Solid oxide fuel cells (SOFCs) are promising and rugged solid-state power sources that can directly and electrochemically convert the chemical energy into electric power. Direct-hydrocarbon SOFCs eliminate the external reformers; thus, the system is significantly simplified and the capital cost is reduced. To reduce operating temperatures of SOFCs, intermediate-temperature proton-conducting SOFCs (P-SOFCs) are being developed as alternatives, which give rise to superior power densities, coking and sulfur tolerance, and durability. Due to these advances, there are growing efforts to implement proton-conducting oxides to improve durability of direct-hydrocarbon SOFCs.

- proton-conducting oxides

- direct-hydrocarbons SOFCs

- coking

- durability

1. Introduction

2. Proton-Conducing Oxides

The protons are produced via hydration [31], as shown in Equation (1), where Kröger–Vink notation is used to describe oxygen vacancy V∙∙O, lattice oxygen OXO and proton. This defect reaction indicates oxygen vacancies are required for the formation of protons OH∙O; thus, oxygen vacancy concentration is normally increased by the acceptor doping to improve the proton conductivity, i.e., the substitution of the Zr4+ or Ce4+ host with trivalent dopants (e.g., Y3+/Yb3+).

In the 1980s, Iwahara et al. first recognized that BCY is a proton conductor [15]. However, it was noted that BCY is chemically unstable in the presence of water and carbon dioxide [31,36]. Their poor chemical stability hinders their practical applications and much attention has been shifted to zirconate-based proton conductors, especially BZY, due to their enhanced chemical stability [16]. However, with the increased concentration of Zr4+, its poor sintering ability tends to be a thorny issue. Additionally, BZY displays high grain boundary resistance, resulting in lower proton conductivity than BCY [31]. The researchers, therefore, developed BCZY by synergizing the benefits of both BZY and BCY, improving conductivity and stability [16]. Liu et al. demonstrated that BaCe0.7Zr0.1Y0.2O3 possesses improved chemical stability under 2% CO2 and 15% H2O atmosphere and enhanced conductivity (9 × 10−3 S cm−1) at 500 °C [17]. The same team then pioneered a novel proton conductor, BaCe0.7Zr0.1Y0.1Yb0.1O3 [18], leading to benchmarking proton conductivity and stability under hydrocarbons with hydrogen sulfide.

To tackle the issues associated with sintering, a sintering aid (e.g., ZnO) was added to facilitate the densification and lower the sintering temperatures, increasing the feasibility of using proton-conducting oxides for building fuel cells [37]. A variety of other sintering aids, including NiO and CuO, have also been investigated for fabricating proton-conducting oxides [38]. In 2015, Duan and O’Hayre et al. [22] applied the solid-state reactive sintering method to P-SOFCs fabrication and demonstrated P-SOFCs with remarkable performances and durability with both hydrogen and methane as fuels.

3. Unique Surface Properties of Proton-Conducting Oxides

4. The Rationale for Developing Direct-Hydrocarbon P-SOFCs

-

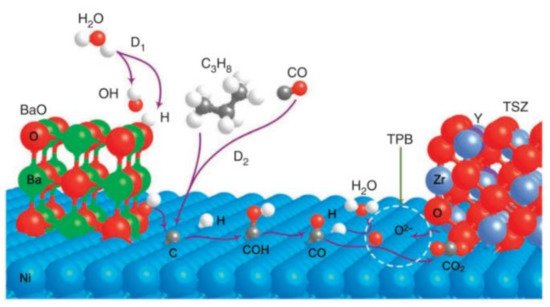

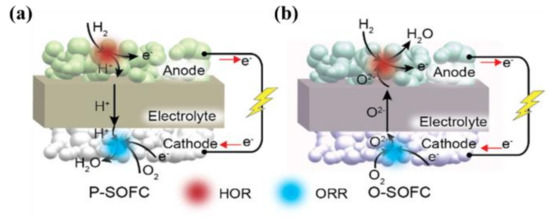

Unlike O-SOFCs (Figure 2b), as illustrated in Figure 2a, P-SOFCs can produce water in the cathode, which will not dilute the fuel stream, potentially improving the performances, enhancing fuel utilization, and reducing system complexity and cost (that is, no external condenser required for condensing water and recycling fuel), as well as enhancing overall energy efficiency [4][41].

-

Intermediate-temperature P-SOFCs (500–600 °C) enable significantly higher efficiency than low temperature (50–100 °C) PEMFCs and can approach that of HT-SOFCs (700–900 °C) [42][43]. Reduced operating temperatures (versus O-SOFCs) enable the relaxing of the stack and balance-of-plant constraints, potentially lowering the cost while also improving the reliability, thermal cycling tolerance, and dynamic response.

-

High hydrocarbon conversion could be achieved in the P-SOFCs because of the continuous removal of hydrogen from the anode which shifts the reaction equilibriums of steam reforming and water gas shift reaction [22].

-

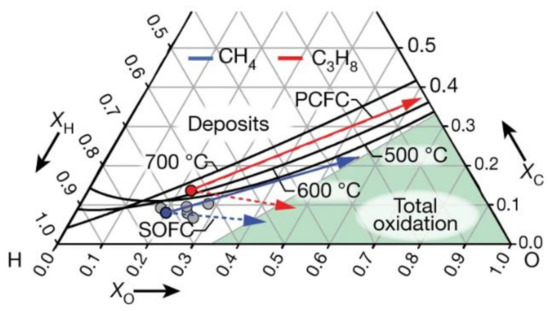

As shown in Figure 3 [20], the composition of P-SOFC anode gas stream lies in the thermodynamic coking boundary of the whole reaction range or just outside it. On the contrary, with increasing the fuel utilization, the composition of anode gas steam in O-SOFC moves away from the coking boundary rapidly. However, the experimental studies of P-SOFCs contradicts the thermodynamic predictions [20][22][34][40], which is due to unique surface properties of proton-conducting oxides. P-SOFCs are therefore coking and sulfur tolerant, and highly active for internal reforming.

5. Notable Achievements on Coking-Tolerant Direct-Hydrocarbon P-SOFCs

|

Year |

Anode/ Electrolye/ Cathode |

Fuel |

Peak Power Density (mW cm−2) |

Stability |

Reference |

|---|---|---|---|---|---|

|

2003 |

Ni/BCY/Pt |

CH4 |

~13 at 700 °C |

- |

[44] |

|

2008 |

Pt/BCY/Pt |

C3H8 |

~43 at 650 °C |

- |

[2] |

|

2015 |

Ni-BZY20/ BZY20/ BCFZY |

28.6% CH4+ 71.4% H2O |

142 at 500 °C |

No degredation for 200 h, 0.15 A cm−2 at 500 °C |

[22] |

|

2016 |

Ni-BCZY/ BCZY/ PSCFM |

C2H6 |

120 at 650 °C 349 at 750 °C |

No degredation for 200 h, 0.65 A cm−2 at 750 °C |

[46] |

|

2016 |

Ni-BCZYYb/ BCZYYb/ BCZY-LSCF |

CH4 (3% H2O) |

800 at 650 °C 560 at 600 °C 320 at 550 °C |

No degradation for 200 h, 0.50 A cm−2 at 550 °C |

[47] |

|

2016 |

PBMn-Ni- BCZYYb/ BCZYYb/ BCZY+ NBCCo |

50% CH4 +50% CO2 |

560 at 700 °C |

No degradation for 36 h, 1.0 A cm−2 at 700 °C |

[39] |

|

2017 |

Ni-BCZYYb/BZCY-LSGM/BZCY-LSCF |

Humidified 60% CH4+ 40% CO2 |

210 at 500 °C 320 at 550 °C 560 at 600 °C |

No degradation for 80 h, 1.5 A cm−2 at 650 °C |

[48] |

|

2018 |

Ni-BZY/ BZY/BCFZY |

Natural gas with 19.5 p.p.m. H2S impurity |

372 at 600 °C |

~10% degradation for 1000 h, 0.25 A cm−2 at 500 °C |

[20] |

|

2018 |

Ni-BZY/BZY/ LSCF-PNM |

33% CH4 + 33% H2O + 33% N2 |

55 at 550 °C 96 at 600 °C 132 at 650 °C |

No degradation for 20 h, 0.6 V at 550 °C |

[49] |

This entry is adapted from the peer-reviewed paper 10.3390/su13094736

References

- Lelieveld, J.; Klingmüller, K.; Pozzer, A.; Burnett, R.T.; Haines, A.; Ramanathan, V. Effects of fossil fuel and total anthropogenic emission removal on public health and climate. Proc. Natl. Acad. Sci. USA 2019, 116, 7192.

- Feng, Y.; Luo, J.; Chuang, K.T. Propane Dehydrogenation in a Proton-conducting Fuel Cell. J. Phys. Chem. C 2008, 112, 9943–9949.

- Abdelkareem, M.A.; Elsaid, K.; Wilberforce, T.; Kamil, M.; Sayed, E.T.; Olabi, A. Environmental aspects of fuel cells: A review. Sci. Total Environ. 2021, 752, 141803.

- O’hayre, R.; Cha, S.-W.; Colella, W.; Prinz, F.B. Fuel Cell Fundamentals; John Wiley & Sons: Hoboken, NJ, USA, 2016.

- Abdalla, A.M.; Hossain, S.; Petra, P.M.; Ghasemi, M.; Azad, A.K. Achievements and trends of solid oxide fuel cells in clean energy field: A perspective review. Front. Energy 2020, 14, 359–382.

- Steele, B.C.H.; Heinzel, A. Materials for fuel-cell technologies. Nature 2001, 414, 345–352.

- McIntosh, S.; Gorte, R.J. Direct Hydrocarbon Solid Oxide Fuel Cells. Chem. Rev. 2004, 104, 4845–4866.

- Yue, W.; Li, Y.; Zheng, Y.; Wu, T.; Zhao, C.; Zhao, J.; Geng, G.; Zhang, W.; Chen, J.; Zhu, J.; et al. Enhancing coking resistance of Ni/YSZ electrodes: In situ characterization, mechanism research, and surface engineering. Nano Energy 2019, 62, 64–78.

- Viinikainen, T.; Rönkkönen, H.; Bradshaw, H.; Stephenson, H.; Airaksinen, S.; Reinikainen, M.; Simell, P.; Krause, O. Acidic and basic surface sites of zirconia-based biomass gasification gas clean-up catalysts. Appl. Catal. A Gen. 2009, 362, 169–177.

- Boldrin, P.; Ruiz-Trejo, E.; Mermelstein, J.; Bermúdez Menéndez, J.M.; Ramírez Reina, T.; Brandon, N.P. Strategies for Carbon and Sulfur Tolerant Solid Oxide Fuel Cell Materials, Incorporating Lessons from Heterogeneous Catalysis. Chem. Rev. 2016, 116, 13633–13684.

- Skafte, T.L.; Blennow, P.; Hjelm, J.; Graves, C. Carbon deposition and sulfur poisoning during CO2 electrolysis in nickel-based solid oxide cell electrodes. J. Power Sources 2018, 373, 54–60.

- Wei, K.; Wang, X.; Budiman, R.A.; Kang, J.; Lin, B.; Zhou, F.; Ling, Y. Progress in Ni-based anode materials for direct hydrocarbon solid oxide fuel cells. J. Mater. Sci. 2018, 53, 8747–8765.

- Wang, W.; Qu, J.; Julião, P.S.B.; Shao, Z. Recent Advances in the Development of Anode Materials for Solid Oxide Fuel Cells Utilizing Liquid Oxygenated Hydrocarbon Fuels: A Mini Review. Energy Technol. 2019, 7, 33–44.

- Da Silva, F.S.; de Souza, T.M. Novel materials for solid oxide fuel cell technologies: A literature review. Int. J. Hydrogrn Energy 2017, 42, 26020–26036.

- Iwahara, H.; Uchida, H.; Ono, K.; Ogaki, K. Proton Conduction in Sintered Oxides Based on BaCeO3. J. Electrochem. Soc. 1988, 135, 529–533.

- Katahira, K.; Kohchi, Y.; Shimura, T.; Iwahara, H. Protonic conduction in Zr-substituted BaCeO3. Solid State Ion. 2000, 138, 91–98.

- Zuo, C.; Zha, S.; Liu, M.; Hatano, M.; Uchiyama, M. Ba(Zr0.1Ce0.7Y0.2)O3–δ as an Electrolyte for Low-Temperature Solid-Oxide Fuel Cells. Adv. Mater. 2006, 18, 3318–3320.

- Yang, L.; Wang, S.; Blinn, K.; Liu, M.; Liu, Z.; Cheng, Z.; Liu, M. Enhanced Sulfur and Coking Tolerance of a Mixed Ion Conductor for SOFCs: BaZr0.1Ce0.7Y0.2−xO3−δ. Science 2009, 326, 126.

- Choi, S.; Kucharczyk, C.J.; Liang, Y.; Zhang, X.; Takeuchi, I.; Ji, H.-I.; Haile, S.M. Exceptional power density and stability at intermediate temperatures in protonic ceramic fuel cells. Nat. Energy 2018, 3, 202–210.

- Duan, C.; Kee, R.J.; Zhu, H.; Karakaya, C.; Chen, Y.; Ricote, S.; Jarry, A.; Crumlin, E.J.; Hook, D.; Braun, R.; et al. Highly durable, coking and sulfur tolerant, fuel-flexible protonic ceramic fuel cells. Nature 2018, 557, 217–222.

- Fabbri, E.; Pergolesi, D.; Traversa, E. Materials challenges toward proton-conducting oxide fuel cells: A critical review. Chem. Soc. Rev. 2010, 39, 4355–4369.

- Duan, C.; Tong, J.; Shang, M.; Nikodemski, S.; Sanders, M.; Ricote, S.; Almansoori, A.; O’Hayre, R. Readily processed protonic ceramic fuel cells with high performance at low temperatures. Science 2015, 349, 1321.

- Mogensen, M.; Kammer, K. Conversion of Hydrocarbons in Solid Oxide Fuel Cells. Annu. Rev. Mater. Res. 2003, 33, 321–331.

- Kee, R.J.; Zhu, H.; Goodwin, D.G. Solid-oxide fuel cells with hydrocarbon fuels. Proc. Combust. Inst. 2005, 30, 2379–2404.

- Ge, X.-M.; Chan, S.-H.; Liu, Q.-L.; Sun, Q. Solid Oxide Fuel Cell Anode Materials for Direct Hydrocarbon Utilization. Adv. Energy Mater. 2012, 2, 1156–1181.

- Saadabadi, S.A.; Thallam Thattai, A.; Fan, L.; Lindeboom, R.E.F.; Spanjers, H.; Aravind, P.V. Solid Oxide Fuel Cells fuelled with biogas: Potential and constraints. Renew. Energy 2019, 134, 194–214.

- Mohammed, H.; Al-Othman, A.; Nancarrow, P.; Tawalbeh, M.; El Haj Assad, M. Direct hydrocarbon fuel cells: A promising technology for improving energy efficiency. Energy 2019, 172, 207–219.

- Gür, T.M. Comprehensive review of methane conversion in solid oxide fuel cells: Prospects for efficient electricity generation from natural gas. Prog. Energy Combust. Sci. 2016, 54, 1–64.

- Wang, W.; Su, C.; Wu, Y.; Ran, R.; Shao, Z. Progress in Solid Oxide Fuel Cells with Nickel-Based Anodes Operating on Methane and Related Fuels. Chem. Rev. 2013, 113, 8104–8151.

- Meng, Y.; Gao, J.; Zhao, Z.; Amoroso, J.; Tong, J.; Brinkman, K.S. Review: Recent progress in low-temperature proton-conducting ceramics. J. Mater. Sci. 2019, 54, 9291–9312.

- Fabbri, E.; Bi, L.; Pergolesi, D.; Traversa, E. Towards the Next Generation of Solid Oxide Fuel Cells Operating Below 600 °C with Chemically Stable Proton-Conducting Electrolytes. Adv. Mater. 2012, 24, 195–208.

- Duan, C.; Huang, J.; Sullivan, N.; O’Hayre, R. Proton-conducting oxides for energy conversion and storage. Appl. Phys. Rev. 2020, 7, 011314.

- Konwar, D.; Nguyen, N.T.Q.; Yoon, H.H. Evaluation of BaZr0.1Ce0.7Y0.2O3−δ electrolyte prepared by carbonate precipitation for a mixed ion-conducting SOFC. Int. J. Hydrogen Energy 2015, 40, 11651–11658.

- Chen, Y.; deGlee, B.; Tang, Y.; Wang, Z.; Zhao, B.; Wei, Y.; Zhang, L.; Yoo, S.; Pei, K.; Kim, J.H.; et al. A robust fuel cell operated on nearly dry methane at 500 °C enabled by synergistic thermal catalysis and electrocatalysis. Nat. Energy 2018, 3, 1042–1050.

- Ormerod, R.M. Solid oxide fuel cells. Chem. Soc. Rev. 2003, 32, 17–28.

- Takeguchi, T.; Kani, Y.; Yano, T.; Kikuchi, R.; Eguchi, K.; Tsujimoto, K.; Uchida, Y.; Ueno, A.; Omoshiki, K.; Aizawa, M. Study on steam reforming of CH4 and C2 hydrocarbons and carbon deposition on Ni-YSZ cermets. J. Power Sources 2002, 112, 588–595.

- Yang, L.; Choi, Y.; Qin, W.; Chen, H.; Blinn, K.; Liu, M.; Liu, P.; Bai, J.; Tyson, T.A.; Liu, M. Promotion of water-mediated carbon removal by nanostructured barium oxide/nickel interfaces in solid oxide fuel cells. Nat. Commun. 2011, 2, 357.

- Li, X.; Liu, M.; Lai, S.Y.; Ding, D.; Gong, M.; Lee, J.-P.; Blinn, K.S.; Bu, Y.; Wang, Z.; Bottomley, L.A.; et al. In Situ Probing of the Mechanisms of Coking Resistance on Catalyst-Modified Anodes for Solid Oxide Fuel Cells. Chem. Mater. 2015, 27, 822–828.

- Hua, B.; Yan, N.; Li, M.; Sun, Y.-F.; Zhang, Y.-Q.; Li, J.; Etsell, T.; Sarkar, P.; Luo, J.-L. Anode-Engineered Protonic Ceramic Fuel Cell with Excellent Performance and Fuel Compatibility. Adv. Mater. 2016, 28, 8922–8926.

- Wang, W.; Chen, Y.; Wang, F.; Tade, M.O.; Shao, Z. Enhanced electrochemical performance, water storage capability and coking resistance of a Ni+BaZr0.1Ce0.7Y0.1Yb0.1O3−δ anode for solid oxide fuel cells operating on ethanol. Chem. Eng. Sci. 2015, 126, 22–31.

- Marrony, M. Proton-Conducting Ceramics: From Fundamentals to Applied Research; CRC Press: Boca Raton, FL, USA, 2015.

- Zhu, H.; Braun, R.J.; Kee, R.J. Thermodynamic Analysis of Energy Efficiency and Fuel Utilization in Protonic-Ceramic Fuel Cells with Planar Co-Flow Configurations. J. Electrochem. Soc. 2018, 165, F942–F950.

- Duan, C.; Kee, R.; Zhu, H.; Sullivan, N.; Zhu, L.; Bian, L.; Jennings, D.; O’Hayre, R. Highly efficient reversible protonic ceramic electrochemical cells for power generation and fuel production. Nat. Energy 2019, 4, 230–240.

- Coors, W.G. Protonic ceramic fuel cells for high-efficiency operation with methane. J. Power Sources 2003, 118, 150–156.

- Feng, Y.; Luo, J.-L.; Chuang, K.T. Carbon deposition during propane dehydrogenation in a fuel cell. J. Power Sources 2007, 167, 486–490.

- Liu, S.; Chuang, K.T.; Luo, J.-L. Double-Layered Perovskite Anode with in Situ Exsolution of a Co–Fe Alloy To Cogenerate Ethylene and Electricity in a Proton-Conducting Ethane Fuel Cell. ACS Catal. 2016, 6, 760–768.

- Hua, B.; Yan, N.; Li, M.; Zhang, Y.-Q.; Sun, Y.-F.; Li, J.; Etsell, T.; Sarkar, P.; Chuang, K.; Luo, J.-L. Novel layered solid oxide fuel cells with multiple-twinned Ni0.8Co0.2 nanoparticles: The key to thermally independent CO2 utilization and power-chemical cogeneration. Energy Environ. Sci. 2016, 9, 207–215.

- Konwar, D.; Park, B.J.; Basumatary, P.; Yoon, H.H. Enhanced performance of solid oxide fuel cells using BaZr0.2Ce0.7Y0.1O3−δ thin films. J. Power Sources 2017, 353, 254–259.

- Lei, L.; Keels, J.M.; Tao, Z.; Zhang, J.; Chen, F. Thermodynamic and experimental assessment of proton conducting solid oxide fuel cells with internal methane steam reforming. Appl. Energy 2018, 224, 280–288.

- Li, M.; Hua, B.; Luo, J.-L.; Jiang, S.P.; Pu, J.; Chi, B.; Li, J. Enhancing Sulfur Tolerance of Ni-Based Cermet Anodes of Solid Oxide Fuel Cells by Ytterbium-Doped Barium Cerate Infiltration. ACS Appl. Mater. Interfaces 2016, 8, 10293–10301.

- Li, M.; Hua, B.; Luo, J.-L.; Jiang, S.P.; Pu, J.; Chi, B.; Jian, L. Carbon-tolerant Ni-based cermet anodes modified by proton conducting yttrium- and ytterbium-doped barium cerates for direct methane solid oxide fuel cells. J. Mater. Chem. A 2015, 3, 21609–21617.