Bitumen aging and rejuvenation include a series of chemical transformations that the material undergoes and that results in the variation of its physical characteristics. The paper presents a summary of chemical analyses on aged/rejuvenated bitumen with the aim of both encouraging the use of an increasing quantity of RAP in hot mix asphalt and trying to give indications for further research.

- bitumen

- aging

- rejuvenation

- reclaimed asphalt

- recycling

1. Introduction

Nowadays, the world is living through the most severe environmental crisis ever, due to biodiversity loss; air, soil, and water pollution; resource exhaustion; and disproportionate land use. To face these issues, the concepts of circular economy and sustainability are getting more and more attention by administrations, technicians, and researchers. Indeed, these topics have become important themes of research with a steep increase in the number of papers and journals [1]. One of the sectors that greatly contributes to the environmental impact is road construction, which entails the exploitation of raw materials, the emission of pollutants, and the generation of wastes [2].

In the sector of road pavement engineering, the easiest way to promote the circular economy is to encourage the use of Reclaimed Asphalt (RAP). RAP is defined as removed and/or reprocessed pavement material composed of bitumen and aggregates. Four methods—hot in-plant recycling, hot in-place recycling, cold in-plant recycling, and cold in-place recycling—allow RAP recycling in new bituminous mixtures, determining the saving of virgin resources and the progressive cyclic reuse of this waste material, in a sustainable and circularly economic way [3].

The most widespread method to recycle RAP is the hot in-plant technique, which allows both the aggregates and binder contained in the RAP to be exploited. Unfortunately, the aged, stiff, and brittle binder from the RAP increases the mixture stiffness and can therefore cause fatigue and low-temperature damages [4,5]. For this reason, road agencies usually limit the maximum amount of RAP that can be recycled in new hot mixes [6]. With the aim of solving this issue, many products worldwide have been used with the function of rejuvenating agents, which allow restoring (fully or partly) the mechanical properties that the RAP binder loses with aging [7].

In the scientific literature, there are several studies concerning the aging and rejuvenation of bitumen. For instance, the use of polymer-modified bitumen is one of the hottest topics in this field [8]. Bitumen including elastomeric or plastomeric polymers experiences different changes with aging with respect to neat bitumen, as a function of the polymer type and content [9,10,11,12,13]. Moreover, it is a theme of research whether RAP including polymer-modified bitumen is as recyclable as the RAP containing neat bitumen, in terms of final mix performance and emission during mix production [14,15].

This paper tries to recap the most recent research and innovation in the field of chemical analyses on virgin, aged, and rejuvenated bitumen. With respect to other reviews on aging and rejuvenation chemistry, the present state of the art is more updated (the most recent paper was published in 2009 [23]) and includes discussion about both processes (while the review by Loise et al. [24] only deals with rejuvenation, and specifically on additives). The aim is to provide a useful summary and some inputs for further research on this topic, in order to encourage the use of an increasing quantity of RAP in Hot Mix Asphalt (HMA).

2. Bitumen Aging

Bitumen aging is defined as the series of chemical transformations that the material undergoes and that results in the variation of its physical characteristics [61]. In general, two different aging processes, namely short-term aging and long-term aging, are identified.

Short-term aging is the phenomenon that bitumen suffers during HMA manufacturing (mixing, hauling, paving, and compacting) because of the high processing temperatures (> 150 °C). Long-term aging is the phenomenon that affects bitumen during the entire service life of the mix, which is subjected to traffic and environmental stresses. The severity of this process is mainly related to the bitumen’s exposure to air, which depends on the mix air voids and the position of the HMA layer within the pavement structure [39].

Despite some studies [62,63] that have identified several variables that affect bitumen aging, the most widely recognized mechanisms include:Physical and steric hardening (reversible mechanisms);Loss of low-weight components (volatiles) by evaporation;Oxidation, with the consequent changes at the molecular level that cause a change in the SARA fractions.

The oxidation and evaporation of volatiles, which are irreversible processes, are accelerated during the HMA production and paving when the bitumen is hot [64]. When the mix reaches the air temperature, the evaporation of volatiles becomes much less influential, while oxidation continues in the long-term aging. Furthermore, the greater importance of oxidation compared to that of physical hardening is given by the different nature of these processes: oxidation is irreversible, while physical hardening can be recovered. For these reasons, oxidation is considered the main process in the aging of bitumen.

These mechanisms are described in detail in the following sections.

Physical hardening deals with the changes in the bitumen viscoelastic properties due to the material cooling below the glass transition region. However, the process does not entail any change in the chemical structure and is reversed when the bitumen is re-heated to air temperatures [65]. Assuming that the material volume consists of the volume of the oscillating molecules and the free volume between the molecules [66,67], when the bitumen temperature decreases, both molecular mobility and free volume reduces, maintaining the same proportion between occupied and free volume. When the glass transition temperature is reached, the free volume decrease becomes slower than the decrease of molecule oscillation, entailing a kind of “over-hardening” for the bitumen [68].

Physical hardening should not be confused with steric hardening. Steric hardening is a chemical process in which the bitumen molecules rearrange and form wax compounds in the maltenes, due to the presence of linear alkanes in the asphaltenes [69]. The process happens at intermediate temperatures but takes three times longer than physical hardening [70]. While the former type of hardening occurs within 1–2 days at temperatures below the glass transition temperature of bitumens (−35/−15 °C), the latter is manifested at room temperature, and requires days or even weeks.

The evaporation of saturated and aromatic components has been also reported as an aging mechanism of bitumen. It has been quantified that the loss of volatiles can be double for a temperature increase of 10 °C during HMA manufacturing at the plant [73]. The volatile evaporation causes the unbalancing of the SARA fractions, determining the predominance of resins and asphaltenes over saturates and aromatics. The evaporation of volatile compounds is an irreversible mechanism that significantly affects bitumen aging, even if to a lower extent than the oxidation process [74].

Thurston and Knowles, in 1941, demonstrated how bitumen components, in particular asphaltenes and resins, absorb oxygen [63]. It is widely accepted today to consider the oxidative process of bitumen as the most important mechanism that happens during aging.

Bitumen oxidation is an irreversible process that deals with the “capture” of oxygen atoms by the bitumen components (particularly the asphaltenes), which undergo an alteration of their chemical characteristics. Moreover, this aging process could be photo-catalyzed in the case of the bitumen in pavement surface layers, in particular for polymer-modified binders [23]. As oxidation is due and depends on the access to oxygen in the mixture, the voids content, the HMA layer depth, the bitumen content, and the presence of cracking are factors that can influence the quantity of bitumen exposed, and therefore the quantity of potentially aged bitumen.

Within bitumen morphology, oxidation includes dehydrogenation, the reaction of the alkyl sulfides into sulphoxides, and the reaction of the benzyl carbons into ketones, which in turn form carboxylic acids with dicarboxylic anhydride. These reactions can be quantitatively determined by functional group analysis through FTIR spectroscopy. cm⁻¹ are due to the increase in C=O bonds (carbonyl groups)—for example, ketones, carboxylic acids, and anhydrides—while those around 1030 cm⁻¹ are due to the increase in S=O bonds (sulphoxide groups). Consequently, the peak areas of the two wavenumbers can be considered as concentration measurements of carbonyl compounds and sulphoxides, respectively [75].

It is important to highlight that the carbonyls, ketones, and sulfoxides generated through oxidation are characterized by a marked polarity. Therefore, they associate with the polar groups in the bitumen forming agglomerates with a high molecular weight [76]. These large and “heavy” clusters, which typically involve the asphaltene fraction, determine the reduction of the molecular mobility within the bitumen colloidal system, resulting in increased viscosity, stiffness, and brittleness [77].

Temperature is a key factor in the oxidation phenomenon. In particular, the degree of oxidation is doubled every time the temperature increases by 10 °C (after 100 °C) [73]. The influence of temperature was also observed in the laboratory by Lu et al. They noted that it takes 4–8 longer times to obtain the same aging when the pressure aging vessel (PAV) temperature is decreased from 100 to 75 °C.

This issue has been neglected for many years as it only involves the upper pavement layer, because of the low ability of the radiations to penetrate in depth. However, the amplifying effect on the aging of the bituminous binder due to ultraviolet radiation should be considered, particularly in the most exposed surfaces of geographic regions characterized by high levels of solar radiation and humidity [79]. Many authors associated the increase in bitumen viscosity, as a consequence of oxidation, with the number of radiations that invested the material [80,81,82]. [81] observed the detrimental effects of ultraviolet radiation in association with high temperatures in promoting oxidation.

To date, the most frequently used methodologies to age bitumens are the thin film oven test (TFOT), rolling thin film oven test (RTFOT), pressure aging vessel (PAV), and ultraviolet test (UV). Most of them are often characterized by increases in temperature, oxygen pressure, or a combination of these two in order to generate the aging conditions, which are as close as possible to the conditions in which real bitumen can be found. While the first two methodologies are mainly adopted to reproduce short-term aging, which occurs during storage, mixing, hauling, and laying of an HMA, the last ones can simulate long-term aging that occurs during the service life of the pavement.

As regarding the different SARA fractions, aging can generally be summarized as follows:the saturates remain almost unchanged;the aromatics decrease;the resins see a small increase;the asphaltenes increase.

As explained before, the four bitumen fractions are ranked, as a function of the increasing polarity, as follows: saturates, aromatics, resins, and asphaltenes. The next fractions, aromatics and resins, oxidize and respectively shift into resins and asphaltenes. Since aromatics evolve into resins, but there is poor supply from the saturates (which are mainly inert), a global decrease of the aromatic content with aging is observed. Differently, the resin content only experiences a slight increase or decrease since there is the contemporary uptake of the oxidized resins into asphaltenes and of the oxidized aromatics into resins [83].

The relationship between resins and asphaltenes plays a crucial role in aging: the asphaltene fraction is the component that grows the most; at the same time, the resin content increases to a lesser extent, facilitating the mutual contacts between asphaltenes. When the ratio between aromatics and resins is not high enough to allow the peptization of the asphaltene micelles, or when the solvation capacity of the system is insufficient, the micelles tend to bond to each other [84]. This determines the formation of larger irregular structures in which voids are present (filled by the external liquid of the component micelles). Thus, in terms of colloidal models, aged bitumen tends to assume a gel structure, causing a stiffer and more brittle behavior [85].

In this study, five different bitumens were separated into the SARA fractions before and after aging. how, during aging, the asphaltenes increase while the contents of aromatics and resins decrease. Moreover, the amount of saturates tends to remain stable. This phenomenon was investigated in terms of the colloidal index (CI), which proved to grow with aging, particularly in the long-term step.

In particular, an unaged bitumen and three long-term-aged bitumens were separated into their SARA fractions, which were subsequently analyzed through FTIR spectroscopy. The absorbance spectra showed that:The saturates spectrum remains unchanged, confirming that this fraction is little affected by aging;The aromatic spectrum shows some changes (an increase of the peaks in the carbonyl band, main aromatic band and across the entire fingerprint area), but no significant increase in sulfoxides;The interpretation of the resin spectrum is complex, because of the position of this fraction in the polarity gradient. In general, aging results in uptake from 2-quinolones and carbonyls into ketones and in the growth of the sulfoxides content;The asphaltenes spectrum shows significant variations in the fingerprint area. In particular, the aging determines an increase in sulfoxides (1030 cm−1), main aromatic (1600 cm−1), and carbonyl (1700 cm−1) peaks.

Thus, the increase of the carbonyls affects the aromatics and the resins, while the increase of the sulfoxides affects the resins and the asphaltenes.

Using GPC, Li et al. evaluated the molecular weight of the bitumen components [51].Table 3shows that the molecular weight increases when moving from saturates, to aromatics, to resins and asphaltenes. In particular, the saturates have the shortest molecular chains, denoting an approximate structure. In addition, they include a higher number of polar groups that have a low sensitivity to temperature changes. Therefore, when the asphaltene content increases, the bitumen tends to maintain its mechanical properties (stiffness, viscosity), even when increasing temperature [51].

FTIR spectroscopy has been used for many years to analyze the bituminous binders [87], particularly to investigate the polymer modification mechanisms and the effects of aging. Table 4summarizes the main changes noticed in the bitumen FTIR spectrum as a consequence of aging.

The more significant changes in the FTIR spectrum associated with bitumen oxidation are the rise carbonyl the S=O and C=O bands are mainly related to short-term aging and long-term aging, respectively. Even the aromatic C=C band (1600 cm−1) shows a slight increase that is associated with the increase of the resins and especially the asphaltenes, which include condensed aromatic rings. The polarity band (around 3450 cm−1) is highly marked in the spectra of resin and asphaltene components, but this has not been exactly associated with the bitumen aging process [93].

In order to quantify the effects of bitumen oxidation, two indices have been introduced:Carbonyl index:IC=O=A1690ArefSulphoxide index: IS= where A1690is the area of the C=O peak centered at 1690 cm−1, A1030is the area of the S=O peak centered at 1030 cm−1, and Arefis the area of the reference ethylene and methyl peaks, centered at 1460 and 1375 cm−1, respectively [96].

With the aim to estimate the effects of bitumen aging on its properties, the variation of the indices in unaged, short-term-, and long-term-aged bitumen can be calculated. When increasing the aging, the heights and the areas of the peaks in correspondence of the wave numbers of 1690 cm−1and 1030 cm−1(respectively for the carbonyl C=O and sulphoxide S=O bands) increase, so the two indices also increase [97,98,99,100]. Moreover, a recent study [101] proposed the Chemical Aging Index (CAI), calculated as IC=Oplus IS=O, in order to better understand the variation of both indices during aging.

There is a certain agreement that the bee structures are associated with wax crystallization [102]. [105] demonstrated that the valleys, due to their lower thickness and roughness, are less strong than the hills. Other studies proposed that the formation of the bee structure is associated not only with asphaltenes but also with resins and aromatics, and so it is strictly correlated to the bitumen performance [106,107]. One more point of discussion is related to the presence of these phases in the whole bitumen volume or only on the surface [108].

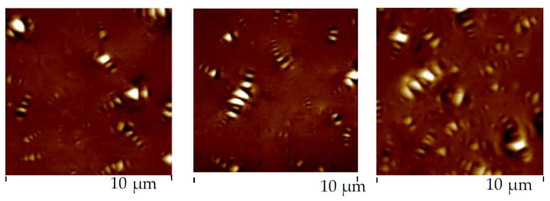

[51] tried to identify the changes in the bee structures during short- and long-term aging in different bitumens. Before aging, these show the distinct elliptic bee structures, which are short and thick. In general, the bee structures became larger and irregular when increasing the aging level. In addition, peculiar phenomena happened in the AFM diagrams, such as the increase of the bee stripes number or the formation of sunk regions, columnar peaks, blocky structures, or cracks.

[109] investigated wax-including bitumens in comparison with a non-waxy bitumen using AFM. They noted that aging led to a decrease in the number and an increase in the dimensions of the bee structures in the bitumen with wax, probably because of the highly increased stiffness of the aged binder and/or the reduced compatibility between the saturated crystalline fraction and the more polar bitumen matrix. On the other hand, for a non-waxy bitumen, no structure was observed either on the unaged or PAV-aged state. This demonstrated that asphaltenes are not the fraction responsible for the structures, unless they contain n-heptane insoluble crystallizable materials.

Zhang et al. [110] also studied the aging effect on the bee structures. They confirmed that aging entails an increase in the bee structure number, dimension, and roughness (Figure 8), which is associated with a contemporary decrease of the penetration and increase of the ring and ball softening point and viscosity.

3. Bitumen Rejuvenation

Including RAP in HMA requires a careful study of the mixture, because its mechanical properties are strongly conditioned by the presence of the aged bitumen contained in RAP. In particular, improper use of RAP can lead to premature cracking linked to the excessive stiffness of the bitumen (thermal and fatigue cracking) In order to achieve the proper mechanical properties for the HMA, additives are included in the mixture. In the following paragraph, the concept of rejuvenator is provided, clarifying which are the main distinctions within this category and explaining the benefits associated with their use.

A rejuvenator is an agent that allows renovating the properties that the bitumen loses with aging [115]. Thus, rejuvenators should reduce aged bitumen viscosity and stiffness and improve ductility [24]. The literature does not seem very clear about this; the term “rejuvenator” is often used for any additive, without specifying what the effective mechanisms of action in bitumen are. According to different authors [24,116,117], rejuvenators can be classified, based on the effect, as:Softening agents (also called fluidifying agents or rheological rejuvenators), which include: ○Incompatible softeners, which mainly have a viscosity lowering effect;○Soluble softeners, which restore the balance in the SARA composition by re-enriching the maltene fraction;Real rejuvenators or compatibilizers, which help to renovate the physical and chemical characteristics of the bitumen through the disruption of the intermolecular associations between the asphaltenes.

The softening agents are usually based on extracts of lubricating oils. Slurry oil, flux oil, and lube stock belong to this category. The softening agent allows an increase in bitumen ductility and a decrease in viscosity and brittleness by merely supplying oily components to maltene fraction, but does not achieve any change in the complex structure. Regarding their composition, real rejuvenators should have a high content of aromatics, which allows keeping the asphaltenes dispersed and maintains a low content of saturates, which have poor compatibility with the asphaltenes.

In the first phase, the rejuvenator forms a low-viscosity layer around the particles of aggregates covered with aged bitumen. In the third phase, the rejuvenator penetrates the aged bitumen, and the viscosity of the internal and external surfaces gradually decreases. Finally, in the last phase, over time, the rejuvenator manages to reach all the aged bitumen [119]. Karlsson and Isacsson [122], found out that the diffusion of the rejuvenator into the aged bitumen is mainly influenced by the viscosity of the maltene phase.

During the last decades, many studies have tried to estimate the efficacy of different rejuvenators. According to the literature, there are many different sources from which we can obtain rejuvenators. In general, according to their nature, rejuvenators can be classified as additives derived from oil and biological additives. [125] stated that although the two categories may show differences, both additives can be used successfully to soften the aged bitumen and allow the fulfillment of the requirements in terms of penetration, softening point, and rheological characteristic.

Besides fuels and bitumens, rejuvenators able to improve the properties of an aged binder are often produced from the processing of crude oil. These products include aromatic extracts, paraffinic oils, naphthenic oils, and spent motor oils [126]. These petroleum products have been the main agents used for many years to improve the characteristics of aged bitumen. These are called bio-rejuvenators, and they are products such as tall oil, rapeseed oil, soybean oil, sunflower oil, corn oil, used cooking oil, castor oil residues, and organic oils.

Among the numerous studies carried out during the last decades, the most relevant and suitable are reported hereafter, together with a brief description of the used rejuvenators and the main results.

Bocci et al. [129] focused on the evaluation of the mechanical and performance characteristics of HMA made with a high amount of RAP and a bio-rejuvenator. They found out that, using appropriate dosages of this additive, acceptable performance, similar to that reached with virgin materials, can be achieved. Thus, the evaluation of the correct dosage of rejuvenators plays a fundamental role in obtaining a mixture that can easily meet the specifications.

Krol et al. [131] evaluated the effects of several vegetable oils (rapeseed oil, soybean oil, sunflower oil, flaxseed oil) on the mechanical characteristics of bitumen and mixes. Furthermore, they also developed chemical processes to make new additives. These studies aimed to improve the performance of bituminous binders using only very cheap raw materials.

Zargar et al. [132] studied the possibility of using waste cooking oil (WCO) as a rejuvenator in aged bitumen. They highlighted that by adding a specific dosage of this additive, the same values of penetration index, softening point, and viscosity of a virgin bitumen can be obtained. Gökalp and Emre Uz [133] confirmed that using WCO leads to improvements in penetration index, viscosity, and fatigue resistance.

During the last years, many studies have compared the effect of WCO with respect to waste engine oils (WEO) in restoring the original properties of an aged bitumen. [135] confirmed that both WCO and WEO have rejuvenating properties, but WCO has higher efficacy than WEO, which implies the use of higher dosages. [136] investigated different contents of RAP and WCO/WEO rejuvenators. Differently from the previous studies, they noted that WEO allows a higher reduction of indirect tensile strength and stiffness with respect to WCO under the same dosage, but WCO allows a higher content of RAP to be recycled.

The differences between bio-additives and aromatic additives were also studied from a molecular point of view by FTIR. [92] showed that using biological additives involves an increase of particular functional groups (C=O) in bitumen. [137] stated that using rejuvenators such as seed oil or tall oil can increase the carbonyl and sulphoxide indices since they contain functional groups [138], through the analysis of the carbonyl, sulphoxide, and aromatic indices, assessed the degree of aging and rejuvenation of some mixtures including bio-additives.

Zeng et al. [139] tested castor oil as a rejuvenating agent, and they found out that using this additive, it is possible to obtain an improvement of the rheological properties of the aged binder.

The studies carried out by Elkashef et al. [140] and Nayak and Sahoo [141] focused on the use of soybean oil and Pongamia oil. They concluded that both products are good rejuvenators, capable of restoring the rheological properties that the binder lost with aging.

Kehzen et al. [142] tried to evaluate tung oil (also called “China wood oil”) as an additive, showing how its addition improves the elasticity of an aged binder. In addition, with suitable amounts of tung oil, good performances of the mixture at high temperatures are also ensured.

Several studies regard the effects of rejuvenators engineered and “built” in the laboratory. [143] tested a rejuvenating agent made of rubber oil, plasticizers, and surfactants, and demonstrated that the blend of these ingredients allows the binder to recover the malleability and ductility lost during the aging processes. [144] obtained a rejuvenator by modifying pyrolytic condensate of scrap tires with tire crumb. Moreover, mechanical and rheological tests showed that the amount of RAP can reach up to 60% when this engineered rejuvenator is added to the mixture.

Zaumanis et al. [124,145,146] tested the rejuvenating effect of many products of both biological and hydrocarbon nature, such as cotton seed oil, vegetable oil, used cooking oil, used motor oil, aromatic extract, distilled tall oil, distilled tall oil, exhausted motor oil, naphthenic oil, and aromatic extract.

Radenberg et al. [147] carried out a study testing 21 different types of rejuvenators commonly used in the road sector; the products were distinguished between “rheologically effective” and “chemically effective”. While the former led to an increase in the maltenic phase, the latter reversed the effects of the oxidation process in the agglomerated compounds.

Table 5presents recent publications concerning the use of additives to rejuvenate the aged bitumen in RAP. For a correct understanding, a brief description of the nature of the additives tested is also included.

As previously explained, aging determines morphological changes in the bitumen: in particular, it causes more intense molecular interactions by introducing polar groups, which lead to an increase of the colloidal agglomerates into the bitumen volume. As the molecular structure strongly influences the rheological properties, any alteration of the balances and interactions of the polar and non-polar components in the bitumen can determine a modification of the thermal and mechanical properties in a mixture.

From a chemo-morphological point of view, rejuvenation is the inverse process of aging. True rejuvenation breaks the molecular aggregations and rebalances the SARA fractions, leading to an improvement in the rheological properties of the bitumen [170]. Remembering the classification made in the previous section, real rejuvenators are additives capable of both replenishing the lost volatile components and flaking the large agglomerates of asphaltenes into much smaller compounds. [161,170,171], which explain in detail the effect of rejuvenation in the aged bitumen morphology, are summarized hereafter.

The approach adopted by Pahlavan et al. to investigate the rejuvenating process is based on molecular dynamics (MD) simulation and quantum mechanical studies through density functional theory (DFT). It starts from the analysis of the asphaltene monomer and the related oxidized dimer, which consists of a structure resulting from the interaction of two monomers of asphaltenes.

The electrons of the C=O groups located around the oxidized asphaltenes (red dots inFigure 9) change the distribution of π electrons on these flat-shaped molecules. This determines an insufficiency of electrons at the π bonds in the central part of the asphaltenes with a consequent decrease of the repulsive forces between the asphaltenes. This decrease leads to the formation of the dimer (two asphaltene monomers).

Figure 10shows the most probable sites of interaction between a rejuvenator and an asphaltene dimer. When the rejuvenator reaches the zones, it detaches the aromatic ring planes allowing access to more additive. The effectiveness of this second step depends on the chemistry of the rejuvenator. If the additive has polar properties, it creates interference on the Van der Waals forces that keep the polyaromatic cores stuck.

Of course, the rejuvenating effect of an additive is higher if it achieves both the steps, in particular, because the “intercalating” is noticeably facilitated when preceded by the “lock and key”.

Figure 11shows the side views of the dimer before and after rejuvenation. The simulation allowed observing an increase in the distance between the asphaltene sheets when the rejuvenator is used. In particular, in zones A and B (on the right in the side views), the increase of the gap between the polyaromatic cores was higher than in zone C (on the left in the side views).

As mentioned in the previous chapters, one way to evaluate the aging and rejuvenation of bitumen is to monitor the progress of the four SARA fractions. With oxidative aging, aromatics and resins are converted into asphaltenes leading to an increase in the contacts between the micelles in the colloidal system, increasing bitumen stiffness. The application of rejuvenators should increase the maltene content of the aged binder and consequently restore the proportions of the system.

The high content of resins stabilizes the asphaltenes and the relative micelles of the colloidal system, but the addition of further asphaltenes is typically discouraged in favor of a higher content of aromatics. Despite the structure of bio-based asphaltenes being different from that of hydrocarbon-based asphaltenes [173], the lack of aromatics and abundance of asphaltenes do not tend to rebalance the SARA composition. Conversely, the vegetable oil (VB) additive shows a great content of resins and aromatics, with low percentages of saturated and asphaltenes. Lastly, the hydrocarbon-based additive (PB) is characterized by a large percentage of aromatics and a lower percentage of asphaltenes in comparison to the biological binder (BB).

The evolution of the percentages of the SARA fractions using these rejuvenators can also be analyzed by monitoring the Colloidal Index (CI). In particular:Adding the biological rejuvenator (BB) (10% by weight) causes a decrease in the CI from 0.61 of the aged binder to 0.51 (bringing it back to values similar to that of virgin bitumen). However, by increasing the percentage of the same additive up to 30%, the index increases to the unit value (exceeding even that of the aged binder without additives);Adding the vegetable-oil-based additive (VB), a progressive decrease in the index by increasing the percentage of rejuvenator occurs. With an additive content of 30%, a CI lower than that of virgin bitumen is reached.

From the comparison between the three rejuvenators, it is clear that the content of resins and aromatics brought by the additives plays a fundamental role in the process. Resins are more effective than aromatics because of their high polarity and ability to disperse the asphaltenes micelles in the maltenic phase and consequently stabilize the colloidal system.

A very important aspect to consider in the rejuvenating process is the amount of additive that has to be introduced into the aged bitumen to ensure the greatest benefit to the process. The results of CI help to find an optimal rejuvenator content for each type of additive. However, it has to be considered that for some products, as in the case of the biological additive, due to the different nature of the asphaltene molecules that compose it, the CI may increase with increasing rejuvenator dosage, but an improvement in physical and rheological behavior of the bitumen is still achieved.

The same study [172] also investigated the molecular size distribution of the rejuvenated bitumens through GPC. The results show that:the large molecules (LMS) increase from 83% for the non-aged binder to 87% for the aged binder, at the expense of the percentage of medium-sized molecules (MMS), which is reduced by 14% to 10%. The increase in LMS is a consequence of the increase in the number of asphaltenes in the system and their agglomeration.the addition of a rejuvenator tends to decrease the percentage of larger LMS molecules by increasing the presence of medium-sized molecules (MMS).

[174], who tested the effects of waste cooking oil as a rejuvenator for aged bitumen. The aged binder gets higher Mw and Mn values than the virgin one, denoting the formation of larger molecules in the binder during the aging process. Compared to the virgin bitumen, the higher poly-dispersion of the aged binder indicates that there is a greater distribution of molecular weights. Adding waste cooking oil with different dosages, there is no chemical reaction between the additive and the aged binder.

Figure 13shows the curves obtained by the GPC of the virgin, aged, and subsequently rejuvenated bitumen with different dosages of additive.

Compared to the virgin binder (red line), the aged one (black line) has a higher percentage of LMS compared to a lower small and medium-size molecules. Adding the waste cooking oil, the LMS tends to decrease; the typical LMS concentration of the virgin binder can be recovered by adding 20% additive. Increasing the percentage of waste cooking oil, MMS greatly increase and SMS decrease. Therefore, it can be concluded that by adding waste cooking oil, the distribution of the molecular size cannot be totally restored.

FTIR analysis can be used to investigate the evolution of the functional groups present in an aged binder when it is rejuvenated with additives. S=O, C=O, and C-C in more detail. In fact, the rejuvenated binder spectra are a union of those of the aged binder and the rejuvenator, without any new groups [155,175]. In terms of carbonyl index (IC=O) and sulphoxide index (IS=O), both increased with aging and were decreased by adding rejuvenators.

[92] focused on the analysis of the functional groups via FTIR when a biological or aromatic rejuvenator is added to a bituminous binder. Qualitative analyses were conducted by studying the spectra of the virgin bituminous binder, the biological additive, and the aromatic additive, in order to identify the representative functional groups. On the other hand, when the biological rejuvenator is added, the resulting spectrum shows two distinct peaks in correspondence of the functional groups C=O (1744 cm−1) and C-O (1162 cm−1). Therefore, from the quantitative point of view, these bands can be a good reference for the identification of a specific biological rejuvenator in the bituminous binder.

Recently, Menapace et al. [176] investigated the AFM images when adding tall oil to two different types of aged bitumen:TOAS: blend of virgin and aged bitumen extracted from Recycled Asphalt Shingles (RAS) from re-roofing or roof removal projects;MWAS: blend of virgin and aged bitumen extracted from RAS from the excess material obtained during the shingles’ production.

Regarding the TOAS-type bitumen, after long-term aging, there is a significant increase in roughness and a decrease in the phase contrast of the colloidal structure (Figure 16). The reduced size of the bee-shaped structures that have formed with aging indicates a relatively lower molecular mobility than for the virgin binder. At the same time, a slight decrease in roughness and phase contrast are noted, and the bee structures are no longer visible. It is possible to hypothesize that the species used for the construction of the bee domains require a certain molecule agglomeration to create bee-shaped structures.

In the MWAS bitumen, the long-term aging seems to form rippled structures that are slightly different from the typical bees (Figure 17). When the rejuvenator is used, the dispersed domains degenerate on the binder surface as if they were liquid, to form a single interconnected phase. After a second long-term aging process, numerous bee-shaped structures appear on the surface (c). The edges of these structures are not as smooth as in the original ones, but show a more irregular conformation.

In conclusion, the rejuvenator (tall oil), through the separation of the agglomerates formed by aging, allows the attenuation or even elimination of the bee-shaped structures, which, however, reappear when the binder ages again.

[177] tried to evaluate the evolution of the bee structures during the aging and rejuvenating steps. For this purpose, three different rejuvenators, coming from bio (R1, R2) and oil (R3) sources were used. They highlighted that the virgin binder displays clear bee-like structures and with increasing aging, the number of bees rises. The interesting aspect is that the addition of the three different rejuvenators causes a very different change in the surface morphology of the bitumen: size and quantities of the bee-like structure differ completely as a function of additive type and origin.

4. Aging of a Rejuvenated Bitumen (Re-Aging)

The growing use of RAP in the road sector is leading to new pavement mixtures composed not only of virgin materials, but also of old recycled bitumen and rejuvenators. Therefore, it is very important to understand the changes that occur in the properties of an HRMA when it is subjected to aging during its service life (which indeed is a “second aging” or “re-aging” for the RAP material). Hereafter, a literary review regarding the re-aging changes in the chemical and rheological properties of the recycled bitumen is provided.

Generally, the second aging in a rejuvenated binder is less harmful with respect to the aging of a virgin bitumen. Based on the studies carried out by Mazzoni et al. [178] and Bocci et al. , it is reasonable to expect that HMA including a high amount of RAP and a rejuvenator suffers fewer aging phenomena and can be less stiff than an alike mixture with no RAP.

From the chemical point of view, in a recent study, Ingrassia et al. [2] focused on evaluating the possibility of recycling binders that were already rejuvenated. Two virgin binders (one ordinary bitumen and a bio-binder) and two aged binders (one recovered from RAP and one “Bio-RAP” binder produced in the laboratory) were combined to reproduce the RAP hot recycling process. =Oindices and an additional parameter, named chemical aging index AIFTIR, and calculated with the following equation:AIFTIR(Ico+Iso)aged(Ico+Iso)unaged

Basically, the analysis of AIFTIRshows that the susceptibility to aging of recycled blends is significantly lower than that of the reference virgin binder. In fact, recycled bituminous blends (already containing a certain amount of oxidized binder) are less susceptible to further long-term aging.

[180] tried to analyze, from the chemical point of view, the effects of aging on a rejuvenated bituminous binder. Several types of bitumen were analyzed in this study. As expected, an increase in the content of asphaltenes was found, confirming the oxidative transformations that contribute to increasing the polarity of the bitumen components in terms of SARA fraction. Although precise correlations have not been found out, it can be stated that the chemical properties of an aged rejuvenated bitumen (second aging) are very close to that of an aged virgin binder (primary aging).

The second aging is of fundamental importance to understand the condition of the HRMA at the end of its second useful life. Continuous recycling of RAP would allow an increase in circularity related to the road construction field. For this reason, in the next future, more studies regarding this aspect need to be carried out.

This entry is adapted from the peer-reviewed paper 10.3390/su13126523