its design and functionality [78]. Furthermore, due to its low storage capabilities and lack of real-time performance, microcontroller-based systems are less effective in the present scenario.

Table 2 provides a detailed specification between the various data processing modules utilized in solar PV systems.

Table 2. Comparison for the specification of various data processing modules.

| Arduino Uno | Raspberry Pi3 | PLC (FX1N-14MR) | BeagleBone | ATMEGA 16 | |

|---|---|---|---|---|---|

| Communication protocol | 4x SPI, 2x I2C, PCM/I2S, 2x UART | 1x SPI, 2x I2C, PCM/I2S, 1x UART | Ladder logic, Ethernet, RS-232, RS-422 and RS-485 modules | 4x UART, 2x SPI, 2x I2C, 2x CAN BUS | Serial, 12C, SPI |

| Size of Board | 69 × 53 mm | 85 × 56 mm | 110 × 95 × 17 mm | 86 × 56 mm | As per Requirement |

| Speed of Clock | 16 MHz | 1.2 GHz | 140–180 MHz | 1.0 GHz | 0–16 MHz |

| RAM | 16 MHz | 1 GB LPDDR2 | - | 512 MB DDR3 | 1 KB SRAM |

| Supply Voltage | 5 V | 5 V | 24 V | 5 V | 2.7–5.5 V |

| GPIO pins | 14 | 26 | 14 | 69 | 32 |

| Storage Memory | 32 KB | Micro SD | 8 MB | 4 GB, micro-SD | 16 KB Flash memory, 512 Byte EEPROM |

| USB port | - | 4 × USB 2.0 | - | 1 × USB | - |

| Processor | ATmega328P | Broadcom BCM2837, ARM Cortex- A53 64-b Quad Core | SLC 5/03 CPU | AM335x ARM Cortex-A8 | 8 bit processor |

| Power consumption | 98.53 mA @ 9 V | 400 mA @ 5.1 V | 400 mA (Approx) | 500 mA | 1.1 mA @ 3 V |

| Weight (Approx) | 30 g | 45 g | 120 g | 39.68 g | 20 g |

| Cost (Approx) | USD 30 | USD 25–35 | USD 45 | USD 30 | USD 3 (Approx) |

This entry is adapted from the peer-reviewed paper 10.3390/su13158120

This entry is offline, you can click here to edit this entry!