Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Subjects:

Optics

The fundamental advantages of volume holographic optical elements are very appealing for lightweight and cheap solar concentrators applications and can become a valuable asset that can be integrated into solar panels.

- holographic solar concentrator

- holographic lens

- volume phase holographic optical elements

1. Introduction

Solar energy conversion processes provide clean, sustainable and renewable energy, thus there is a growing interest in research and development in the study of conversion systems and their cost effectiveness. An improvement in this sense needs simultaneous consideration of three issues: initial cost, durability-reliability and performance[1]. Considering the current technology, photovoltaic (PV) cells with triple-junction InGaAs are the most efficient (37%); nevertheless, their high cost makes them unattractive, even if their use for domestic applications, as well as in the aerospace industry, is desirable. This problem can be solved by using optical concentrators that allow focussing the sun’s rays onto the active solar cell area, thus letting to reduce a significant amount of the expensive PV material[2]. Consequently, in the last 15 years, solar concentration technologies were explored to direct all the available light towards small solar cells.

Currently, there are two principal types of concentrators involved in conversion technology: conventional solar concentrators (e.g., lenses or mirrors) and holographic solar concentrators. Holographic optical elements (HOEs) could in part overcome the limitations of the conventional solar concentrator, such as complex designs, thermal management due to the excessively heated of the solar cell when illuminated with concentrated solar radiation and active solar tracking. Additionally, holography is much more versatile and cheaper with respect to other concentrating optical systems.

In particular, volume holographic optical elements (V-HOEs) have been proposed for use as solar concentrators[3][4] thanks to the following features: (i) potential to achieve nearly 100% efficiency for certain wavelengths and directions; (ii) very rapid and low-cost effective manufacturing and easy customizability of the recorded devices; (iii) narrowness and lightness; (iv) potential to fabricate elements with multiple optical responses (multiplexing); and (v) potential to be very inexpensive in mass production. V-HOEs applications range from spectral splitting applications to increase the conversion efficiency of PV cells[3][5][6] to simultaneous concentration and spectral splitting applications[7].

Despite all these advantages offered by V-HOEs, currently only a few holographic concentrators, patented by Prism Solar Technologies[8], are on market. They work by total internal reflection by means of multiplexed gratings[9], have low cost (around 1 $/W) and are easy to be integrated into buildings[10]. Nevertheless, Prism Solar Modules are still under test and maybe this is the main reason for which this technology is not yet so diffused.

However, with the aim of obtaining high performance of V-HOEs as solar concentrators, it is necessary to keep in mind that volume holograms have high efficiency only when the incident rays vary in a given portion of the plane (angular selectivity) and their efficiency depends on the wavelength: it is high for a bandwidth centred on a wavelength determined by both the refractive index modulation obtained in the recording material and the angle of incidence (chromatic selectivity)[4]. Thus, V-HOEs should be designed to have a high efficiency for the spectrum of the sunlight inside the PV conversion range (for multijunction PV cells, 350 ÷ 1750 nm[11]).

It is worth noting that, due to the chromatic selectivity, the V-HOE diffraction efficiency depends on the wavelength[10]. Exploiting this feature, the heating of the cell, due to the solar spectrum region associated with wavelengths above 1200 nm, can be managed. Thus, one of the main problems of conventional solar concentrators can be overcome allowing a higher conversion efficiency and so lower cost/watt[12][13].

V-HOEs can be used as solar concentrators in both earth and space (satellites) applications. Regarding the first application, several studies are reported in the literature, whereas for aerospace applications only a few works are available[4][14][15][16], maybe due to the hostile space environment that has to be taken into account.

To obtain an efficient V-HOE as solar concentrator, the main requirements are: (i) the recording material, (ii) the concentration ratio, (iii) the angular selectivity, (iv) the possibility to implement the passive solar tracking, (v) the efficiency of single and multiplexed elements and (vi) the possibility to split the solar spectrum. The resulting system performance depends on each of these points. However, in our knowledge, the aforementioned focusing points required to achieve an efficient V-HOE as solar concentrator are never considered all together. Thus, we think that future researches should be focused on all of these features.

2. V-HOE Recording Process

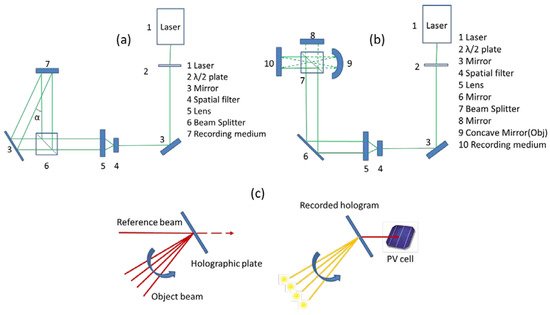

The simplest V-HOE is a VHG which acts as a non-focusing element; therefore, it basically redirects the light [17]. Usually, a hologram can be recorded by interference between two beams, namely reference and object beam, respectively. When the two interfering beams are two collimated light beams, a VHG can be recorded. A scheme of the experimental setup typically used to record VHGs is shown in Figure 1a; the angle α between two incident beams is related to the final grating period of the recorded VHG. The interference fringe pattern leads to a photoinduced modulation of the refractive index in a photosensitive thick film.

Figure 1. (a) Set-up for volume holographic grating recording; (b) Set-up for volume phase holographic lenses recording; (c) Schematic representation of the recording of multiplexed holographic lenses: the reference beam is fixed while the object beam incident angle is changed during the process. The multiplexed holographic lenses recorded behaves like a passive solar tracker: the light coming from the sun in different positions, that is, at different times of the day, is always focused on the same point, where a photovoltaic cell is positioned.

When in the object beam path a focusing optics is placed during the recording process, the interference between a reference (collimated) beam and an object (converging) beam is induced. Thus, an interferometric pattern that replaces the response of the focusing optical systems used as object is generated, obtaining a V-HOE that acts as a focusing element. This V-HOE shows the same effect as spherical or cylindrical lenses[4][18]. A typical recording setup is reported in Figure 1b.

Conventional concentration modules need the aid of complex mechanical systems (active solar tracking) to improve their efficiency. These aiding systems increase the complexity of the PV cell power system design, the panel volume and development costs. The possibility to reduce or even eliminate, the moving system using multiplexed holographic lenses as passive solar trackers, makes the system more competitive in the perspective of new generation solar panel development. As a result, there are fewer problems related both to the wear of moving parts and possible vibrations due to movements[16]. Multiplexed V-HOEs can be achieved by changing the angle between the two incident wavefronts during the writing process, as schematically shown in Figure 1c. In this way, a V-HOE that addresses the solar radiation incident with different angles, on a single photovoltaic cell, can be realized.

3. Holographic Materials for Solar Concentrators

The holographic recording medium should be able to resolve fully all the fringes resulting from interference between the two incident beams. These fringe spacing can range from tens of micrometres to less than one micrometre, corresponding to spatial frequencies in the range of a few hundred to several thousand cycles/mm. If the performance of the recording medium for these spatial frequencies is low, the diffraction efficiency of the hologram will be poor.

Currently, to record a V-HOE several photosensitive materials can be used, among them substrates based on silver halide emulsions, dichromatic gelatines and photopolymers are the most widely used.

3.1. Silver Halide Emulsions

Silver halide emulsion is one of the oldest recording materials for holography. It is a fine suspension of microscopic grains of silver halide (usually silver bromide, grain size in the range of tens of nanometres) in a colloid sol, usually consisting of gelatin. Typically, a layer of emulsion with a thickness in the range of 5 to 15 µm, is coated onto glass or film substrate. The recorded image is then developed by chemical post-processing, allowing multiple holograms recording. Additionally, emulsions show high sensitivity (10−5 to 10−3 mJ/cm2) and good resolution (greater than 6000 lines/mm).

Silver halide emulsions were recently used to obtain a panchromatic holographic material for the fabrication of wavelength multiplexed holographic solar concentrators[19].

3.2. Dichromatic Gelatines

Dichromatic gelatine (DCG) is composed of ammonium or potassium dichromate, gelatin and water and needs chemical post-processing. Ammonium dichromate becomes progressively harder on exposure to light, inducing high refractive index modulation, thus allowing high diffraction efficiency, high resolution, low noise and high optical quality[20][21][22]. The drawback of DCG is its low exposure sensitivity and limited spectral response.

Even if DCG can be considered an ideal recording material for volume phase holograms, it is very sensitive to environmental changes, therefore it requires a cover plate to ensure environmental stability thus weighting the structure[23]. This reason makes it virtually less eligible for solar concentration applications.

3.3. Photopolymers

Photopolymers are the most studied holographic materials since the 1970s; they are based on polymerization and cross-linking reactions induced by absorption of light and they offer several advantages respect to silver halide and DCG. Indeed, photopolymerizable materials show high diffraction efficiencies, allow real-time monitoring of the recording process, do not require development processes but only a bleaching process, can be produced from raw materials at low cost and give the possibility to modulate the properties through chemical synthesis[4]. Additional, photopolymers can be mass produced allowing to reducing production costs[24][25].

Typically, a photopolymer is made from a photoinitiator system, one or more polyfunctional monomers or oligomers and a polymeric binder. When it is exposed to light, the polymerization occurs in the areas of constructive interference (high-light intensity areas) leading to increased consumption of the monomers, while the polymerization is limited or absent in the areas of destructive interference (low-light intensity areas). The difference of monomer consumption rate leads to a concentration gradient that drives monomer diffusion from dark to illuminated areas[26][27][28]. Thus, the polymer concentration distribution will take over the sinusoidal pattern of the light intensity, resulting in a permanent modulation of the refractive index, that is, a volume-phase hologram.

Some examples of the most commonly used photopolymers as recording material for holography are: (i) a photopolymer developed within Bayer MaterialScience based upon an orthogonal two chemistry formulation; it is capable of achieving transmission above 90% in the film samples[29]; (ii) photopolymer materials developed by DuPont for recording volume phase holograms, in particular new materials with panchromatic sensitivity, designed for multicolour holographic recording have been developed[30]; (iii) acrylamide-based photopolymers have also been extensively used for fabrication of HOEs in solar energy applications[31].

Regarding the resistance of these materials for holographic concentrators in environmental conditions, there are durability tests on some of the most widely used photopolymers in conventional Fresnel-type solar concentrators, such as acrylic polymers[32].

The fabrication of lenses for concentrators and protective layers for photovoltaic cells is often made by using polymethyl methacrylate (PMMA)[33] since it allows a good resistance to UV radiation and high transmittance (>92%). The UV sensitivity can be further reduced by introducing protective layers or by adding radical scavengers or antioxidants to the formulation of the material. Also polydimethylsiloxane (PDMS) shows very high stability against UV radiation and making it suitable for use in the space environment[34]. Additional, PDMS features greater optical transmittance compared to PMMA.

Considering all the advantages offered by photopolymeric materials, to obtain solar compliant holographic materials that should be less sensitive to thermal and photochemical degradation phenomena, the study of new photopolymers based on inorganics or hybrid organic/inorganic components instead of organic material is still in progress. Some examples in this sense are photopolymers containing nanoparticles of inorganic species such as SiO2, ZrO2 and TiO2 [35], that show a lower shrinkage due to the polymerization and a higher refractive index modulation[36][37] and photopolymer containing zeolite nanocrystals as inorganic dopant, that allows to improve compatibility between inorganic particles and polymer and reduce the optical losses due to scattering[38]. Finally, the sol-gel chemistry versatility allows obtaining a high level of interpenetration between the organic and inorganic networks, as reported in Refs.[4][39][40][41]. Photopolymer with a very low outgassing level and a high resistance to strong thermal excursions, that can be useful for some applications, was obtained by sol-gel techniques[4].

4. V-HOE Based Solar Concentrators

4.1. Solar Concentrator and Spectral Splitting

Since the pioneering work published by Ludman in 1982[42], V-HOEs have been proposed as solar concentrators; additionally, by using DCG as a recording material, they have been employed to obtain a spatial separation of the solar spectrum allowing the use of solar cell materials with optimized band gaps achieving high PV efficiency[3][43]. Moreover, an optimized holographic concentrating and spectral splitting systems can reduce the cooling requirements of the photovoltaic cells and, considering V-HOE design versatility, PV cells can be placed on a side of the hologram, thus avoiding shadow effects and simplifies cooling[5][44]. In this case, the hologram not only concentrates the solar radiation but also split and directs the red and near-infrared spectrum on one PV cell and the green and blue spectrum on another one, while the far-infrared wavelengths of the solar spectrum are diffracted away from the cells, reducing the main cause of overheating.

5.2. Multiplexed Hologram

To improve the angular selectivity, multiplexed solutions have been considered. Bainier et al. reported a detailed study on superimposed transmission holograms recorded on the same holographic medium based on DCG. In particular, the authors compared a system consisting of a single holographic element as a concentrator with the maximum of reconstruction wavelength (620 nm) centred in the middle of the range of the PV cell (i.e., 500–800 nm) and a system composed of two holographic recordings with the two maximum reconstruction wavelengths (514.5 and 620 nm) designed both to overlap the operating spectrum of the PV cell (GaAs with an efficiency of 23%) and to avoid the coupling effect. Both the reflecting and transmitting version for the double hologram system were characterized, with one of the two holograms superimposed on the same holographic medium in the transmission configuration. Theoretical and experimental evaluation of the energy efficiency of the holographic systems were carried out. Values of 6 and 5% for the single holographic elements and of 11 and 9% for the double holographic element were obtained, respectively.

5.3. Holographic Solar Deflector

In 2010, Castro et al.[9] designed and characterized a holographic grating, recorded on dichromatic emulsion, able to deflect the direct sunlight on a PV cell with the higher energy efficiency possible. A detailed study of the effects of incident spectra that vary hourly, daily and seasonally was performed, and, in order to maximize the energy collection efficiency per year. The designed cell is composed by two cascaded holographic grating on each side of the PV cell (holograms A and B), that are conjugated (i.e., A and A’ or B and B’) to provide peak energy collection at different seasons.

5.4. Cylindrical Holographic Lenses

Cylindrical holographic lenses, that allow obtaining a compact and wide-angle structure, were also considered as a solar concentrator. With the aim to take into account a specific set of designed parameter, such as bandwidth, angular selectivity, PV cell size, optical polarization and so on, a proper simulation tool has been developed[10][13]. The possibility to realize a high-efficient system that only requires one-axis tracking was demonstrated.

5.5. Commercial and Space Holographic Concentrators

Regarding commercial systems that make use of holographic concentrators, the best performing solutions are offered by Prismsolar, which propose patented enhanced glass-on-glass holographic modules composed of highly efficient bifacial N-type silicon cells with holographic technology. A single module is made alternating strips of bifacial solar cells with parallel strips of holographic film. It allows to collect not only the light that hits the solar cells directly, as normally occurs but also the light that hits the holographic film, which diffracts the light and a portion of this light is guided to the cell through total internal reflection, thus increasing the total harvested sunlight[8][45].

This entry is adapted from the peer-reviewed paper 10.3390/app9010193

References

- P.J. Call; Overview of solar energy conversion technologies: Quantum processes and thermal processes. Materials Science and Engineering 1982, 53, 7-16, 10.1016/0025-5416(82)90006-4.

- Michael J. Patterson; James S. Sovey; History of Electric Propulsion at NASA Glenn Research Center: 1956 to Present. Journal of Aerospace Engineering 2013, 26, 300-316, 10.1061/(asce)as.1943-5525.0000304.

- W. H. Bloss; M. Griesinger; E. R. Reinhardt; Dispersive concentrating systems based on transmission phase holograms for solar applications. Applied Optics 1982, 21, 3739-3742, 10.1364/ao.21.003739.

- Ferrara, M.A.; Bianco, G.; Borbone, F.; Centore, R.; Striano, V.; Coppola, G.. Volume holographic optical elements as solar concentrators; Naydenova, I., Eds.; InTechOpen: London, UK, 2017; pp. 27–50.

- Jacques Ludman; Juanita Riccobono; Nadya Reinhand; Irina Semenova; José Martín; William Tai; Xiao-Li Li; Geof Syphers; Holographic solar concentrator for terrestrial photovoltaics. Proceedings of 1994 IEEE 1st World Conference on Photovoltaic Energy Conversion - WCPEC (A Joint Conference of PVSC, PVSEC and PSEC) 2002, x, 1212–1215, 10.1109/wcpec.1994.520181.

- A.G. Imenes; D.R. Mills; Spectral beam splitting technology for increased conversion efficiency in solar concentrating systems: a review. Solar Energy Materials and Solar Cells 2004, 84, 19-69, 10.1016/j.solmat.2004.01.038.

- C. Bainier; D. Courjon; C. Hernandez; Solar concentrating systems using holographic lenses. Solar & Wind Technology 1988, 5, 395-404, 10.1016/0741-983x(88)90006-9.

- Prismsolar . Prism Solar Technologies. Retrieved 2021-6-9

- Jose M. Castro; Deming Zhang; Brian Myer; Raymond K. Kostuk; Energy collection efficiency of holographic planar solar concentrators.. Applied Optics 2010, 49, 858-870, 10.1364/ao.49.000858.

- Daniel Chemisana; Ma Victoria Collados; Manuel Quintanilla; Jesus Atencia; Holographic lenses for building integrated concentrating photovoltaics. Applied Energy 2013, 110, 227-235, 10.1016/j.apenergy.2013.04.049.

- Dimroth, F.; Karam, N.H.; Ermer, J.H.; Haddad, M.; Colter, P.; Isshiki, T.; Yoon, H.; Cotal, H.L.; Joslin, D.E.; Krut, D.D.; et al. Next generation GaInP/GaInAs/Ge multi-junction space solar cells. In Proceedings of the 17th European Photovoltaic Solar Energy Conference, Munich, Germany, 22–26 October 2001; ETA: Florence, Italy; WIP: Munich, Germany, 2001.

- Riccobono, J.R.; Ludman, J.E. Solar holography. Holography for the New Millennium; Ludman, J., Caulfield, H.J., Riccobono, J., Eds.; Springer: New York, NY, USA, 2002; pp. 157–178.

- Paula Bañares-Palacios; Samuel Álvarez-Álvarez; Julia Marín-Sáez; María-Victoria Collados; Daniel Chemisana; Jesús Atencia; Broadband behavior of transmission volume holographic optical elements for solar concentration. Optics Express 2015, 23, A671-A681, 10.1364/oe.23.00a671.

- Renk, K.; Jacques, Y.; Felts, C.; Chovit, A. Holographic Solar Energy Concentrators for Solar Thermal Rocket Engines; No. NTS-6006; NTS Engineering: Long Beach, CA, USA, 1988.

- Jérôme Loicq; Luis Miguel Venancio; Yvan Stockman; Marc P. Georges; Performances of volume phase holographic grating for space applications: study of the radiation effect. Applied Optics 2013, 52, 8338-8346, 10.1364/ao.52.008338.

- G. Bianco; P. Ferraro; V. Striano; V. Pagliarulo; G. Coppola; Fabio Borbone; S. Grilli; A. Roviello; Maria Antonietta Ferrara; Multiplexed holographic lenses : realization and optical characterization. 2015 Fotonica AEIT Italian Conference on Photonics Technologies 2015, 2015, Issue CP667, 10.1049/cp.2015.0165.

- Samuel C. Barden; James A. Arns; Willis S. Colburn; Volume-phase holographic gratings and their potential for astronomical applications. Optical Astronomical Instrumentation 1998, 3355, 866-876, 10.1117/12.316806.

- M. G. Moharam; L. Young; Criterion for Bragg and Raman-Nath diffraction regimes. Applied Optics 1978, 17, 1757-1759, 10.1364/ao.17.001757.

- Vadivelan, V.; Recording of Holographic Solar Concentrator in Ultra Fine Grain Visible Wavelength Sensitive Silver Halide Emulsion. American Journal of Electronics & Communication 2015, 2, 15–17, 10.15864/ajec.1109.

- J. Hull; J Lauer; D Broadbent; Holographic solar concentrators. Energy 1987, 12, 209-215, 10.1016/0360-5442(87)90079-x.

- J. A. Quintana; P. G. Boj; J. Crespo; M. Pardo; M. A. Satorre; Line-focusing holographic mirrors for solar ultraviolet energy concentration.. Applied Optics 1997, 36, 3689-3693, 10.1364/ao.36.003689.

- Ranjan, R.; Khan, A.; Chakraborty, N.R.; Yadav, H.L.. Use of holographic lenses recorded in dichromated gelatin film for PV concentrator applications to minimize solar tracking; Perlovsky, L., Dionysiou, D.D., Zadeh, L.A., Kostic, M.M., Gonzalez-Concepcion, C., Jaberg, H., Sopian, K., Eds.; WSEAS Press: Athens, Greece, 2009; pp. 49–52.

- B. J. Chang; Dichromated Gelatin Holograms And Their Applications. Optical Engineering 1980, 19, 195642-195642-, 10.1117/12.7972582.

- Friedrich-Karl Bruder; Thomas Fäcke; Fabian Grote; Rainer Hagen; Dennis Hönel; Eberhard Koch; Christian Rewitz; Günther Walze; Brita Wewer; Mass production of volume holographic optical elements (vHOEs) using Bayfol® HX photopolymer film in a roll-to-roll copy process. Practical Holography XXXI: Materials and Applications 2017, 10127, 101270, 10.1117/12.2250933.

- Dinesh Vather; Izabela Naydenova; Dervil Cody; Monika Zawadzka; Suzanne Martin; Emilia Mihaylova; Stephen Curran; Paul Duffy; Josune Portillo; Daniel Connell; et al. Serialized holography for brand protection and authentication. Applied Optics 2018, 57, E131-E137, 10.1364/ao.57.00e131.

- Guoheng Zhao; Pantazis Mouroulis; Diffusion Model of Hologram Formation in Dry Photopolymer Materials. Journal of Modern Optics 1994, 41, 1929-1939, 10.1080/09500349414551831.

- Dana Mackey; Paul O'reilly; Izabela Naydenova; Theoretical modeling of the effect of polymer chain immobilization rates on holographic recording in photopolymers.. Journal of the Optical Society of America A 2016, 33, 920-929, 10.1364/josaa.33.000920.

- Michael R. Gleeson; John T. Sheridan; Friedrich-Karl Bruder; Thomas Rölle; Horst Berneth; Marc-Stephan Weiser; Thomas Fäcke; Comparison of a new self developing photopolymer with AA/PVA based photopolymer utilizing the NPDD model.. Optics Express 2011, 19, 26325-26342, 10.1364/oe.19.026325.

- David Jurbergs; Friedrich-Karl Bruder; Francois Deuber; Thomas Fäcke; Rainer Hagen; Dennis Hönel; Thomas Rölle; Marc-Stephan Weiser; Andy Volkov; New recording materials for the holographic industry. SPIE OPTO: Integrated Optoelectronic Devices 2009, 7233, 72330-72330, 10.1117/12.809579.

- Sylvia H. Stevenson; DuPont multicolor holographic recording films. Electronic Imaging '97 1997, 3011, 231-241, 10.1117/12.271356.

- Hoda Akbari; Izabela Naydenova; Suzanne Martin; Using acrylamide-based photopolymers for fabrication of holographic optical elements in solar energy applications. Applied Optics 2014, 53, 1343-1353, 10.1364/ao.53.001343.

- David C. Miller; Sarah R. Kurtz; Durability of Fresnel lenses: A review specific to the concentrating photovoltaic application. Solar Energy Materials and Solar Cells 2011, 95, 2037-2068, 10.1016/j.solmat.2011.01.031.

- Paul Schissel; Gary Jorgensen; Cheryl Kennedy; Rita Goggin; Silvered-PMMA reflectors. Solar Energy Materials and Solar Cells 1994, 33, 183-197, 10.1016/0927-0248(94)90207-0.

- Joyce A. Dever; Bruce A. Banks; Li Yan; Effects of Vacuum Ultraviolet Radiation on DC93-500 Silicone. Journal of Spacecraft and Rockets 2006, 43, 386-392, 10.2514/1.15226.

- R. A. Vaia; C. L. Dennis; L. V. Natarajan; V. P. Tondiglia; D. W. Tomlin; T. J. Bunning; One-Step, Micrometer-Scale Organization of Nano- and Mesoparticles Using Holographic Photopolymerization: A Generic Technique. Advanced Materials 2001, 13, 1570-1574, 10.1002/1521-4095(200110)13:20<1570::aid-adma1570>3.0.co;2-x.

- Lei Zhao; Jun-He Han; Ruo-Ping Li; Long-Ge Wang; Ming-Ju Huang; Resisting shrinkage properties of volume holograms recorded in TiO 2 nanoparticle-dispersed acrylamide-based photopolymer. Chinese Physics B 2013, 22, 124207, 10.1088/1674-1056/22/12/124207.

- Naoaki Suzuki; Yasuo Tomita; Kentaroh Ohmori; Motohiko Hidaka; Katsumi Chikama; Highly transparent ZrO2nanoparticle-dispersed acrylate photopolymers for volume holographic recording. Optics Express 2006, 14, 12712-12719, 10.1364/oe.14.012712.

- Mohesh Moothanchery; Izabela Naydenova; Svetlana Mintova; Vincent Toal; Nanozeolites doped photopolymer layers with reduced shrinkage.. Optics Express 2011, 19, 25786-25791, 10.1364/oe.19.025786.

- P. Cheben; T. Belenguer; A. Nunez; F. Del Monte; David Levy; Holographic diffraction gratings recording in organically modified silica gels. Optics Letters 1996, 21, 1857-1859, 10.1364/ol.21.001857.

- G. Bianco; Maria Antonietta Ferrara; Fabio Borbone; A. Roviello; V. Pagliarulo; S. Grilli; P. Ferraro; V. Striano; G. Coppola; Volume holographic gratings: fabrication and characterization. Holography 2015, 9508, 950807, 10.1117/12.2179121.

- G. Bianco; Maria Antonietta Ferrara; Fabio Borbone; A. Roviello; V. Striano; G. Coppola; Photopolymer-based volume holographic optical elements: design and possible applications. Journal of the European Optical Society-Rapid Publications 2015, 10, 15057-1–15057-3, 10.2971/jeos.2015.15057.

- Jacques E. Ludman; Holographic solar concentrator. Applied Optics 1982, 21, 3057-3058, 10.1364/ao.21.003057.

- Klaus Froehlich; Ernst Ulrich Wagemann; H. Schulat; Hartmut Schuette; Christo G. Stojanoff; Fabrication and test of a holographic concentrator for two-color PV operation. Optical Materials Technology for Energy Efficiency and Solar Energy Conversion XIII 1994, 2255, 812-822, 10.1117/12.185419.

- Jacques E. Ludman; Juanita Riccobono; Irina V. Semenova; Nadya O. Reinhand; William Tai; Xaoli Li; Geof Syphers; Evangelos Rallis; Guy Sliker; José Martín; et al. The optimization of a holographic system for solar power generation. Solar Energy 1997, 60, 1-9, 10.1016/s0038-092x(96)00148-x.

- aSolarus . Bifacial Solar PV. Retrieved 2021-6-9

This entry is offline, you can click here to edit this entry!