3D Printing, also known as fused filament fabrication (FFF), continues to open new routes to the production of high-performance and complex structures with enhanced properties and dynamic shapes that are unattainable via conventional fabrication methods.

- antimicrobial

- antibacterial

- 3D printing

- fused filament fabrication

1. Introduction

3D Printing, also known as fused filament fabrication (FFF), continues to open new routes to the production of high-performance and complex structures with enhanced properties and dynamic shapes that are unattainable via conventional fabrication methods. Developing new material for different applications of the 3D Printing technology [1] usually involves many challenges, such as the mechanical properties [2] as well as the failure mechanism [3,4,5]. The FFF technology opened new horizons for a wide range of applications [1,2] but limitations still face this fast-moving sector [6,7,8]. Although the 3D Printing technology contributes to the increasing levels of wasted material of polymeric base [9,10], on the contrary, there are unlimited benefits that are continuously increasing day by day. Owing to its innovation-driven approach, 3D Printing has been expanding to several fields, such as analytical chemistry for chromatography [3] and fluorescence techniques [4], optic fibers for increased optical and mechanical performance [5,6], membrane technology for increased adsorption of chemicals [7], space technology to develop tools on-site [8], and medicine for the development of implants and medical devices [3,5,7,9,10,11,12,13].

The ease of modeling and experimentation helps with progressive growth and expansion of knowledge in these fields, which can be of significant value to clinical areas. 3D Printing has been extensively employed in the biomedical field, especially in biomodelling, for the fabrication of scaffolds and implants, such as for dental restorations and tissue engineering, bone and fracture healing [1,14] and even for drug delivery because it is highly flexible and faster than current methods such as machining [15,16]. Moreover, the positive effects on the mechanical and biological properties of designed microporous scaffolds manufactured by commercial 3D Printing technology promote the use of 3D printed scaffolds as viable candidates for further research for clinical applications [16,17]. 3D Printing is also a highly cost-effective approach, cutting costs and improving economic efficiency.

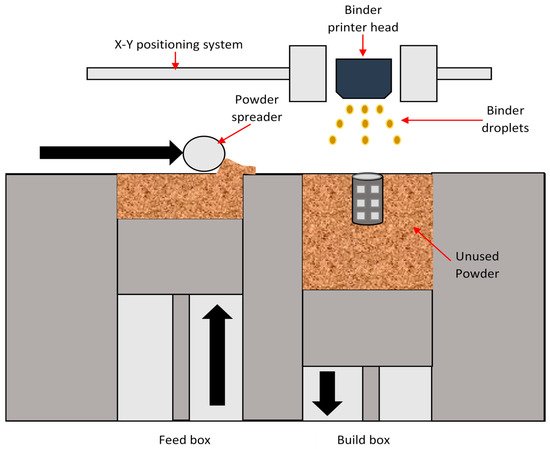

Several techniques that have been commonly applied worldwide for 3D Printing include FFF, selective laser sintering (SLS), digital light processing (DLP), and stereolithography (SLA) [13,18,19,20]. Of these, FFF has been extensively used to develop medical devices. In FFF, the feedstock to the 3D printer is a simple filament made from a thermoplastic material that is heated to soften and extrude through a printer head or nozzle, which builds layers driven in an X–Y orientation. FFF has been reported to be an excellent technique to fabricate small mechanical parts, providing sufficient precision, which allows rapid modifications to be made during the process itself. A simple FFF schematic is shown in Figure 1 [18].

With the use of 3D Printing increasing in biomedical applications, the surface properties of the developed 3D printed material are essential because this material will be in direct contact with the human body. Common microorganisms that are highly associated with infections include Staphylococcus spp. strains, such as Staphylococcus epidermidis [21], and Gram-negative Enterobacteriaceae strains, such as Escherichia coli (E. coli) [22]. The adhesion of bacteria to the surface is facilitated by several factors, such as hydrophobicity and surface tension, which is followed by accumulation resulting in a biofilm [23]; however, it may not always be harmful [24]. Thus, having an active antibacterial surface on the 3D-printed material is of vital necessity to prevent any microorganisms from developing on human tissues and infecting the human body. Even though conventional approaches involve the release of metal ions, such as fluoride, silver, or zinc, to prevent and fight bacterial infections, this method still results in decreased mechanical properties, causing toxicity to surround tissues. Additionally, the fabrication of antimicrobial materials is preferred for coating the surfaces of materials, even though this adds an additional process, costing time and money in any clinical field [25].

Polymer composite materials have gained the attention of researchers worldwide in a variety of fields, from printing and packing applications to several other applications [17,26,27,28]. Due to filler addition, significantly enhanced properties, such as mechanical and thermal properties and conductivity, are attained; thus, increasingly, applications prefer the use of polymer composite materials instead of pure polymers. One of the most promising techniques that has been used is the addition of metallic particles as fillers to provide enhanced antimicrobial and antiviral properties to the commonly developed polymer composite materials being used in several applications. Currently, viral transmission through either touch or contaminated liquids, such as blood, poses a massive threat to populations worldwide. The issue of the inactivation of viruses in media requires an upfront solution, and the development of novel means to inactivate viruses is highly desirable. One of the most novel developed strategies is to incorporate copper nanoparticles (NPs) into the matrix. Copper has potent virucidal properties, and copper’s neutralization of infectious bronchitis virus, poliovirus, human immunodeficiency virus type 1 (HIV-1), and other enveloped or nonenveloped single- or double-stranded DNA or RNA viruses has been well reported [29]. The ability of free copper ions in copper NPs to break the membranes of microorganisms alters their DNA, thus eliminating them, which confirms their great potential for keeping material surfaces free of pathogens. Based on the broad-spectrum antiviral effectiveness of copper, the incorporation of copper NPs in any intended hybrid composite material could inherently add significant value to the final product, especially with regard to the COVID-19 pandemic situation [30].

Another metal that has caught the attention of researchers worldwide is silica. Due to its high chemical and thermal stability and excellent antimicrobial properties, silica has been used in several applications to provide enhanced features to composites. For instance, for the treatment of bacteria, silver NPs are widely used in several industries. The main challenges in the use of silver NPs is to provide an antimicrobial specifically for antibacterial surface suitable for a wide range of substrates with mechanical and thermal resistance with prolonged antibacterial properties and that is suitable for wide temperature ranges. Moreover, the agglomeration of silver NPs has always remained a challenge because it decreases their antiviral effects. A study reported excellent antiviral capabilities for a hybrid material against two model viruses for different water conditions. silver NPs incorporated with SiO2 showed minimized agglomeration and minimal particle release in water environments [31].

Another study reported the production of a series of mesoporous silica nanoparticles (MSNPs) using room-temperature ionic liquids (RTILs) to study the mass-transport properties by investigating the controlled release profiles of these materials and utilizing the RTIL templates as antibacterial agents. The study showed that the antibacterial activity was dependent on the rate of diffusional release of the pore-encapsulated RTIL, which was in turn governed by the particle and pore morphology of the MSN materials, thus showing the good potential for silica-based mesoporous materials to be used in several applications that require controlled release delivery [32]. The literature also supports the idea of the production of antibacterial silver nanocluster–silica composite coatings by radiofrequency co-sputtering techniques, which can result in peculiar antibacterial properties [33]. Additionally, another method by which silica is gaining popularity is allowing monomers to be attached to its surface, providing enhanced properties. For instance, silica particles were used to treat water, and the results supported excellent biocidal efficacy against bacteria, thus showing their good potential to combat microorganisms in water [34,35]. Thus, the use of silica-based composite materials with added antimicrobial and antiviral properties enhanced with copper NPs can open pathways for its significant use in fields that require high-purity surfaces, such as medicine, food packing, and space industries [2,10,23].

Additionally, polysaccharides are now also considered to develop material for antimicrobial materials. Bacteria is a large reservoir for the development of polysaccharides. These materials have exhibited antibacterial property by formulating films which have shown broad anti-bacterial activity [36]. Since these bacterial polysaccharides can follow an ordered structure, it is seen as an excellent bioprinting material to provide antibacterial effect. Commonly used bionics are alginate, bacterial cellulose and hyaluronic acids [37].

Antimicrobial mechanisms in 3D printed material simply by exploiting the antimicrobial property of the incorporated NPs. NPs are usually synthesized following up physio-chemical processes such as using solvents and through reactions such as reduction and oxidation. However, a lot of green/bio NPs are also considered to reduce the adverse effects of toxic solvents and harmful by-products produced [38].

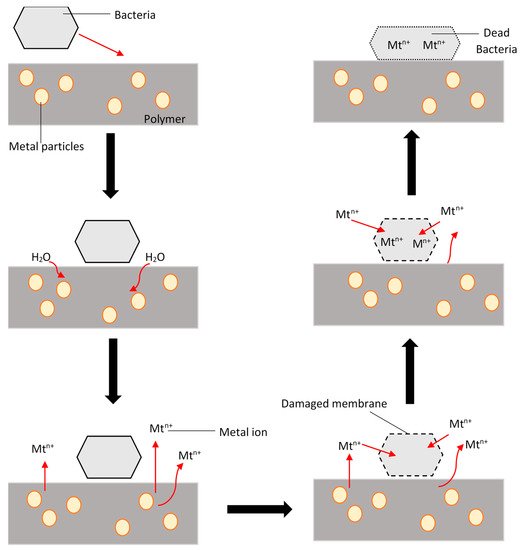

Furthermore, to fully understand the mechanism of how metal ions produce this antimicrobial effect for instance against bacteria, a simple representation of how these metallic particles at a micro or nanoscale are illustrated in Figure 2 for a polymer/composite material. Initially, the adsorption of bacteria on the surface of the polymer triggers the diffusion of water through the matrix. Next, the water, along with dissolved oxygen, reaches the surface of the metal particles, which allows the dissolution process. This leads to the formation of metal ions. Consequently, the metal ions deposit on the surface of the composite and damage the membrane of the bacteria, which results in the metal ions diffusing into the bacteria. The same can be applied for any polymer/metal material with a biocide agent that is embedded in the matrix [39].

Since metallic ions have been extensively used to provide antipathogenic effects, the combination of 3D Printing alongside metallic particles can result in successful developments of antimicrobial materials, tools, and surfaces [40]. Li et al. [19] successfully prepared an antimicrobial photosensitive resin using the DLP technique with active bacterial resistance. Yue et al. [41] also successfully developed an antimicrobial composite FFF that was positively grafted with metal ions capable of killing any bacteria contacting the surface using SLA. Another study conducted by Muwaffak et al. [42] used hot-melt extrusion to integrate metal ions into a polymer-based filament, which was then used to 3D print a wound dressing. Gutierrez et al. [15] followed a more natural approach by developing antimicrobial alginate hydrogels that were used to 3D print. Ben et al. [29] used surface-modified β-tri-calcium phosphate (β-TCP) granules for 3D Printing for bone tissue engineering. In another study conducted by Huang et al., polymer/ceramic blends prepared with the FFF technique to develop bone scaffolds were characterized [43].

In particular, the use of antimicrobial composite material along with FFF specifically for bio-applications has been widely studied [44,45]. For instance, biodegradable polymers such polylactic acid- (PLA) based polymers are often used to develop filament that possess antibacterial properties using FFF as discussed by Bronstein et al. [46]. Moreover, the antibacterial property is added with the help of processing techniques such as co-extrusion with particles for instance using chitosan as studied by Mania et al. [18] or using metallic nanoparticles as done by Rezić et al. [47]. Biomedical applications such as dental resins as studied by Bayarsaikhan et al. [48] and drug delivery as highlighted by Shaqour et al. [49,50] highly promote a practical approach of using 3D Printing along with compatible antibacterial material. Bartolomé et al. [51] and Navaruckiene et al. [52] both emphasize the use of FFF as a promising approach for bio fabrication of antibacterial material and suggest that using metallic particles alongside biodegradable polymers show great compatibility to the human body and is expected to be considered as the more superior and dynamic approach of development in the field in the upcoming years.

Thus, several metal ions have been incorporated to prepare antibacterial materials compatible with 3D Printing technology, which can serve as a cost-effective approach, especially in the field of biomedicine, which requires high purity and highly anti-pathogen surface materials. 3D Printing can offer a higher precision compared to conventional methods that can cater to more customizable solutions that are increasingly being desired.

2. Techniques and Effectiveness of Developed Antibacterial 3D-Printed Materials

| Polymer Name | Particle Name | Particle Size | Weight/Volume % | Chemical Agent | Ref |

|---|---|---|---|---|---|

| PCL | Graphene oxide | Not specified | 0%, 5%, and 7.5%, | Not specified | [53] |

| Thiol-ene-acrylate | QUA, SH-QUA | Not specified | 2 wt%, 4 wt%, 6, wt%, 8 wt%, 10 wt% | phenylbis(2,4,6-trimethylbenzoyl), phosphineoxide photoinitiator, 1,2,3-benzenetriol |

[19] |

| stereolithographic resins- UDMA | Ag-HNT | Nanoparticles | 1%, 2%, 5% | triethylene glycol dimethacrylate (TEGDMA), photosensitizer | [55] |

| alginate beads | Copper nanoparticles | Nanoparticles | 4 wt% alginate concentration; 50-mM copper salt concentration | Bacterial cellulose | [15] |

| PLA | Copper nanoparticles | Nanoparticles | 1% antibacterial nanoparticle additive | - | [58] |

| PCL | Metal ions (Ag, Cu, Zn) | Not specified | Ag-10% w/w Cu-10% and 25% w/w Zn-10% w/w |

Tetrahydrofuran (THF) dichloromethane (DCM) - |

[42] |

| UDMA | QA_Cn (n=2 to n=16)pQA_C12 | Not specified | Nitrogen (N%) linearly related to alkyl chain pQA-C12–25 wt% |

camphorquinone (CQ); ethyl 4-(dimethylamino)benzoate (EDMAB); glycerol dimethacrylate (GDMA); 2-hydroxyethyl methacrylate (HEMA) for pQA_Cn12 |

2015 [41] |

| Polymer Name | Nozzle Diameter | Filament Diameter/Printer Settings | Printing Temperature | Filament Process | Tests Done | Reference |

|---|---|---|---|---|---|---|

| PCL | xy distances ranged from 200 μm to 400 μm, z-steps from 20 μm to 80 μm, and staggering between layers from 50 μm to 200 μm |

Not specified | Not specified | internal diameter of 184 μm (28G) for scaffold plotting |

1,4,6,12,16 | [53] |

| Thiol-ene-acrylate | Not specified | Not specified | Not specified | Not specified | 1,2,9,14 | [19] |

| stereolithographic resins | Not specified | Resolution of the device = 50 lm in the Z-direction; exposure time of each layer = 12 s |

Not specified | Not specified | 1,2,8,5,14,15,18 | [55] |

| alginate beads | 1.75 mm | 3D structures of 30 × 30 × 1 mm3 (length × width × height) 1.5 mm of thread spacing; dispensing head temperature of 25 °C; ink extruded with 23-G needle tip at 25 °C; printing speed of 50 mm s−1; extrusion pressure of 1 bar |

25 °C | Not specified | 1,5,18 | [15] |

| PLA | Not specified | 40% infill (hexagon pattern); 50-mm/s print speed; 150–200-mm/s travel speed; 50 °C heated bed; 0.15-mm layer height; 1-mm shell thickness |

200 °C | Not specified | 1,13 | [58] |

| PCL | 1.75 mm | - square dressings (20 _ 20-1 mm) for antimicrobial studies and circular dressings (10-mm diameter; 1-mm thickness) −0.1 (mm layer height), with two shells, 100% infill and speed while extruding and while traveling was set to 50 mm/s |

170 °C | Extruded/Single screw Ag-80 °C Cu-60 °C Zn-75 °C |

1,2,3,4,7,11,17 | [41] |

| UDMA | Not specified | z-stage with the substrate moved upward by 200 μm; resolution of the device ~300 μm in the XY-plane and 25 μm in the Z-direction |

Not specified | Not specified | 1,7,12,14,15,19 | [41] |

| Reinforcement Material | Antimicrobial Synthesis Method | Printing Method | Antimicrobial Activity (%) | Application | Reference |

|---|---|---|---|---|---|

| Graphene oxide | Dissolution | Wet spinning + AM | 80% | Fibrous scaffolds | [53] |

| QUA, SH-QUA | Dissolution (Copolymerization) | DLP | 100% | Dental tooth | [19] |

| Ag-HNT | Dissolution in SLR | DLP | 99% | Dental composite resin | [55] |

| Copper nanoparticles | Ionic cross-linking | FFF | Not specified | Composite hydrogel | [15] |

| Copper nanoparticles | Purchased PLACTIVE© | Extrusion + FFF | 99% | Finger prosthesis | [58] |

| Metal ions (Ag, Cu, Zn) | Hot-melt extrusion | FFF | Not specified | Wound dressing | [41] |

| QA_Cn (n=2 to n=16) pQA_C12 | Dissolution (Copolymerization) | SLA | 99% | Dental composite resin | [41] |

3. Applications Using 3D-Printed Antibacterial Materials

3.1. Biomedical Field

3.2. Use of Composite Materials in 3D Printing for Material Chemistry

3.3. Use of Metallic Fillers in Composites in 3D Printing Membrane Technology

3.4. Space Applications

3D Printing has recently also been accepted for use in space applications. 3D Printing in the consistent microgravity environment of the International Space Station (ISS) can be used to develop parts made from particular materials needed in space. For example, the first 3D-printed tool on the ISS was a wrench built using FFF by depositing 104 layers of plastic [79]. The ability to manufacture 3D-printed parts and tools on demand will dramatically reduce the time it takes to get parts to orbit and increase the reliability and safety of space missions while reducing costs. Current space missions take months to years to get parts to orbit [8]. Moreover, FFF with extrusion-based machines functions similarly in microgravity as it does on the ground, allowing for a fool-proof concept of 3D Printing in space [10].

The extrusion-based fused filament fabrication method using thermoplastics represents a robust and straightforward methodology that is applicable to printing parts for both current and future human spaceflight exploration missions [80]. Literature reports have indicated that polymeric-based materials have potential as space-capable materials because they can produce extravehicular activity, repair tools, and even satellite structures that can be created on-site and on-demand. This will enable safer, less mass-intensive missions and scientific experiments, provide an advantage to FFF [81]. Among the most commonly used thermoplastic polymer materials are acrylonitrile butadiene styrene and PLA because these materials have been reported to maintain their shape at cabin temperatures [80].

According to the database maintained by NASA on the ISS, 17% of the total spare parts are made of metallic materials. It has been reported that powder bed fusion and, in particular, laser beam melting (LBM) are the preferred FFF technologies for commercially producing ready-to-use high-performance metallic parts with desired size specifications [82]. A stainless steel metal powder was successfully processed in the LBM process under microgravity (μ-g) conditions in a parabolic flight campaign, which showed no significant deviations from a part manufactured at 1 g, thus supporting the feasibility of the LBM process for 3D Printing ready-to-use metal parts in space.

3D Printing systems have been advancing in the medical field as well. A bioprinting system for the ISS has already been developed. This technique allows 3D Printing of thick tissue and organs using adult stem cells, supporting that 3D bioprinting can result in exact movements and control of the final dispensation [83]. Advances in the medical field could be a great breakthrough for the space industry. The literature also shows that NPs of various metals and metal oxides, such as zinc oxide nanoparticles (ZnONPs), cuprous oxide nanoparticles (CuONPs), silver nanoparticles (AgNPs), copper (I) iodide nanoparticles (CuINPs), gold nanoparticles on silica nanoparticles (Au-SiO2NPs) and some quaternary ammonium cations, which are commonly called QUATs, are very promising for inactivating viruses. The increasing use of polymer composite materials worldwide in a variety of fields promotes filler addition (whether metallic or non-metallic), which significantly enhances the properties such as mechanical, thermal, and conductivity properties [17,26,27,28]. One of the most novel strategies developed is the incorporation of copper NPs into the polymer matrix. Copper has strong virucidal properties, and copper’s neutralization of infectious bronchitis virus, poliovirus, human immunodeficiency virus type 1 (HIV-1), and other enveloped or nonenveloped single- or double-stranded DNA or RNA viruses has been well reported [29]. Based on the wide range antiviral potency of copper, the incorporation of copper NPs in an intended composite material could inherently add significant value to the final 3D-printed product, especially with regard to providing antipathogenic surfaces, such as medical equipment that requires high purity for use by astronauts in a safer and more efficient way. Additionally, another mineral that has caught the attention of researchers worldwide is silica. Owing to its high chemical and thermal stability and good antimicrobial properties, silica has been used in several applications to provide enhanced properties to composite materials, thus making it a good candidate for the final 3D-printed product.

Investigations into the properties of regolith materials [84] (material deposited on the soils of planets) are also being conducted via powder bed fusion-based 3D Printing, which show the recent advancements in this field. Nevertheless, developing such particulate matter is not easy or efficient. Perhaps already developed materials, such as composite materials, would provide a better alternative to investigate further. However, owing to the high costs involved to develop larger quantities of polymer composite material, there is a need to shift toward a cost-effective approach to develop them commercially, which can be easily applied industrially and could potentially be advanced using 3D Printing.

Moreover, because thermoplastics have the ability to be recycled as feedstock and then printed again, using recycled materials as printer feedstocks could be a viable approach. One goal is to utilize non-metallic composite materials (recycled fiber-based composite materials) that could provide an effective long-term solution to the buildup of trash in space and its effective disposal [85]. Currently, the in-space manufacturing program conducted by NASA is focused on evolving manufacturing technologies from Earth-reliant to Earth-independent technologies. This is directed toward future hardware fabrication via FFF, which includes feedstock recycling, the development of parts, printable electronics, and investigations into additive manufacturing of metallics and external repairs [80,86].

Furthermore, it is noteworthy to state that due to the sudden rise in the COVID-19 pandemic, extensive researches worldwide have been conducted focusing on the production and development of antimicrobial material just in the span of a year [87,88,89,90]. More and more focus has been provided on the fabrication of antimicrobial surfaces with the incorporation of polymeric base along with additives [18,46,91,92,93]. The positive results from such antimicrobial studies have been promising and are providing hope to fight against such potent diseases.

This entry is adapted from the peer-reviewed paper 10.3390/polym13091523