Union Internationale des Chemins (UIC) defines the high-speed railway (HSR) as a high-speed railway system that contains the infrastructure and the rolling stock. The infrastructure can be newly built dedicated lines enabled for trains to travel with speed above 250 km/h or upgraded conventional lines with a speed up to 200 or even 220 km/h. HSR requires specially built trains with increased power to weight ratio and must have an in-cab signalling system as traditional signalling systems are incapable of above 200 km/h.

- speed

- infrastructure

- rolling stock

- in-cab signaling system

- absence of level crossing

- HSR Technologies

HSR systems were divided into four groups depending on their relationship with conventional rail [1]; dedicated line, mixed high-speed line, conventional mixed line, and fully mixed [2]. Each of these types of HSR has some advantages and disadvantages.

Dedicated HSR represents a line that is fully separated from a conventional line, has a high capacity, high safety, and no level crossings. The line has fences all along the line, often built on viaducts or in long tunnels, and has a high construction cost, such as the case in Japan and Taiwan.

Mixed HSR lines have a wider area to serve, increased accessibility as high-speed trains run on dedicated and conventional lines, high capacity of HS lines stretch over larger areas, reduced building costs. HSR trains can use conventional rails in city centres in areas where land is more expensive to build dedicated lines. However, stretches of conventional lines have less capacity and can be a bottleneck for increased traffic, reduces safety, increases maintenance costs, whilst the rolling stock must be equipped with two signalling systems for HSR and conventional rails, such as the case in France and China.

Mixed conventional rail represents lines that are used by HSR trains and by conventional trains. Mixed traffic reduces the capacity of the line because of big differences in the speed of trains, and it also reduces safety. It can be a suitable solution if a country has a different gauge from the standard gauge size to be part of the European railway network and supports interoperability of international services, such as the case in Spain. This type is more difficult and expensive to maintain, needs special rolling stock, which is also more expensive to purchase and maintain.

Fully mixed lines represent lines used by all types of trains, including freight, have maximum flexibility to be used to full capacity, reduces safety, reliability, and punctuality, and increases maintenance costs. An example of such lines as those used in Germany.

There are two ways to develop the HSR system: build new systems or upgrade conventional railways. Building lines, operating, and maintaining them is an expensive business, but it gives an opportunity to develop a system that can operate at a higher speed and with bigger time savings [3].

Each new project includes planning, land purchasing, infrastructure building, and rolling stock costs. Upgrading existing lines will exclude the need for land purchasing, which may bring big savings. Upgrading conventional rail creates lots of disruption for traffic, and it does not allow reaching the required speed on the new lines. However, it is less expensive as it costs approximately US$4.37 million/km in 2007 prices [4]. Table 1 shows the HSR technologies in selected countries. Despite this difference, there is a lot in common in all HSR systems. All are powered by electricity, have a continuous welded rail, which reduces the noise level and the track vibration, in addition to being built on ballast track or on concrete slab tracks.

Table 1. High-speed rail technologies in selected countries Adapted from ref. [5]

|

Country |

Japan |

France |

Germany |

Italy |

Spain |

Korea |

UK |

|

Line |

Tokyo-Osaka |

Paris-Lyon |

Hannover-Wurzburg |

Roma-Paris |

Madrid-Barcelona |

Seoul-Pusan |

London- Birmingham |

|

Length of line in km |

515 |

427 |

327 |

260 |

522 |

412 |

225 |

|

Max. speed (km/h) |

260/300 |

300 |

250 |

250 |

300 |

250 |

360 |

|

Travel time |

2h 30min |

1h 50min |

2h |

1h 35min |

2h 30min |

1h 55min |

52min |

|

Radius of curvature Rmin (m) |

2500 |

4000 |

7000 |

3000 |

4000 |

7000 |

7200 |

|

Max. longitudinal gradient (%) |

20 |

35 |

12.5 |

8 |

30 |

35 |

N/A |

|

Distance of axes of two tracks (m) |

4.2 |

4.2 |

4.5 |

4.2 |

N/A |

5.0 |

5.0 |

|

Superelevation (mm) |

200 |

180 |

150 |

160 |

N/A |

N/A |

N/A |

All HSRs must have advanced signalling systems and automated train control systems. The Automated Train Control (ATC) systems were first developed in Japan and introduced for Shinkansen trains. The system was named Digital Communication and Automatic Train Control (DS-ATC) system. In Europe, it is the European Train Control System (ETCS). The next step in the development of the control systems was the introduction of ERTMS. The ERTMS system was first introduced in Italy on a 204 km line between Rome and Naples. The ERTMS combines GSM-R (communication) and ETCS (signalling) systems. With rapid progress from 2G to 5G network UIC is working on developing the successor of GSM-R, the Future Rail Mobile Communication System (FRMCS) [4]. The system can be introduced to railways as early as 2025. Another common thing for all HSRs is that they are very expensive to build [5] and only two of them recovered construction costs, Shinkansen in Japan, and Paris-Lyon line in France [6].

Rolling Stock is another part of the HSR systems. High-speed trains have a large variety in axle loading ranging from 11.4 t for the Hitachi train to 23 t axle loading for Bombardier and Acela Express [7]. This large difference can be explained by the type of railway that uses this rolling stock. The Shinkansen line that uses Shinkansen-Series 700 is fenced throughout to secure the entire length of the track. In contrast to these, the Acela Express operates on an upgraded line with level crossings. Amtrak trains are equipped with an anti-collision structure to meet USA crash standards. Zefiro, a high-speed train manufactured by Bombardier, is one of the most efficient and advanced trains in the world.

- Differences Between HSR and Conventional Rail

The fundamental principle is the same, but the biggest difference lies within speed and capacity. To increase the capacity of the line, it is very important that trains that operate on the line must not have a big difference in operational speeds.

HSR and conventional rail have the following technological differences:

In track quality: HSR requires a specific design, higher standards of surface, welded rails, and a different and more advanced signalling system. Most HSRs are built on slab tracks. HSR has a larger curve radius than conventional rail. For a speed of 300 km/h, the minimum radius is 4000 m, grades of 3.5% rather than 1–1.5% for existing lines with mixed traffic [8]. HSR track is protected by fences from wild and farm animals. HSR lines do not have any level crossings and have fewer stops than conventional lines.

In traction power: For higher speeds, there is a need to have a more powerful rolling stock.

In signalling system: The signalling system depends on the speed of trains. Railway lines with speeds under 160 km/h use trackside signals to control the safe movements of trains, but if speeds exceed 160 km/h, the driver cannot reliably read signals placed on the trackside. So, for speed above 160 km/h, use onboard signalling [9]. When the speed of the HSR is above 200 km/h, the traditional signalling systems become inefficient [1]. HSR trains require in-cab signalling systems.

In power supply: HSR needs at least 25 kV, but conventional rail voltage can be lower. There are three main electrification systems that are in use for HSR, and they are: 3 kV DC, 15 kV AC, and 25 kV AC. The lines electrified at a higher voltage have lower losses during the transformation and transmission of the energy from the power station to the train. It was found that for trains on lines electrified by 3 kV DC it is necessary to produce 22.6% more than the energy received by the pantograph. For lines electrified by 25 kV AC, it is necessary to produce only 8% more energy than received by a pantograph. Another advantage of using 25 kV AC is the possibility to supply power to high-speed trains with a greater distance between substations, which means a reduction in construction and maintenance costs [10]. HSR can be powered by lower voltage, but it will increase the amount of energy that it needs to produce to power high-speed trains, increase the carbon dioxide emissions, and increase the cost of construction and maintenance of HSR lines.

Technological innovations can promote a faster and less costly transition to the decarbonisation of railways. To speed up the decarbonisation of HSR, the technical innovation will play a significant role. One of these innovations relates to using the Flexible Medium Voltage DC Electric Railway System (MVDC-ERS). It will increase the efficiency of the power distribution and support and consolidate the renewable energy sources [11].

- Selected HSRs from Europe, Asia, and USA

According to the UIC on 2020, there were 20 countries worldwide that have HSR in operation: 13 countries in Europe (Austria, Belgium, Denmark, Finland, France, Germany, Italy, Poland, Czech Republic, Spain, Switzerland, the Netherlands, and the U.K.), 3 countries in Asia (China, Taiwan-China, Japan, and South Korea), 4 other countries (Saudi Arabia, Morocco, Turkey, and the USA), and another 24 countries worldwide planning to build HSR. The total length of HSR in operation, under construction, and planned to build is 104,413 km worldwide [7]. Table 2 shows all countries with HSR systems in operation worldwide in 2020.

Table 2. High-speed lines in operation worldwide Adapted from ref. [7]

|

Year of Introducing HSR System |

Country |

Length of HSR Line in Operation in 2020 (km) |

|

1964 |

Japan |

3041 |

|

1977 |

Italy |

921 |

|

1981 |

France |

2734 |

|

1991 |

Germany |

1571 |

|

1992 |

Spain |

3330 |

|

1995 |

Finland |

1120 |

|

1997 |

Belgium |

209 |

|

2000 |

USA |

735 |

|

2003 |

United Kingdom |

113 |

|

2003 |

China |

35,388 |

|

2004 |

Switzerland |

144 |

|

2004 |

South Korea |

893 |

|

2006 |

The Netherlands |

90 |

|

2007 |

Taiwan |

354 |

|

2009 |

Turkey |

594 |

|

2012 |

Austria |

254 |

|

2015 |

Poland |

224 |

|

2018 |

Saudi Arabia |

449 |

|

2018 |

Morocco |

200 |

|

2019 |

Denmark |

56 |

|

N/A |

Czech Republic |

64 |

3.1. HSR in Japan

The first high-speed line was opened in Japan on 1 October 1964. It took five years to construct a 515 km line between Tokyo and Osaka. It provided a tremendous boost to the economy in Japan and encouraged countries around the world to develop HSR in their own countries. The core of the success of the Shinkansen lies in the decision to build dedicated lines for high-speed trains. A new double-track high-speed standard-gauge line for speeds up to 250 km/h. It was innovative to operate commercial services at this speed. Because of geological and geographical conditions in Japan, HSR requires many long tunnels and bridges. The disadvantage of this decision was the very expensive civil engineering work. Approximately 13% (86 km) of the line is in tunnels, and 33% (174 km) on bridges and viaducts [12] (p. 14). HSR infrastructure in Japan must be resistant to earthquakes, floods, and deep snow.

From the beginning of building Shinkansen, it was decided not to use outside signals to provide information for the driver but to provide indications inside the cabin. It was achieved by transmitting coded signals to the train through track circuits and receivers installed at intervals along the track. In-cab signalling is mandatory today for all high-speed systems around the world. The track of Shinkansen was divided into sections, and if only one section ahead is clear, the train can move forward. This means that the train ahead was only one block away. In this case, the train can move only with reduced speed, and if the train ahead is two or more blocks ahead, then the train behind can move on at full speed [12] (p. 18). This system increases the capacity of a track.

Along with the new infrastructure, there is also a new generation of a train that has been built. One innovation of the Shinkansen rolling stock was that instead of putting traction equipment in a locomotive, it was spread along the length of the train. This reduces the maximum axle load to 16 tonnes [12] (p. 20). This increases the speed of the train, minimises infrastructure maintenance, and reduces energy consumption. However, with distributed power, the noise in passenger saloons is higher than with concentrated power (locomotive) trains [13]. The maximum length of trains in Japan is the same as in Europe, which is 400 metres. In Japan, high-speed rolling stock (HSRS) was designed for a 15–20-year life cycle, but in Europe, it is around 30 years [13], and because of this, HSRSs in Japan do not need major renovation or technological innovations within their life cycle. This is an example and a suitable balance between economic benefits, shorter asset life, and low maintenance costs.

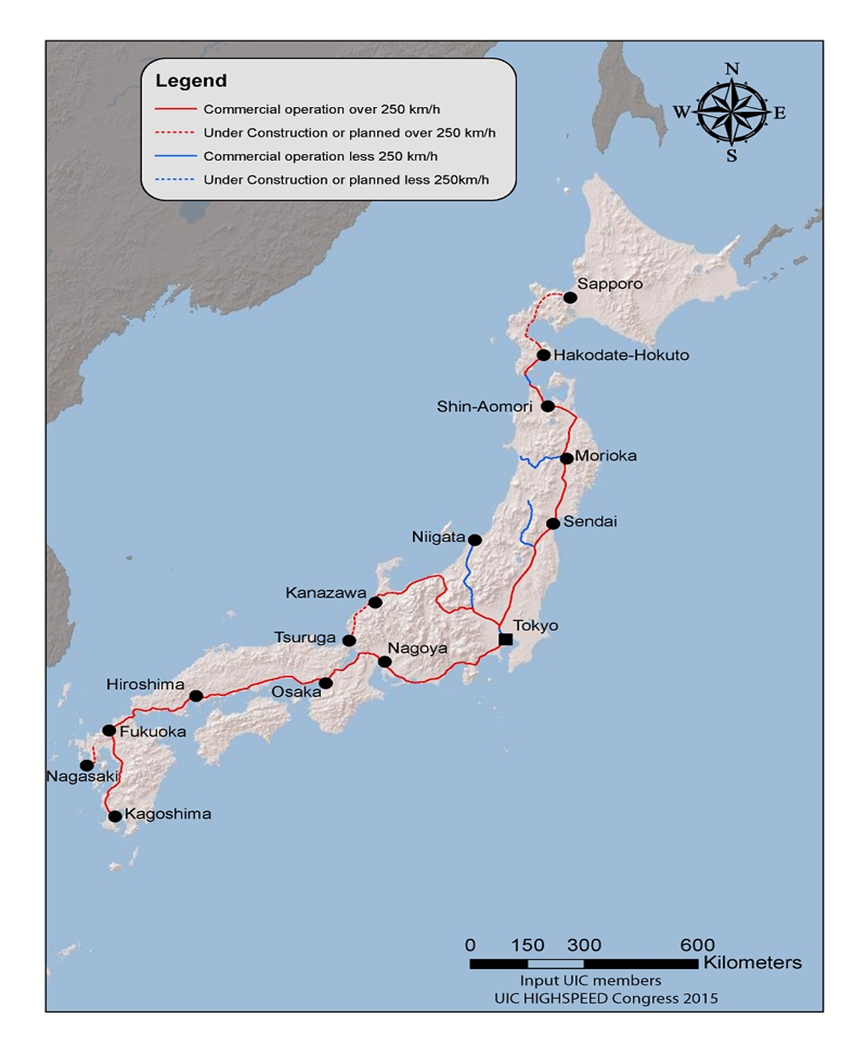

In 1964, it took four hours to travel from Tokyo to Osaka. By 2021, it reduced the time to 2 h 30 min after speeds were increased to 285 km/h [14]. In 2015, the number of departures of the Shinkansen bullet from Tokyo had increased to 14 times per hour (358 departures per day), and daily ridership increased to 445,000 with an average delay per train of 0.2 min. Totally 355 million passengers use a high-speed railway every year [15]. E5 series Shinkansen train has 10 cars with a capacity of 731 seats, that is more seats per train than in Germany or France [16]. This is one reason for the profitability of the Shinkansen. Figure 1 shows the plan of the Shinkansen HSR lines in Japan.

Figure 1. HSR network in Japan, in 2015 Reprinted from ref. [7]

Figure 1. HSR network in Japan, in 2015 Reprinted from ref. [7]

The safety records and punctuality on Shinkansen lines are outstanding. The HSR carried out thousands of scheduled journeys per day, and the average delay across all high-speed lines is 0.2 min per train, including weather-related delays. For over 50 years of operation and carrying over 10 billion passengers without an accident in which passengers could be killed or injured, Shinkansen trains are the most safe and reliable in the world. Shinkansen is the great economic success of Japan, and today the Shinkansen has an operational revenue of around US$19 billion a year [17]. This success has many reasons, and one of them is that the railway company owns the entire infrastructure, stations, the rolling stock, the track, and land around the railways. There is less bureaucracy, less management, and decisions are taken more quickly. With the future decline in Japan’s population, there will be a slowdown in new developments of HSR, as there will not be enough demand for high-speed trains.

3.2. HSR in France

The first high-speed trains were introduced in Europe, in France over three decades ago in 1981, and they have carried over 2 billion passengers during these years [18]. It was an immediate successful implementation of TGV. It caused a decrease in air and road traffic, especially for flights. TGV offered a shorter trip time, higher comfort, frequent services, and competitive prices. Figure 2 shows the HSR network in France in 2015.

Figure 2. HSR network in France, in 2015 Reprinted from ref. [7]

Figure 2. HSR network in France, in 2015 Reprinted from ref. [7]

France has 450 TGV trains, and they are serving around 230 destinations, operating in France and outside to Belgium, Germany, Spain, Italy, Luxembourg, and Switzerland [19]. Around 130 million passengers use the HSR in France every year [20]. From the beginning, the French railways had a very substantial government investment, and it was the government’s determined ambition to build a railway corridor to connect the south of France with Paris. This corridor, Paris to Marseille via Lyon, is the most important one in France and serves around 40% of the population [21].

After more than 30 years of operating high-speed trains in France, almost 40 percent of these trains travel on conventional track [19]. Around 60 percent of TGV trains are travelling on new lines designated only for TGV, and all other traffic was prohibited. The new lines have higher gradients unsuitable for freight traffic. In France, the new HSRs were designed to avoid tunnelling, and this gives the benefit of the possibility to implement the double-deck trains. The TGV Duplex was introduced in 1996. This train can travel at speeds up to 300 km/h [22]. The big achievement of the HSR system in France is that the TGV system is compatible with existing conventional railways.

National Society of French Railways (SNCF) has one of the fastest train services in the world. In April 2007, TGV test train reached 574.8 km/h [23]. The latest TGV Duplex Oceane trains have a maximum operational speed of 320 km/h, and they comprise two powered cars, one at each end and eight carriages with a capacity of 556 seats, with the same number of staffs on the train as the TGV. The length of the TGV Duplex is 200 m. These two trains can be coupled together to increase the capacity of the train on busy lines [7].

There are two different ways to power high-speed trains: it can be as in Japan, with distributed traction, or as in France, with TGV, centralised traction. With increasing awareness about the damaging effect caused by transport on the environment and looking for ways to increase the efficiency of transport, it looks more economically appropriate to use distributed traction to power high-speed trains.

There are other ways to increase the capacity of trains, and one of them can be double-deckers (France, Germany, and Japan) or the widening of carriages (Sweden, Japan). Increasing the capacity of trains gives the possibility to reduce operational costs, and this can reduce the railways’ fares. To increase the capacity of railway lines, it is needed to electrify the line, implement more advanced signalling systems, increase the speed of trains, and have dedicated lines for high-speed trains only.

One of the most important developments in the construction of TGV-PSE was the introduction of articulated suspension between passenger vehicles. Using this innovation can reduce the weight of the train, reduce the aerodynamic drag, decrease the level of noise from the train, and improve passenger comfort [24]. Figure 3 shows non-articulated and articulated bogies that are used in high-speed rolling stock.

Figure 3. Non-articulated and articulated bogies Reprinted from ref. [12]

Figure 3. Non-articulated and articulated bogies Reprinted from ref. [12]

A traditional coach has two bogies, and each bogie has two axles; on TGV-PSE coaches, each bogie supports two coaches. Advantages of articulated trains are a more comfortable ride, passengers on the train are less affected by running noise, but the downsides of articulated trains are increased axle load, and that maintenance of these bogies is more difficult. TGV uses the 25 kV AC electrification system, but it can also work on 1500 DC. All TGV trains have at least two electrification systems. To extend track formation life and increase the speed of trains, the weight on one axle was restricted to 17 tonnes [7]. Minimising the axle load will reduce infrastructure and other structural maintenance, reduce construction costs, and reduce the noise level.

The new generation of TGV trains are lighter, have a 15% lower energy consumption, and are designed to be 98% recyclable with a maximum speed of 360 km/h [3]. Reducing the weight has been achieved by using aluminium instead of steel and by using articulated bogies. The train has a regenerative braking system that recovers 8% to 17% of electricity and puts it back in the network [25]. It sufficiently reduces CO2 emissions and increases the efficiency of high-speed trains.

TGV trains have been installed with Automatic Protection System (APS) and been fitted with in-cab signalling system TVM430. The tracks have been divided into 1500-metre sections, and the in-cab signalling system TVM430 informs the driver of the maximum speed possible on any section. If the train’s current speed is higher than the speed limit for that section, then ATP applies the brakes automatically. The TVM430 signalling system allows three minutes of headway, and this increases the capacity of the track to 22,000 passengers in one hour in one direction [26]. This capacity of rail track is equal to a six-lane motorway.

The safety of passengers for any railway network is a crucial requirement. To improve the safety of high-speed trains in France, the lines were redesigned without level crossings. In addition, lines were fully fenced, and advanced equipment was fitted to detect obstructions that occur on a railway line.

From 2008, the profitability of TGV steadily declined, and it was pronounced that there was a need to reduce several stations served by TGV to make the HSR network profitable. HSR services carry only 7% of passengers but account for 61% of the total French rail network traffic [27]. Since the economic crisis in 2007, the number of passengers using high-speed trains continues to decline.

Most HSRs around the world are not profitable but need to look at what benefit they can bring in areas where they pass through, and one example of this can be the city of Lille. It is a suitable example of how a city can flourish from the bypassing of high-speed trains. The development of the TGV HSR and TGV station brought prosperity to the city, blooming commercial activities, and tourism [3].

High-speed trains are the most efficient mode of transport. This is one reason that society continues to fund HSR services. HSR saves time and energy, improves accessibility, increases economic activity, and generates employment [20]. However, with a low-density population in France and only a few larges populated urban areas, it looks unlikely that in the current condition, the HSR will be profitable.

3.3. HSR in Spain

Construction of the HSR in Spain began in 1989 in the corridor between Madrid and Seville, and high-speed trains (AVE) started to run in 1992. Spain’s HSR network is one of the widest in the world. In 2020, the length of the HSR network was 3330 km, 1293 km under construction, and 676 planned to build [7], with an average cost of €14 m per kilometre. HSR in Spain has a fleet of 229 trains with an average age of 11 years and in 2015 carried over 35 million passengers [28].

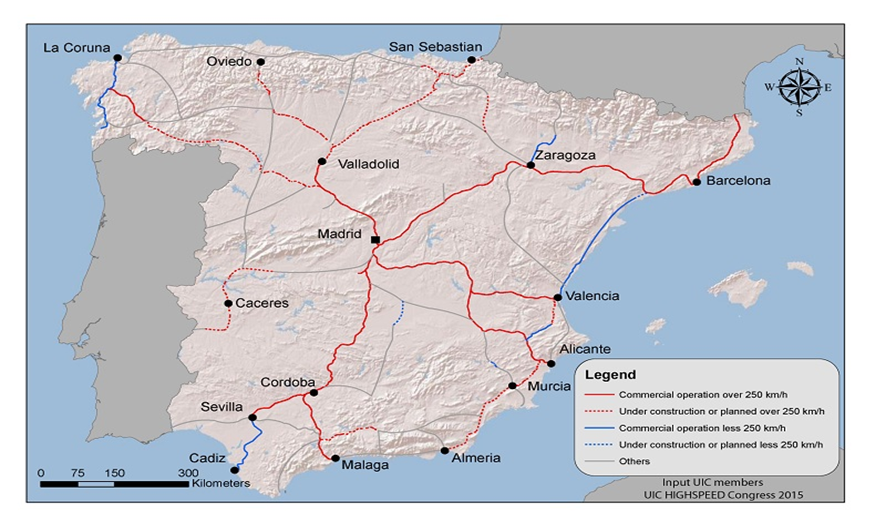

The Spanish HSR has a standard gauge of 1435 mm and is electrified with 25 kV AC and represents 16% of the total Spanish network [29]. Figure 4 shows the HSR network in Spain in 2015.

Figure 4. HSR network in Spain, in 2015 Reprinted from ref. [7]

Figure 4. HSR network in Spain, in 2015 Reprinted from ref. [7]

One of the advantages of 25 kV AC is the possibility to supply power to high-speed trains with a greater distance between substations (approximately 50 km apart), which means reduced construction and maintenance costs. In Spain, they have 59 AC substations and 384 DC substations [30].

The Spanish railway network has two different sizes of rail line gauges: standard gauge (1435 mm) and Iberian gauge (1668 mm). Talgo trains have automatic gauge changing equipment, which allows for the change from one type of gauge to another without stopping at speeds up to 15 km/h and have operational speeds of 220 km/h [31]. Spanish National Railway Network (RENFE) has a punctuality level of 98%. If a train arrives with a delay of over five minutes, all passengers will receive a 100% refund of the ticket price [32].

The Talgo 350, class S102 has the nickname “The Duck”, which has served since 2005 and has an operating speed of up to 300 km/h. It is one of the fastest trains in Europe. These trains have 12 coaches and two locomotives with a capacity of 314 and a maximum axle load of 17 tonnes [7]. The new generation of Talgo trains is Talgo Avril. This train is designed for speeds up to 380 km/h, with a low floor to improve the accessibility for vulnerable passengers [33].

This train will consume less energy because of its lightweight construction, will produce less noise and vibration, and generate less carbon dioxide emissions. The Talgo Avril train comprises two powered cars, one in the front and one at the back, and 12 carriages with a capacity of up to 600 passengers. The train can automatically switch between different track gauges (1435 or 1668 or 1520 mm) and can be run on diesel or electric or both [34]. In addition, this train can use AC or DC electrification systems to run the train.

HSR in Spain on many routes is not profitable because of the low occupancy of trains. There are a few reasons for low occupancy: high unemployment, high ticket prices, many towns with HSR stations are small and can only generate a few passengers. Spanish Government subsidises HSR heavily, and the cost is around US$3 billion per year [35].

3.4. HSR in Germany

Germany has 1571 km HSR in operation, 147 km under construction, and 291 km in the planning stage [7]. The development of HSR in Germany relieved the increasing demand for air and auto travel. The HSR now connects all the largest cities of Germany, and it is in the centre of the country’s transport system. Germany has twice the density of the population of France and taking into consideration that the territory of Germany is smaller than that of France, this can be a suitable foundation for the success of the HSR system.

The Intercity Express (ICE) trains were designed and built by a Siemens-led consortium and are operated by the German Federal Railways (DB). ICE1 was introduced into service in 1991, and it composes of 2 power cars, one in the front and one at the back, and 12 carriages between them. It has a maximum axle load of 19.5 tonnes, 358 m long, and has a capacity of 703 seats. Germany has 59 sets of ICE1. The train has a 280 km/h maximum operational speed, powered by electricity from the overhead catenary 15 kV. ICE1 has three signalling systems, LZB, PZB, and ZUB, which are suitable for traffic to Switzerland [7].

The latest ICE3 trains were introduced in 2000 with a maximum operational speed of up to 300 km/h. The power system of ICE3 has been moved from the two ends to the underside of the cars, which is the same system as used in Japan. The train comprises eight coaches, four of which are powered. As trains do not have a power car, it increases the capability of trains as more seating is available for passengers; it has 429 seats per train [7]. The distributed power system has other advantages, and one of them is the low axle load, which is 16 tonnes per axle [7], and this will reduce maintenance costs.

ICE3 has one of the best braking systems. Braking equipment on ICE3 comprises three systems, and one of them is the regenerative system. In addition, ICE3 has a smaller loading gauge than previous ICE1 and ICE2. These changes have been made to allow operation on the European network [36]. For example, France did not allow ICE trains on their network before as ICE was too wide and too heavy. French railways have a restriction of 17 tonnes on one axle for HSR lines.

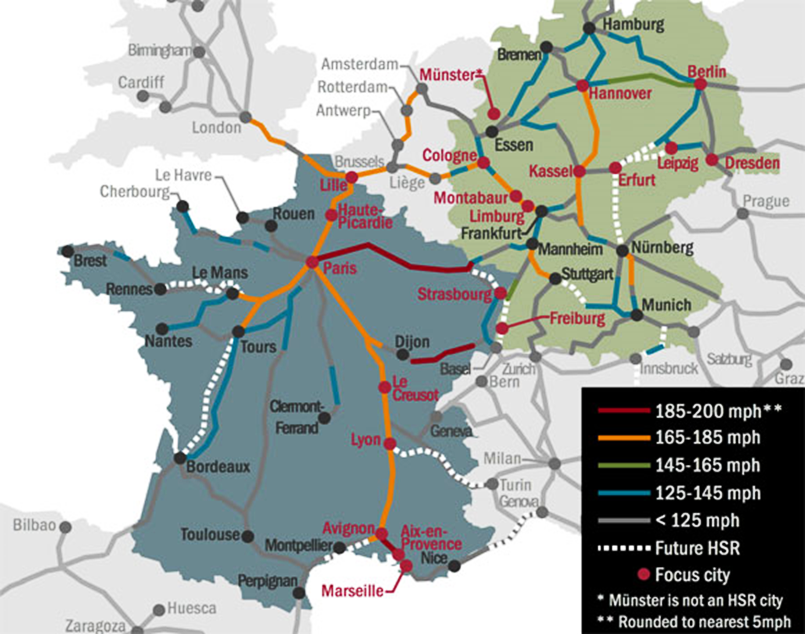

All railway lines in Germany have a standard gauge of 1435 mm and are electrified at 15 kV AC 16.7 Hz. The new lines are designed for speeds up to 300 km/h [7]. Figure 5 shows the HSR network in Germany in 2015.

Figure 5. HSR network in Germany and France Adapted from ref. [37]

Figure 5. HSR network in Germany and France Adapted from ref. [37]

From the beginning, DB allowed all categories of trains, including high-speed trains and freight trains to use the conventional lines and HSR lines also, but only some trains must run at a lower speed. This decision to allow freight trains to use the HSR was due to the amount of income that freight transportation brought into Germany. This decision differed from Japan and France, where HSR lines are dedicated only to passenger traffic. The mix of traffic brings some disadvantages. For example, if trains with different speeds use the same line, it will decrease the line capacity and can increase safety problems.

It is problematic to produce a timetable that satisfies both passenger traffic and freight traffic because of the significant speed differences. Most of the daylight time was allocated to passenger trains, but during the night, the line needed to be maintained. This caused some serious delays for freight transport. Increasing the number of real-time sensors to monitor the condition of infrastructure and rolling stock and implementing proactive maintenance instead of reactive will decrease the cost and time that needs maintenance.

Many railways’ tracks have been upgraded in Germany, but with the mix of traffic, German HSR lines cannot compare with the French network. To travel fast, there is a need to have not only advanced rolling stock but modern infrastructure too. Travelling time in France will be half of that in Germany for the same length of a journey on railways. For example, the travelling time from Paris to Marseille (661 km) is 3 h and 17 min [38], but a similar distance between Hamburg and Munich (791 km) will take 6 h [39]. Another reason that affects travelling time on DB is that there are too many stops for high-speed trains in rural areas with not enough demand for passengers travelling on trains.

The biggest environmental impact from HSR is noise pollution. In Germany, noise legislation for railways has been in force since 1974 [40]. The maximum noise levels for the new build or upgraded transport infrastructure in Germany are as follows in Table 3.

Table 3. German maximum noise level in dB(A) for newly built or upgraded transport infrastructures Reprinted from ref. [41]

|

Location |

L Day |

L Night |

|

Near schools, hospitals |

57 |

47 |

|

Residential areas |

59 |

49 |

|

Central or mix areas |

64 |

54 |

|

Industrial areas |

69 |

59 |

Germany spends annually €150 million to mitigate noise pollution from railways, and by 2020, they reduced the noise level by 10 dB [42]. Because of this legislation, some parts of newly built high-speed lines have been built in cut-and-cover tunnels to reduce the noise level and visual impact for areas with a high density of population.

The safety of passengers travelling on the railways is paramount for every railway. At the present time, only ICE trains and Eurostar have been fitted with a warning system that can detect damages in bogies and wheels early. ICE has been equipped with a train control system (LZB) [14]. This signalling system provides the driver with information for several kilometres ahead. The LZB system improves passenger safety and allows an increase in track capacity. Similar signalling systems for high-speed trains have been developed in Japan and France. Apart from the advanced train control systems, passenger safety in Germany was secured by not having level crossings on HSR lines.

3.5. HSR in Italy

Italy was the second country after Japan that introduced high-speed trains, and the first train went into operation in 1977, but the line was only completed in 1992. Italy has 921 km of HSR in operation and 327 km under construction [7]. Italy was the only country in the world that opened the HSR network for competition. From 2012, NTV (Nuovo Transporto Viaggiaton), a private HSR company, began to operate [43].

ETR460 Pendolino, a tilting train that went into service in Italy in 1988 [7]. For a country with many mountains, it was convenient to use tilting technology on conventional lines. By introducing tilting technology, the train can travel around 30% faster. This active tilting technology soon spread around the world, and now around 70% of all high-speed trains are using it [44]. Pendolino is electric powered with 3 kV DC with a designed maximum operational speed of up to 250 km/h [7].

The train is formed from nine cars. The maximum axle load of an unloaded train is 13.5 tonnes, a train length of 237 m with 480 seats [7]. Different variations of this train are now used in Germany, Spain, and the USA. The ETR500 high-speed train went into service in 1995. It was the first high-speed train that was designed in Italy and only to be used inside Italy. It has concentrated power, two locomotives, one at each end and 12 trailers, and the total length of the train is 354 m. There were 59 sets of trains manufactured [7]. There was another version of ETR500 designed and built for the Italian and French railway systems. The train was designed for maximum operational speeds up to 300 km/h with improved aerodynamic performances, and the maximum capacity of the train is 671 passengers. The train can run on 3 kV DC and 25 kV AC [7]. There was some back down in the integrated Italian HSR network in the European system, as Italy has some HSR lines using 3 kV DC electrification instead of the standard European system of 25 kV AC [7].

The latest high-speed train in Italy, the ETR1000, went into operation in 2015. Trenitalia is investing €1.5 billion in these trains and will build 50 sets of them. At that moment, they produced 13 sets of these trains. Trains can travel up to 400 km/h with a maximum operational speed of 300 km/h, and it is the fastest train in Europe [45]. ETR1000 is 202 m long with distributed traction along the carriages, four motored coaches, and four trailer coaches [7].

The train has been designed to be compatible with different signalling systems and different electrification systems within the European HSR network. The train has compatibility with the European Traffic Control System (ETCS). The ETR1000 can carry 457 passengers. The cost of this train is around US$40 million [46].

With expanding the HSR network and upgrading conventional lines, HSR in Italy is getting more attractive to customers. HSR lines in Italy run from Turin to Salerno, and Italy has more HSR lines in development: from Milan to Venice, from Milan to Genoa, and from Naples to Bari. Figure 6 shows the HSR network in Italy in 2015.

Figure 6. HSR network in Italy in 2015 Reprinted from ref. [7]

Figure 6. HSR network in Italy in 2015 Reprinted from ref. [7]

On the HSR line from Rome to Florence operated by the “Frecciarossa”, ETR500 trains have four departures every hour from Rome with a maximum operational speed of 300 km/h. The Italian railway has a standard track gauge of 1435 mm and is electrified by 3 kV DC. It will take only 1 h and 30 min on HSR to travel from Rome to Florence compared to a conventional train that takes 3 h and 20 min [47]. The majority of the lines were built close to existing corridors to reduce the environmental impact of the projects. The Italian government had lots of investments put into developing the HSR system in Italy. Table 4 shows the construction costs of the selected HSR lines in Italy.

Table 4. Capital costs of HSR in Italy Reprinted from ref. [1]

|

HSR Line |

Construction Costs ($ Billions) |

Miles |

Cost per Mile |

|

Toronto-Milano |

11.68 |

78 |

130.0 |

|

Milano-Bologna |

10.73 |

115 |

77.0 |

|

Bologna-Firenze |

8.82 |

49 |

163.0 |

|

Roma-Napoli |

8.48 |

129 |

58.0 |

The Rome-Florence line is mostly straight and with no level crossings, with one line in each direction. It is planned to upgrade this line by changing the electrification system from 3 kV DC to the European standard of 25 kV AC [1]. The same trains also operate on the Rome to Naples line, which is 205 km with two departures every hour and a top speed up to 300 km/h [7]. This line has 39 km of tunnels and 39 km of viaducts and bridges. Rome-Florence line was the first to introduce the ERTMS [1].

ERTMS is the most advanced signalling technology in the world. This system uses wireless technology to replace the signals along the railway track. A computer inside the train cabin controls the speed limit of the train and braking distance. The ERTMS system can automatically reduce the speed of the train if it exceeds the maximum allowed speed on the line [48].

One of the significant features of the Italian HSR network is the wide introduction of ERTMS that it integrated into interconnection with the European railway network. It opened the possibility to drive the same rolling stock with the same team around Europe with no need to change on the border and carry on at speeds up to 300 km/h. With building the HSR lines in Italy, they delegated conventional railways to freight transport and to serve the regional passengers. This system increases the safety of passengers travelling by train as it prevents human error. It reduces operational and maintenance costs, as there is no need to install and maintain signals along the railway tracks, and it increases the capacity of tracks. This system is known around the world as the most advanced and safe signalling system for high-speed trains.

3.6. HSR in USA

USA has only one HSR, the Northeast Corridor (NEC) from Boston to Washington D.C., 735 km long, and the same track is shared by freight and passenger trains with much lower speeds. In the future, HSR networks in the USA will expand, with 763 km under construction, and is planning to build another 2108 km [7]. There are many reasons the USA is behind other countries by implementing the HSR system. One of those reasons is that in the USA, the land that the tracks are on is regulated by the individual states, but transportation decisions are regulated through federal policy. The development of land and infrastructure is not run by one department, and often the local interest opposes national interest. Another reason is that policies in the USA encourage car ownership: larger subsidies in highway construction, low density of suburban housing, and cheap fuel.

It was December of 2000 when Amtrak introduced a new train, Acela Express, the first high-speed train in the USA that can travel at a maximum speed up to 240 km/h. Amtrak is the private company that owns the line and provided the railway service from 1971 with very limited federal subsidies. The Acela Express runs between Washington D.C. and Boston. This area has a very high density of population. At the end of 2012, Acela Express brought around 25% of the total Amtrak’s service revenue [49]. On the northeast corridor from Washington, D.C. to New York, high-speed trains carried over 3.5 million rail passengers every year and have 76% percent of the market share between Washington, D.C., and New York [1].

The track Washington D.C.-Boston stretches through areas with a very high density of population and does not have fences to protect trains from frequently encountered debris. In addition, the line between Washington D.C. and Boston has many level crossings. The trains in these circumstances must be built to ensure the safety of drivers and passengers. As the Amtrak needs to have an anti-collision structure, trains are 45% heavier than the similar French TGV trains [7]. Figure 7 shows the service map of Acela Express.

Figure 7. Acela Express service map Reprinted from ref. [50]

Figure 7. Acela Express service map Reprinted from ref. [50]

The Acela Express train comprises two powered cars, one at each end, and six passenger carriages, and in use are 20 sets of trains. The maximum axle load is 23 tonnes, a length of 203 m with a seating capacity of 304 seats. A total of 44 of those are first class, and 260 are second class [7]. The Acela Express uses the conventional line that has been upgraded, and this limits the maximum speed to 240 km/h, but by using the tilting-train technology, it provided the possibility to cut journey time [51]. Avelia Liberty, the new trains, will start operating in 2021, and there have been orders to manufacture 28 new trains. Avelia Liberty will comprise 2 locomotives and 10 passenger cars with a total seat capacity of 512 [7].

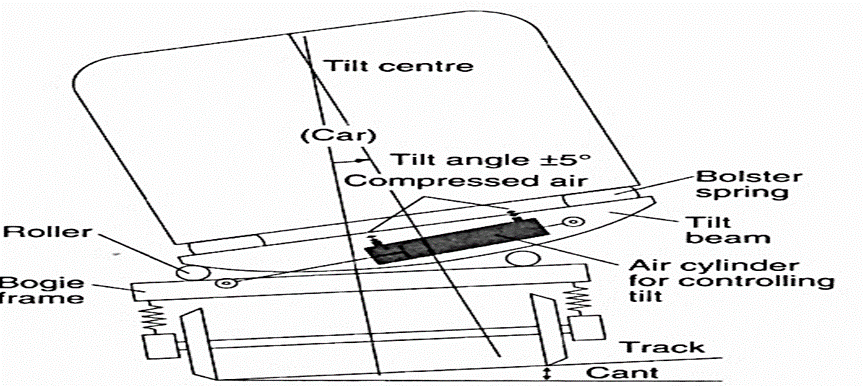

Avelia Liberty will be a tilted train with concentrated power and a maximum operational speed of 257 km/h [7]. The new trains will cut travel time by approximately 30 min. Tilting-track technology can be an alternative option for building new tracks or straightening existing ones. The tilting technology prevents passengers from having some discomfort from the lateral acceleration, also much cheaper than having to build new tracks [52]. This technology allows the train to have higher speeds in curves, which can reduce the journey time. Figure 8 shows the tilting bogie technology called passive tilt.

Figure 8. Roller-type tilt system Reprinted from ref. [12]

Figure 8. Roller-type tilt system Reprinted from ref. [12]

When the train runs on a curve, the tilting system tilts the body of the carriage up to a 5° gradient [12]. In addition, another tilting system has been developed, the controlled tilt system, called active tilt (Figure 9). Active tilt technology was first implemented in the United Kingdom. The onboard train computer stores all information about the curve radius, alignment, elevation, and the railway line where the train will run. Tilting the carriages start approximately from 30 to 40 metres before the carriages enter the curve as it was found that it will reduce the passengers feeling the sense of motion sickness [12]. The Acela Express has active tilt technology [7].

Figure 9. Principles of controlled tilt systems Reprinted from ref. [12]

Figure 9. Principles of controlled tilt systems Reprinted from ref. [12]

3.7. HSR in China

The first HSR line, 405 km between Qinhuangdao and Shenyang North, went into operation in 2003, with a maximum speed of 250 km [7]. By 2020, China has the largest HSR system in the world, approximately 60% of the length of the world’s HSR network. In 2020, China had 35,388 km of newly built passenger dedicated HSR lines, 5250 km under construction, and is planning to build another 1328 km [7]. HSR network in China will consist of eight horizontal and eight vertical HSR lines, which will connect the largest cities of China that have a population of 500,000 or more [53]. It will connect the south and north of China and west and east. The next step will be to connect China with Taiwan by an underwater tunnel [54].

China has some unproportioned population density, with more people living in the east part of China than in the west. The development of a new HSR will help to satisfy increasing demand in travel to the east of China. The most famous line in China is a line between Beijing and Shanghai. The line’s length is 1318 km, it cost around €28 billion to build, and it is the third longest HSR in the world [55]. It took less than two years to build this line. HSR started operating in 2011. Trains can run at speeds up to 350 km/h. The line has 23 stops, and in the first year after opening, over 52 million passengers travelled on it [53].

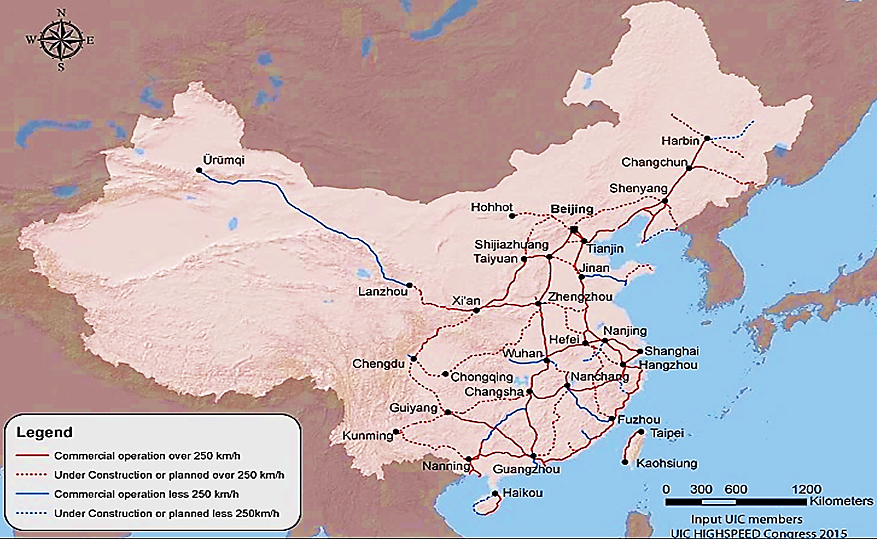

Around 90 trains depart every day between Beijing and Shanghai. There are two types: super-fast with speed up to 300 km/h and just fast with speed up to 250 km/h. The journey time by the fastest train from Beijing to Shanghai is 4 h 48 min [55]. HSR lines can transport freight during night-time. Figure 10 shows the HSR network in China in 2015.

Figure 10. HSR network in China, in 2015 Reprinted from ref. [7]

Figure 10. HSR network in China, in 2015 Reprinted from ref. [7]

China has around 2500 high-speed train sets. The train CRH380-AL has been designed and manufactured in China, and it first went into service in 2011. It has a maximum operational speed of up to 300 km/h. CRH380-AL can be formed from 8 to 16 carriages with a capacity of up to 1061 passengers. The 16-carriage train has distributed power with 14 motored coaches and 2 trailer coaches, and it is 403 m long [7].

This train, equipped with a 25 kV AC 50 Hz electric system, has two braking systems, and one of them is the regenerative system, which generates electricity when the braking system slows the train down [7]. The train can accelerate up to 380 km/h [56].

3.8. HSR in Turkey

The first HSR line, 221 km between (Ankara-)Sincan and Eskisehir, went into operation in 2009 with a maximum speed up to 250 km [7]. With the opening of HSR, the travel time between Ankara and Istanbul has been reduced by more than half to just 3 h from 6 h and 30 min. The HSR lines are equipped with an ETCS Level 1 signalling system. In 2016, there were 38 high-speed trains per day, but by 2023, it will increase to 300 services per day, which will carry 120,000 passengers, and passenger numbers can increase to 945 million per year [57]. The development of HSR is funded mostly by the government and by credits from foreign banks [58]. Turkey has the fifth largest HSR network in Europe and the ninth largest in the world. Figure 11 shows the HSR network in Turkey in 2015.

Figure 11. HSR network in Turkey, in 2015 Reprinted from ref. [7]

Figure 11. HSR network in Turkey, in 2015 Reprinted from ref. [7]

Ankara-Eskisehir CAF (Spanish railway vehicle constructor) manufactured trains Class HT65000. The trains have a maximum operational speed of 250 km/h, have distributed power, comprising four motor coaches and two trailer coaches, and have a capacity of 419 seats [7]. In 2013, the State Railways of the Republic of Turkey (TCDD) ordered Siemens to manufacture 17 EMU (Electric Multiple Unit) Velaro-D Class HT80000, with distributed power, with four motored coaches and four trailer coaches, and with a maximum operational speed of 300 km/h [59]. In addition, Turkey intends to purchase another 106 high-speed trains [60]. However, one of Turkey’s targets is to manufacture all HSR stock in-house and convert existing RS to be compatible with HSR.

In 2020, Turkey had 594 km of HSR in operation, 1652 under construction, and is planning to build another 5173 km [7]. HSR will connect 16 of the largest cities, and the government is planning to connect 55% of the population within an HSR network by 2023 [61]. Turkey wants to integrate into the EU and be a part of the European Single Market and part of the European Transport Network.

3.9. HSR in Taiwan

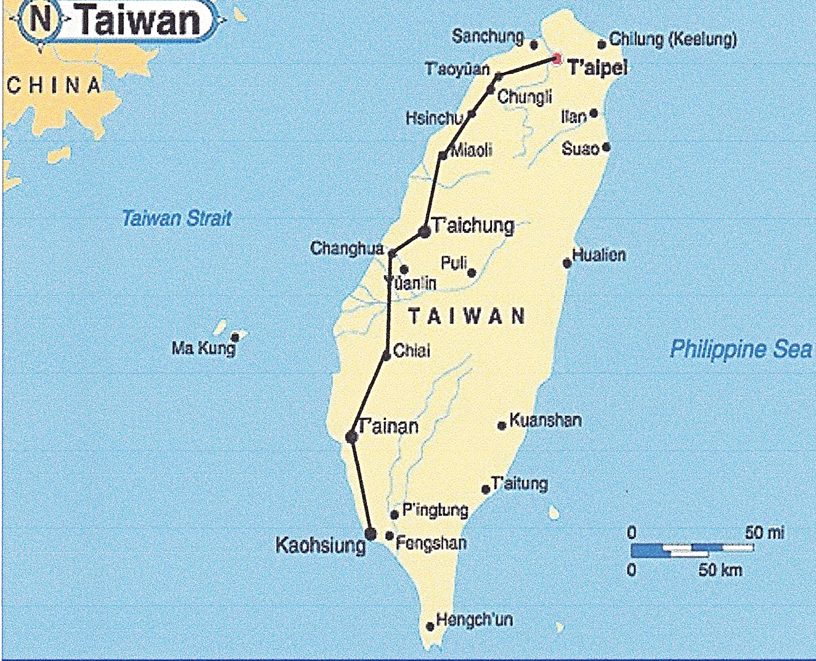

Figure 12 shows the route of HSR in Taiwan. The HSR in Taiwan comprises one double-track line 354 km long [7]. The line runs along Taiwan’s western corridor from the capital of Taiwan (Taipei) to the main industrial city of Kaohsiung on the south of the island. These are the two largest cities in Taiwan. The first 345 km of HSR in Taiwan went into operation on 5 January 2007 with a maximum operational speed of 300 km/h from Taipei to Kohsiung [7]. In 2016, an additional 9 km was built from Taipei to Nangang [7]. In September 2018, the government announced that by 2029 they will build a new HSR line from Kaohsiung to Pingtung 17.5 km long. The estimated cost of a new line is US$1.78 billion [62].

Figure 12. HSR network in Taiwan Adapted from ref. [63]

Figure 12. HSR network in Taiwan Adapted from ref. [63]

The line has a standard gauge of 1435 mm and is built on the slab track. To avoid crossing roads on the same level, 90.7% of the line was built in tunnels and on viaducts. The total cost of HSR was estimated to be US$15 billion [64]. Figure 13 shows the ratio of HSR structure type by length.

Figure 13. Ratio of HSR structure type by length Adapted from ref. [65]

Figure 13. Ratio of HSR structure type by length Adapted from ref. [65]

This line links towns and cities with 94% of the total population in Taiwan. The development of this line reduced the number of car journeys and the number of flights. As a result, it reduced the dependency of Taiwan on the export of petroleum and reduced CO2 emissions from the transport sector.

In 2013, ridership in a single day reached 200 thousand, and in 2018 it increased to 285 thousand. In 2017, the number of passengers using HSR increased to 60.57 million with 198 daily services. The total number of trains reached 51,751 with a 65.16% occupancy rate [63]. THSRC has an excellent punctuality rate of 99.72% [64].

The HSR in Taiwan is based on the technology of the Shinkansen. This is a new line, and as often to reduce the cost of the project, the stations are located outside of cities. Passengers can reach a station by a free shuttle bus from the centres of towns. In 2017, it provided 393,819 free shuttle journeys [64].

According to UIC HS Rolling Stock tables, Taiwan has in operation 34 trains, Class T700. The design of trains is based on the Series 700 Shinkansen and modified for THSR. Trains went into operation in 2007 [7]. The number of trains will increase to 54 by 2033. Each train comprises nine motor coaches and three trailer coaches. The maximum operational speed is 300 km/h. Each EMU has a length of 304 metres and has 989 seats, one coach first class with 66 seats and 11 coaches second class with 923 seats [7]. The train is powered by an overhead electric line with a voltage of 25 kV 50 Hz, equipped with a signalling system that allows operation on both tracks in both directions. The HSR line is equipped with an Automatic Train Control (ATC) system. The trains are equipped with an earthquake early warning system. This system allows the train to stop or slow down 10 s before an earthquake hits [64].

To cover 354 km without stops, it takes only 96 min, and in 2007 there were 61 trains every 24 h in each direction, from 7 am to 9:06 pm. In 2015, the number of stations reached 11, and the running time of trains stopped at each station was reduced to 138 min. In 2017, the number of stations increased to 12 [66]. Table 5 shows the increased ridership on HSR in Taiwan from 2013 to 2017.

Table 5. Operational statistics Reprinted from ref. [64]

|

Year |

Total Ridership (Millions) |

Train Services per Year |

Occupancy (Passenger-km/Seat-km) |

Punctuality Rate (% of Trains Arriving within Five Minutes of Scheduled Time) |

Passenger-km (Millions) |

|

2013 |

47.49 |

48859 |

57.59% |

99.38% |

9.118 |

|

2014 |

48.02 |

50467 |

57.12% |

99.61% |

9.235 |

|

2015 |

50.56 |

50532 |

59.65% |

99.66% |

9.655 |

|

2016 |

56.59 |

51106 |

63.52% |

99.43% |

10.488 |

|

2017 |

60.57 |

51751 |

65.16% |

99.72% |

11.103 |

3.10. HSR in South Korea

Figure 14 shows the HSR network in South Korea. In 2020, the total length of HSR lines in operation was 893 km, with another 49 km planned to build. The first HSR line from Seoul to Dongdaegu went into operation on 1 April 2004 [7]. The HSR network comprises two corridors, one from Seoul to Busan, an area where over 70% of the population lives, and another one from Seoul to Gwangju. The lines have a standard gauge of 1435 mm and are built on ballasted track with concrete sleepers. The estimated cost of 411 km HSR from Seoul to Busan was US$17 billion [67]. It was an expensive project, as 190 km is in tunnels and 120 km on bridges and viaducts. The HSR network gives an opportunity for commuters to travel to most parts of the country in 1 h 30 min. Figure 15 shows the ratio of structure type by the length of HSR in the corridor Seoul-Busan.

Figure 14. HSR network in South Korea, in 2015 Reprinted from ref. [7]

Figure 14. HSR network in South Korea, in 2015 Reprinted from ref. [7]

Figure 15. Ratio of structure type by length of HSR Adapted from ref. [68]

Figure 15. Ratio of structure type by length of HSR Adapted from ref. [68]

With the opening in 2004 of HSR, the travel time on the Seoul-Busan route was reduced from 4 h and 10 min to 2 h and 40 min and after developing a new line between Daegu and Busan times was cut to 1 h 46 min [69]. Table 6 shows the HSR lines in South Korea.

Table 6. High-speed lines in South Korea on 1 October 2019 Adapted from ref. [1]

|

Section |

Status |

Date |

Length (km) |

Max. Operational speed (km/h) |

|

Seoul-Dongdaegy |

completed |

2004 |

288 |

305 |

|

Dongdaegy-Busan |

completed |

2010 |

130 |

305 |

|

Osong-Gwangju |

completed |

2015 |

184 |

305 |

|

Suseo-Pyoengtaek |

completed |

2016 |

61 |

305 |

|

Seoul-Gangneung |

completed |

2017 |

230 |

250 |

|

Gwangju-Mokpo |

planned |

2025 |

49 |

305 |

In the first 10 years, from 2004 to 2014, KTX carried around 414 million passengers with an average of 150,000 per day [70].

According to UIC HS Rolling Stock tables, Korea has in operation 117 KTX (Korea Train Express) trains, with a maximum operational speed of 300 km/h [7]. The train design was based on the French TGV Reseau. The first 46 trains went into operation in 2004. A total of 12 of them were supplied by Alstom and 34 manufactured in Korea by Hyundai Rotem. Korea was the fourth country in the world after Japan, France, and Germany, which uses its own technology to build trains with a maximum speed of 330 km. The first 46 trains have a set formula of 2 locomotives, 2 motorised trailers, and 16 trailer coaches. The trains are 388 m long with a maximum number of seats of 935 and with maximum traction power of 13.200 kW. The latest 71 trains manufactured by Hyundai Rotem comprise two locomotives and eight trailer coaches. They are 201 m long with 363 seats, 30 seats in first class and 333 seats in second class, and a maximum traction power of 8800 kW [7].

These trains a lighter as the car body is made from aluminium alloy, and the powered car body is made from mild steel, compared to the first 46 trains, in which the bodies were made from steel. The weight of 10 cars is 434 tonnes. The train is powered by an overhead electric line with a voltage of 25 kV 60 Hz, equipped with an Automatic Train Control (ATC) system, which is continuously checking the speed of the train [7].

- Conclusions and Prospects

In the present chapter, different HSR systems worldwide have been discussed and what they have in common, and how they differ from each other. HSRs worldwide have some technical and organisational differences, such as a difference in operating voltages (Spain), different gauges (Spain, Japan), signalling systems (France, Germany), and languages (Eurostar). The most challenging of them is the Eurostar, which crosses three different railway networks. It has three different power collection systems and signalling systems for Belgium, France, and the U.K. The first HSR was built in 1964, but now 44 countries worldwide have constructed or are planning to construct HSR systems. Amongst them are countries such as India, Indonesia, South Africa, Iran, Brazil, and Russia, and the numbers are growing.

High-speed trains can be very competitive for trips between 150 and 700 km for links between urban centres with a high density of population. It can break the dependency of the transport system on fossil fuels. HSR is powered by electricity and can be almost zero carbon, but it must be powered by renewable energy, as the energy type can significantly influence the level of environmental impact. To support the decarbonisation of railways, there is a need to improve the operational strategies, optimise scheduling, and maximise the use of rolling stock and infrastructure.

The role of the HSR for moving people and goods will steadily increase. HSR must be cheap to build, cheap to maintain, and with high occupancy of seats. Sometimes, it would be more beneficial to upgrade the existing railway network than build new HSR lines. There is a need to ask, are the conventional lines profitable, and if not, why would the new HSR perform any different?

The HSR network in Europe was developed in different countries at different times and standards and to link all the railway networks into one system. There is a need to have compatible technical standards. The standardisation and harmonisation of track gauge, maximum load per axle, systems of electric traction, signalling systems, and line profiles is crucial to operating effectively across Europe. The differences in railway technical standards in Europe create an additional cost for all railway systems. By reducing the number of different HSR technologies and increasing the standardisation, it will improve safety, reduce the capital cost, and increase the compatibility of railways and, in the long term, will reduce the journey costs.