The process of inorganic polymerization or the sol–gel method is an inexpensive, low-energy consuming, and stable process for obtaining high-purity ceramics, which offer versatility for the production of different kinds of devices, some of which can be used in surface-enhanced spectroscopy such as Surface Enhanced Infrared Absorption Spectroscopy (SEIRAS) and Surface Enhanced Raman Spectroscopy (SERS).

- sol–gel

- ceramics

- SEIRAS

- SERS

- spectroscopy

1. Introduction

The process of inorganic polymerization or the sol–gel method is an inexpensive, low-energy consuming, and stable process for obtaining high-purity ceramics, which offer versatility for the production of different kinds of devices, some of which can be used in surface-enhanced spectroscopy such as Surface Enhanced Infrared Absorption Spectroscopy (SEIRAS) and Surface Enhanced Raman Spectroscopy (SERS) [1,2,3]. The sol–gel process uses reactants such as alkoxides and metal salts involved in a relatively easy hydrolysis reaction [4]. The alkoxides or salts are partially hydrolyzed and then polymerized through condensation, allowing the formation of a tridimensional structure, a gel [5]. Sol–gel-derived ceramics, glasses, and composites offer distinct properties that can be taken advantage of in order to shape or fashion materials with uses ranging from thin films to matrixes, fibers, and monoliths, amongst others [6,7]. A variety of uses such as corrosion protection [8], antibacterial activity [9], bioactive behavior [10], energy storage [11], and catalytic activity [12] can be achieved. Sol–gel ceramic materials can be tailor-made in the nanoscale dimension [13]. Single component or composites [14] allow for exploitation of the properties of the constituents as well as the properties of the ultrastructure of the material [15].

Through various synthesis and surface modification techniques that focus on the production of nanostructures with complex shapes, it has been possible to obtain amplification surfaces with different degrees of success for spectroscopy [16]. The shape of the nanostructures can increase the number of hot spots on the amplification surface, but the function ultimately depends on the reproducibility of the nanostructures and the response, the characteristics of the materials used such as chemical and mechanical resistance, as well as the cost–benefit ratio of the materials used. The use of sol–gel ceramic precursors and the electrospinning technique make the production of fibrous ceramic enhancement substrates for infrared and Raman spectroscopy possible [17]. Such materials have an increased surface area, which provides the capability to enhance spectroscopy signals due to better contact with the analytes [18].

Sol–gel ceramics can also provide the chemical and mechanical resistance much needed for reuse of the substrates [19]. In this review, we discussed the use of the sol–gel method for the obtention of ceramics such as silica, zirconia, titania, hydroxyapatite, lithium niobate, and alumina and their role in the production of enhancement substrates. Lastly, some advances in this research path have been highlighted.

2. Electrospinning of Sol–Gel Ceramic Precursors

| Ceramic | Diameter (nm) | Use | Reference |

|---|---|---|---|

| Silica | ≈500 | Beryllium uptake | [108] |

| Zirconia | ≈360 | Dye sorption | [109] |

| Zirconia | ≤200 | Fuel cells | [110] |

| Titania | ≤80 | Heat transport | [111] |

| Titania | ≈160 | Antimicrobial activity | [112] |

| Hydroxyapatite | ≤330 | Bioactive behavior | [113] |

| Hydroxyapatite | ≈150 | Metal adsorption | [114] |

| Lithium niobate | ≈190 | Piezoelectric behavior | [115] |

| Alumina | ≤250 | Filtration device | [116] |

| Alumina | ≤250 | Catalyst support | [117] |

3. Sol-Gel Ceramics for SEIRAS and SERS

Different approaches have been taken to incorporate electrospun ceramic nanofibers on the SEIRAS and SERS technologies in order to resolve some of the issues of the mass adoption of such techniques, for example, the reusability, reproducibility, and stability of the enhancement substrates. Xie et al. [117] developed a material using titanium and fluorine-doped tin oxide sheets as supports. The precursor of choice for the sol–gel titania was titanium butoxide. They were able to obtain two kinds of morphologies: a nanorod array where the surface of the support is covered with rods arranged randomly, mostly pointing up and covered with silver nanoparticles, and a nanopore array, a honeycomb-like structure with more regular features and covered with silver nanoparticles. The materials were capable of detecting concentrations of 5 × 10−12 M of 4-mercaptobenzoic acid. The use of titania’s photocatalytic activity allowed for the material to be regenerated using UV radiation. Xie and Meng [118] created a material composed of sol–gel titania, a nanotube array covered in silver nanoparticles and decorated with graphene oxide. The addition of graphene oxide was proposed as a solution for increased adsorption since it can chemically enhance the spectroscopy signals in comparison with a TiO2/Ag material. The material was successful in enhancing the Raman signals of bisphenol A concentrations as low as 5 × 10−7 M.

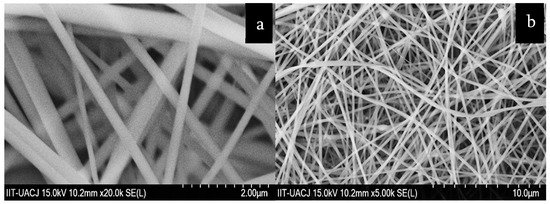

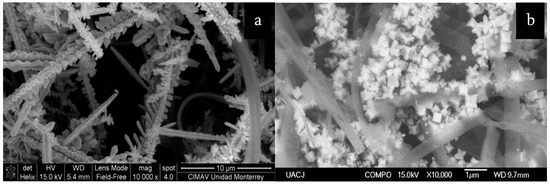

Roque-Ruiz et al. [119] developed a fibrous material composed of coaxial fibers with an amorphous silica core and a crystalline TiO2 sheath, mostly anatase (Figure 7a). Tetraethyl orthosilicate and titanium tetra-isopropoxide were used as precursors. The composite was decorated with silver nanoparticles that formed an outer cover of dendritic structures. Concentrations of 1 nM pyridine were tested and different peaks in the Raman spectrum were amplified between 3 and 13 orders of magnitude. Singh et al. [120] developed a material consisting of a silica thin film covered by TiO2 and gold nanoparticles. The titania nanoparticles were obtained using the sol–gel method and deposited on top of a silicon substrate, then covered with a thin film of gold, and annealed in order to form the gold nanoparticles. The substrate was tested for enhancement, achieving an enhancement factor of 107 for R6G and 108 for methylene blue. Prakashan et al. [121] produced a ceramic matrix of SiO2–TiO2–ZrO2 with gold–silver nanoparticles specifically for the detection of vitamin A. The matrix was obtained using a non-hydrolytic version of the sol–gel method, with tetraethylorthosilicate, titanium (IV) isopropoxide, and zirconium (IV) propoxide as precursors, and then, the nanoparticles were mixed into the matrix using sonication. Although the substrate was not tested for enhancement of Raman or infrared signals, it was tested for amplification of UV/Vis spectroscopy utilizing surface plasmon resonance sensing, achieving a detection of concentrations as low as 10 µM of vitamin A. Prakashan et al. [122] also tested a similar SiO2–TiO2–ZrO2 ceramic matrix, but instead of Au and Ag nanoparticles, the gold was substituted for copper, in this case, for the detection of mercury. The spectroscopic technique used was also the sensing of SPR. The material had high selectivity for such metals, achieving detection of concentrations as low as 0.01 µM of Hg. The material could possibly be used for enhancement of infrared and Raman spectroscopy.

Hareesh et al. [123] synthesized a TiO2–ZrO2 thin film with embedded silver nanoparticles for the detection of R6G through SERS. The ceramic film was obtained using the sol–gel method with titanium (IV) isopropoxide and zirconium (IV) propoxide as precursors. Two sols were produced and then mixed with silver nitrate and dimehtylformamide in order to form silver nanoparticles. The substrate was able to detect a concentration of R6G as low as 10-18 M, as referenced by the article, as a single R6G molecule. Ji et al. [124] used zirconium nitrate as the precursor for producing ZrO2 nanoparticles through the sol–gel method. Sintering temperatures ranging from 450 to 650 °C were used, and two crystalline phases were obtained, tetragonal and monoclinic, with the latter in the highest proportion. The diameter of the particles ranged from 8.1 to 17.6 nm, or an average of 10.5 nm, and such sizes increased with the increase in sintering temperature. The highest enhancement factor of 4.32 × 103 was achieved through the adsorption of 4-MBA on the surface of the particles and calcination at 500 °C. Hu et al. [125] produced through templating a nanoarray consisting of silver nanopillars in a flower-like disposition covered with anodized aluminum oxide for corrosion protection of the silver. In order to fashion such a material, sol–gel silica was used in one step of a multi-step process as corrosion protection for the aluminum metal sheet used as a substrate. A Raman enhancement test was carried out on the material, detecting R6G concentrations from 10−10 M to 10−7 M. Li et al. [126] produced a composite of α-Fe2O3–SiO2–Ag for the detection of pesticides. The iron and silver nanoparticles were obtained using iron (III) hexachloride and silver nitrate, respectively. The silica was obtained through the sol–gel method using TEOS as a precursor and ammonia as a catalyzer. The iron nanoparticles had a cube-like morphology and were covered by a layer of silica; then, the silver nanoparticles coated the exterior of the Fe–SiO2 nanoparticles. The final composite was tested for signal enhancement in analyzing different concentrations of p-aminothiophenol ranging from 1 × 10−4 M to 1 × 10−4 M, and concentrations of thiram ranging from 1 × 10−3 M to 1 × 10−7 M. The composite achieved a detection of thiram in concentrations lower than 7 ppm, which is lower than the limit set by the United States Environmental Protection Agency as of 2016 for such a fungicide.

Shi et al. [127] developed a ZrO2–Ag–SiO2 composite for SERS applications. Silica nanoparticles were prepared using TEOS as a precursor and ammonia as a catalyzer. Silver nanoparticles were deposited on top of the SiO2 as an intermediate layer, and then, the SiO2–Ag composite was covered in a ZrO2 layer obtained through the sol–gel method and using zirconium (IV) propoxide as a precursor. The estimated diameter of the silica nanoparticles was 340 nm and that of the silver nanoparticles was 30 nm. The composite had a SERS activity capable of detecting concentrations of 4-ATP and R6G in the ranges of 10−9 M and 10−8 M, respectively. Soto-Nieto et al. [128] produced a fibrous composite of silica, hydroxyapatite, and silver for the enhancement of spectroscopic signals in SEIRAS and SERS. Silica and hydroxyapatite were obtained using the sol–gel method with TEOS and triethyl phosphite–calcium nitrate as precursors, respectively. Fibrous mats were fabricated through electrospinning by mixing the sols with PVP and by sintering at temperatures from 200 to 1150 °C. The fibers had an average diameter of 304 nm (Figure 7b). The fibrous mats were doped with silver nanoparticles using electrodeposition and AgNO3 as the precursor. The SEIRAS enhancement factor was estimated as 2.01 × 106, and the SERS enhancement factor was estimated as 3.46 × 108.

This entry is adapted from the peer-reviewed paper 10.3390/cryst11040439