Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Subjects:

Forestry

Tropical forests are among the most diverse ecosystems in the world, completed by huge biodiversity. An expansion in natural resource extraction through open-pit mining activities leads to increasing land and tropical forest degradation. Proper science-based practices are needed as an effort to reclaim their function.

- open-pit mining

- biodiversity

- tropical forests

- degraded land

- reclamation

1. Introduction

Mining is one of the most important economic sectors in Indonesia. Mining products contribute up to 17% per year of Indonesia’s total export value, and from several major mining products, coal mining contributes a value of 87.27% [1]. Data from verified resources and reserves as of December 2019 showed that coal mining had the potential to reach 88,338.66 and 25,070.50 million tons, respectively. This potential was spread across 23 provinces with the greatest potential discovered in East Kalimantan, South Sumatra, and South Kalimantan [2].

Coal and mineral resources have an important role in Indonesian economic development [3]. Mining materials contribute around 5 percent to Indonesia’s total gross domestic product (GDP) [4]. The Indonesian coal industry is one of the world’s largest coal producers and exporters, while the production of other minerals is developing more slowly. The potential mineral deposits comprise ferrum and associates (iron, nickel, mangan, cobalt, titanium, chromite, and molybdenum), precious metals (gold, silver, and platinum), base metals (tin, zinc, copper, lead, and mercury), and rare metals (bauxite and monazite) [5]. However, almost all of the mineral and coal resource deposits in Indonesia are located in tropical rainforest lands [6].

Tropical rainforest lands carry the physical, chemical, and biological characteristics of the forest soils. They are naturally stable and resilient bodies that can be temporarily altered by natural driving forces like fire and flood [7]. However, the impacts of anthropogenic perturbations associated with extensive human activities, such as mining, on the soil’s physical, chemical, and biological properties and the long-term sustainability happen to be one of the burning issues that have become global [8]. Many of the problems remain peculiar to the forest stakeholders and require a special effort to clarify the adverse experiences and in turn review the solutions to manage the difficulties.

Although the world’s demand for renewable energy is growing and coal consumption fell 0.6% in the last six years, global coal use (24.2%) is still the main energy source after oil [9]. Until now the coal industry has had a positive impact on Indonesia’s economic growth and infrastructure development in remote areas. However, surface mining or open-pit mining techniques potentially harm the environment including extensive forest degradation, biodiversity loss [10,11], landslides, soil erosion, soil pollution from mining waste, and tailing dust [12], also leading to social conflicts [13].

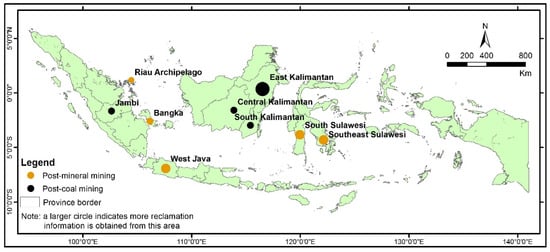

Globally, many mining sites are located in forest areas, including in Indonesia, and reforestation is still considered the best choice in providing ecological and economic benefits [14]. Several national-scale mining companies (the distribution can be seen in Figure 1) have proven how they conduct post-mining landscape reclamation and reforestation activities, especially post-mining lands, which were originally a forestry area that was loaned to extract mining materials. The main problem in reforestation of post-mining sites refers to the degraded condition of forest tree growth ranging from high toxicity coming from different pollutants, lack of macro and micronutrients, organic matter, and disturbance of water regime in soils [15]. Reforestation activities that aim to return the sites to their original baseline condition become very unlikely [16]. Efforts to cover overburdened areas with hydroseeding technology are the first step to reduce surface erosion. The success of planting fast-growing tree species and some technological inputs to increase soil fertility has become the main direction for mining companies [17].

Figure 1. Some post-mining areas focused on in this study.

2. Open Pit Mining Process and Landscape Management

2.1. Land Clearing

Technical mining activities in Indonesia refer to the guidelines issued by the Directorate of Mineral and Coal Engineering and Environment, Ministry of Energy and Mineral Resources. As with other open-pit coal mining operations, before the coal extraction process can be executed, companies are required to peel, save, and temporarily store the layers of soil materials found to be reused as a plant growth medium in revegetation activities [32,33]. This soil stockpile is placed in a safe place, and if it is not used immediately, then the surface is planted with grasses or legume cover crops (LCC) to reduce possible erosion. In case the stockpiled topsoils stay for a long period, the physical, chemical, and biological nature of the topsoils may be degraded [34] until they have been spread as final layers on the surface of the reclamation area. Hence, the topsoils in the stockpile area should be managed properly. Soil materials, often called topsoil in mining, which can be used as plant growth medium according to SNI (Indonesian National Standard) 6621: 2016, are soil materials originating from horizons A and B, and can also include horizon C if they are considered suitable as planting media. The principles used in the management of topsoil are (1) using it as soon as possible in reclamation activities, (2) keeping it safe from erosion and sedimentation, and (3) improving the quality of soil fertility.

The handling of overburden (OB) material or waste rocks is also important to determine whether they are categorized as NAF (non-acid forming) or PAF (potentially acid-forming) materials [35], as both materials have different characteristics. OB-PAF is waste rocks containing sulfide minerals. When OB-PAF is exposed to water and air, an oxidation reaction will form, which will generate sulphuric acid known as acid mine drainage (AMD) [36,37]. Therefore, OB-PAF must be stacked and placed separately from OB-NAF. The sampling method, sample preparation, and OB material characteristic test are described in SNI 6597:2011, while the stacking procedure including monitoring is described in detail in SNI 7082:2016 regarding the procedure for stacking overburden to prevent the formation of acid mine drainage in coal open-pit mining activities. In SNI 6597:2011, the characteristics of OB materials are divided into four types, i.e., non-acid-forming, low-capacity acid-forming potential, high-capacity acid-forming potential, and acid-forming.

2.2. Landscaping

2.2.1. Overburden Materials Placement and Acid Mine Drainage Control

Reclamation of ex-mining land is carried out by following the Guidelines for Reclamation of Post-Mining Land issued by the Ministry of Energy and Mineral Resources (Director General of Mining Circular No. 3043/20/DJP/1993) and the Decree of the Minister of Energy and Mineral Resources No. 1827K/30/MEM/2018 concerning Guidelines for Environmental Implementation of Mineral and Coal Mining [18]. Reclamation activities begin with landscaping, which is rearranging all the remaining mining materials in the designated location with a calculated slope and thickness. The placement of OB materials according to their geochemical characteristics is one of the most important activities in this landscaping process. Some of the materials are categorized as OB-PAF, which can cause AMD problems in the future [38,39]. As OB-PAF turns out to be AMD, the high acidity condition will adversely affect the chemical nature of surface water in the vicinity, resulting in poor water quality to support the living organism in the soil [40]. The high acid conditions cause heavy metals present in the coal such as Fe [41], Hg, Cd, Pb, Cr, Cu, Zn, and Ni, which can be dissolved and carried to the waters fast [42].

To avoid the formation of AMD, generally, OB-PAF is stacked in a designated place and then encapsulated with other materials, such as OB-NAF materials or limestone. The materials are then compacted to prevent water infiltration and oxygen reaction with sulphidic minerals contained in OB-PAF materials [35,37]. Research in the Lati coal mine [43] as well as in the Sangatta and Bengalon coal mines [44] showed that encapsulation is the most effective method in preventing AMD. With the increasing use of coal as an energy source, the amount of coal combustion ash (CCA) produced has also increased. This CCA has a great potential to be used as a dry cover for OB-PAF materials [45,46]. The existence of AMD can be handled in two ways, active and passive handlings [35,36,37].

Most large mining companies in Indonesia have implemented an integrated approach to managing AMD in their mine sites. This approach includes the development of a geochemical model of OB or waste rock, AMD prevention through encapsulation of OB-PAF material, and active as well as passive treatment methods [43,47,48]. In addition to active treatment using lime, several coal mines have also prepared constructed wetland areas to carry out passive treatment using various plant species to reduce Fe and Mn levels, as well as to increase pH. Plants that have been studied intensively are purun (Eleocharis dulcis) [49,50], Fimbristilys hispidula, Mariscus compactus, and Typha angustifolia [51], and Eichhornia crassipes [52].

2.2.2. Soil Materials Placement and Mine Soil Characteristics

OB materials are very difficult to use directly as a growing medium due to their chemical–physical properties that are not suitable for plant root growth. OB materials are structureless with high bulk density due to the movement of heavy machinery and often contain an elevated concentration of traced metals. Their characteristics hamper water circulation, limiting their capability to support the growth of plant roots [53,54]. Therefore, sowing topsoil over the arranged OB materials will serve as a growing medium for revegetation plants [55,56].

In general, the soil thickness sown over OB materials ranges from 50–125 cm. However, due to the thinning of the native soil [57] in the site, in several reclamation areas, the thickness of sown soil was only 10–80 cm. This soil mixture was reported to have very low levels of organic C, total N, and available P, was poor in other plant nutrients, and decreased the activity of microorganisms [58,59,60]. However, according to [61], the productivity of reclaimed sites after mining significantly depends more on the physical nature of the mine soils as compared to their chemical nature. Therefore, soil amendments with various materials available around the mine site to recover physical and chemical characteristics of the mine soils need to be performed by using, for instance, composted chicken manure, sawdust, lime, or NPK fertilizers [62,63,64].

2.2.3. Revegetation Process

Landscaping activities, especially the arrangement of OB materials followed by sowing of soil material as a plant growth medium over the surface of the final reclamation land, are very costly. According to [56], the most commonly accepted way to keep mine soil from being degraded by erosion during the reclamation process is through revegetation. For Indonesian conditions, the commonly used revegetation plants are fast-growing pioneer plants. Revegetation in ex-mining lands not only protects the mine soil from degradation due to erosion but also improves the quality of the mine soil itself. Improving the quality of mine soil does not solely come from trees but also from the legume cover crops (LCC).

Revegetation not only improves the quality of the mine soil but also the microclimate conditions. Revegetation makes the land surface become covered by plant canopy, and the percentage of the cover becomes denser with the increasing age of the revegetated plants. As revegetation trees grow over time, the microclimate of the reclaimed sites also changes, as indicated by a lower light intensity on the ground, a lower air temperature, and a relatively higher humidity [65,66,67]. A more detailed explanation of revegetation activities can be found in Section 4.

2.2.4. Erosion Control

In Indonesia, as a humid tropical country, the rain falls evenly throughout the year with a fairly high average monthly rainfall. The high rainfall intensity during the wet season can lead to erosion and landslides in reclamation areas, which always become a major concern to control. To overcome this condition, the Ministry of Energy and Mineral Resources issued Technical Guidelines for Erosion Control in General Mining Activities (Decree of the Director-General of General Mining No. 693.K/008/DDJP/1996), which contains erosion control techniques, both vegetatively and civil engineering [18]. Due to the materials that formed the reclamation area were often dominated by fine earth-sized fractions that were easily eroded by water flow; waterways were reinforced with rock blocks or used tires, as shown in Figure 3. Escarpments formed due to terrace construction or morphological changes due to the construction of waterways are stabilized with rock blocks, rip-rap, or gabions.

Figure 3. The drainage system constructed and reinforced with stone or other materials to reinforce the drain base.

The critical phase occurs when the soil material has been spread over the final surface but the revegetation plants are still small and the LCC has not grown to cover all the land surface. Therefore, a combination of LCC, grass, and local upland rice that can quickly cover the soil surface is highly desirable (Figure 4).

Figure 4. (a) The critical phase of the final surface against erosion and landslides after reclamation; (b) use of local upland rice and legumes as land cover crops to reduce the risk of erosion. Photo by Kaltim Prima Coal.

The amount of erosion in reclamation areas varies greatly depending on the age and success of the reclamation. Using the USLE equation, research in 17 coal mine reclamation areas in Kutai Kertanegara district, East Kalimantan [57], found that erosion rates in reclamation areas aged < 1 year ranged from 36.5 to more than 4900 tonnes ha−1 year−1, in areas aged 1–5 years erosion rates ranged from 1.9 up to 341.0 tonnes ha−1 year−1, and in areas > 5 years, erosion rates ranged from 2.1 to 201.1 tonnes ha−1 year−1. High erosion rates in older reclamation areas usually occur in areas where revegetation plants do not grow optimally due to a lack of plant maintenance. Regarding the use of the USLE equation to calculate the amount of erosion in the reclamation area, the use of this equation in reclamation areas requires sufficient consideration because the conditions are very different from the conditions used in USLE, namely predicting soil loss in forest areas [68]. USLE was developed for agricultural watershed areas in America with data originating from America as well [69]. In contrast to Zulkarnain et al. [57], which states that the cause of high erosion in this reclamation area is soil compaction, which causes a decrease in the rate of soil permeability so that run-off increases, Hamanaka et al. [70] state that the causes of high erosion include unfavorable soil physical property of upper layer reclamation surface as affected by an uneven mixture of mine soils with OB materials, and as a result, the soil erodability turns to be somewhat high.

Because the erosion rate measured by the USLE equation approach often yields very high values, according to the advice of regulators some companies combine erosion measurement methods using erosion sticks (Figure 5). Erosion sticks are measured at a certain period, for example, two times a year. The actual erosion value is calculated from the height difference between the two measurements. The results of the 2017 erosion measurement using this method in Lati, Sambarata, and Binungan coal mines show that the average soil loss is less than 1 mm year−1, lower than the tolerable erosion rate of 1–2 mm year−1. In the <2-year-old revegetation area with poor cover conditions, the measured erosion was the highest, but the category was still very low [71].

Figure 5. Measurement of the rate of erosion using erosion sticks. Photo by I. Iskandar.

2.2.5. Drainage System and Settling Ponds

Open-pit coal mining operations have caused a large part of the land surface to be exposed. The operations can have substantial environmental impacts not only on the undisturbed land surface, but also on piles of waste rocks, pit walls, and other mining facilities, such as hauling roads. The exposed soil surface is very susceptible to erosion, and uncontrolled management will lead to other problems such as polluting the nearest rivers [72]. To improve water quality outside the mine site, the local government issued a regulation regarding the environmental quality standard (EQS) of liquid waste from coal mining industries. According to Minister of Environment Decree number 113/2003 [22], the EQS of liquid waste from these industries has to have a pH characteristic of 6–9, a suspended residue of 400 mg L−1, a total Fe 7 mg L−1, and a total Mn 4 mg L−1. To comply with this regulation, companies flow their water, which generally comes from rainwater and a sump pit, to the calculated settling ponds to reach the EQS within a certain time. Adjusted to the characteristics of the local location, for example, a coal mining company in East Kalimantan built a configuration of two types of settling ponds, namely dam blocking with a dry dam concept and a labyrinth pond. Dry dam ponds were built to regulate the outflow, while labyrinth ponds were made as settling ponds. The company claimed that this method was effective and efficient in controlling water flow discharge at a relatively low and constant level, as well as facilitating the maintenance of settling ponds [73]. In addition to dry dam ponds and labyrinth ponds facilities, several companies have also added constructed wetland area facilities to increase pH and reduce Fe and Mn levels in AMD to meet the required EQS. A coal mining company in South Sumatra uses aquatic plants such as Fimbristilys hispidula (Vahl) Konth, Mariscus compactus (Retz) Druce, and Typha angustifolia L. [51,74]. The addition of constructed wetland facilities in coal mines that produce AMD needs to be done to anticipate the post-mining period, and the company has stopped controlling AMD with the active method.

The general regulation regarding wastewater is to reach the expected EQS, which is the particle settling time that is longer than the predicted results of the calculation. Therefore, to precipitate colloidal particles from the suspension, a larger settling pond or the use of chemical flocculants is required. The problem that usually arises after the construction of the settling pond is the maintenance and rehabilitation of this facility [69]. Aluminum (Al2(SO4)3), ferric sulfate (Fe2(SO4)3), ferric chloride (FeCl3), and polyaluminum chloride or PAC (Al(OH)1.5(SO4)0.125Cl1.25) are the most commonly used inorganic flocculants [75]. The use of biocoagulant seeds of Moringa oleifera showed promising results to reduce TSS, total Fe, and total Mn [76].

2.2.6. Ex Mine Pit Management

The open-pit coal mining system produced a mine hole that could not always be returned to its previous condition. When the bottom of the hole was below the natural groundwater level, and when the dewatering process had also been stopped, the pit was soon be filled with groundwater, rainwater, and surface runoff from the surrounding area. A pit lake was formed when the former mine pit was filled with water [77]. The existence of these pit lakes was often seen as a significant long-term risk to health, safety, and the environment, which was often difficult to overcome, such as poor water quality (high levels of metals and acidic pH due to oxidation of sulfide minerals), unstable and steep slopes, risk of landslides, and high risk of sinking [78,79]. However, if managed properly, pit lakes could also be used for various purposes, such as recreation areas, natural conservation, fisheries, industrial water sources, raw materials for drinking water, protection against flood hazards, and of course education and research purposes. EQS for water quality refers to Government Regulation No. 82/2001 concerning Water Quality Management and Water Pollution Control, while the water utilization regulations refer to Government Regulation No. 121/2015 concerning the Exploitation of Water Resources [22], which among other things obliges companies not to interfere with, override, or negate people’s rights to water, and so on. Ex-mining pits must also meet the requirements as stated in the Decree of the Minister of Energy and Mineral Resources 1827K/30/MEM/2018 concerning Guidelines for Environmental Implementation of Mineral and Coal Mining, which covers the main criteria: slope stabilization, safeguards, restoration, and monitoring, as well as management according to the designation, and maintenance of post-mining pits [18].

This entry is adapted from the peer-reviewed paper 10.3390/land10060658

This entry is offline, you can click here to edit this entry!