The pandemic has resulted in the loss of lives and has caused economic hardships. Most of the devices used to protect against the transmission of the novel COVID-19 disease are related to textile structures. Hence, the challenge for textile professionals is to design and develop suitable textile structures with multiple functionalities for capturing viruses, passivating them, and, at the same time, having no adverse effects on humans during the complete period of use. In addition to manufacturing efficient, biocompatible, and cost-effective protective face masks, it is also necessary to inform the public about the benefits and risks of protective face mask materials.

- textiles

- facemask

- COVID-19

- nanoparticles

- anti-viral

1. Textile Materials

Textile materials and structures are used by humans from birth until death. They are composed of textile fibers mainly joined together by surface friction forces. Textile fibers (natural fibers/synthetic fibers) are a very specific form of polymer because their geometry and behavior are unique. Fiber is a generic name for long (length l approx. 10−2 to 10−1 m) thin (diameter d approx. 10−6 to 3. 10−5 m) rod-like formations prepared from polymeric or non-polymeric substances. The typical length to diameter ratio l/d is about 103 [1]. Many important properties of fibers are not directly related to fiber chemical compositions but to supermolecular structure and morphology created during the growth phase in case of natural fibers, and after spinning, by operation of drawing and thermal treatment (setting) in case of chemical and synthetic fibers [1]. Polymeric fibers have a typical fibrous structure characterized by the hierarchy of long thin element bundles (molecular chains, micro-fibrils, macro-fibrils) oriented preferably in the fiber axis direction and having more or less ordered three-dimensional arrangements. (semi-crystalline state). Due to this special structure, fibers have high anisotropy of physical and mechanical properties. Textile fibers have special organoleptic properties (luster, hand), technological properties (length, strength, crimp, surface roughness, etc.), and utility properties (sorption, ability to set, abrasion resistance, etc.). Their structural features, properties, and behavior are described in detail, e.g., in [2]. For the construction of face masks, hydrophobic synthetic fibers are usually selected but natural fibers have the characteristic of attracting, e.g., water droplets on their surface.

The majority of users, laymen, may think that based on extensive use of textiles during their life, they understand textile behavior and the right applications. This is an incorrect assumption due to the new developments happening in the textile domain. Textile specialists and fiber manufacturers are routinely producing textiles that go beyond standard fiber materials and change their areas of application. Not without reason, in Japan, they decided to label fibers with new effects with the term “Shingosen” (new fiber) to suppress users’ experience with fibers of similar chemical compositions, but with significantly different behaviors. Many new effects on textiles are obtained by finishing with chemical agents. When the fabric treatment proves to be sensitive at elevated temperatures, it is simply recommended to lower the washing temperature. Instead of washing, the textiles are then only soaked in tepid water, which becomes beneficial to many microorganisms. Temperature is replaced by detergents, which are often not known to affect treated fabrics. The textile fabrics themselves have some properties that directly impact their use for protective face masks. They generally have poor permeability to UV radiation, especially of shorter wavelengths. This limits the use of sterilization by UV C radiation (with shorter wavelengths below 280 nm) only for textile surfaces, which is often not enough.

For cotton fabrics, the amount of penetrating UV is usually small. Thus, all methods of virus mitigation and antimicrobial treatments based on photocatalytic oxidation (e.g., with TiO2) are non-functional if the photoactive layer is covered with, e.g., cotton fabric. The use of highly effective antimicrobial agents (e.g., Triclosan) have already been banned and withdrawn from the market. Perfluorinated compounds containing perfluorooctanoic acid and their salts have been included by the Stockholm Convention in the list of prohibited substances and their use is restricted by European Directive 2006/122/EC (this applies, for example, to Gore-Tex material). It may not be placed on the market or used as a substance or constituent of preparations in a concentration equal to or greater than 0.005% by mass. Under REACH directives, the use of substances containing perfuloroalkanes will be completely banned by 2020. Titanium dioxide is likely to face a similar fate. For each kind of face masks finishing, it will therefore be necessary, not only to verify their real functionality, but also the possible health risks.

At present, modern textile structures with possible antimicrobial treatments [3], including simple and effective sterilization, are an essential part of protective face masks where possible re-use is planned. This brings together several yet-unsolved problems [4][5] that, as a result, can make the impact of the use of these face masks on the health of wearers worse than being infected by viruses [2][6][7][8]. It should be kept in mind that the total wearing time of protective face masks associated with the possible release of unhealthy particles can be extremely long. In accumulation, the concentration of inhaled particles in the human body may exceed permissible limits, thus having a negative effect.

2. Protective Face Masks

2.1. Capturing Mechanisms

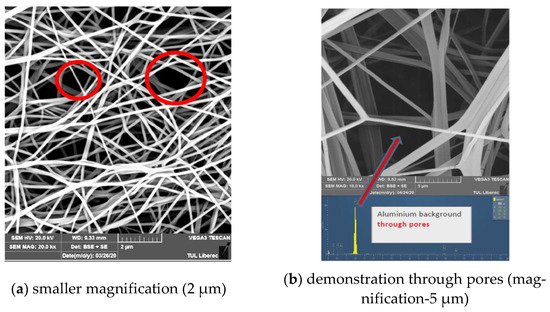

Principally there are different mechanisms for capturing or deactivating viruses. The majority of them are dangerous for human cells as well. For some mechanisms, the kinetics is too slow to be used for the real functioning of face masks. Other mechanisms are too dangerous for humans and can be used for external sterilization only. Many face masks work on the principle of mechanical capture. A thin barrier layer capable of stopping the spread of the virus (for electrospun “nanofiber” layers it is approximately 2 micrometers high) should ideally have pores smaller than the size of the “dry” virus (from 50 nm). Due to limited thickness, the bigger portion of pores is straight through-pores (see Figure 1). It is demonstrated in Figure 1b that the pores shown through the background are composed of only alumina.

Figure 1. Pores in melt-blown PP (polypropylene) nanolayer used for face masks.

A thicker barrier layer capture system is based on the increase of tortuosity and larger no throughput pores.

The term “nano” suggests that it is a material with pores in the nano range. In many cases, this term is used as a desirable attribute that is enjoyed by the general public. Experts understand according to the current European standard (nanotechnologies—terminology and definitions for nano-objects—nanoparticle, nanofibre, and nanoplate: ISO/TS 80004-2: 2015 E), nanomaterials are defined as materials that have at least one dimension (here diameter) in the range 1–100 nm. This range of diameters of the fiber segments in “nano” face masks or “nanolayers” prepared by electrospinning usually exceeds this limit (see Figure 1). These materials are then not “nano” according to the standard. The required pore size cannot be achieved using standard “nanofiber” layers, where there is a wide pore size distribution from nano to micrometers. By layering the individual “nanofiber” layers, it is possible to create a system with a much narrower pore size distribution [9], but the problem is how to combine these layers? A serious limitation is that the “nano-fibrous” layers are mechanically unstable and can, in a short time, cease to protect due to mechanical macro-breakage of the structure (formation of holes) and thus directly endanger the wearer. The problem is also caused by the fiber segments, which are released after only several cycles of abrasion (friction between the layers or mechanical action from the outside). It is, therefore, necessary to verify the durability of face masks containing “nano-fibrous” structures during use to test the released fragments ([9]) like the so-called microplastics.

For mechanical barrier layers of higher thickness, the tortuosity of the pores will play an important role, as viruses penetrating the water droplets can be deposited on the pore walls. Table 1 shows the differences between types of electrospun polyamide (PA) 6 nano-membrane and spunbond polyamide (PA) 6 micro-membrane [10].

Table 1. Characteristics of typical membranes.

| Characteristic | Micro Membrane | Nano Membrane |

|---|---|---|

| Fiber radius r [nm] | 1520 | 140 |

| Membrane thickness h [mm] | 0.53 | 0.00185 |

| Planar mass gsm [g/m2] | 100 | 1.3 |

| Volume porosity PO [–] | 0.83 | 0.36 |

| Sr [m2/g] | 1.196 | 12.987 |

| Ssr [m2/m2] | 119.62 | 16.88 |

The typical porosity of micro membranes is much higher than that of nanomembranes and the mean path from one side to another is relatively very long. Droplets will therefore be more frequently in contact with fiber surfaces with the possibility of attachments. We hypothesize that coronaviruses glycoproteins can adhere to sites with polar groups (as is e.g., surface of cotton or PA 6) capable attract them by electrostatic hydrogen bonds. When viruses spread from infected people, they are probably mostly in water droplets of a much larger size. The overall mean cough droplet size distribution was found to be 0.62–15.9 microns [11]. These droplets can easily change shape (like all liquids) and penetrate through significantly smaller pores than solid particles. The assessment of the quality of the capture by the penetration of solid particles or oil particles used, e.g., for testing of filtration materials is therefore only very indicative.

2.3. Filtration Performance Control

The use of layers composed of submicron fibrous segments is motivated by the effectivity of mechanical virus capture. A serious limitation is a small thickness (through pores) and the negative influence of breathing under the mask. One possibility for avoiding these limitations is to use modified melt blow technology for the preparation of thicker layers containing a random mixture of both micro and nanofibers [12]. Standard melt blowing is a production process providing fibers with a diameter of micrometers or tens of micrometers. Common technology leads to fiber diameters from approx. 2 micrometers up to 20 micrometers. The mechanical properties of the melt-blown layers are relatively low, while the filtration properties are excellent. Modified melt blowing can also produce parts of fibers with a diameter under 1 micrometer [12]. The melt blowing applied for the production of layers used here created a mixture of fibers with different diameters in one layer. Advantageously, compared to other manufacturing technologies using electrostatic forces to produce fibers (such as electrospinning), melt blowing has a very low residual electric charge.

This entry is adapted from the peer-reviewed paper 10.3390/ma14081937

References

- Wu, Z.; Fernandez-Lima, F.A.; Russell, D.H. Amino Acid Influence on Copper Binding to Peptides. J. Am. Soc. Mass Spectrom. 2010, 21, 522–533.

- Kryštůfek, J.; Militký, J.; Vik, M.; Wiener, J. Textile Dyeing and Applications; TUL Press: Liberec, Czech Republic, 2013; p. 334.

- Militký, J.; Prince, A.; Venkataraman, M. (Eds.) Textiles and Their Use in Microbial Protection; CRC Press: Boca Raton, FL, USA, 2021.

- Howard, J.; Huang, A.; Li, Z.; Tufekci, Z.; Zdimal, V.; van der Westhuizen, H.; von Delft, A.; Price, A.; Fridman, L.; Tang, L.; et al. Face Masks Against COVID-19: An Evidence Review. Preprints 2020, 2020040203.

- Chua, M.H.; Cheng, W.; Goh, S.S.; Kong, J.; Li, B.; Lim, J.; Mao, L.; Wang, S.; Xue, K.; Yang, L.; et al. Face Masks in the New COVID-19 Normal: Materials, Testing, and Perspectives. Research 2020.

- Greene, V.W.; Vesley, D. Method for evaluating effectiveness of surgical masks. J. Bacteriol. 1962, 83, 663–667.

- Rengasamy, S.; Eimer, B.; Shaffer, R.E. Simple respiratory protection—Evaluation of the filtration performance of cloth masks and common fabric materials against 20–1000 nm size particles. Ann. Occup. Hyg. 2010, 54, 789–798.

- Swennen, G.R.J.; Pottel, L.; Haers, P.E. Custom-made 3D-printed face masks in case of pandemic crisis situations with a lack of commercially available FFP2/3 masks. Int. J. Oral Maxillofac. Surg. 2020, 49, 673–677.

- Lee, S.; Obenorf, K. Use electrospun nanofiber web for protective textile materials as barriers to liquid penetration. Text. Res. J. 2007, 77, 696–702.

- Mishra, R.; Militký, J. In The Textile Institute Book Series, Nanotechnology in Textiles; Woodhead Publishing: Cambridge, UK, 2019; pp. 35–161.

- Yang, S.; Lee, G.W.; Chen, C.M.; Wu, C.C.; Yu, K.P. The Size and Concentration of Droplets Generated by Coughing in Human Subjects. J. Aerosol Med. Off. J. Int. Soc. Aerosols Med. 2007, 20, 484–494.

- Novák, O.; Chaloupek, J. Preparation of Microporous Layers by Melt-Blown Technology; 2021; Unpublished work.