Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Subjects:

Water Resources

Wastewater from domestic, industrial and commercial developments maintains considerable amounts of thermal energy after discharging into the sewer system.

- wastewater heat recovery

- shower water heat recovery

1. Introduction

The wastewater in domestic, industrial, or commercial buildings maintains considerable thermal energy quantities, which is discharged to the sewer system with temperature ranging from 10 to 25 ∘C. It is estimated that 6000 GWh per year of thermal energy is lost in sewers in Switzerland [1], equivalent to 7% of country’s total heating demand. Wastewater in sewer pipes in Germany is estimated to contain enough energy to heat 2 million homes [2]. This resource can be exploited through heat exchangers and heat pump technologies, applied at different points in the sewer system, from end-user to water treatment, that is, at the component level, in buildings, in public sewers, and at WWTPs. These locations have their respective advantages and disadvantages concerning their energy, economic and environmental prospects. For example, low heat loss is present at component level WWHR, while greater heat density is available at WWTPs.

2. Energy Recovery Options

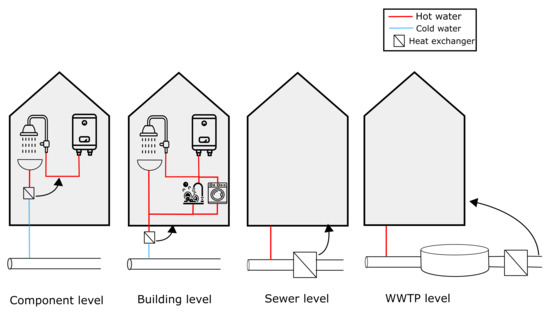

There are four main possible locations within the sewer system for energy recovery from wastewater: (i) at the component level; (ii) at building level; (iii) in the sewer pipe network, and (iv) from WWTPs. Figure 1 shows these possible options of WWHR.

Figure 1. Possible options of heat recovery from wastewater [1].

2.1. Heat Recovery at Component Level

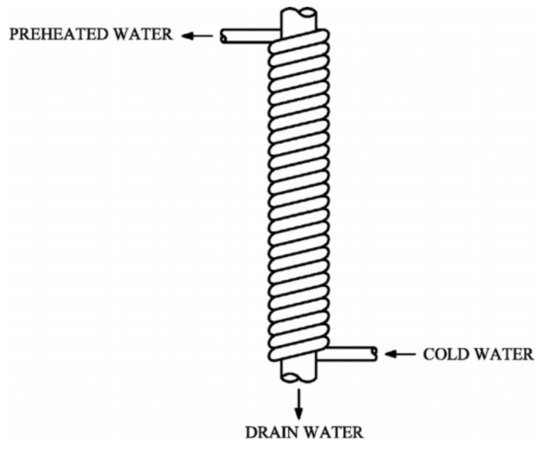

At this level of WWHR, heat is recovered from wastewater directly after it is produced in specific activities relating to a single component (e.g., showering, cooking, food processing, etc.). Heat is extracted using a heat exchanger directly after the component used in the activity. The recovered heat may be used to preheat incoming cold-water, as in domestic or commercial shower facilities, or be used in conjunction with a heat pump for other purposes. Figure 2 shows the basic working principle of a vertical counter-flow heat exchanger.

Figure 2. Basic working principle diagram of a vertical WWHR unit [3].

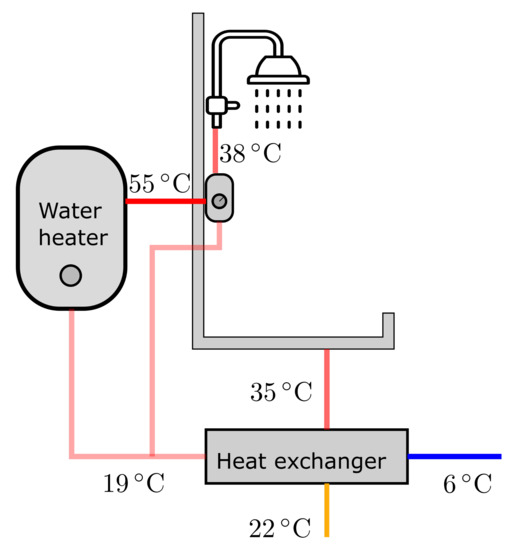

Shower water heat recovery is the most common application seen in practice at this level. This application has the advantage of a continuous simultaneous counter flow of wastewater and incoming cold-water supply for use in the shower. Therefore, heat recovered here can be achieved with high effectiveness, and there is no time lag present between waste heat availability and heat demand for showering, eliminating the need for heat storage and resulting losses [4]. A general schematic of shower water heat recovery is shown in Figure 3.

Figure 3. General schematic of shower water heat recovery [5].

In real applications, heat exchangers are placed under the shower tray in either horizontal or vertical orientations. Both have their respective advantages and disadvantages. In the vertical configuration, the wastewater is discharged as a falling film flow, whereas in the horizontal orientation, water flows at the bottom of the pipe. Therefore, the effective surface area over which heat is exchanged is larger in the vertical orientation, which leads to higher efficiency [6]. Wong et al. [7] analyzed shower water heat recovery in high-rise residential buildings in Hong Kong. The study investigated the installation of a single-pass counter-flow heat exchanger installed beneath shower drains in the horizontal configuration. The result showed an annual energy saving of 4–15% from shower water heat recovery. The savings were dependent upon drainage pipe diameter and length, which governs the effective area of heat exchange surface.

An experimental study conducted at the Canadian Center of Housing Technology analyzed the performance of five vertical heat exchangers for WWHR at component level [3]. The results showed a 9% to 27% reduced natural gas usage for hot water preparation in domestic shower applications. The energy savings increased with the number of showers and lower temperature of the incoming cold-water supply. Another critical factor is the configuration of the WWHR system. The energy savings are higher when recovered energy is used to heat the water flowing into the hot water tank and shower valve, compared to heating only the water entering the hot water tank. Similar results for such configurations have been observed by Tomlinson [8]. Tomlinson [8] argued that the overall water flow is balanced in the first configuration, that is, flow on both sides of the heat exchanger are equal, resulting in higher heat recovery.

On the other hand, a major disadvantage of vertical heat exchangers is the large space requirements for their installation, requiring around 1–2 m of vertical space below the shower tray. In many existing buildings, such facilities are not possible due to space limitations. Besides, longer heat recovery units are preferred for better efficiency, which is more expensive and space-consuming. Consequently, researchers have also investigated improving the horizontal heat exchanger’s design to achieve higher effectiveness [9][10]. McNabola and Shields [10] proposed a new horizontal WWHR heat exchanger design to maximize the heat exchange between wastewater and cold-water supply. The design was based upon placing the cold-water supply pipe into the wastewater pipe, thus increasing the contact surface area. The results showed that the effectiveness of over 50% could be achieved for the proposed design, which is comparable to some existing vertical WWHR units. Currently, several proprietary horizontal WWHR heat exchanger also exists in the market with similar effectiveness to vertical WWHR heat exchangers [11].

Another study investigated the possibility of using a storage-type WWHR unit [12]. In this case, wastewater is stored in an insulated steel tank and cold-water pass through a copper coil immersed into wastewater. The proposed system is smaller in height than a vertical WWHR unit and can recover 34% to 60% of available energy in wastewater. However, such an implementation would not be economically viable due to the additional tank and insulation cost. Such a design could be successful combined with a heat pump system [13][14][15].

For overall viability of a WWHR component level application, it is vital to consider the financial analysis of the system [16]. The economic viability of the WWHR unit not only depends upon heat exchanger characteristics but also can depend upon user behaviour like shower length, shower head flow rate, desired water temperature, number of showers and so forth [17]. Słyś and Kordana [18] analyzed the effect of shower length and shower head flow rate upon the payback period and net present value (NPV) of a vertical WWHR heat exchanger. The study observed that with increases in shower length and shower head flow rate, that is, higher water consumption, NPV of the WWHR system increases. The considered WWHR unit’s payback period, under the same flow rate conditions, decreased by 66% with an increase in shower length from 5 to 12 min. The study concluded that WWHR units could have significant financial savings in dwellings with large amounts of water usage.

Apart from additional space requirements for WWHR, another challenge is that such installations can be cost-effective only when fitting a new bathroom or renovating an existing one. The additional cost of retrofitting the WWHR system in the existing bathrooms and changing the water pipe infrastructure for the sole purpose of heat recovery can increase the device’s overall payback period.

Another major issue of the WWHR system is the fouling of the heat exchanger. Fouling is the accumulation of unwanted deposits on the surface of heat exchanger [19]. It increases the heat exchanger’s thermal resistance, generally referred to as fouling resistance. Due to fouling resistance, the heat exchanger’s heat capability decreases, leading to fewer energy savings. Fouling also adds additional maintenance cost to the device. Evidently, the horizontal heat exchangers are more prone to fouling than vertical heat exchangers due to the continuous build-up of unwanted deposits on the horizontal plate. There is a lack of information on fouling and maintenance of horizontal WWHR units for showers. One study performed by a horizontal WWHR unit manufacturer observed that after applying a large amount of shampoo, soap and hair-conditioner on the heat exchanger surface and keeping it overnight, there was a performance drop of 5.5% for only first 10 min for the device [20]. The study also reported the same performance for the device over a two years interval. Future work is required to examine the fouling performance of a range of heat exchanger types for shower applications.

Apart from the shower systems, wastewater heat can be recovered from other components, such as dishwashers and washing machines. These components discharge wastewater at fairly high temperatures; for example, exit water temperature for atypical household dishwasher ranges from 19 ∘C to 61 ∘C depending upon the washing stage [21]. The water consumption during the whole washing cycle is around 33 l. Paepe et al. [21] proposed a storage-based heat recovery system for domestic dishwashers and analyzed its technical and economic performance. The study showed a 25% reduction in total heating demand from the dishwasher with a payback period of 6 years.

Large scale components such as dishwashers in industrial kitchens and washing machines in launderettes use a large amount of hot water thus can have significant potential for WWHR. Wemhoff et al. [22] analyzed the viability of WWHR for dishwashers in a university’s dining facility in Philadelphia. The study calculated a payback period of 2 years for the proposed installation of a 146 kW shell-and-tube heat exchanger. The annual source pollution reduction of 13 kg SO2, 6.5 kg NOx and 6.5 metric tons CO2 was shown.

Adhikari [23] performed a feasibility study to examine WWHR in a public laundry facility with two washing machines with average wastewater temperature and flow of 60 ∘C and 0.11 kg/s. The study reported 103 MWh/year of heat recovery from laundry facility’s wastewater leading to almost €6371 of economic savings.

A myriad of other hot wastewater generating components exist in domestic, commercial and industrial settings, aside from showers, dishwashers or washing machine, for example, sinks in hair salons, swimming pools/spa applications, food processing, and so forth. These have received scant attention in the literature to date.

2.2. Heat Recovery at Building Level

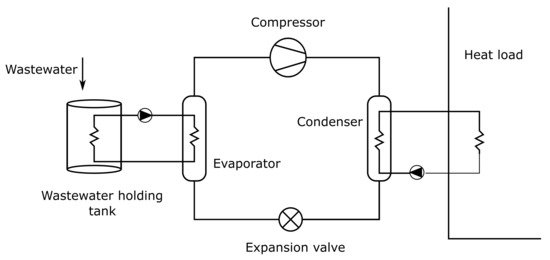

At this level, heat is recovered from the collective wastewater discharge from a single whole building is considered. The wastewater flow and temperature characteristics of this discharge depend upon building type. Wastewater in domestic building can maintain a temperature of 10–25 ∘C over the year [13]. The energy savings from WWHR at the building level can be higher when compared to the individual component level due to the higher volume of wastewater and accumulation of multiple hot water activities [18]. However, discharge at the building level also includes cold wastewater in the mix, which reduces energy potential. At this level, to perform heat recovery, wastewater is commonly collected in a holding tank, and heat is recovered using a heat exchanger [23][24] or water source heat pump [13][14][15]. For fouling prevention, usually a grease trap system is used to intercept debris in wastewater. If the recovered heat is not immediately used, it can be stored in a hot water tank (HWT) for later use. A general schematic diagram of WWHR with a heat pump is shown in Figure 4. Researchers have investigated the potential of WWHR at the building scale with numerical feasibility studies, and experimental lab-scale approaches [14][15][25][26][27][28][29].

Figure 4. Schematic diagram of WWHR with heat pump.

2.3. Heat Recovery at WWTP Level

Another critical location for energy recovery from wastewater is at WWTPs. There are three possible heat recovery points at a WWTP—from raw wastewater before treatment, from partially treated water within the WWTP, and from effluent discharge after treatment. Heat recovery from raw wastewater is similar to recovering heat from within the sewer pipe system. At the WWTP, the influent’s temperature and the available energy are highest, offering the greatest potential for WWHR. However, the water quality is the lowest, offering significant technical challenges in exploiting it. As we move through the WWTP, the temperature reduces and the water quality increases, whereby at the effluent discharge, the technical difficulty of recovering heat from raw wastewater is removed at the cost of a lower temperature fluid.

WWTPs process and treat large amounts of wastewater from sewers and then discharge into near water bodies on a daily basis. This cleansed water temperature is stable and has low daily and weekly variations compared to the influent temperature [1][30]. Even in wet weather, the effluent temperature does not have erratic variations like the influent temperature [1].

The potential of WWHR in treated wastewater is higher than sewer pipe wastewater since the downstream water from WWTP can be cooled down to much lower values [1] and effluent water flow is higher. Relatively low variation in water temperature improves the performance of heat pump systems. Since the water is already treated, another advantage is lower bio-fouling and solid matter interference with the heat exchanger, thus improving heat transfer efficiency. However, since the heat consumers are usually not located near WWTP, a major disadvantage of this energy recovery option is that the heat supply must be transported over long distances, thus leading to high heat losses.

Energy consumption in WWTPs is large, for example WWTPs contribution to primary energy consumption in the US is 0.8% of national energy consumption [31]. Most of the energy consumption is in the form of electricity. On the other hand, WWTPs have a significant amount of energy at their disposal, coming from raw and effluent water and other processes like electricity generation from the incineration of biogas produced from anaerobic digestion and bio-solids [32]. Therefore, WWTPs can be considered as regional energy cells which can deliver energy into local energy supply networks (heat and electricity) [33]. However, with heat supply, the feasibility of such energy cells depends on consumer distance and the treatment capacity of the WWTP. Also, a major constraint for recovered heat usage is that a local district heating network should be present to which recovered heat can be injected. Therefore, on-site consumption can be preferred in such cases to heat buildings in the WWTP precinct.

Regarding the energy potential, heat available in effluent at WWTP is substantial due to high water volumes. Other than water amount, energy potential depends upon the temperature drop of effluent after energy recovery. Based upon different studies in the literature, the temperature drop can be up to 8 ∘C; however, it depends upon the lower temperature limit allocated by relevant environment protection organizations to protect the ecology of receiving waters. Đurđević et al. [34] presented a theoretical case study to analyze the utilization of WWHR in the city of Rijeka, Croatia. The location considered for the case study had a WWTP in operation with a capacity of 540,000 PE and 3000 L/s of effluent water at maximum load. Based upon considered water flow and a temperature drop of 6.5 ∘C, 75 MW of heat recovery potential was shown, which was 72% of the existing natural gas power heat plant capacity. The study also analyzed the COP of the proposed heat pump, which decreased from 4.7 to 2.87 with an increase in condensation temperature from 60 ∘C to 90 ∘C.

As previously mentioned, the delivery of recovered heat from a WWTP to consumers could be impractical because of the high heat losses; or in some situations, a district heat distribution network may not be present. Therefore, in such cases, on-site usage of recovered heat can be more sensible. However, in these cases, only a fraction of available heat in wastewater is used. For example—Chae and Kang [35] performed a study to estimate the energy independence of WWTPs with three different energy resources—photovoltaic panels, small-hydropower and WWHR. Under the considered design conditions for photovoltaic panels, hydropower turbine, and heat pump, 6.5% of total energy consumption was estimated to be covered by the proposed energy resources. Heat recovery from wastewater had the highest potential among them, at around 3.65%. The payback period of the heat recovery system considered in the study was estimated to be 6.8 years. Even though the recovered heat supplied all of the heating demand required by the buildings in the WWTP precinct, the heating demand was only limited to 2.2% of available heat (temperature drop = 3 ∘

C) in effluent water. Therefore, much of the available heat in effluent water remained unexploited.

Apart from supplying the space-heating and hot water demand of WWTPs, recovered heat can also be used for low-temperature treatment processes. Pochwala and Kotas [36] presented such a case study. The heat was recovered from raw wastewater and used to heat an on-site building to raise the temperature of a sequential biological reactor (SBR) to the optimum value for the treatment process. The recovered heat supplied 98% of the heat demand of WWTP.

It is evident that heat recovery from effluent water at WWTPs is an abundant source of energy supply. However, to realize the full potential of this form of energy recovery, a local district heating/cooling network is necessary. Most existing heat recovery practices from WWTP effluent around the world are large scale capacity heat pumps and supply heating/cooling to district heating, and cooling networks [1].

This entry is adapted from the peer-reviewed paper 10.3390/w13091274

References

- Schmid, F. Sewage water: Interesting heat source for heat pumps and chillers. In Proceedings of the 9th International IEA Heat Pump Conference, Zürich, Switzerland, 20–22 May 2008; pp. 1–12.

- Mueller, E. Heizen und Kühlen mit Abwasser; Institut Energie in Infrastrukturanlagen: Winterthur, Switzerland, 2009; Available online: (accessed on 24 September 2020).

- Zaloum, C.; Gusdorf, J.; Parekh, A. Performance Evaluation of Drain Water Heat Recovery Technology at the Canadian Centre for Housing Technology; Sustainable Buildings and Communities, National Resources Canada: Ottawa, ON, Canada, 2007.

- Zaloum, C.; Gusdorf, J.; Parekh, A. Drainwater Heat Recovery Performance Testing at Canadian Centre for Housing Technology; Technical Series, CCHT, 07-116; Canada Mortgage and Housing Corporation: Ottawa, ON, Canada, 2007.

- Frankowski, C. Drain Water Heat Recovery: A Review of Performance, Economics, Practical Issues and Applications. Ph.D. Thesis, University of British Columbia, Vancouver, BC, Canada, 2013.

- Shields, K. Drain Water Heat Recovery. Master’s Thesis, Trinity College Dublin, University of Dublin, Dublin, Ireland, 2011.

- Wong, L.; Mui, K.; Guan, Y. Shower water heat recovery in high-rise residential buildings of Hong Kong. Appl. Energy 2010, 87, 703–709.

- Tomislon, J. Heat Recovery from Wastewater Using a Gravity-Film Heat Exchanger. In Federal Energy Management Program; Department of Energy: Washington, DC, USA, 2005. Available online: (accessed on 26 September 2020).

- Pochwat, K.; Kordana, S.; Starzec, M.; Słyś, D. Comparison of two-prototype near-horizontal Drain Water Heat Recovery units on the basis of effectiveness. Energy 2019, 173, 1196–1207.

- McNabola, A.; Shields, K. Efficient drain water heat recovery in horizontal domestic shower drains. Energy Build. 2013, 59, 44–49.

- Kimmels, A. Shower Heat Recovery: Overview of Commercially Available DWHR Systems; Meander Heat Recovery: Selpenden, Norway, 2011; Available online: (accessed on 24 September 2020).

- Torras, S.; Oliet, C.; Rigola, J.; Oliva, A. Drain water heat recovery storage-type unit for residential housing. Appl. Therm. Eng. 2016, 103, 670–683.

- Spriet, J.; McNabola, A. Decentralized drain water heat recovery: A probabilistic method for prediction of wastewater and heating system interaction. Energy Build. 2019, 183, 684–696.

- Ni, L.; Lau, S.; Li, H.; Zhang, T.; Stansbury, J.S.; Shi, J.; Neal, J. Feasibility study of a localized residential grey water energy-recovery system. Appl. Therm. Eng. 2012, 39, 53–62.

- Chen, W.; Liang, S.; Guo, Y.; Cheng, K.; Gui, X.; Tang, D. Investigation on the thermal performance and optimization of a heat pump water heater assisted by shower waste water. Energy Build. 2013, 64, 172–181.

- Pochwat, K.; Kordana-Obuch, S.; Starzec, M.; Piotrowska, B. Financial Analysis of the Use of Two Horizontal Drain Water Heat Recovery Units. Energies 2020, 13, 4113.

- Zaloum, C.; Lafrance, M.; Gusdorf, J. Drain Water Heat Recovery Characterization and Modeling; Sustainable Buildings and Communitiues: Ottawa, ON, Canada, 2007.

- Słyś, D.; Kordana, S. Financial analysis of the implementation of a Drain Water Heat Recovery unit in residential housing. Energy Build. 2014, 71.

- Bott, T.R. Fouling of Heat Exchangers; Elsevier: Amsterdam, The Netherlands, 1995.

- Velan, D. Cost Competitive Horizontal Drain Water Heat Recovery—An opportunity to save energy in many homes and commercial buildings. In Proceedings of the ACEEE Hot Water Forum, Portland, OR, USA, 26–28 February 2017; Available online: (accessed on 24 September 2020).

- De Paepe, M.; Theuns, E.; Lenaers, S.; Van Loon, J. Heat recovery system for dishwashers. Appl. Therm. Eng. 2003, 23, 743–756.

- Wemhoff, A.; Dai, T.; Fleischer, A. The Potential for Thermal Waste Energy Recovery in Industrial Kitchens. In Proceedings of the ASME 2017 International Mechanical Engineering Congress and Exposition, Tampa, FL, USA, 3–9 November 2017; Volume 58417, p. V006T08A039.

- Adhikari, P. Feasibility Study of Waste Heat Recovery from Laundry Facility: Case Study-Mr Washing Man Oy. 2017. Available online: (accessed on 24 September 2020).

- Ip, K.; She, K. Waste heat recovery from showers: Case study of a university sport facility in the UK. In Proceedings of the Water Efficiency Conference 2016, Coventry, UK, 7–9 September 2016; Water Efficiency Network, University of Bath: Bath, UK, 2016; pp. 114–121. Available online: (accessed on 24 September 2020).

- Dong, J.; Zhang, Z.; Yao, Y.; Jiang, Y.; Lei, B. Experimental performance evaluation of a novel heat pump water heater assisted with shower drain water. Appl. Energy 2015, 154, 842–850.

- Baek, N.; Shin, U.; Yoon, J. A study on the design and analysis of a heat pump heating system using wastewater as a heat source. Sol. Energy 2005, 78, 427–440.

- Wallin, J.; Claesson, J. Analyzing the efficiency of a heat pump assisted drain water heat recovery system that uses a vertical inline heat exchanger. Sustain. Energy Technol. Assessm. 2014, 8, 109–119.

- Postrioti, L.; Baldinelli, G.; Bianchi, F.; Buitoni, G.; Di Maria, F.; Asdrubali, F. An experimental setup for the analysis of an energy recovery system from wastewater for heat pumps in civil buildings. Appl. Therm. Eng. 2016, 102, 961–971.

- Wallin, J.; Claesson, J. Investigating the efficiency of a vertical inline drain water heat recovery heat exchanger in a system boosted with a heat pump. Energy Build. 2014, 80, 7–16.

- Tuncay, E. The Effect of Wastewater Treatment Plant Effluent on Water Temperature, Macroinvertebrate Community, and Functional Feeding Groups Structure in the Lower Rouge River, Michigan. Ph.D. Thesis, University of Michgan-Dearbon, Dearborn, MI, USA, 2016.

- Pabi, S.; Amarnath, A.; Goldstein, R.; Reekie, L. Electricity use and management in the municipal water supply and wastewater industries. Electr. Power Res. Institute Palo Alto 2013, 194. Available online: (accessed on 26 September 2020).

- Stillwell, A.S.; Hoppock, D.C.; Webber, M.E. Energy recovery from wastewater treatment plants in the United States: A case study of the energy-water nexus. Sustainability 2010, 2, 945–962.

- Kollmann, R.; Maier, S.; Shahzad, K.; Kretschmer, F.; Neugebauer, G.; Stoeglehner, G.; Ertl, T.; Narodoslawsky, M. Waste water treatment plants as regional energy cells-evaluation of economic and ecologic potentials in Austria. Chem. Eng. 2014, 39.

- Đurđević, D.; Balić, D.; Franković, B. Wastewater heat utilization through heat pumps: The case study of City of Rijeka. J. Clean. Prod. 2019, 231, 207–213.

- Chae, K.J.; Kang, J. Estimating the energy independence of a municipal wastewater treatment plant incorporating green energy resources. Energy Convers. Manag. 2013, 75, 664–672.

- Pochwała, S.; Kotas, P. Possibility of obtaining wastewater heat from a sewage treatment plant by the means of a heat pump-A case study. E3S Web Conf. 2018, 44, 00144.

This entry is offline, you can click here to edit this entry!