It is a fact that electric vehicles (EVs) are beneficial for climate protection. However, the current challenge is to decide on whether to reuse an EV battery or to recycle it after its first use. The concept of reusing (second life) of the battery is promising because, at the end of the first life, batteries from EVs can be used in several applications such as storing energy generated from renewable sources to support the government grid.

- battery recycling

- battery reuse

1. Electric vehicles (EVs)

Electric vehicles (EVs) could play a major role in mitigating the effect of climate change. It is expected that EVs can help in decarbonising and building a sustainable world. The deployment of EVs is being boosted by public administrations in several regions of the world. The global deployment of EVs increased from 17,000 in the year 2010 to 8.5 million by the year 2020 [1]. Such rising trends correspond to increasing demand for high-performance batteries for EVs such as Li-ion batteries (LIB) [2], which is regarded as the most promising chemistry for EVs due to their intrinsic characteristics and significant cost reduction in the past decade (from USD 1100/kWh in 2010 to USD 156/kWh in the year 2019) [3][4][5].

The expected large increase of electric batteries’ presence in the automotive sector in coming years [6] will pose a challenge of how to deal with the batteries when their first useful life is finished. Given the high environmental impact associated with the manufacturing of a new battery [7], once the battery is removed from the vehicle treating it as waste is not an appropriate solution. In this situation, the battery industry is facing two options to deal with the battery’s end-of-life (EoL) phase,

-

Redirect the battery to a second life-use circuit where the useful life is extended providing alternative energy storage services, thus, reducing the environmental impact per kWh delivered by the battery.

-

Transfer the battery to a recycling circuit where a large percentage of valuable components, in particular critical raw materials (CRM), are retrieved and reused to manufacture new batteries, thus reducing the environmental impact of the manufacturing process.

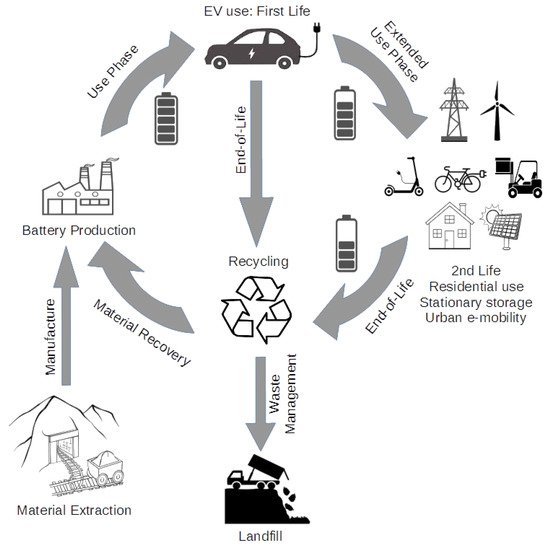

Despite having two alternatives, once the second life use is finished the battery is sent to the second option to be recycled as part of a circular economy strategy to minimize the amount of waste produced. A visual representation of the battery’s life in a circular economy perspective is shown in Figure 1.

Figure 1. Battery life in a circular economy perspective.

According to [8], the estimated number of used EV batteries available will increase from 50,000 in the year 2020 to 150 million in the year 2035, showing the importance of having a recycling infrastructure and established reuse procedures ready to deal with the incoming wave of aged batteries.

Nonetheless, the manufacture of batteries has an important environmental impact. The generation of EVs developed in the year 2010 using LIB had a battery energy of 16 or 24 kWh at most with a range of about 100 km. The global warming potential (GWP) was the first category that life-cycle assessments analysed, noting that, for first EVs, the production of the battery represented about 40% of the total environmental impact of a vehicle, which put the EV in a worse position from an environmental perspective in comparison to an internal combustion engine vehicle (ICEV) [9]. Thus, it was during the use phase when EVs gained a better overall picture, although it strongly depended on the country where the EV was run and, in some cases, the benefits were not so evident [10].

In order to fulfil the range-anxiety standards, EV battery capacity has continuously increased since then, giving the EV battery cost decrease a similar final cost for EVs over time. Nowadays, the battery energy of EVs ranges from 30 to 90 kWh with an average selling close to 44 kWh [11].

2. Development

After 10 years of development, batteries have improved in all possible directions (performance, cost and environmental burdens). Nonetheless, the GWP of the production phase of EVs with 64 kWh of battery energy storage capacity is still 25% higher in comparison to diesel vehicles. Although the GWP was triggering the entrance of EVs into the mobility sector, there are other categories in which the environmental impact of EV manufacturing substantially worsens in comparison to ICEV, which are abiotic depletion, photochemical oxidation, acidification and eutrophication, all of them having impacts higher than 50% [12]. Knowing that many of the materials used in battery manufacturing are considered critical materials [13], abiotic depletion is now the principal reason for developing new battery chemistries with lower environmental impact.

Nevertheless, EV batteries could be reused in other applications after their 1st life on a vehicle. There are two reasons to support this idea: (i) for smaller batteries, they are not considered appropriate for transport purposes after they’ve lost about 20% or 30% of their initial capacity and should be replaced [14]; (ii) for bigger batteries, they will be mostly misused as daily trips demand around 5 to 10 kWh [15]. This fact suggests that the EV EoL, according to the ageing trend taken from the EV degradation tool [16] transposed to kWh delivered, will be reached before the aforementioned threshold.

EV battery reuse represents an opportunity to increase its lifetime until its full operational life is completed. This life enlargement could avoid the manufacture of new batteries for these secondary uses and, consequently, reduce the potential environmental burden.

There are multiple applications in which batteries could be reused. Some are based on stationary applications as batteries can be used in the whole electricity chain, from huge storage systems supporting electricity generation to small devices for residential purposes [17][18] as well as other uses for micro or urban electro-mobility. Moreover, battery reuse gives time to improve the recycling processes and increase the recycling industry capacity [17].

Finally, recycling plays an important role because many of the key performance materials are considered critical materials and because all batteries (from first and second life) will end up here. The manufacturing cost of batteries strongly depends on the exploitation of resources that are difficult to obtain (from a technical, quantity and social perspective). Moreover, going to the main source, to extract raw materials involves a significant increase in ecological footprint. Thus, recycling of batteries has become quite important.

As evidence of the importance of recycling, several countries count on lithium battery recycling plants, such as the United States, Canada, South Korea, China and also in Europe, which pursues an interest in being more sustainable and lowering the production costs of these batteries by reusing their raw materials. Different processes with different efficiencies are accessible depending on the recycling interest, ranging from high recoveries of copper and aluminium to high recoveries of all the components of the battery in the form of compounds such as cobalt sulphate, nickel sulphate or lithium carbonates [19].

The main recycling option is hydrometallurgical recycling, which is normally accompanied by a pre-processing method that can be either mechanical, such as crushing or cutting of the battery components, or a pyrometallurgical method with a melting or pyrolysis process of the battery elements. In most of these recycling plants, the focus is on obtaining metals such as cobalt and nickel.

3. Reuse

There are multiple stationary applications where electric energy storage systems could be installed that can be gathered in two groups [20]. The first group is oriented to electricity generation and grid distribution with larger-scale installations such as time-shifting, seasonal energy storage, large-scale renewable integration, transmission and distribution investment deferral or grid regulation. The second group is more oriented to a user-level perspective, in this case, there are both relatively high, medium and small-scale installations depending on the final user (industry, tertiary or residential building) like energy management, power quality, power reliability, distributed renewable integration and transportation applications.

In both groups, power requirements range from a few KW to several hundred MW and some of them require fast response times while others do not. Similarly, their storage capacity range from kWh to MWh and the services might ask for several hours of energy delivery or only for some minutes of support.

In this sense and given that EV batteries had an average energy capacity of 44 kWh in 2019 and that the largest capacity of existing EV batteries is currently around 100 kWh, more than one battery will be necessary for most applications and even a combination of batteries to meet the energy requirements [21].

The particularity of battery reuse is that the availability of second-life batteries does not depend on the investment of the repurposing manufacturer, in contrast to new raw material factories, where one can invest more to increase the extraction rates. For battery reuse, the availability of batteries depends basically on the rate of EV retirement, knowing that retirement might come from ageing or from an accident, in which case the safety procedures are quite relevant [22] and not all batteries will be accepted for reuse.

Thus, the volume of vehicle batteries to come in future years will depend on the EV sales from previous years, driving habits and the environment where the vehicle drives. In any case, the good news is that stationary application storage needs are lower than for electric mobility and, in 10 years, most of them could be covered with the growing electric mobility market.

However, there is an issue that is expected to occur at least in the early stages of the collection of these batteries, which is the heterogeneity in terms of battery models, forms, control, chemistry and electrical characteristics among others. This heterogeneity will increase with the continuous advances in this field that will bring better performant batteries, because a new product is inherently different to any other previously in the market and, thus, another battery should be considered by remanufacturers. However, the higher selling rates expected for future years of all existing models will de-crease the necessity to have a multiplicity of EV battery adaptations from mobility to stationary applications. The inhomogeneity in batteries is always undesirable [23].

In this sense, and to be able to make use of the volume of batteries that reach these early stages, second-life batteries should preferably be installed in small-medium scale applications to minimize this variability for a single installation while larger-scale installations should wait for newer vehicles to age. However, a possible direction with high added value is to use them through individual control of cells that build a battery. This direction opens the possibility of combining chemistries in a single battery unit, as the combination of cells would focus on some electrical storage parameters, such as the state of charge of the batteries, and would be able to make individual use of the energy available in each cell to maximize the overall battery performance. The distribution of current would also be managed by a control body in which, once the energy reserves of a cell have been exhausted, it would open the circuit of that cell to continue making use of the rest through active balancing techniques [24].

This heterogeneity is also affected by the SOH of batteries and cells within (which active balance also covers). Several authors have already highlighted that the 70% SOH limit marked by car manufacturers is not mandatory and batteries will arrive at all kind of SOH because it will be marked by the final owner who has the final responsibility to decide when to proceed to the EV retirement [25].

However, for newer and bigger battery capacities and seeing the battery ageing tendencies of EV fleets [16], this limit is not expected to be reached in most of the cases due to its misuse during its lifetime in the vehicle.

Thus, it is expected that, for the first generation of EV batteries sold, many batteries will reach their EoL as soon as they are removed from the vehicle and should proceed to recycle. However, for newer EV models, batteries will present much better conditions for their use in the second life, which can be either in stationary storage applications or in EVs as spare parts for those with manufacturing defects or crashes that need low-cost replacements.

For all that, battery reuse might follow three possible directions depending on the goal of the remanufacture pursues. Direct reuse and battery dismantling to the module or cell level [26]. Direct reuse offers lower costs but it provides less adaptability options due to stacking problems. The option of module dismantling allows for a more versatile solution, capable of going from small to large systems. However, a new battery management system (BMS) and control systems should be implemented. This option is called to be the one mostly used by remanufacturing companies. Finally, the dismantling into cells maximizes the versatility and reduces the inhomogeneity of the resulting battery, as an individual selection of cells according to their SOH and other characteristics can be undertaken. Nonetheless, the cost rises due to an increase in the manipulation, testing and need to implement completely new control systems at the cell, module and battery level [27].

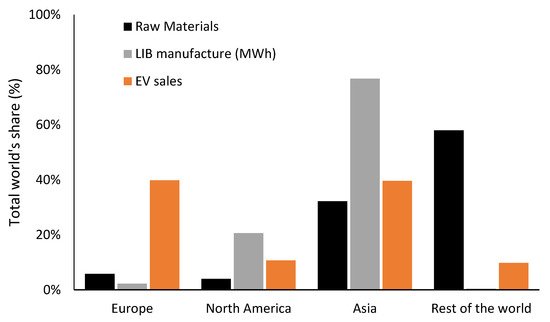

Overall, going for battery reuse strategies give the chance to Europe to become a potential battery manufacturer. At the moment, Europe is dependent on raw materials and also on new batteries built elsewhere. Once battery recovery begins, Europe will be capable of positioning itself as a potential world provider, as most EVs are being sold mainly in Europe (39.8%), China (39.6%) and North America (10.7%) [28][29] as shown in Figure 2.

Figure 2. Percentage of electric vehicle (EV) world sales.

This entry is adapted from the peer-reviewed paper 10.3390/en14082217

References

- BloombergNEF. Electric Vehicle Outlook 2020; BloombergNEF: London, UK, 2020.

- Lebedeva, N.; Di Persio, F.; Boon-Brett, L. Lithium Ion Battery Value Chain and Related Opportunities for Europe; Publications Office of the EU: Luxembourg, 2016.

- Blagoeva, D.T.; Aves Dias, P.; Marmier, A.; Pavel, C.C. Assessment of Potential Bottlenecks Along the Materials Supply Chain for the Future Deployment of Lowcarbon Energy and Transport Technologies in the EU. Wind Power, Photovoltaic and Electric Vehicles Technologies, Time Frame 2015–2030; Joint Research Centre (European Commission): Luxembourg, 2016.

- IEA. Global EV Outlook 2018: Towards Cross-Modal Electrification; IEA: Paris, France, 2018.

- Zubi, G.; Dufo-López, R.; Carvalho, M.; Pasaoglu, G. The lithium-ion battery: State of the art and future perspectives. Renew. Sustain. Energy Rev. 2018, 89, 292–308.

- Rietmann, N.; Hügler, B.; Lieven, T. Forecasting the trajectory of electric vehicle sales and the consequences for worldwide CO2 emissions. J. Clean. Prod. 2020, 261, 121038.

- Peters, J.F.; Baumann, M.; Zimmermann, B.; Braun, J.; Weil, M. The environmental impact of Li-Ion batteries and the role of key parameters—A review. Renew. Sustain. Energy Rev. 2017, 67, 491–506.

- Acatech—National Academy of Science and Engineering; Circular Economy Initiative Deutschland. Resource-Efficient Battery Life Cycles. Driving Electric Mobility with the Circular Economy; National Academy of Science and Engineering: Munich, Germany, 2020.

- Girardi, P.; Gargiulo, A.; Brambilla, P.C. A comparative LCA of an electric vehicle and an internal combustion engine vehicle using the appropriate power mix: The Italian case study. Int. J. Life Cycle Assess. 2015, 1127–1142.

- Canals Casals, L.; Martinez-Laserna, E.; Amante García, B.; Nieto, N. Sustainability analysis of the electric vehicle use in Europe for CO2 emissions reduction. J. Clean. Prod. 2016, 127, 425–437.

- IEA. Global EV Outlook 2020; IEA: Paris, France, 2020.

- Marmiroli, B.; Venditti, M.; Dotelli, G.; Spessa, E. The transport of goods in the urban environment: A comparative life cycle assessment of electric, compressed natural gas and diesel light-duty vehicles. Appl. Energy 2020, 260, 114236.

- Song, J.; Yan, W.; Cao, H.; Song, Q.; Ding, H.; Lv, Z.; Zhang, Y.; Sun, Z. Material flow analysis on critical raw materials of lithium-ion batteries in China. J. Clean. Prod. 2019, 215, 570–581.

- Heymans, C.; Walker, S.B.; Young, S.B.; Fowler, M. Economic analysis of second use electric vehicle batteries for residential energy storage and load-levelling. Energy Policy 2014, 71, 22–30.

- Canals Casals, L.; Rodríguez, M.; Corchero, C.; Carrillo, R.E. Evaluation of the End-of-Life of Electric Vehicle Batteries According to the State-of-Health. World Electr. Veh. J. 2019, 10, 63.

- Geotab EV Battery Degradation Comparison Tool. Available online: (accessed on 1 September 2020).

- White, C.; Thompson, B.; Swan, L.G. Repurposed electric vehicle battery performance in second-life electricity grid frequency regulation service. J. Energy Storage 2020, 28, 101278.

- Jiao, N.; Evans, S. Business Models for Sustainability: The Case of Second-life Electric Vehicle Batteries. In Proceedings of the Procedia CIRP; Elsevier B.V.: Amsterdam, The Netherlands, 2016; Volume 40, pp. 250–255.

- Lv, W.; Wang, Z.; Cao, H.; Sun, Y.; Zhang, Y.; Sun, Z. A Critical Review and Analysis on the Recycling of Spent Lithium-Ion Batteries. ACS Sustain. Chem. Eng. 2018, 6, 1504–1521.

- Gallo, A.B.; Simões-Moreira, J.R.; Costa, H.K.M.; Santos, M.M.; Moutinho dos Santos, E. Energy storage in the energy transition context: A technology review. Renew. Sustain. Energy Rev. 2016, 65, 800–822.

- Coelho, V.N.; Coelho, I.M.; Coelho, B.N.; Cohen, M.W.; Reis, A.J.R.; Silva, S.M.; Souza, M.J.F.; Fleming, P.J.; Guimarães, F.G. Multi-objective energy storage power dispatching using plug-in vehicles in a smart-microgrid. Renew. Energy 2016, 89, 730–742.

- Wöhrl, K.; Geisbauer, C.; Nebl, C.; Lott, S.; Schweiger, H.-G. Crashed Electric Vehicle Handling and Recommendations—State of the Art in Germany. Energies 2021, 14, 1040.

- Hunt, I.; Zhang, T.; Patel, Y.; Marinescu, M.; Purkayastha, R.; Kovacik, P.; Walus, S.; Swiatek, A.; Offer, G.J. The Effect of Current Inhomogeneity on the Performance and Degradation of Li-S Batteries. J. Electrochem. Soc. 2018, 165, A6073–A6080.

- Scott, K.; Nork, S. Active Battery Cell Balancing. Available online: (accessed on 27 March 2021).

- Saxena, S.; Le Floch, C.; Macdonald, J.; Moura, S. Quantifying EV battery end-of-life through analysis of travel needs with vehicle powertrain models. J. Power Source 2015, 282, 265–276.

- Canals Casals, L.; Amante García, B. Assessing electric vehicles battery second life remanufacture and management. J. Green Eng. 2016, 6, 77–98.

- Rallo, H.; Benveniste, G.; Gestoso, I.; Amante, B. Economic analysis of the disassembling activities to the reuse of electric vehicles Li-ion batteries. Resour. Conserv. Recycl. 2020, 159, 104785.

- Roland Irle Global Plug-in Vehicle Sales Reached over 3.2 Million in 2020. Available online: (accessed on 27 March 2021).

- Mayyas, A.; Steward, D.; Mann, M. The case for recycling: Overview and challenges in the material supply chain for automotive li-ion batteries. Sustain. Mater. Technol. 2019, 19, e00087.