The objective of fully mechanizing olive harvesting has been pursued since the 1970s to cope with labor shortages and increasing production costs. Only in the last twenty years, after adopting super-intensive planting systems and developing appropriate straddle machines, a solution seems to have been found. The spread of super-intensive plantings, however, raises serious environmental and social concerns, mainly because of the small number of cultivars that are currently used (basically 2), compared to over 100 cultivars today cultivated on a large scale across the world. Olive growing, indeed, insists on over 11 million hectares. Despite its being located mostly in the Mediterranean countries, the numerous olive growing districts are characterized by deep differences in climate and soil and in the frequency and nature of environmental stress. To date, the olive has coped with biotic and abiotic stress thanks to the great cultivar diversity. Pending that new technologies supporting plant breeding will provide a wider number of cultivars suitable for super-intensive systems, in the short term, new growing models must be developed. New olive orchards will need to exploit cultivars currently present in various olive-growing areas and favor increasing productions that are environmentally, socially, and economically sustainable. As in fruit growing, we should focus on “pedestrian olive orchards”, based on trees with small canopies and whose top can be easily reached by people from the ground and by machines (from the side of the top) that can carry out, in a targeted way, pesticide treatments, pruning and harvesting.

- light interception

- Olea europaea

- pedestrian orchard

- super-intensive planting system

- training form

1. Planting Systems and Light Interception

Before describing the different types of plantings, it is useful to point out that the vegetative growth potential of a tree is significantly affected by planting density, which also determines, in addition to the amount of total light intercepted, the volume of soil available to each root system for water and nutrient uptake (unit of soil volume) [1].

Numerous studies have shown that the total amount of radiant energy intercepted by vegetation, useful for vegetative growth and fruiting, is greater in plantings consisting of many small trees rather than a few and large ones, thanks to the greater surface/volume ratio of the canopy [2]. In addition, many small trees are more efficient than few large ones. In the former, the incidence of photosynthetically active organs (leaves) and vegetative structures most directly involved in fruiting (two-year-old branchlets, one-year-old wood and current-year shoots) is higher [3]; in plantings with few large trees, on the other hand, woody tissues predominate (stem and branches of different age and order) which, although fundamental in establishing bearing, transport and reserve structures, are “carbohydrate consumers” rather than “assimilate producers” [4]. Trees of limited dimensions, as indicated above, also have a greater ratio between exposed leaf surface and canopy volume compared to large trees, so that, per unit of soil, the amount of light overall intercepted by the planting increases [5][6]. It should also be considered that light penetrates and is distributed more evenly within the canopy of small rather than large trees, where the gradient of light from the outermost and upper parts of the canopy to the innermost and lower ones is rather marked, with a consequent increase in the incidence of respiration compared to photosynthesis and therefore, with less availability of photoassimilates for production [5][6].

The amount of light intercepted, together with water and mineral elements absorbed by the roots, is, in fact, one of the main factors determining the productivity of a plant [7]. Numerous scientific investigations have been carried out to study the effect of increasing planting density on olive production [8][9][10][11][12]. Yet, the results are not unequivocal. Some cases have been observed in which production increases linearly and continuously with increasing density [13]. On the other hand, there are many cases in which producing high-density plantings is limited by between and within-tree shading and by competition for water and nutrients after 12 years from planting [14]. In addition to a quantitative effect, light also has a qualitative impact on production [15][16][17][18] and the sensitivity of plants to plant diseases, as it affects the balance between vegetative and reproductive activities [19]. In the current year, for shoots receiving less than 30% of the incident radiation at the Mediterranean latitudes, the lignification and flower induction processes are difficult to complete, despite their being carried out during the summer under higher light intensities and longer days [20]. Under low light conditions, oil accumulation and synthesis of fatty acids and other secondary metabolites (polyphenols, vitamins, sterols, volatile compounds) do not proceed regularly [21][22][23][24], with negative outcomes on the product quantity and quality. Regardless of the planting system and the training form, to keep a plant efficient from a vegetative and productive point of view, some fundamental ecophysiological aspects, such as the amount of light reaching most of the canopy necessary to ensure vegetative growth and fruiting, must not be overlooked. Therefore, it is necessary to avoid that portions of the foliage constantly remain in the shade as it often occurs in high-density and super-intensive plantings [22][25][26]. Pruning can help ensure satisfactory lighting in the canopy, guaranteeing sufficient exposure even to the innermost leaves through an adequate number of thinning cuts and a balanced distribution in the vegetation space.

Unlike some fruit tree species, in the olive germplasm, there are very few low-vigor cultivars with a compact growth habit that can help reduce the shading between contiguous trees [27][28][29][30]; in addition, although some physiological mechanisms which slow down vegetative growth through the root system are known, rootstocks that can consistently contain the vigor of the plant have not been selected yet [31]. To modulate the vegetative growth of the tree, trying to reduce it to the essential (renewal of the vegetation to ensure regular and consistent fruiting), one must, therefore, rely above all on cultivation management, particularly on pruning, soil management, fertilization, and irrigation. Most of the information reported for planting densities greater than 400 trees/ha refer to plantings established with trees of the Italian cultivars Frantoio and Leccino, trained to “monocone”, a cone-shaped central-leader tree [9][32][33] and spaced at 6 × 3 m (555 trees/ha); and plantings established with trees from the Spanish cultivars Arbequina and h and the Greek cultivar Koroneiki, trained to a central leader, but spaced at considerably shorter distances (4 × 1.6 m or 1562 plants/ha) to form hedgerows [34]. This combination of the cultivar-planting system is the only one that, up to now, has allowed to significantly increase planting density and, therefore, the total amount of light intercepted by the olive orchard system, especially in the first 5–6 years from planting [18][35].

By changing even a single term of the cultivar-planting system combination, the physiological response of the olive orchard to light interception also changes. Hence, it is necessary to re-adapt the management practices, especially pruning, irrigation, fertilization and pest control [36][37]. The technical foundations of precision agriculture must increasingly refer to these assumptions.

2. Planting Systems

A complete summary of the different types of plantings has been reported by Rallo et al. [38] and, regarding hedgerow systems, by [39]. Therefore, in this review, we give only a brief description of the three most common systems: traditional, intensive, and super-intensive. We highlight their main characteristics and the relative strengths and weaknesses, fundamental aspects for establishing the conditions to propose new planting systems.

2.1. Traditional Plantings

In general, traditional olive groves, which have also increased the value of dry and marginal lands in the recent past, are characterized by low planting density and by three-dimensional (3D) training forms, such as the globe and the vase, with the numerous variants adopted locally [40]. In traditional plantings, generally, the canopies of adjacent trees never touch each other, so the fruiting is well distributed over the entire upper and peripheral part of the canopy [41]. The number of trees/ha rarely exceeds 300 units, with tree distances of 5–7 × 6–8 m, mostly arranged in squares. The highest planting densities are usually adopted in the northernmost areas of cultivation in environments with a climate limiting vegetative growth [42]. Indeed, the olive trees present in these environments, due to the occurrence of suboptimal temperatures for vegetative growth during most of the year, grow slower than those cultivated in areas where the annual temperature trend, especially during the autumn and winter months, better matches the climatic needs of the species. On the other hand, in warmer Mediterranean environments with modest rainfall and long periods of summer-autumn drought, the temperatures are favorable for the growth of the olive tree, and it is necessary to keep the planting density low to reduce water stress problems [43]. Such phenomena are favored when the leaf area index (total leaf area per unit of soil surface) of each tree/olive grove is rather high [44]. In arid environments, traditional plantings are, in fact, characterized by large trees, with canopies that very frequently exceed 5 m in height and diameter and over 130 m3 in volume. The overall volume of the canopies easily reaches 15,000–30,000 m3/ha depending on the number of trees/ha, which varies between 100 and 200, and on their height. The trees are also characterized by the extensive development of the root systems and by the high capacity of the trunk and large branches to accumulate water and nutrient reserves. These characteristics can allow the tree to overcome environmental stresses, especially those caused by high light intensity, high temperatures (the large canopy protects the wood structure from sunburn) and long periods of drought, climatic factors typical of the driest environments in the Mediterranean area [14]. Indeed, often the plants, although in dry conditions, do not show any symptoms of water stress until the end of July to the beginning of August [45]. The different portions of the canopy, usually always well lit, in the ON years (high bearing years) yield abundantly, but the low planting density significantly reduces productivity per unit area. As for table olive cultivation, if the crop load is wisely regulated, the quality of the drupes is excellent due to their large size, the excellent pulp/pit ratio and the high carbohydrate content, a useful food source for microorganisms that, properly selected, ensure that fermentation processes proceed correctly during processing [46].

From the production point of view, the main disadvantages of traditional plantings lie in the marked alternate bearing, favored by the age of the trees, often affected by wood decay, which depresses the phloem shoot-to-root flow and, therefore, the vigor necessary to stimulate the annual renewal of vegetation, even in the high-yielding years [40]. This phenomenon is often accentuated by the unavailability of water for irrigation and by long intervals between pruning events, which is usually practiced, for economic reasons every 4–5 years [47]. Furthermore, mechanizing harvest operations in these situations is not always easy, which represents the main reason for the economic inefficiency of these systems [48]. Indeed, the size of the plants often makes using trunk shakers and/or rod vibrating combs difficult [49][50]. In addition, there are further limitations related to the location of the plantings themselves (areas difficult to reach) and the layout of the land (steep slopes), which often make harvesting the product directly from the ground (mechanical picking) or from nets the only feasible practices [51].

Due to the large size of the trees, fruit is generally harvested by laying nets on the ground, rarely with the aid of machines, on which the drupes drop naturally [52]. Where conditions make it possible, facilitators, vibrating combs mounted on mechanical arms or limb shakers, induce the detachment of the fruit. In such cases, harvest operations require using numerous people (even eight to twelve). In some farms located on flat and irrigated land, to reduce using workers, the soil is irrigated and leveled with heavy rollers, then trees are shaken to drop the olives directly on the ground; fruit is then aligned with small windrowers and finally collected with pickers directly loading the olives in boxes. Afterward, the olives, in the best of scenarios, are cleaned from leaves and soil with sorting machines operating in the field before being loaded into bins and transferred to the mill [49].

Pruning is definitely dangerous, especially when the olive grove is located on steep, rocky or terraced grounds, due to the need to use ladders to reach the top of tall trees. On flat or slightly sloping ground, baskets mounted on lifting arms moved by the pruner himself can be used instead, with rather high costs, however, and modest efficiency of the harvesting work. Pruning generally involves using chainsaws varying in power and /dimensions, making the operation tiring, dangerous, and, on the whole, rather expensive and therefore, often unsustainable; for this reason, pruning, over the years, tends to be done at long intervals (every 4–5 years).

Pesticide treatments involve using large volumes of water, which, to reach the top of the trees, are sprayed with long-range spears; this operation often determines the drift and dripping of pesticides on the ground and, consequently, a high polluting impact on the environment. For the aforementioned reasons, traditional plantings are being abandoned, and, most likely, the possibility to keep them will be increasingly linked to the multifunctional role of olive growing, typical of agroforestry systems, rather than to specialized olive production. Indeed, this type of olive growing provides ecosystem services (i.e., carbon sequestration, rural landscape, recreation, cultural heritage, biodiversity and soil conservation), which, in some contexts, may even become prevalent over the productive task [53][54][55][56].

2.2. Intensive Plantings

Within these typologies fall olive orchards characterized by planting densities of 300–1000 trees/ha, with trees arranged in squares or rectangles, depending on the planting density, and to the training form adopted, usually three–dimensional o 3D [57]. Due to the wide range of planting densities that can be adopted, three different categories of intensive plantings can be distinguished: low, medium, and high planting density.

In the low planting densities, up to a maximum of about 400 plants/ha, the trees are generally arranged in squares at a distance of 5–7 × 5–7 m and trained to 3-D forms, especially the globe (in areas with high light intensity and low atmospheric humidity) and the vase (more suitable in the less sunny and humid areas), the latter with numerous variants developed in the different olive-growing districts [40]. The harvest is carried out with machines that are either self-propelled or coupled to the tractor, which uses a hook and shaking head applied to the trunk [58]. For the full efficiency of the shakers available today, the main branch scaffold of the trees must be around one meter or more from the ground, and the trunk, at the gripping point of the shaking head, must have a diameter between 20 and 80 cm [59]. In traditional olive groves, when the developing canopy exceeds 50–60 m3, the shaking arm must be applied to the main branches instead of the trunk, but this makes harvesting more complex and the mechanization of fruit capture more complicated, increases the risk of damage to woody structures and considerably increases the time required. The power of the shakers is an important element in determining their work efficiency. For this purpose, machines with a power greater than 70 kW are preferable. A shaking head with a gripper with two clamping bearings can be used on trunks of variable sizes, although vibration transmission is limited to the two points of contact. On the other hand, a head with three bearings better transmits the vibration to the tree, reducing the risk of bark damage, but the size of the trunk (20–50 cm) cannot vary much compared to the first type. Furthermore, harvesting early to improve the quality of the final product requires stronger vibrations (1560 to 1800 rpm of the eccentric masses are required) and larger masses, capable of generating accelerations greater than 200 m/s2. As for the duration of the vibrations, short and repeated operations with a low hardness fixing material are preferable to a single longer-lasting vibrational motion. For high harvesting efficiency, the canopy volume of each tree should be less than 50–60 m3. To allow pruning from the ground using rod tools without ladders, the tree’s overall height should not exceed approximately 4.5 m; pruners and hacksaws mounted on telescopic rods allow reaching the top of such canopies easily. In order to avoid frequent states of water stress during summer in drier environments, when the olive orchards are on rather loose soils, the total volume of the canopy must be contained within 10,000 m3/ha (200 plants/ha with canopies of 50 m3). In irrigated olive orchards, rather than letting the trees widely exceed the aforementioned dimensions, it is preferable to increase the planting density up to about 400 plants/ha, especially if the cultivars used are characterized by modest vigor and early and abundant fruiting. In irrigated olive orchards, the total canopy volume/ha can even rise to 16,000 m3/ha (400 plants/ha with canopies of 40 m3). The “low-density” intensive plantings have attracted increasing attention in modern olive growing, thanks to the possibility of harvesting with self-propelled machines equipped with a trunk shaker head and an inverted umbrella. The inverted umbrella consists of a series of elements arranged to form an inverted cone, which opens to cover a circular area of variable size and intercepts the fruits before they reach the ground. These machines are generally equipped with a fruit storage bin (300–400 kg capacity) right below the umbrella itself to make harvesting more continuous without unloading the olives that have fallen into the umbrella directly in boxes. The possibility of reducing the number of people assigned to each harvest site to no more than two makes this system very interesting.

For the medium-density plantings, two training forms can be adopted: the vase and the single cone or monocone [9][32]. As for the vase, suitable for up to 500 plants/ha and with low-vigor cultivars, the variant called “polyconic vase”, which is overall smaller in size than the classic vase thanks to the more careful geometry applied in managing the 3–4 main branches, is preferred particularly in central Italy [33]. The distribution of the secondary and tertiary branches and the fruiting shoots on the main branch, with an increasing length from the top towards the trunk, gives the main branches a conical shape that favors light interception and penetration even in the lower and inner part of the canopy [60]. Furthermore, the particular configuration and distribution of the vegetation on the canopy favors the transmission of vibrations applied to the trunk by the shaker head, with positive effects on the harvesting efficiency. For higher densities (up to 800 plants/ha), it is preferable to choose the monocone, a training form that significantly reduces the radial expansion of the tree and, therefore, decreases tree spacings, especially along the rows [9]. The monocone is distinguished from the vase by the presence of a central axis, generally contained within about 5 m in height, bearing primary branches of decreasing length starting at about 1 m from the ground and up for a couple of meters, upon which the fruiting shoots are positioned. In the last meter from the top, fruiting branches are born directly on the main axis. The monocone is suitable for planting densities of 400–800 trees/ha, with distances of 5–6 m between rows and 2–3 m on the row; the in-row distances vary considerably concerning the availability of water, the vigor of the cultivar and the length of the growing season. The monocone was designed for planting systems organized in hedgerows (2D) by arranging the trees according to rectangle spacings. Compared to the typical discontinuous rows, for example, when the vase shape is adopted, the plantings with monocone-trained trees and the increase in unit production also favor the mechanization of the harvest with self-propelled trunk shakers of the type “side by side”. These are made of two units: the self-propelled one, equipped with a motor, with an arm holding the shaking head and a conveyor panel; the receiving one, either self-propelled or towed by a tractor, equipped with an automatic collection trolley [61][62]. This second unit also has conveyor panels, which, depending on the tree size, can be more or less extended, a conveyor belt and an elevator for fruits, an aspirator–defoliator and a harvest box holder. Pruning can also be partially mechanized through topping and, less frequently, hedging operations carried out with disk saws inserted on mobile bars and operated by a tractor. The hardened steel discs rotate at a speed of 2000–2500 rpm, while the bar, with a single hydraulic arm, can be raised beyond 4 m in height and tilted to all intermediate cutting positions between vertical and horizontal. Yet, these are “non-selective” pruning operations that often require manual finishing made by expert operators to balance the structure of the canopy [63].

Unfortunately, monocone never became popular due to the considerable vigor of a large number of olive cultivars that, in the original idea, was to be contained by using supposedly dwarfing rootstocks, which, unfortunately, have not been found. Indeed, in monocone-trained olive trees, the potential vegetative growth can be expressed in the central axis only, instead of the 3–5 primary branches of the polyconic vase. With age, due to the reduced amount of light reaching the lower branches, monocone trees tend to shed their vegetation and grow radially in search of light, developing strong primary branches with a high incidence of wood compared to the fruiting vegetation. A great amount of vegetation is also present in the apical part of the canopy because of greater light availability, which further affects the illumination and vigor of the basal portions. In a few years, the trees tend to produce only on the upper branches, more exposed to light and more prone to vegetative renewal. This tendency, which can be hindered only by meticulous pruning carried out at regular intervals, favors the onset of reciprocal shading between and within trees, leading to a rapid and drastic reduction of the tree production efficiency. Fruit production moves to the upper part of the canopy, the most distant from the ground and, therefore, difficult to manage. Moreover, the monocone makes using reverse umbrella harvesters difficult, forcing using shakers with lateral interceptor frames [64][65]. In summary, when choosing the type of planting to be adopted, it is now possible to opt for two different categories depending on the availability of water: plantings under rain-fed conditions with a density of 300–400 trees/ha and trained to classic vase or globe; plantings supplied with low irrigation volumes, sometimes with just “rescue” irrigation events, with a density of 400–800 trees/ha and trained to a polyconic vase or monocone.

2.3. Super-Intensive Plantings

This is the last generation of plantings characterized by a very high planting density (about 1600 trees/ha). However, new cultivars have recently been selected, including ‘Oliana’, ‘Sikitita’ and ‘Lecciana’, which compared to those traditionally used, the Spanish ‘Arbequina’ and ‘Arbosana’ and the Greek ‘Koroneiki’, allow to further intensify planting densities up to 2500 trees/ha (3.5–4 × 1.2–1.6 m) [66]. One of the main advantages of super-intensive plantings lies in the possibility of harvesting olives with fully mechanized continuous systems. For this operation, the same straddle machines adopted for the grape harvest, suitably modified, are used [67][68]. The substantial differences between these machines and those used in viticulture consist in (1) the greater number of shaking elements to better adapt them to the greater height of the productive zone of the olive canopies; (2) the possible addition of a conveyor in the front of the harvesting tunnel to facilitate entry of the row into the harvesting chamber; (3) the possibility of adjusting the width of the tunnel itself, a necessary operation as there is increased the width of the “canopy wall” over time [39]. Other major advantages of super-intensive plantings lie in (1) the early and abundant fruiting that is achieved starting at 3–4 years from planting; (2) the speed of harvesting (2–3 h/ha) and pruning (topping, hedging, and trimming); (3) in the stability of production (on average 1.5 tons of oil/ha/ year). The planting system is nowadays supported by standard cultivation protocols that facilitate its management [69].

In the last ten years, extensive research has been conducted to optimize, through more precise crop management, the efficiency of this planting system. In particular, the importance of the correct row orientation and the relationship between tree height and the distance between rows and thickness of the vegetation has been stressed out to increase the overall orchard light interception and its distribution within the canopy. Few and targeted mechanical pruning operations (topping, hedging), in fact, allow reaching quantities of intercepted light and photosynthetic efficiency that are greater compared to other planting systems [25][70][71]. Investigations on the dynamics of transpiration and the determination of tree water status in hedgerow systems have allowed the development of targeted deficit irrigation leading to a significant improvement of water use efficiency [22][72][73], which is difficult to achieve in other systems. Studies on root system distribution, nutrient absorption and balance have made it possible to adapt the inputs to the actual tree nutritional needs, reducing the environmental impact of fertilization. The search for appropriate soil management models also has allowed reducing erosion and surface runoff even in situations of sloping land [74]. In SHD systems, the efficient use of machines also allows for continuous operations, including pruning, pest control treatments and harvesting, which is nearly impossible in plantings established with trees trained to 3D canopy shapes (discontinuous systems).

The greater efficiency of SHD plantings compared to other systems, however, shows all its weaknesses in countries where olive growing is mostly practiced in the hills, on sloping land, in small farms (on average two hectares) and where water availability is modest and discontinuous and relies on small reserves accumulated during the winter. These agronomic contexts prevail in many olive-growing areas of the Mediterranean basin, including some southern European countries (Italy, Greece), where over time, cultivars resistant to abiotic and biotic stress have been selected [75]. Other trials have also shown the high production potential and sustainability of hedgerow systems, even with cultivars different from those selected for SHD plantings [76]. Therefore, to keep the advantages of hedgerow systems and transfer them to the agronomic contexts described above, the new concept of “pedestrian olive orchards” is under evaluation, and some information will be reported in the next section.

Other major limitations of SHD plantings lie in the fact that currently, they can only be established in irrigated areas (3000–5000 m3/ha/year) and with a rather narrow range of genotypes that practically only rely on 2–3 cultivars [77][78][79]. However, in recent years, the varietal pool for super-intensive t with new genotypes [80], including some Italian accessions [45][69]. The cultivars are characterized by slow vegetative growth, modest vigor, early fruiting, low degree of alternate bearing, high fertility (high incidence of nodes bearing inflorescences), self-fertility (allowing for establishing extended mono-varietal plantings), cluster fruiting (3–5 fruits/panicle), and good peacock spot and bacterial gall resistance. Cultivars that bear fruit on the distal part of one-year-old or current-year shoots, definitely thinner and only partially lignified compared to the standard-bearing shoots, are well suited for continuous mechanical harvest [69]. These are cultivars with more flexible branches than standard branches, originating from the apical bud or from axillary buds of one-year-old shoots [81]. Thanks to the numerous current-year anticipated shoots (feathers), characterized by low cambium activity and radial growth, even the 2–3 year-old branches are quite flexible, causing no damage to the beaters of the straddle machine [81][69] and suffering themselves no serious injuries or breakages during the beating actions. Furthermore, the relatively open crotch angle of branches and fruit-bearing shoots favors the penetration of light into the innermost areas of the canopy, with beneficial effects on the constant fruiting and production efficiency of the tree as well as on the air circulation that enhances the already low sensitivity to fungal diseases. In super-intensive plantings, the production capacity of plants is determined by the possibility of keeping the canopy in the space reserved for each tree, a condition that is achieved through annual pruning, based on both thinning cuts (removal of entire branchlets) and on shortening cuts (“return cuts”) of the fruiting branches. Branches that have exceeded a diameter at the base of 3 cm must be eliminated to not compromise the harvesting efficiency of the straddle machine [69][82]. In super-intensive plantings, the branches of contiguous trees, due to the short distance between the trees in the row, easily overlap, forming unproductive areas of the crown (due to lack of light), which, for obvious reasons, must be kept to a minimum [21][83]. Tree growth and production data for “only” 25 years are currently available for this planting system. The most complete published data set shows a continuous increase in oil production per hectare up to 14 years after planting [13]. Currently, it is impossible to give final indications on the relative economic life of super-intensive systems. However, there is the real possibility that their duration can reach 30 years, with constant annual production levels close to those recorded to date (Luis Rallo, personal communication).

In optimal cropping conditions (fertile soils with good availability of water for irrigation, adequate crop management), economically sustainable yields (3–4 t/ha of fruit) occur already in the third year from planting; full production, which on average ranges between 8 and 10 t/ha, can be obtained at the 5th year from planting. In the following years, with targeted pruning carried out annually and with adequate water and fertilizer inputs (fertigation), productions of about 14 t/ha have been reported, although often followed by a significant drop in fruiting in the subsequent year, mainly due to light deficiency problems, especially in the lower and inner part of the canopy [84][85][86]. In general, to maintain good production levels, it is essential to avoid excessive bundling of vegetation, an issue that becomes frequent when the total canopy volume of the planting exceeds 10,000–12,000 m3/ha.

Maintaining a balance between the thickness of the canopy and the space between the two adjacent rows (i.e., space never occupied by vegetation) is also extremely important. When this ratio is equal to or close to 1, the optimal level of light penetration and distribution inside the trees is achieved [36]; if the ratio is greater than 1, there is shading between trees and fruiting moves mostly in the upper part of the canopy [13][85][87]. When the ratio is smaller than 1, due to the “excessive” distance between rows (lower planting density), there is a reduction in leaf area per hectare and photosynthesis, which translates into less fruiting per hectare.

2.4. High-Density Intensive Plantings: The “Pedestrian Olive Orchards”

Planting densities in the range of 800–1200 trees/ha have so far not received much attention even if the trials carried out anticipate good development possibilities, both for the high yields that can be achieved and for the wide variety of cultivars that can be used. Another important aspect is flexibility in using machines for harvesting and pruning, although the latter must be integrated with manual finishing operations.

The first modern and high-density intensive systems for olive growing were developed in the late 1960s, with the search for new training forms to reduce the height of trees. At that time, high-density plantings using trees trained to open bush, hedge and palmette were already evaluated to develop new olive growing systems. Among the aforementioned training forms, the remarkable production potential of the palmette emerged [88], the only form that allowed to develop of wall-shaped (two-dimensional) planting systems, efficient from an ecophysiological (high surface/volume ratio; high current and two-year shoot/tree wood) and agronomic (high tree production efficiency) standpoint. Unfortunately, the widespread use of sharecropping and direct farming, which until the 1970s guaranteed great availability of cheap labor, as well as the absence in the olive production business, of an entrepreneur figure willing to invest for maximizing profits and innovating, did not bring out the problem that would be revealed later in all its seriousness. Since the 1980s, following the massive exodus from the countryside to the industrialized areas of Europe, the problem of mechanizing olive harvest has taken on high priority. After this, production of the trunk and/or branch shaking harvesters increased, upon which olive harvesting and the whole intensive olive growing systems are still based. The most extraordinary innovation in this direction, however, arrived at the end of the last century and was the super-intensive planting system, although this is a model very different from those that allow obtaining “tailor-made” extra-virgin olive oils. To this purpose, within the intensive planting category, high-density olive orchards help preserve the peculiarity of products obtained from specific cultivars.

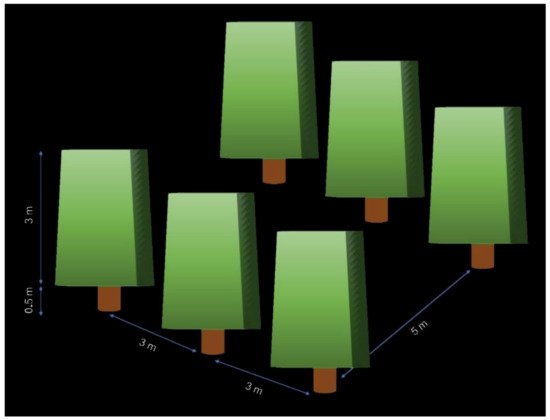

Trees are arranged according to rectangular layouts, at spacings of 4–5 × 2–3 m (Figure 1), trained to a shape resembling a “free palmette” (2D tree shape; Figure 2a) to form continuous walls (Figure 2b), 2–3 m in height depending on the growth habit, the vigor of the cultivar and the type of machinery to be used for harvesting: straddle for relatively thin canopies (no more 1 m wide) or shaker equipped with side-by-side interceptor frame for thicker canopies (no larger than 2 m). As for pruning, bars with circular disk saws can be used, also equipped with conveyors of air jets to fold the current-year vegetation (fruiting the following year) along the row and thus avoid their removal. The relatively modest soil surface area available for each tree (8–15 m2/tree), especially in the early years, is still sufficient to allow the tree, even a medium-vigor one, to express its full growth potential and quickly fill the space available on the row (up to 3 m) and in height, up to 3 m to allow the operator to reach the top of the tree from the ground while pruning with the aid of telescopic rod tools.

Figure 1. Typical layout of a high-density pedestrian olive orchard with trees trained to “free palmette” forming continuous walls.

Figure 2. Example of high-density “pedestrian olive orchard” in southern Sicily: (a) 'Calatina' olive tree trained to “free palmette”; (b) continuous walls of “Calatina” trees trained to “free palmette”.

After more than 15 years of trials with a wide array of Sicilian cultivars with different vigor, growth and fruiting habits, the results obtained with this new type of planting, which we call “pedestrian olive orchard” similar to fruit crops, are definitely interesting; hence, the cultivation model is to be considered mature to be further investigated. From recent trials with a selected number of major and minor Sicilian genotypes, low vigor cultivars that are early fruiting, highly productive, with flexible, weeping branches have resulted in the most suitable for high-density pedestrian olive orchards. For example, minor cultivars like Calatina planted at 5 × 2 m have reported more than twice the yield efficiency (in kg of olives per m3 of canopy) and yield per ha compared to major cultivars like Nocellara del Belice (Caruso, unpublished data) over the first six years from planting. It is, therefore, generally believed that in the various olive-growing areas of the world, the model should be developed with low vigor, native cultivars to be more easily transferred to growers with specific indications on the cultivation protocols to be followed in particular pruning, fertilizing, and irrigation. In short, it is a matter of developing, starting from the aforementioned reference model, plantings suitable for specific regional/district areas and this unlike super-intensive plantings, which are based on cultivars with global agronomic potential.

This entry is adapted from the peer-reviewed paper 10.3390/agriculture11060494

References

- Baldini, E. Arboricoltura Generale; Clueb: Bologna, Italy, 1979; pp. 11–18.

- Jackson, J.E.; Palmer, J.W. A computer model study of light interception by orchards in relation to mechanised harvesting and management. Sci. Hortic. 1980, 13, 1–7.

- Gucci, R.; Cantini, C. Potatura e Forme di Allevamento Dell’olivo; Edagricole: Milano, Italy, 2001; pp. 107–135.

- Mariscal, M.J.; Orgaz, F.; Villalobos, F.J. Radiation-use efficiency and dry matter partitioning of a young olive (Olea europaea) orchard. Tree Physiol. 2000, 20, 65–72.

- Jackson, J.E.; Palmer, J.W. Light distribution in discontinuous canopies: Calculation of leaf areas and canopy volumes above defined ‘irradiance contours’ for use in productivity modelling. Ann. Bot. 1981, 47, 561–565.

- Jackson, J.E.; Sharples, R.O. The influence of shade and within-tree position on apple fruit size, colour and storage quality. J. Hortic. Sci. 1971, 46, 277–287.

- Stutte, G.W.; Martin, G.C. Effects of light intensity and carbohydrate reserves on flowering in olive. J. Amer Soc. Hort. Sci. 1986, 111, 27–31.

- Pastor, M.; Humanes, J. Plantation density experiments of non-irrigated olive groves in Andalusia. Acta Hortic. 1990, 286, 287–290.

- Fontanazza, G. Olivicoltura Intensiva Meccanizzata; Edagricole: Milano, Italy, 2000.

- Tous, J.; Romer, A.; Plana, J.; Baiges, F. Planting density trial with ‘Arbequina’olive cultivar in Catalonia (Spain). Acta Hortic. 1999, 474, 177–180.

- León, L.; De la Rosa, R.; Guerrero, N.; Rallo, L.; Barranco, D.; Tous, J.; Romero, A.; Hermoso, J.F. Ensayos de variedades de olivo en plantación de alta densidad. Fruticultura profesional. Espec. Olivic. 2006, IV-160, 21–26.

- Diez, C.M.; Moral, J.; Cabello, D.; Morello, P.; Rallo, L.; Barranco, D. Cultivar and tree density as key factors in the long-term performance of super high-density olive orchards. Front. Plant Sci. 2017, 8, 1790.

- Diez, C.M.; Trujillo, I.; Martinez-Urdiroz, N.; Barranco, D.; Rallo, L.; Marfil, P.; Gaut, B.S. Olive domestication and diversification in the Mediterranean Basin. New Phytol. 2015, 206, 436–447.

- Pastor, M.; Humanes, J.; Vega, V.; Castro, A. Diseňo y Manejo de Plantaciones de Olivar. Monofrafiias; Consejeria de Agricultura y Pesca-Junta de Adalucia: Sevilla, Spain, 1998; pp. 57–77.

- Patumi, M.; d’Andria, R.; Fontanazza, G.; Morelli, G.; Giorio, P.; Sorrentino, G. Yield and oil quality of intensively trained trees of three cultivars of olive (Olea europaea L.) under different irrigation regimes. J. Hortic. Sci. Biotechnol. 1999, 74, 729–737.

- Servili, M.; Sordini, B.; Esposto, S.; Urbani, S.; Veneziani, G.; Di Maio, I.; Selvaggini, R.; Taticchi, A. Biological Activities of Phenolic Compounds of Extra Virgin Olive Oil. Antioxidants 2014, 3, 1–23.

- Reale, L.; Nasini, L.; Cerri, M.; Regni, L.; Ferranti, F.; Proietti, P. The Influence of Light on Olive (Olea europaea L.) Fruit Development Is Cultivar Dependent. Front Plant Sci. 2019, 10, 385.

- Proietti, P.; Nasini, L.; Ilarioni, L.; Balduccini, A.M. Photosynthesis and vegetative-productive activities of the olive cultivars ‘Arbequina’, ‘Leccino’ and ‘Maurino’ in a very high density olive grove in central Italy. Acta Hortic. 2011, 924, 111–116.

- Viruega, J.R.; Roca, L.F.; Moral, J.; Trapero, A. Factors affecting infection and disease development on olive leaves inoculated with Fusicladium oleagineum. Plant Dis. 2011, 95, 1139–1146.

- Tombesi, A.; Cartechini, A. L’effetto dell’ombreggiamento della chioma sulla differenziazione delle gemme a fiore dell’olivo. Riv. Ortoflorofruttic. Ital. 1986, 70, 277–285.

- Gómez-del-Campo, M.; García, J.M. Canopy fruit location can affect olive oil quality in ‘Arbequina’ hedgerow orchards. J. Am. Oil Chem. Soc. 2012, 89, 123–133.

- Proietti, P.; Nasini, L.; Ilarioni, L. Photosynthetic behavior of Spanish Arbequina and Italian Maurino olive (Olea europaea L.) cultivars under super-intensive grove conditions. Photosynthetica 2012, 50, 239–246.

- Marra, F.P.; Camposeo, S.; Vivaldi, G.A.; Proietti, P.; Nasini, L.; Caruso, T.; Campisi, G. Growth and yields of ‘Arbequina ‘high-density planting systems in three different olive growing areas in Italy. Acta Hortic. 2014, 1057, 341–348.

- Ripa, V.; De Rose, F.; Caravita, M.A.; Parise, M.R.; Perri, E.; Rosati, A.; Giordani, E. Qualitative evaluation of olive oils from new olive selections and effects of genotype and environment on oil quality. Adv. Hortic. Sci. 2008, 22, 95–103.

- Connor, D.J.; Gómez-del-Campo, M. Simulation of oil productivity and quality of N–S oriented olive hedgerow orchards in response to structure and interception of radiation. Sci. Hortic. 2013, 150, 92–99.

- Cherbiy-Hoffmann, S.U.; Hall, A.J.; Rousseaux, M.C. Fruit, yield, and vegetative growth responses to photosynthetically active radiation during oil synthesis in olive trees. Sci. Hortic. 2013, 150, 110–116.

- Famiani, F.; Farinelli, D.; Gardi, T.; Rosati, A. The Cost of Flowering in Olive (Olea Europaea L.). Sci. Hortic. 2019, 252, 268–273.

- Rosati, A.; Paoletti, A.; Al Hariri, R.; Famiani, F. Fruit production and branching density affect shoot and whole-tree wood to leaf biomass ratio in olive. Tree Physiol. 2018, 38, 1278–1285.

- Rosati, A.; Paoletti, A.; Al Hariri, R.; Morelli, A.; Famiani, F. Resource investments in reproductive growth proportionately limit investments in whole-tree vegetative growth in young olive trees with varying crop loads. Tree Physiol. 2018, 38, 1267–1277.

- Bartolini, G.; Prevost, G.; Messeri, C.; Carignani, G. Olive Germplasm: Cultivars and Word-Wide Collections; FAO: Rome, Italy, 1998.

- Nardini, A.; Gasco, A.; Raimondo, F.; Gortan, E.; Lo Gullo, M.A.; Caruso, T.; Salleo, S. Is Rootstock-Induced Dwarfing in Olive an Effect of Reduced Plant Hydraulic Efficiency? Tree Physiol. 2006, 26, 1137–1144.

- Palliotti, A.; Famiani, F.; Proietti, P.; Boco, M.; Antognozzi, E.; Preziosi, P.; Ferradini, N.; Guelfi, P. Effects training system on tree growth, yield and oil characteristics in different olive cultivars. Acta Hortic. 1999, 474, 189–192.

- Pannelli, G.; Alfei, B. L’olivo a Vaso Policonico. In Terroir e Sostenibilità; Edagricole: Milano, Italy, 2019.

- Tous, J.; Romero, A.; Plana, J. “IRTA-i-18®”, a clone of the “Arbequina” olive variety. Olivae 1999, 77, 50–52.

- Palmer, J.W. The effect of row orientation, tree height, Time of year and latitude on light interception and distribution in model apple hedgerow canopies. J. Hortic. Sci. 1989, 64, 137–145.

- Dervis, S.; Mercado-Blanco, J.; Erten, L.; Valverde-Corredor, A.; Pérez-Artés, E. Verticillium wilt of olive in Turkey: A survey on disease importance, pathogen diversity and susceptibility of relevant olive cultivars. Eur. J. Plant Pathol. 2010, 127, 287–301.

- Lavee, S.; Avidan, B.; Meni, Y. “Askal”, una nueva variedad de almazara sobresaliente por su comportamiento agronómico para olivares intensivos y superintensivos. Olivae 2003, 97, 53–59.

- Rallo, L.; Barranco, D.; Castro-García, S.; Connor, D.J.; Gómez-del-Campo, M.; Rallo, P. High-density olive plantations. Hortic. Rev. 2013, 41, 303–384.

- Connor, D.J. Towards optimal designs for hedgerow olive orchards. Aust. J. Agric. Res. 2006, 57, 1067–1072.

- Godini, A.; Bellomo, F. Olivicoltura superintensiva in Puglia per la raccolta meccanica con vendemmiatrice. In Proceedings of the International Congress of Oliveculture, Spoleto, Italy, 21–23 April 2002; pp. 230–234.

- Proietti, P.; Tombesi, A.; Boco, M. Olive leaf photosynthesis in relation to leaf age and fruiting during the growing season. Italus Hortus 1995, 3, 17–21.

- Farinelli, D.; Tombesi, S. Performance and oil quality of ‘Arbequina’ and four Italian olive cultivars under super high density hedgerow planting system cultivated in central Italy. Sci. Hortic. 2015, 192, 97–107.

- Pastor, M.; Vega, V.; Hidalgo, J.C. Ensayos en plantaciones de olivar superintensivas e intensivas. Vida Rural 2005, 218, 30–34.

- Fernández, J.E.; Rodriguez-Dominguez, C.M.; Perez-Martin, A.; Zimmermann, U.; Rüger, S.; Martín-Palomo, M.J.; Diaz-Espejo, A. Online-monitoring of tree water stress in a hedgerow olive orchard using the leaf patch clamp pressure probe. Agric. Water Manag. 2011, 100, 25–35.

- Marino, G.; Macaluso, L.; Marra, F.P.; Ferguson, L.; Marchese, A.; Campisi, G.; Caruso, T. Horticultural performance of 23 Sicilian olive genotypes in hedgerow systems: Vegetative growth, productive potential and oil quality. Sci. Hortic. 2017, 217, 217–225.

- Martorana, A.; Di Miceli, C.; Alfonzo, A.; Settanni, L.; Gaglio, R.; Caruso, T. Effects of irrigation treatments on the quality of table olives produced with the Greek-style process. Ann. Microbiol. 2016, 67, 37–48.

- Giametta, G.; Zimbalatti, G. Mechanical Pruning in New Olive-Groves. J. Agric. Eng. Res. 1997, 68, 15–20.

- Zimbalatti, G.; Bernardi, B.; Castro-Garcías, S. Oliveti tradizionali, oltre gli scuotitori. Olivo Olio 2017, 3, 52–55.

- Bernardi, B.; Falcone, G.; Stillitano, T.; Benalia, S.; Strano, A.; Bacenetti, J.; De Luca, A.I. Harvesting system sustainability in Mediterranean olive cultivation. Sci. Total Environ. 2018, 625, 1446–1458.

- Farinelli, D.; Ruffolo, M.; Boco, M.; Tombesi, A. Yield efficiency and mechanical harvesting with trunk shaker of some international olive cultivars. Acta Hortic. 2012, 949, 379–384.

- Sola-Guirado, R.R.; Bernardi, B.; Castro-García, S.; Brescia, A.; Zimbalatti, G. Assessment of aerial and underground vibration transmission in mechanically trunk shaken olive trees. J. Agric. Eng. 2018, 49, 191–197.

- Lavee, S. Integrated mechanical, chemical and horticultural methodologies for harvesting of oil olives and the potential interactions with different growing systems. A general review. Adv. Hortic. Sci. 2011, 24, 5–15.

- Proietti, S.; Sdringola, P.; Regni, L.; Evangelisti, N.; Brunori, A.; Ilarioni, L.; Nasini, L.; Proietti, P. Extra Virgin Olive oil as carbon negative product: Experimental analysis and validation of results. J. Clean. Prod. 2017, 166, 550–562.

- Regni, L.; Nasini, L.; Ilarioni, L.; Brunori, A.; Massaccesi, L.; Agnelli, A.; Proietti, P. Long term amendment with fresh and composted solid olive mill waste on olive grove affects carbon sequestration by prunings, fruits, and soil. Front. Plant Sci. 2017, 7, 2042.

- Regni, L.; Gigliotti, G.; Nasini, L.; Agrafioti, E.; Galanakis, C.M.; Proietti, P. Reuse of olive mill waste as soil amendment. In Olive Mill Waste: Recent Advances for Sustainable Management; Galanakis, C.M., Ed.; Academic Press: Cambridge, MA, USA; Elsevier: Cambridge, MA, USA, 2017; pp. 97–116.

- Proietti, S.; Sdringola, P.; Desideri, U.; Zepparelli, F.; Brunori, A.; Ilarioni, L.; Nasini, L.; Regni, L.; Proietti, P. Carbon footprint of an olive tree grove. Appl. Energy 2014, 127, 115–124.

- Scaramuzzi, F. The landscape planning policy in Italy contrains olive growing competitiveness. In Olive Growing Systems, Olea, Rome FAO Olive Network; FAO: Rome, Italy, 2007; pp. 14–17.

- Vieri, M.; Sarri, D. Criteria for introducing mechanical harvesting of oil olives: Results of a five-year project in Central Italy. Adv. Hortic. Sci. 2010, 24, 78–90.

- Pannelli, G. Cultivation models for olive groves and mechanisation of harvesting: Technical and economic considerations. Adv. Hortic. Sci. 2010, 24, 21–28.

- Proietti, P. Changes in photosynthesis and fruit characteristics in olive in response to assimilate availability. Photosynthetica 2003, 41, 559–564.

- Ferguson, L. Trends in olive fruit handling previous to its industrial transformation. Grasas Aceites 2006, 57, 9–15.

- Fridley, R.B.; Hartmann, H.T.; Melschau, J.J.; Chen, P.; Whisler, J. Olive Harvest Mechanization in California; University of California: Berkeley, CA, USA, 1971; Volume 855.

- Lodolini, E.M.; Polverigiani, S.; Grossetti, D.; Neri, D. Pruning Management in a High-Density Olive Orchard. Acta Hortic. 2018, 1199, 385–390.

- Famiani, F.; Proietti, P.; Inglese, P. Progettazione e impianto dell’oliveto. In Collana Divulgativa dell’Accademia Volume VI; Accademia Nazionale dell’Olivo e dell’ Olio: Spoleto, Italy, 2011.

- Pannelli, G.; Gucci, R. La gestione della chioma. In Collana Divulgativa Dell’Accademia Volume V; Accademia Nazionale dell’ Olivo e dell’ Olio: Spoleto, Italy, 2011.

- Anifantis, A.S.; Camposeo, S.; Vivaldi, G.A.; Santoro, F.; Pascuzzi, S. Comparison of UAV Photogrammetry and 3D Modeling Techniques with Other Currently Used Methods for Estimation of the Tree Row Volume of a Super-High-Density Olive Orchard. Agriculture 2019, 9, 233.

- Tous, J.; Romero, A.; Hermoso, J.F.; Msallem, M.; Larbi, A. Olive orchard design and mechanization: Present and future. Acta Hortic. 2014, 1057, 231–246.

- Camposeo, S.; Vivaldi, G.A. Yield, Harvesting Efficiency and Oil Chemical Quality of Cultivars ‘Arbequina’ and ‘Arbosana’ Harvested by Straddle Machine in Two Apulian Growing Areas. Acta Hortic. 2018, 1199, 397–402.

- Lodolini, E.M.; Polverigiani, S.; Cioccolanti, T.; Santinelli, A.; Neri, D. Preliminary Results about the Influence of Pruning Time and Intensity on Vegetative Growth and Fruit Yield of a Semi-Intensive Olive Orchard. J. Agric. Sci. Technol. 2019, 21, 969–980.

- Larbi, A.; Vázquez, S.; El-Jendoubi, H.; Msallem, M.; Abadía, J.; Abadía, A.; Morales, F. Canopy light heterogeneity drives leaf anatomical, eco-physiological, and photosynthetic changes in olive trees grown in a high-density plantation. Photosyn. Res. 2015, 123, 141–155.

- Rosati, A.; Paoletti, A.; Caporali, S.; Perri, E. The role of tree architecture in super high density olive orchards. Sci. Hortic. 2013, 161, 24–29.

- Cuevas, M.V.; Martín-Palomo, M.J.; Diaz-Espejo, A.; Torres-Ruiz, J.M.; Rodriguez-Dominguez, C.M.; Perez-Martin, A.; Pino-Mejías, R.; Fernández, J.E. Assessing water stress in a hedgerow olive orchard from sap flow and trunk diameter measurements. Irrig. Sci. 2013, 31, 729–746.

- Vivaldi, G.A.; Strippoli, G.; Camposeo, S. Ecophysiological response to irrigation of two olive cultivars grown in a high-density orchard. Agric. Sci. 2013, 4, 16–20.

- Russo, G.; Vivaldi, G.A.; De Gennaro, B.; Camposeo, S. Environmental sustainability of different soil management techniques in a high-density olive orchard. J. Clean. Prod. 2015, 16, 498–508.

- Marino, G.; Macaluso, L.; Grilo, F.; Marra, F.P.; Caruso, T. Toward the valorization of olive (Olea europaea var. europaea L.) biodiversity: Horticultural performance of seven Sicilian cultivars in a hedgerow planting system. Sci. Hortic. 2019, 256, 108583.

- Tous, J.; Romero, A.; Hermoso, J.; Ninot, A. Mediterranean clonal selections evaluated for modern hedgerow olive oil production in Spain. Calif. Agr. 2011, 65, 34–40.

- De la Rosa, R.; Kiran, A.I.; Barranco, D.; León, L. Seedling vigour as a preselection criterion for short juvenile period in olive breeding. Aust. J. Agric. Res. 2006, 57, 477–481.

- Camposeo, S.; Godini, A. Preliminary observations about the performance of 13 varieties according to the super high density olive culture training system in Apulia (southern Italy). Adv. Hortic. Sci. 2011, 24, 16–20.

- Larbi, A.; Ayadi, M.; Ben Mabrouk, M.; Kharroubi, M.; Kammoun, N.; Msallem, M. Agronomic and oil characteristics of some olive varieties cultivated under high-density planting conditions. In Proceedings of the Vol. II of Olivebioteq 2006—Second International Seminar-Biotecnology and Quality of Tree Products around the Mediterranean Basin, Marsala-Mazara Del Vallo, Italy, 5–10 November 2006; pp. 135–138.

- Rallo, L.; Barranco, D.; De la Rosa, R.; León, L. New Olive Cultivars and Selections in Spain: Results after 25 Years of Breeding. Acta Hortic. 2018, 1199, 21–26.

- Moutier, N.; Ricard, J.M.; Le Verge, S. Vigour control of the olive tree in a high-density planting system: Two experimental approaches. Acta Hortic. 2011, 324, 185–294.

- Lodolini, E.M.; Polverigiani, S.; Sirugo, M.; Neri, D. Damage to Several Olive Cultivars by Two over-the-Row Harvesters in High-Density Orchards. Acta Hortic. 2018, 1199, 415–420.

- Tombesi, A.; Famiani, F.; Proietti, P.; Guelfi, P. Manual, integrated and mechanical olive harvesting: Efficiency and effects on trees and oil quality, Ezzaitouna. Rev. Sci. l’Oléiculture l’Oléotechnie 1996, 2, 93–101.

- Tombesi, A. Planting systems, canopy management and mechanical harvesting. In Proceedings of the Olivebioteq 2006—Second International Seminar—Recent Advances in Olive Industry—Special seminars and invited lectures, Marsala-Mazara Del Vallo, Italy, 5–10 November 2006; pp. 307–316.

- Pastor, M.; García-Vila, M.; Soriano, M.A.; Vega, V.; Fareres, E. Productivity of olive orchards in response to tree density. J. Hortic. Sci. Biotechnol. 2007, 82, 555–562.

- Connor, D.J.; Gómez-del Campo, M.; Comas, J. Yield characteristics of N-S oriented olive hedgerow orchards, cv. Arbequina. Sci. Hortic. 2012, 133, 31–36.

- Trentacoste, E.R.; Connor, D.J.; Gomez del Campo, M. Effect of olive hedgerow orientation on vegetative growth, fruit characteristics and productivity. Sci. Hortic. 2015, 192, 60–69.

- Breviglieri, N. La nuova olivicoltura specializzata intensiva. Ital. Agric. 1961, 3.