Modern-day machine applications require extraordinary performance parameters such as high power-density, integrated functionalities, improved thermal, mechanical & electromagnetic properties. Additive manufacturing (AM)offers a higher degree of design flexibility to achieve these performance parameters, which is impossible to realize through conventional manufacturing techniques.

- additive manufacturing

- conventional electrical machines

- non-conventional electrical machines

- asymmetry in machines

- metal 3D-printing

- future electrical machines

- electrical machine design

1. Introduction

Additive manufacturing (AM) or 3D-printing is an all-encompassing terminology used for the processes where the manufacturing is done in layers, rendered from the digital model of a specific item or assembly. Recently, there has been a growing interest in the field of AM as it has emerged as an alternative manufacturing process, offering virtually unlimited potential for a wide range of industrial and special-purpose applications [1]. The AM offers various benefits over other conventional manufacturing processes, such as realizing complex/special purpose geometries, a wide range of multi-material usage possibilities, and rapid prototyping.

Due to the promising aspects of what it has to offer, AM has also attracted interest from the electrical machines’ manufacturing point of view. For electrical machines, as compared to the conventional manufacturing processes, the AM process has not yet progressed to an advanced stage. With the ongoing advances in the field of AM, it would soon find its place as the better alternative for electrical machines’ manufacturing. This is due to the fact that flexibility in design possibilities offered by employing AM, such as integration of structural and thermal management components with the active parts, make it the best solution for a wide range of applications such as special-purpose machines for aerospace, medical, robotics and automotive industry where high power-density, ruggedness, and compact structure is required. With the forecasted improvements in the field of AM, the manufacturability and performance of electrical machines could be significantly improved.

2. Trends of AM in Construction of Electrical Machines

When considering AM for electrical machines, it offers virtually unlimited possibilities from prototyping to mass-personalized production. Employment of AM in production of electrical machines is a promising aspect offering various benefits over conventional manufacturing techniques, such as; realization of 3D-designs (including electrical, magnetic, mechanical and thermal considerations) [2], recyclable constructions [3] and optimal material utilization. Basic and standardized AM techniques for manufacturing processes have been described in [4][5] almost all of which have been used in manufacturing electrical machines or its parts, at various instances [6][7][8]. Among all the AM processes, selective laser melting (SLM), fused deposition modeling (FDM) and binder jet printing (BJP) technology are the ones shown to be most promising for the manufacturing of electrical machines [9].

2.1. Part-Wise Approach

From design and manufacturing point of view, any electrical machine can be subdivided into two basic subassemblies; active parts like core, coils/windings, PMs and the passive parts like thermal management components, mechanical assemblies. The research and development is progressing with a significant pace on both fronts with industrial implementations actually ahead of what is reflected in the research literature [6][10][11].

2.2. Holistic Approach

It is only very recently that there has been emphasis on AM of electrical machines. That is why the technological developments and achievements in this field are relatively immature, however, research is progressing at a significant pace regarding the employment of AM in manufacturing electrical machines. Scientific research is a step-wise process so naturally, as a rule of thumb; research efforts were initially focused on the application of AM to produce individual machine components.

3. Future Prospects of Holistic Approach

As presented in previous sections, efforts have resulted in varied level of progress towards production of additively manufactured machine parts; with development in production/integration of thermal management and mechanical assemblies ahead from the production of active parts (core, coils/windings and the permanent magnets). However, to manufacture a fully additively manufactured electrical machine, very little has been done. It is now that the researchers are entertaining the idea of holistic manufacturing of electrical machines through AM and the most natural step forward seems to direct the efforts towards a comprehensive design approach, keeping in view the current state-of-the-art in this field.

3.1. Conventional/Symmetrical Electrical Machines

Conventional machines such as induction and synchronous machines have a widespread use for bulk energy conversion. Usually, they are simple/symmetrical in design and large in size. Industrial manufacturing of such machines, at present, is most feasible with conventional methods owing to the fact that resultant performance parameters obtained are very much mature and offer best results corresponding to operational requirement, cost and time for in-volume production. Employment of AM in industrial production of such machines is hindered, due to the following factors;

-

limitation on the overall size which can be realized with AM at present i.e., relatively small print-bed size

-

relatively less maturity regarding electromagnetic properties of AM materials

-

associated production cost and time

Efforts are being put into these aspects, by researchers and various industries. Until this gap is filled-in, employment of AM in industrial manufacturing of conventional/symmetrical electrical machines is limited mostly to;

-

rapid prototyping

-

production of individual machine parts having application specific complex geometries which are impossible to manufacture otherwise

3.2. Non-Conventional/Asymmetrical Electrical Machines

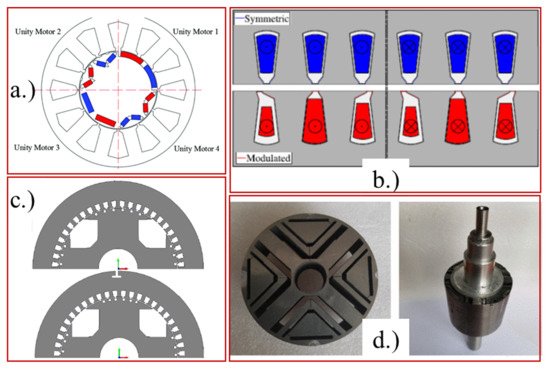

Research work to exploit alternative asymmetrical/non-conventional machine designs is under process by various researchers. Design examples such as those presented in [12][13][14][15][16][17][18][19][20][21] highlight the benefits of introducing asymmetry based on; unity motor asymmetry concept, repositioning of slot openings per-pole-per-phase, altering position of embedded bars on adjacent rotor poles and asymmetrical rotor configuration. Figure 1 presents pictorial representation for such examples and Table 1 showcases various benefits achieved from introduction of asymmetry in design. The associated disadvantages include unbalanced magnetic-pull and increased complexity in design which are needed to be considered during the design process.

Figure 1. Concept of; (a) unity-motor asymmetry in rotor [13] (b) asymmetric slot-opening pattern (induction motor) [19] (c) asymmetric damper-cage topology (synchronous generator) [19] (d) hybrid-pole IPM machine with an asymmetrical magnet configuration in rotor [21].

Table 1. Introduction of asymmetry in machine design with corresponding benefits.

| Type of Asymmetry | Machine type | References | Investigated Performance-Parameter of Interest |

Improvement in Performance Parameter |

|---|---|---|---|---|

| Unity-motor asymmetry |

PM motor | [13] |

|

39.8% reduction 56.6% reduction 81.1% reduction in position error |

| Asymmetric slot-opening pattern |

Induction Motor | [19] |

|

63% reduction |

| Asymmetric damper cage |

Synchronous Generator | [19] |

|

54% improvement |

| Asymmetric flux-barriers configuration in rotor | Synchronous Reluctance Machine | [20] |

|

9.6% increase 22.4% increase 2.3% increase |

| Asymmetrical magnet arrangement in rotor |

Hybrid Pole Interior-PM Machine | [21] |

|

40.9% reduction 28.9 % increase |

4. Potential Candidate Machines for AM

These machines can be further classified into various types depending upon individual construction, application/utilization, performance characteristics and the control schemes involved. A no. of such machines with respect to their design, working principle, performance parameters and utilization will be discussed, in order to narrow down the machine selection for intended design of AM-built electrical machine. The selection of candidate machine types for AM is made while keeping in view following baselines:

-

Least involvement of multi-material utilization

-

Machine topology and design parameters falling within the constraints of present stage AM-capabilities

-

Have the maximum chance of exploiting present stage AM capability to realize complex geometries, which is not possible otherwise.

Another classification that offers potential benefits of AM-utilization is the axial flux topology in electrical machines. Axial flux machines have a few pros over radial flux machines, due to which they deliver significantly high power-density.

4.1. Switched Reluctance Machines (SRM)

These machines offer attractive qualities of high torque and a wide range of operating speed. By controlling switching sequence together with an appropriate electromagnetic design, the torque-speed characteristics of the SRMs can be made suitable for various traction applications in automotive industry. Furthermore, by simply changing the control parameter selection with torque and speed, a given machine design can offer different characteristics. On the other side, the complex control scheme due to on-line parameter variation, noise and vibration are some of its associated issues [22][23].

4.2. Synchronous Reluctance Machine (SynRM)

The synchronous reluctance machine (SynRM) has the advantage of relatively simple construction and low moment of inertia of rotor which gives fast response characteristic and high torque density but as the name suggests, it is essentially a constant-speed machine dependent on supply frequency. The speed control can be achieved over a wide range by employing frequency control scheme. These types of machines are widely used in proportioning devices, synthetic-fibre manufacturing industries, wrapping and folding machines, positioning of control rods in nuclear industries, industrial drive systems requiring synchronized and continuous processes. Potential use of such machines for traction purposes is also reported [24][25][26].

4.3. Claw-Pole Machines

Claw-pole machines (CPM) having electrically excited claw-pole DC fields, yield higher torque density of up-to three times higher than conventional machines. This is mainly due to their ability to produce 3D-hetropolar magnetic field from single-coil excitation within claw-pole halves. The benefit of higher torque density, makes CPM an ideal candidate for a wide range of applications requiring size compactness like in automobile alternators, medium-sized household appliances etc. These machines have a complex design that is not easily realizable using conventional electrical-steel lamination construction and the use of SMCs has shown to be most advantageous regarding the manufacturing purposes [27][28].

4.4. Hysteresis Motors

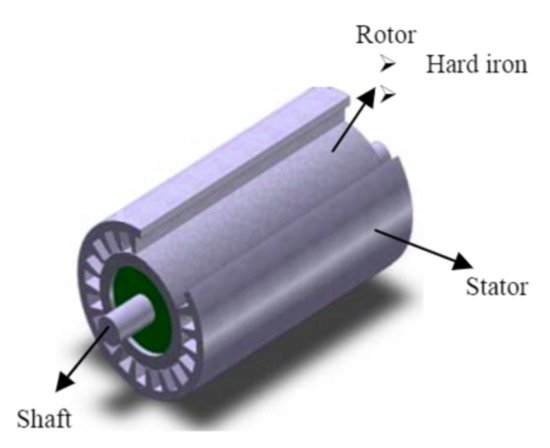

A hysteresis motor is essentially a synchronous motor without the DC excitation. The interaction of rotating stator flux with that of remnant flux (due to hysteresis effect which is normally not desirable in other machines), produces torque. These machines offer constant torque from initial to synchronous speed with the ability to accelerate and synchronize high-inertia loads. However, due to its operation being mainly based on the hysteresis losses, its power factor and torque/volume ratio is low [29]. Still, these machines are useful in low power applications where constant speed and low torque ripple are the main required characteristics such as; precision equipment, clocks, hard disks and gyroscopes etc. [30]. Their construction is relatively simple with a solid rotor of hard-magnetic material. The stator is of slotted construction; to house single or poly-phase windings that produce rotating flux. Figure 2 illustrates the hysteresis motor construction concept [31].

Figure 2. Illustration of hysteresis motor construction [31].

This entry is adapted from the peer-reviewed paper 10.3390/en14071940

References

- Dilberoglu, U.M.; Gharehpapagh, B.; Yaman, U.; Dolen, M. The Role of Additive Manufacturing in the Era of Industry 4.0. Procedia Manuf. 2017, 11, 545–554.

- Aguilera, E.; Ramos, J.; Espalin, D.; Cedillos, F.; Muse, D.; Wicker, R.; MacDonald, E. 3D Printing of Electro Mechanical Systems. In Proceedings of the Solid Freeform Fabrication Symposium, Austin, TX, USA, 12–14 August 2013.

- Hiller, J.D.; Lipson, H. Fully Recyclable Multi-Material Printing. In Proceedings of the Solid Freeform Fabrication, Austin, TX, USA, 3–5 August 2009.

- Wrobel, R.; Mecrow, B.C. A Comprehensive Review of Additive Manufacturing in Construction of Electrical Machines. IEEE Trans. Energy Convers. 2020, 35, 1054–1064.

- Tiismus, H.; Kallaste, A.; Vaimann, T.; Rassolkin, A.; Belahcen, A. Technologies for Additive Manufacturing of Electrical Machines. In Proceedings of the 2019 20th International Conference of Young Specialists on Micro/Nanotechnologies and Electron Devices (EDM), Erlagol, Russia, 29 June–3 July 2019; Volume 2019, pp. 651–655.

- Lorenz, F.; Rudolph, J.; Wemer, R. Design of 3D Printed High Performance Windings for Switched Reluctance Machines. In Proceedings of the 2018 23rd International Conference on Electrical Machines (ICEM), Alexandroupoli, Greece, 3–6 September 2018; pp. 2451–2457.

- Wu, F.; El-Refaie, A.M. toward Additively Manufactured Electrical Machines: Opportunities and Challenges. IEEE Trans. Ind. Appl. 2020, 56, 1306–1320.

- Paranthaman, M.P.; Yildirim, V.; Lamichhane, T.N.; Begley, B.A.; Post, B.K.; Hassen, A.A.; Sales, B.C.; Gandha, K.; Nlebedim, I.C. Additive Manufacturing of Isotropic NdFeB PPS Bonded Permanent Magnets. Materials 2020, 13, 3319.

- Lamichhane, T.N.; Sethuraman, L.; Dalagan, A.; Wang, H.; Keller, J.; Paranthaman, M.P. Additive manufacturing of soft magnets for electrical machines—A review. Mater. Today Phys. 2020, 15, 100255.

- 3D-Multimaterialdruck | Professur Elektrische Energiewandlungssystem und Antriebe | Fakultät für Elektrotechnik und I… | TU Chemnitz. Available online: (accessed on 25 January 2021).

- Silbernagel, C. Submitted: Investigation of the Design, Manufacture and Testing of Additively Manufactured Coils for Electric Motor Applications. 2019. Available online: (accessed on 25 January 2021).

- Nemec, M.; Makuc, D.; Ambrozic, V.; Fiser, R. Simplified model of induction machine with electrical rotor asymmetry. In Proceedings of the XIX International Conference on Electrical Machines—ICEM 2010, Rome, Italy, 6–8 September 2010.

- Sun, X.; Sizov, G.; Melfi, M. Asymmetrical Design in Electrical Machines. In Proceedings of the 2019 IEEE Energy Conversion Congress and Exposition (ECCE), Baltimore, MD, USA, 29 September–3 October 2019; pp. 3786–3792.

- Chen, Q.; Shi, X.; Xu, G.; Zhao, W. Torque calculation of five-phase synchronous reluctance motors with shifted-asymmetrical-salient-poles under saturation condition. China Electrotech. Soc. Trans. Electr. Mach. Syst. 2020, 4, 105–113.

- Caruso, M.; Cecconi, V.; Di Tommaso, A.O.; Miceli, R.; Nevoloso, C. Performance Comparison of Electrical Motors equipped with slightly Asymmetrical Windings. In Proceedings of the 2019 AEIT International Conference of Electrical and Electronic Technologies for Automotive (AEIT AUTOMOTIVE), Torino, Italy, 2–4 July 2019.

- Ren, W.; Xu, Q.; Li, Q. Asymmetrical V-Shape Rotor Configuration of an Interior Permanent Magnet Machine for Improving Torque Characteristics. IEEE Trans. Magn. 2015, 51, 1–4.

- Sanada, M.; Hiramoto, K.; Morimoto, S.; Takeda, Y. Torque Ripple Improvement for Synchronous Reluctance Motor Using an Asymmetric Flux Barrier Arrangement. IEEE Trans. Ind. Appl. 2004, 40, 1076–1082.

- Wanjiku, J.; Khan, M.A.; Barendse, P.S.; Pillay, P. Influence of Slot Openings and Tooth Profile on Cogging Torque in Axial-Flux PM Machines. IEEE Trans. Ind. Electron. 2015, 62, 7578–7589.

- Nuzzo, S.; Marfoli, A.; Papini, L.; Bolognesi, P.; Gerada, C.; Galea, M. The potential of exploiting non-symmetric structures in electrical machines. In Proceedings of the IECON 2019 45th Annual Conference of the IEEE Industrial Electronics Society, Lisbon, Portugal, 14–17 October 2019; Volume 2019, pp. 1393–1398.

- Zhao, W.; Chen, D.; Lipo, T.A.; Kwon, B.-I. Performance Improvement of Ferrite-Assisted Synchronous Reluctance Machines Using Asymmetrical Rotor Configurations. IEEE Trans. Magn. 2015, 51, 1–4.

- Yang, H.; Wang, W.; Lin, H.; Zhu, Z.Q.; Lyu, S.; Niu, S. A Novel Hybrid-Pole Interior PM Machine with Magnet-Axis-Shifting Effect. In Proceedings of the 2019 IEEE International Electric Machines & Drives Conference (IEMDC), San Diego, CA, USA, 12–15 May 2019; pp. 273–279.

- Krishnamurthy, M.; Edrington, C.; Emadi, A.; Asadi, P.; Ehsani, M.; Fahimi, B. Making the case for applications of switched reluctance motor technology in automotive products. IEEE Trans. Power Electron. 2006, 21, 659–675.

- Edvarrd. Characteristics and Work Principles of Switched Reluctance (SR) Motor. 8 December 2014. Available online: (accessed on 3 February 2021).

- Ban, B.; Stipetic, S.; Klanac, M. Synchronous Reluctance Machines: Theory, Design and the Potential Use in Traction Applications. In Proceedings of the 2019 International Conference on Electrical Drives & Power Electronics (EDPE), The High Tatras, Slovakia, 24–26 September 2019; Volume 2019, pp. 177–188.

- Bianchi, N.; Bolognani, S.; Carraro, E.; Castiello, M.; Fornasiero, E. Electric Vehicle Traction Based on Synchronous Reluctance Motors. IEEE Trans. Ind. Appl. 2016, 52, 4762–4769.

- Jurca, F.N.; Mircea, R.; Martis, C.; Martis, R.; Florin, P.P. Synchronous reluctance motors for small electric traction vehicle. In Proceedings of the 2014 International Conference and Exposition on Electrical and Power Engineering (EPE), Brno, Czech Republic, 12–14 May 2014; pp. 317–321.

- Jack, A.; Mecrow, B.; Maddison, C.; Wahab, N. Claw pole armature permanent magnet machines exploiting soft iron powder metallurgy. In Proceedings of the 1997 IEEE International Electric Machines and Drives Conference Record, Milwaukee, WI, USA, 18–21 May 2002.

- Guo, Y.; Zhu, J.G.; Watterson, P.; Wu, W. Comparative study of 3-D flux electrical machines with soft magnetic composite cores. IEEE Trans. Ind. Appl. 2003, 39, 1696–1703.

- Galluzzi, R.; Amati, N.; Tonoli, A. Modeling, Design, and Validation of Magnetic Hysteresis Motors. IEEE Trans. Ind. Electron. 2020, 67, 1171–1179.

- Rajagopal, K. Design of a compact hysteresis motor used in a gyroscope. IEEE Trans. Magn. 2003, 39, 3013–3015.

- Inácio, D.; Inácio, S.; Pina, J.M.; Gonçalves, A.; Neves, M.V.; Rodrigues, A.L.; Pronto, A. Numerical and experimental comparison of electromechanical properties and efficiency of HTS and ferromagnetic hysteresis motors. J. Phys. Conf. Ser. 2008, 97.