1. Introduction

1.1. Secondary Wine Aroma

The combination of two modest substrates such as grapes and microorganisms (those belonging to the grape microbiota and/or those intentionally added) results in a huge variability and diversity of wines. However, this apparently simple conjugation hinders extremely specific chemical reactions that can be modified to obtain a stunning array of aromas and flavors. The wine aroma comprises a mixture of volatiles that can account up to 800 compounds, although just few of them are odor-active [

1]. This complex chemical composition can be split in terms of aromas into three different categories that are mostly related with the three production steps: grape culture, fermentation stage and transformation process, respectively [

2].

Primary or varietal aromas, as this second name indicates, are due to the grape variety. Primary aromas belonging to the same grape variety may present different features depending on natural factors derived from weather, type of soil, fertilization, presence/absence of plagues or even the geographical location, that prompt different cultivation conditions in each area and also each year. Besides, the ripening period and the care of the collector when selecting grapes may have influence in the final primary aroma of wine [

1]. Grapes are known to contain free and sugar-glycosidically-linked terpenes, being the monoterpenes and sesquiterpenes the ones that contribute with aroma and flavor. Among them, the most odoriferous monoterpenes alcohols are linalool, geraniol, nerol, citronellol, 3,6-dimethyl-1,5-octa-dien-1,7-diol, hotrienol and α-terpineol, which provide floral, fruity and citrus aroma to the wine [

3,

4]. Even though just few aromas have been directly associated to specific varieties, each grape variety possesses an aroma fingerprint. Monoterpene glycosides or ethers do not show significant changes in their amount during yeast fermentations. Therefore, they can be used to classify different varieties, such as Muscat and Riesling wines, by the study of their analytical composition based on just 12 monoterpene compounds [

5,

6,

7]. However, the low concentration of these aromas (e.g., hotrienol thresholds between 18 and 400 μg/L and linalool in 50 μg/L) does not permit their sensorial appreciation at least their potential gets boosted in later steps by enzymatic reactions thus, having a major impact in the final wine aroma [

8,

9]. Wine has been demonstrated to have more than 800 volatile compounds with wide range of concentration, from ng/L to hundreds of mg/L [

10]. In addition, other precursors that do not possess odoriferous characteristics, are involved in the development of other aroma substances (e.g., monoterpenes, diols or terpene, polyols, fatty acids, carotenoids, glycosylated precursors of aroma and volatile phenols) [

1].

In the next aromatic level, yeasts and bacteria carry out the fermentation, this is the chemical reactions chain responsible for transforming grape juice into wine and providing secondary aromas to wine. Secondary aromas can be divided into pre-fermentative, those arisen due to the mechanical treatment of grapes, and fermentative, those boosted during alcoholic or malolactic fermentation processes [

1,

2]. The most utilized species for the alcoholic fermentation is

Saccharomyces cerevisiae, although there are about 20 yeast genera with the same capacity such as

Saccharomycodes,

Candida,

Issatchenkia,

Pichia,

Hanseniaspora (

Kloeckera) or

Brettanomyces (

Dekkera) [

3]. These non-saccharomyces species drive the aroma release by the secretion of proteins, mainly enzymes, and the synthesis of new secondary metabolites. In addition, they contribute to color wine stability and they do not use up the available sugar in must. Thus, they are strategically utilized for creating multi-starter, mixed or sequential cultures in combination with

S. cerevisiae [

8,

11,

12]. Normally, after the alcoholic fermentation, wine is submitted to the malolactic fermentation by the inoculation of lactic acid bacteria (LAB). During this stage, malic acid responsible for the tart taste gets decarboxylated by the action of

Oenococcus oeni or

Lactobacillus plantarum, two common used LAB species [

8]. After this fermentation process, wine is microbiologically stabilized. Along the fermentation, the main created aromas belong to the volatile fatty acids, higher alcohols, acetate and ethyl ester categories which make evolve the aroma profile of wine [

3]. These molecules are usually present at high sensory thresholds (the oxidation products of linalool possesses a perception threshold of 6000 μg/L) and their combination creates the matrix of wine aroma [

3,

13]. In fact, by the end of this fermentative stage, the term aroma becomes more complex from a chemical and sensorial point of view and thus, it turns into the term bouquet. Therefore, even though the final wine aroma composition is highly dependent on fermentative species and strains, the grape microbiome is gaining attention, since different works point to its relevance in the final sensorial properties of wines [

8,

12].

Tertiary aromas are created during the last step, aging of wine, where the storage of the final product is the main responsible for the transference of aromas and flavors to wine. The typical aging method is the use of wood barrels mostly built with different oak species such as

Quercus alba,

Q. robur or

Q. petraea [

14]. Wine aged in these barrels may be transferred with volatiles such as guaiacol-oak lactones or vanillin and even with furfural, 5-methylfurfural, eugenol, guaiacol, 5-hydroxymethylfurfural, 4-methylguaiacol, guaiacol and syringol, when applying different toast treatments to wood [

15]. The use of different wood provides different volatiles to aged wine, for instance, brandies aged in

Quercus-barrels were found to contain higher levels of ethyl-2-methylpropanoate, -butyrate and -octanoate and lower levels of butanoic acid, cis-β-methyl-γ-octalactone and syringol than when aged in

Castanea-barrels [

15]. In fact, apart from

Quercus, other kind of woods such as

Acacia,

Prunus or

Castanea are known to contain high concentrations of tannins, a kind of polyphenols, that are utilized to age wines since these non-volatile molecules can be transferred and may contribute to sensory properties such as color, astringency and bitterness [

2,

16].

Among the three classes of aroma, achieving an appropriate combination of secondary aromas represents the most intricate procedure. This stage implies the correct selection of yeasts and bacteria to perform the fermentation steps while avoiding wine spoiling due to cross contamination or due to the innate grape microbiota. Moreover, the high sensory threshold of the volatiles synthesized during this stage will define the wine aroma matrix. For obtaining a wine with well-defined secondary aromas and flavors, it is essential to understand how different microbial species interact with each other and which sensorial properties are capable to provide based on the metabolic pathways they develop.

1.2. Fermentation Implication on Wine Secondary Aroma

As aforementioned, yeasts and bacteria are responsible for the production of the secondary aroma during the pre-fermentative and fermentation processes. Naturally, in traditional winemaking, fermentation of grape juice is carried out by different yeast species following an order. The fermentation is initialized by non-saccharomyces yeasts, which is called spontaneous fermentation. However, these yeasts do not resist the increase of ethanol and so, they are commonly replaced by the strongly winery fermentative yeast

Saccharomyces cerevisiae [

17]. Nevertheless, it has been suggested that some of the non-saccharomyces species could persist from one year to another in wine and become dominant during fermentation like

S. cerevisiae [

18]. In the past, non-saccharomyces wine yeasts were considered as undesired microorganisms but in recent years it is well known that they can enhance the analytical composition and aroma profile of wine [

19]. Therefore, wine fermentation can be defined as a complex process where different microorganisms coexist and microbial interactions influence the final product [

20]. Non-saccharomyces yeasts can influence both the primary and secondary aroma through the production of enzymes and metabolites, respectively [

19]. In this context, and for the development of the following sections, it is important to differentiate between the three types of alcoholic fermentations that can occur. Besides, malolactic fermentation is a process that some type of wines can also undergo (i.e., wines with high acidity) and consequently, causes an improvement of the aromatic profile of wines [

5]. This process will be explained in the following sections.

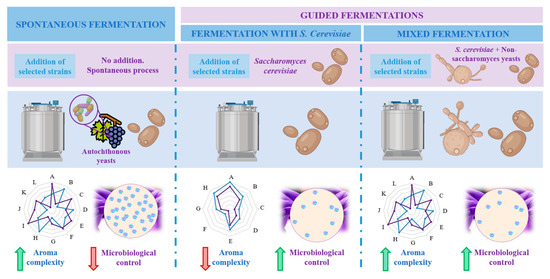

Firstly, spontaneous fermentation is a process that naturally takes place on grape must: at the initial stages, non-saccharomyces species (already present in grapes) dominate grape juice and are then replaced by winery yeasts, commonly

S. cerevisiae, leading to wines with a complex profile but with lower microbiological control and submitted to variability and the risk of spoilage depending on the year and the exogenous microbiota of the grapes [

19]. Next, the second type of fermentation is called guided, since wine is inoculated with selected cultures named as starters which compete and limit the growth of non-saccharomyces strains [

21]. This way, industrial fermentations begun to use starters of selected wine yeast strains of

S. cerevisiae for their fermentative behaviour, their ability to enhance secondary aroma but also to achieve more uniformity in the quality of wines [

19]. However, it is currently accepted that those fermentations that use more than one yeast strain can produce wine with higher quality and complexity and less content in alcohol, while microbiological control is ensured. These are called mixed fermentations [

20]. Mixed cultures have shown to exert additive or synergistic effect (e.g., by metabolites exchange between yeasts) resulting in the enhancement of the chemical and sensory profile of wines [

22,

23]. A representation of the types of fermentations is shown in .

Figure 1. Schematic representation of the types of fermentation, the implied yeasts and the final characteristics of the obtained wine according to aroma complexity and microbiological control. Based on Reference [

19].

It has been also highlighted that the selected inoculation strategy can modulate wine aroma profile in the case of mixed fermentations. If simultaneous inoculation is chosen, non-saccharomyces yeast and

S. cerevisiae are added together, whereas in the case of sequential inoculation, non-saccharomyces starter is inoculated before

S. cerevisiae, thus delaying the development of this last one [

24,

25]. In this sense, both strategies have shown aroma improvements depending on the utilized species. For instance, the aroma compounds resulting from the sequential fermentation of

Issatchenkia terricola and

Pichia kudriavzevii together with

S. cerevisiae where higher than in the case of simultaneous fermentation [

24]. In the other hand, a different experiment carried out with

Torulaspora delbrueckii and

S. cerevisiae showed an increase in the production of esters (fruity aroma) in the case of simultaneous fermentation when compared to sequential fermentation [

26].

At last, it is worth to mention that other parameters during fermentation can also influence the wine aroma. These are temperature, molecular oxygen available during fermentation, maturation or ageing, the nitrogen source also known as yeast assimilable nitrogen (YAN) and the inoculation rate of yeasts as well as other post-fermentative parameters, such as yeasts final autolysis [

27].

1.3. Microorganisms Implied in Wine Aroma

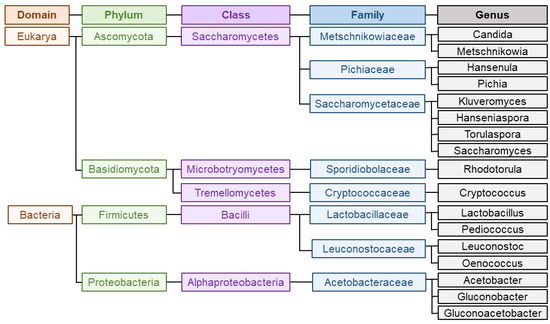

Wine is a complex matrix where the development of alcoholic fermentation, leaded by different yeasts coupled to the volatile compounds released during malolactic fermentation, leaded by LAB and acetic acid bacteria (AAB), defines wine secondary aroma [8]. Yeasts are responsible for alcoholic fermentation, and particularly, the unicellular fungi Saccharomyces cerevisiae governs the process, which can occur spontaneously or guided by the use of starter cultures [17]. Yeast domain counts up to more than 2000 species, among which Saccharomyces has traditionally been the most studied and important genus for industrial fermentation [8]. Within Saccharomyces species, S. cerevisiae is the most known since the first inoculation processes with a pure yeast culture were carried out with this species. This trend continued for many decades and resulted in the generalized use of S. cerevisiae as starter yeasts inmost wine fermentations [28]. However, as aforementioned, non-saccharomyces species also play an important role during fermentation. Among this group, the genera most commonly present and studied are Hanseniaspora, Hansenula, Metschnikowia, Candida, Pichia, Lachancea, Brettanomyces, Kluyveromyces, Schizosaccharomyces, Torulaspora, Zygosaccharomyces and Saccharomycodes [5,8]. In respect of bacteria, most abundant LAB belongs to genera Lactobacillus, Oenococcus, Pediococcus and Leuconostoc whereas most predominant AAB during winemaking are Acetobacter, Gluconobacter or Gluconacetobacter [29]. represents the main groups and taxonomy of the microorganisms implied in wine aroma. The challenge of winemakers and researches lies on the detection, characterization and quantification of all these microorganisms populations during fermentation to assess their participation on the development of wine secondary aroma [29].

Figure 2. Main groups and taxonomy of the microorganisms implied in wine aroma production. Information extracted from Reference [

30].

Therefore, this review presents an overview of the main secondary aromas present in wine, the microorganisms involved in the spontaneous and guided (simultaneous or mixed) fermentations as well as an approach to the aroma variation that wine can suffer when different strains and genetic modifications have occurred.

2. Compounds Involved in Secondary or Fermentative Aroma

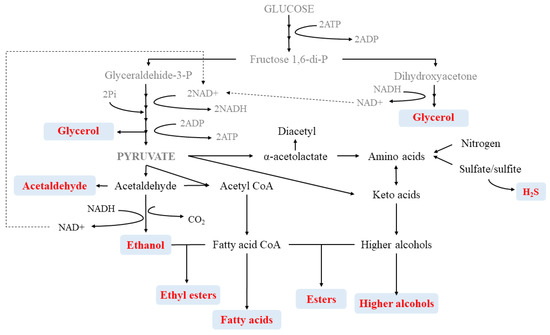

The quality of wine is derived from its aroma which is, in turn, characterized by its volatile composition, mainly created during the fermentation stages. Fermentation is highly dependent on the species and strains selected but also on the components of the wine matrix. Among the main volatiles that define wine, higher alcohols, esters and fatty acids play a key role in the creation of secondary aromas ( and ).

Figure 3. General representation of aroma compound metabolism.

Table 1. Compounds involved in secondary aroma, classes of volatile aroma, main representative, desirable concentration, sensorial properties and producer microorganisms.

| Aromatic Class |

Main Compounds |

Desirable Concentration |

Sensorial Properties |

Producer Organism |

Ref. |

| Fatty acids |

Acetic acid, pentanoic acid, hexanoic acid, octanoic acid, decanoic acid, 9-Decenoic acid, 3-methylbutanoic acid, sobutyric acid |

200–700 mg/L |

In excessive amount: rancid, greasy, and cheesy notes |

S. cerevisiae, P. fermentas, C. zemplinina, H. guilliermondii, H. vineae, H. uvarum |

[3,19,31] |

| Higher alcohols |

1-Propanol-isobutanol, isoamyl alcohol, 2-Phenylethanol, tyrosol, tryptophol, 2-methylbutanol-1, 3-methyl-1-butanol-1 |

<300 mg/L |

Floral, honey, and fruity notes (<300 mg/L).

Pungent aroma (>400 mg/L) |

S. cerevisiae, C. zemplinin, H. uvarum, H. osmophila, H. guilliermondii, P. anomala, P. membranifaciens |

[2,3,5,8,19] |

| Esters |

Ethyl hexanoate, ethyl octanoate, ethyl decanoate, ethyl acetate, isobutyl acetate, amyl acetate, hexyl acetate, 2PA, isoamyl acetate |

150–200 mg/L |

Fruity aroma, including banana or apple, honey, and floral tones |

S. cerevisiae, Candida, Hansenula, Pichia |

[2,3,7,19] |

| Phenolics |

4-Vinyl guajacol, 4-Vinylphenol |

- |

Sweet vanillin aroma |

LAB |

[1,7,31] |

2.1. Volatile Fatty Acids

In the category of aliphatic fatty acids, apart from the most abundant volatile acid, i.e., the acetic acid, the major medium chain fatty acids are hexanoic, octanoic or decanoic. Besides, in the group of the unsaturated fatty acids is worthy to mention 9-decenoic acid which possesses preservative properties and is relevant from an aroma point of view when transformed into ethyl ester [

31].

Yeasts are the primary producers of these fatty acids which are the initial substrate for the final formation of ethyl esters. Among yeasts,

S. cerevisiae is capable of synthesizing mainly hexanoic and octanoic acids in high amounts, but also pentanoic, decanoic and 3-methylbutanoic acids. Other non-saccharomyces species such as the genus

Hanseniaspora has been described to produce acetic acid (in very variable ranges, from 0.6 up to 3.4 g/L) and species such as

Hanseniaspora vineae,

H. uvarum,

H. guilliermondii or

Candida zemplinina displayed higher synthesis rates for isobutyric acid [

3,

19]. However, it has been stated that this group of yeasts does not present a distinct biosynthesis of fatty acids. In fact, the use of mixed fermentations including

S. cerevisiae and non-saccharomyces can modify the chemical profile of the single

S. cerevisiae model. In general terms, this combination shows a reduction in the amount of medium-chain fatty acids, as it happens when inoculating

S. cerevisiae with

H. osmophila. Even though, the utilization of a mixture of

C. stellata and

S. cerevisiae could increase the amount of hexanoic and octanoic acids, followed

Pichia fermentas. Similarly, the application of sequential inoculations based on

S. cerevisiae and non-saccharomyces usually provides wines with lower concentrations of fatty acids [

3]. The use of mixed or sequential fermentations can have benefits to regulate the content of these medium chain fatty acids, since their excessive presence may provide negative aromas with greasy, rancid and cheesy notes [

3,

32].

2.2. Higher Alcohols

The most abundant alcohols in wine, apart from ethanol and glycerol, are diols, higher alcohols and esters. Ethanol provides viscosity, balance taste and fix odors while higher alcohols and glycerol strongly contribute to the aroma complexity of wine and to the overall mouthfeel of wine. Higher alcohols are the result of the catabolism of amino acids by a process known as Ehrlich reaction, which affect directly or indirectly to the synthesis of aroma compounds. Higher alcohols are also involved as ester precursors which are important compounds in wine aroma [

5,

19]. Major higher alcohols are 1-propanol, isobutanol and isoamyl alcohol. Other important volatiles are the precursors of aromatic alcohols such as 2-phenylethanol, tyrosol or tryptophol and other higher alcohols but present in lower amounts, like 2-methylbutanol-1, 3-or methyl-1-butanol-1. Moderate concentrations of some of the volatiles considered to have high odor intensity, such as 3-methyl-1-butanol, 2-phenylethanol or isoamyl alcohol, can provide positive impact in the wine providing flower, honey and fruit aroma notes. However, the higher alcohol concentration plays a key role in the complexity of the aroma composition. Optimal alcohol values under 300 mg/L provide fruity and flowery notes, whereas alcohol values above 400 mg/L become negative by adding pungent and unpleasant aromas [

2,

3,

8,

19]. Among the different fermentation parameters that affect the final concentration of alcohol in wine, yeast strain is one of the key parameters followed by temperature, pH or oxygen, apart from grape ripeness and variety [

33]. Higher alcohol synthesis has been widely studied and related to different species and/or inoculation protocols to obtain wines with an equilibrated higher alcohol composition. Different works have evaluated the efficiency of

S. cerevisiae in terms of higher alcohol production [

34,

35]. Generally, no significant differences have been observed for 1-propanol while isobutanol, isoamyl alcohol, 3-methyl-1-butanol or 2-phenylethanol production seems to be strain-dependent and related to the presence of

S. cerevisiae, both as pure or mixed cultures. In general terms,

H. uvarum,

C. zemplinina or

P. anomala are considered as high alcohol producers, used both as single and mixed (with

S. cerevisiae) fermentation agents [

3,

8,

19]. Nevertheless, the single application of non-saccharomyces yeasts has been stated to produce lower amounts of total alcohols than

S. cerevisiae and so, a reduction of the final amount of higher alcohols when using mixed cultures [

36]. Indeed,

H. osmophila,

H. guilliermondii and

P. membranifaciens were demonstrated to produce lower amounts of higher alcohols when tested against

S. cerevisiae, even though

H. osmophila provided high levels of 2-phenylethanol and isoamyl alcohol. Similarly, for the genus

Candida,

C. zemplinina has been described to synthesize 2-phenylethyl, glycerol and low amounts of ethanol and acetic acid. This combination has prompted its classification as fructophilic species, whereas

C. stellata is classified as low producer. Another study with

H. uvarum strains displayed variability in all produced higher alcohols except for isobutanol whose production seems to be boosted by

Hanseniaspora. Indeed, another species,

H. guilliermondii, also has a higher production rate of isobutanol than

S. cerevisiae. Besides, same species synthesized very low amounts of 1-propanol [

3,

8,

19].

2.3. Esters

Esters are another relevant group, also responsible for the aroma complexity of wines with more than 160 representatives already identified. From a chemical point of view, they can be classified into ethyl fatty acid esters or acetate esters. In the first category, ethyl hexanoate, ethyl octanoate, and ethyl decanoate are the most abundant ones. In these molecules, ethanol represents an important contribution to their structure. In the second class, higher alcohols are essential for the formation of these esters. The major acetate esters are isobutyl acetate, amyl acetate, hexyl acetate, ethyl acetate (fruity aroma), isoamyl acetate (banana aroma) and 2-phenylethyl acetate (2PA), which has been described to provide honey, fruity and floral aromas to the wine [

2,

3,

7]. In white wine, the main fatty acid ethyl esters include ethyl butanoate, caproate, caprylate, caprate and laurate. As other esters, they can also provide fruity tones that become softer with the increasing number of carbons in their chemical structure of the formation of these esters depends on the selection of yeast species and other fermentation parameters such as low temperatures, are [

7]. Different yeasts have been used to give complexity to wines through ester production including

S. cerevisiae but also non-saccharomyces species such as

Candida,

Hansenula and

Pichia since their differential enzymatic mechanisms allow the introduction of novel aromas in wines [

3]. In general terms, esters have positive effects on the aroma of young wines, especially in those with neutral flavors. Nevertheless, as it happens in the case of higher alcohols, excessive amounts of esters may induce negative effects on the quality of wine. A high concentration of esters can hidden varietal aromas and simplify the composition of aroma of the final product or spoil wine, for instance, if ethyl acetate exceeds 150–200 mg/L [

2,

19].

2.4. Volatile Phenols

The positive aroma notes of this group of molecules have been mainly related to the aging process where the main volatile phenols are guaiacol, 4-methyIguaiacol, 4-ethylguaiacol, phenol, o-cresol or vanillin. The enzymes involved in these metabolic steps are mainly associated with LAB, such as β-glucosidases, proteases, esterases, citrate lyases and phenolic acid decarboxylases. In fact, many malolactic fermentations take place in oak barrels even though LAB can synthesize oak-like derived compounds from non-volatile phenols present in wine. Among the non-volatile phenols present in grapes it is common to find phenolic acids (caffeic, ferulic and p-coumaric) or their tartaric esters (caftaric acid, feruloyl tartaric acid, p-coumaroyl tartaric). LAB have the capacity to metabolize cinnamic acids, such as p-coumaric or ferulic, that through a decarboxylation step can be transformed into 4-vinyl guajacol and 4-vinylphenol. Thus, the use of LAB to obtain these compounds before the aging step has gained attention since it can help to modify the aroma complexity of wine. LAB can transform non-volatile phenols that contribute with unpleasant aromas such as pharmacy, smoke, forest, leather or pepper, into volatile pleasant ones, such as those related to vanillin, methyl vanilla or homovainyl alcohol. Apart from those that can be synthesized during fermentation stages due to their presence in grapes, another volatile phenols not present in grapes can be found in wines, i.e., acetovanillone [1,7,31].

This entry is adapted from the peer-reviewed paper 10.3390/foods10010051