Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Subjects:

Polymer Science

Ceramics and polymers are two main candidate materials for membranes, where the majority has been made of polymeric materials, due to the low cost, easy processing, and tunability in pore configurations. In contrast, ceramic membranes have much better performance, extra-long service life, mechanical robustness, and high thermal and chemical stabilities, and they have also been applied in gas, petrochemical, food-beverage, and pharmaceutical industries, where most of polymeric membranes cannot perform properly.

- composite membrane

- polymeric membrane

- ceramic membrane

- nanocomposite

1. Introduction

Ceramics and polymers are the two main materials for various membranes. In particular, ceramic membranes have gained more attention recently, due to their superior performance, hydrophilicity, mechanical robustness, and high thermal and chemical stabilities, which allow at least double lifespan compared with the polymer membranes [20,21]. The common ceramic materials used in membrane applications are Al2O3, TiO2, ZrO2, SiO2 [19,22], and those containing a combination of them such as Al2O3-ZrO2 [23] and TiO2-SiO2 [24], and various metal nanoparticles embedded in ceramics such as Ag-TiO2 [25]. However, the relatively high production cost of the ceramic membranes is a restricting parameter in widening of their applications. Indeed, polymeric materials are still more widely used, although there is a steadily decrease in the overall market share. Polymer membranes have the merits of being low cost, tunable in porous structure, and ease in scale-up. Therefore, the polymer membranes have been dominantly employed for water, wastewater treatment, and desalination [1]. Among them, Poly-ethersulfone (PES) [26], Poly-sulfone (PSf) [27], poly-vinylidene fluoride (PVDF) [28,29], poly-vinylpyrrolidone (PVP) [30], poly-acrylonitrile (PAN) [31,32], poly-vinyl alcohol (PVA) [33,34], and poly-vinyl acetate (PVAc) [35] are widely used as the polymeric membranes (Table 1). In addition to the poor life span, most of these polymeric membranes are inherently hydrophobic to certain extent, leading to low water flux, high fouling tendency, which often causes even shorter lifetime and higher operating cost.

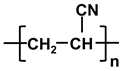

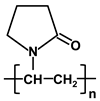

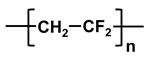

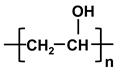

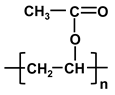

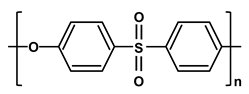

Table 1. Structures of common polymer membranes.

| Polymer | Abbreviation | Structure |

|---|---|---|

| poly-acrylonitrile | PAN |  |

| poly-vinylpyrrolidone | PVP |  |

| poly-vinylidene fluoride | PVDF |  |

| poly-vinyl alcohol | PVA |  |

| poly-vinyl acetate | PVAc |  |

| Poly-ethersulfone | PES |  |

| Poly-sulfone | PSf |

2. Ceramic-Polymer Composite Membrane

Ceramic-polymer composite membranes can be divided into three groups. Nanocomposite membranes are composed of a polymeric membrane in which inorganic NPs are dispersed. This type of membranes has been most widely researched. The preparation for the nanocomposite membrane is mostly-based those well developed for polymer membranes, such as the phase inversion or casting of a polymer solution containing ceramic NPs. Either flat sheet or hollow fiber configurations can be obtained. The nanocomposite membrane has been used for both MF and UF processes. In the TFN membranes, a thin nanocomposite membrane is supported on a polymeric support, where ceramic NPs are located on the surface of the membrane and provide minimal influence on the intrinsic properties of polymeric substrate such as the pore structure. The surface properties of the resultant membrane are basically governed by ceramic NPs. The ceramic-supported polymer membranes consist of a thin polymer layer on a porous ceramic support. In contrast to the other two types of membranes, relatively dense and bulk ceramics, not ceramic NPs, are used in this type of membranes. The high chemical and thermal stability of ceramic supports restrict swelling of the thin polymer layer and improve flux and provide long membrane life. Highly tunable pore distribution and pore size of the polymeric surface layer influence the rejection properties of composite membranes. Coating on a polymer solution or in situ polymerization on a ceramic support has been employed to prepare the ceramic-support membranes. In all three types of membranes, not only the intrinsic properties of ceramic and polymeric components but also the interface properties between them influence the membrane performance significantly.

2.1. Ceramics in Polymer (Nanocomposite) Membranes

This type of membranes is composed of polymeric membranes in which ceramic NPs are dispersed in. Incorporation of the ceramic NPs into polymers could influence not only the hydrophilicity, pore size and distribution, surface roughness, but also can add new properties such as photocatalytic properties, antibacterial properties, etc. [60]. The fabrication of these membranes is mainly performed by casting and phase inversion (PI) using a polymer solution containing ceramic NPs [61].

Metal oxides such as SiO2, Al2O3, TiO2, Fe3O4 have been exclusively used as ceramic fillers for the nanocomposite membranes, where TiO2 is one of the most widely used ceramics in this type of membranes. Additionally, natural minerals such as kaolin [62], cloisite [63] and montmorillonite [64] are studied to reduce material cost for inorganic components. The main advantages of TiO2 incorporation include the enhancement in hydrophilicity as well as antibacterial behavior by photocatalytic properties of TiO2 [65]. By the addition of TiO2, a decrease in contact angle and improvement of water flux have been reported by several groups. Additionally, UV-radiation enhances fouling resistance and antibacterial capability of TiO2-nanocomposite membranes due to the superhydrophilicity and photocatalysis of TiO2 under UV irradiation [66,67]. The UV irradiation also promote flux recovery of the TiO2-nanocomposite membrane [68].

The enhancement in hydrophilicity by the addition of ceramic NPs has also been observed in other transition metal oxides, such as SiO2 [81,82,83,84,85,86], Al2O3 [87,88,89,90], Fe3O4 [91,92,93,94,95], and ZrO2 [96]. The influence of these ceramic fillers on the properties of polymeric membranes is dependent on the type and amount of fillers being added. For example, the addition of mesoporous silica into PES UF membrane does not affect the pore size significantly, but increases the level of porosity, resulting in an improved water flux [85]. Contrarily, the addition of Fe3O4 into PES membrane largely influences both pore size and the level of porosity [94]. The level of porosity increased by the Fe3O4 addition, while the pore size drastically decreased.

2.2. Thin Film Nanocomposite (TFN) Membranes

This type of membranes is composed of a thin nanocomposite membrane supported on polymer substrates. The concept of TFN membrane was first suggested in the 1970s, and it has been widely studied for desalination of seawater/brackish water, removal of heavy metals, organic micropollutants and pharmaceutically active compounds [61]. PSf has widely been used as a supporting layer while PA (polyamide) has been widely employed in the thin top layer. As inorganic compounds, (a) metal oxide NPs, (b) metal NPs and (c) carbon materials such as CNT and GO have been studie.

As in the nanocomposite membranes, TiO2 nanoparticles are among the most used in the thin top layer, and the water flux and antifouling properties are improved [49,100,101,102]. An optimum TiO2 loading in this type of membrane is reported as 0.05~0.1 wt.%. This is much lower than that in TiO2-nanocomposite membranes, which is around 1 wt.%. In the TFN configuration, TiO2 content can be drastically reduced. Exposing TiO2 NPs on the surface significantly influences surface properties of membranes, resulting in reduction of TiO2 content. The TFN membrane could be fabricated at lower material cost compared to the nanocomposite membrane. In contrast, photocatalytic properties of TiO2 in the TFN membranes have not been widely reported. The optimum ceramic NP content is also in the same range (0.05–0.1 wt.%) in the case of SiO2 NPs [103].

2.3. Ceramic-Supported Polymer Membranes

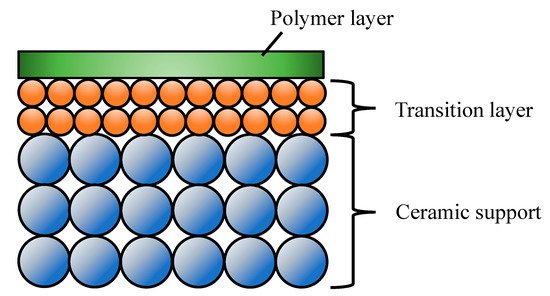

This type of membrane is composed of a thin polymeric film (selective layer, active layer) supported on a ceramic porous substrate (Figure 3, [140]). The ceramic substrates provide the superior chemical, mechanical and thermal stabilities as well as negligible transport resistance and defines the external shape of the membrane [44]. The ceramic-supported polymer composites have attracted much attention for their significant performance in UF [141], pervaporation [44,133,134,135,136,137,138,139,140,141,142,143,144,145,146,147], gas separation [148], etc. The thin polymeric layer, which can consist of one or more intermediate layers, is prepared by processes, such as interfacial polymerization, dip coating, etc. The level of air humidity during dip coating, drying process and polymer solution affected quality of top thin layer significantly [148,149].

Figure 3. Structure of the ceramic-supported polymer composites.

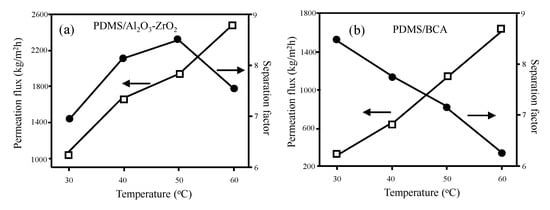

The benefits offered by the ceramic-supported polymer membranes are mainly in high flux and long-term stability. For example, PDMS/Al2O3-ZrO2 nanocomposite membrane shows about two times higher pervaporation flux of ethanol/water than that of the PDMS/Blend cellose acetate (BCA) membrane [163] (Figure 4). Additionally, the separation factor decreased with temperature monotonically in the PDMS/BCA membrane, while the peak of separation factor was shown at 50 °C in the PMDS/Al2O3.

Figure 4. A comparison of pervaporation performance between (a) PDMS/Al2O3-ZrO2 and (b) PDMS/BCA membranes [163]. Reproduced with permission. Copyright in 2011, Elsevier.

Additionally, their superior long-term stability are reported by several research groups [148,150,159,163], where it is considered to be arising from the high structural, thermal, and chemical stabilities of ceramic supports in operating condition. In the polymer-supported membranes, swelling of the polymeric support in the operation could damage the thin top layer, resulting in poor stability of the polymer-supported membranes. The swelling tendency is more prominent at high temperatures. Therefore, most of the commercial PA membranes with polymer support cannot be used above 50 °C. Contrarily, PA supported on Al2O3 tubular membrane demonstrated stable rejection and permeation of MgCl2 at 70 °C, due to the high stability of Al2O3 support which could stabilize the PA top layer [152].

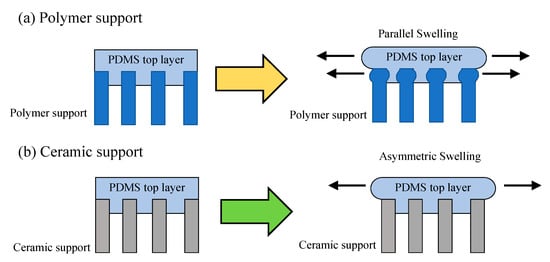

It must be noted that the swelling process is different between the polymer-supported and ceramic-supported polymer membranes (Figure 5) [163]. In the polymer support, top and support layers are swollen in a parallel direction together (Figure 5a). The swelling influences pore structure and membrane performance. On the contrary, only the top layer can be swollen in the ceramic-support membranes (Figure 5b). The ceramic support maintains its pore structure and can suppress the swelling of top polymeric layer. Therefore, influence of the swelling is reduced in the polymer-supported membranes. This would be one of the reasons behind the superior performance of the ceramic-supported composite polymer membranes.

Figure 5. Swelling in (a) polymer-supported PDMS top layer and (b) ceramic-supported PDMS top layer [163]. Reproduced with permission. Copyright in 2011, Elsevier.

Ceramic-supported polymer composite membranes can recover their performance completely by back washing after fouling [158]. For example, PDMS/β-Sialon membrane is fouled by the crystallization of NaCl. After the membrane is scoured and dried to remove the crystallized NaCl on the surface, the flux could be completely recovered. Interestingly, for example, Menne et al. reported a reusable Al2O3 monolith support for PDADMAC/PSS (poly(sodium 4-styrene sulfonate)) film [157]. After fouling, the top PDADMAC/PSS layer is removed by sodium hypochlorite (NaOCl) treatment. Then, a new top layer is built by the coating on the same Al2O3 monolith. Pure water permeability does not change by the removal and rebuilding of the top layer. This reusable ceramic support is expected to reduce material and production costs drastically.

By properly matching the properties between the ceramic support and a polymeric top layer, the ceramic-supported polymer composite membranes can feature high permeability. Additionally, the confinement in swelling of the polymeric top layer by a stable ceramic support provides long-term stability and allows high temperature operation. However, further research would be required to optimize the polymer-ceramic interface, in order to tailor the high performance of the ceramic-supported polymer composite membranes.

This entry is adapted from the peer-reviewed paper 10.3390/molecules26113331

This entry is offline, you can click here to edit this entry!