Baijiu is a type of distilled liquors and is made from grain fermentation induced by Daqu, Xiaoqu and Fuqu as possible sacchariferous agents through solid saccharification, fermentation, distillation in barrels (named Zengtong), long-time storage in porcelain jars and blending processes.

- Baijiu

- automatic technology

- intelligent technology

- solid-state fermentation

- solid-state distillation

1. Introduction

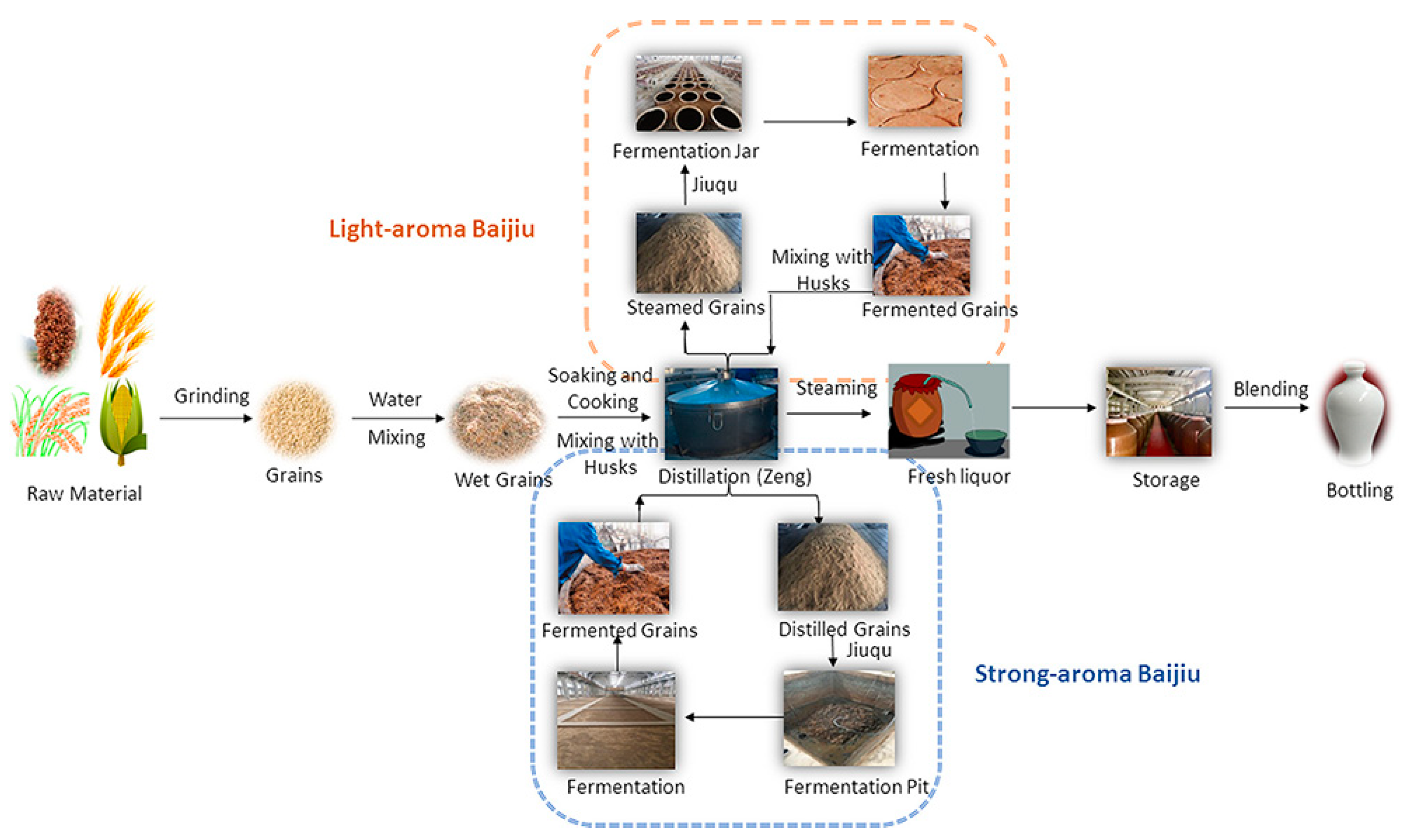

Baijiu is the national liquor of China with a 2000-year history and one of the oldest distilled liquors in the world. Baijiu is also the world's most-consumed spirit; for example, the gross sales of Baijiu in 2019 were more than $80 billion [1]. Furthermore, it is very famous not only in China but also in other countries worldwide [2]. Baijiu, brandy, whisky, vodka, gin, and rum are considered as six of the most famous distilled liquors manufactured worldwide [3]. According to the flavor characteristics, Baijiu can be classified into 12 flavor styles: Nong- (strong), mild (light), Jiang- (soy sauce), Mi-, Feng-, Chi-, Te-, herbal, Fuyu-, sesame, Laobaigan-, and Jian- (Nongjiang-) flavor types. The Nong-flavor type is the most important representative of the Baijiu flavors followed by the mild flavor. As the production processes shown in Figure 1, the raw materials are mixed with whole or powdered grains and are then wetted and cooked. Then, the mixture in a solid state is cooled to the appropriate temperature (about 18–35 °C), mixed with Jiuqu (Koji), and placed in a fermentation jar or pit. When the fermentation is finished, the fermented grains remaining in the solid state are removed for distillation to obtain the base liquor. After a long storage period followed by blending, the commercial liquor can be obtained.

As shown in Figure 1, it represents a traditional solid-state fermentation (SSF) process that all of the materials during transportation, mixing, fermentation, distillation, and reuse are solid. Almost all of the famous high-quality Baijiu brands in China are produced using SSF, except for the Mi- and Chi-flavor Baijiu. In contrast, other distilled liquors worldwide are generally the products of liquid-state fermentation (LSF).

SSF is more challenging than LSF for the following reasons. First, from the perspective of material transportation, the efficiency of the conveying equipment for solid materials is not as high as that of a pump for liquid transportation. Second, from the perspective of heat transfer, the heat exchange among solid materials is more difficult than in liquids. Thus, the temperature distribution in solid materials is often not uniform, making the product quality unstable. This is especially evident during the processes of Daqu production and SSF. Third, because the required temperature variation for SSF is slow and moderate, the traditional fermentation containers (such as pits or earthenware jars) are usually set underground. As such, it is difficult to monitor their fermentation parameters, resulting in a “black box” fermentation process. Fourth, most of the processes in the production of Baijiu (e.g., fermentation, distillation, and storage) are batch operations, in which the materials require manual operations and a long residence time. As a result, it is difficult to apply unified modern food processing equipment and automatic production lines to the manufacture of Baijiu. Nevertheless, during the last decade, there have been great developments in the automation and intellectualization of Baijiu manufacturing. It is a pity that few reports have focused on the advances in this area.

2. Automatic Production Line for Baijiu

A mechanized production line has been built in most manufacturing plants for Baijiu, but the continuity between different production parts is generally low [4][5]. Recently, continuous and automatic production lines for SSF Baijiu have been gradually built for MFB production after the continuous operations for starter-making, fermentation, and distillation have been achieved.

Shandong Jingzhi Liquor Co., Ltd. (Weifang, China) [6] built 13 automatic and intelligent production lines for NFB. Eight sets of key equipment for intelligent and automatic starter addition, steamer-filing, and air cooling were applied in each production line. In addition, remote monitoring was achieved using the Internet. Quantitative control was achieved for the ratio of raw grains to fermented grains, amounts of bran and Jiuqu, and physical and chemical properties of the grains before being placed into the pit. As a result, the operation process was stable, and the process execution rate was more than 98%. Owing to the implementation of automatic and intelligent production for NFB, the average liquor yield was 3% higher than with manual operation.

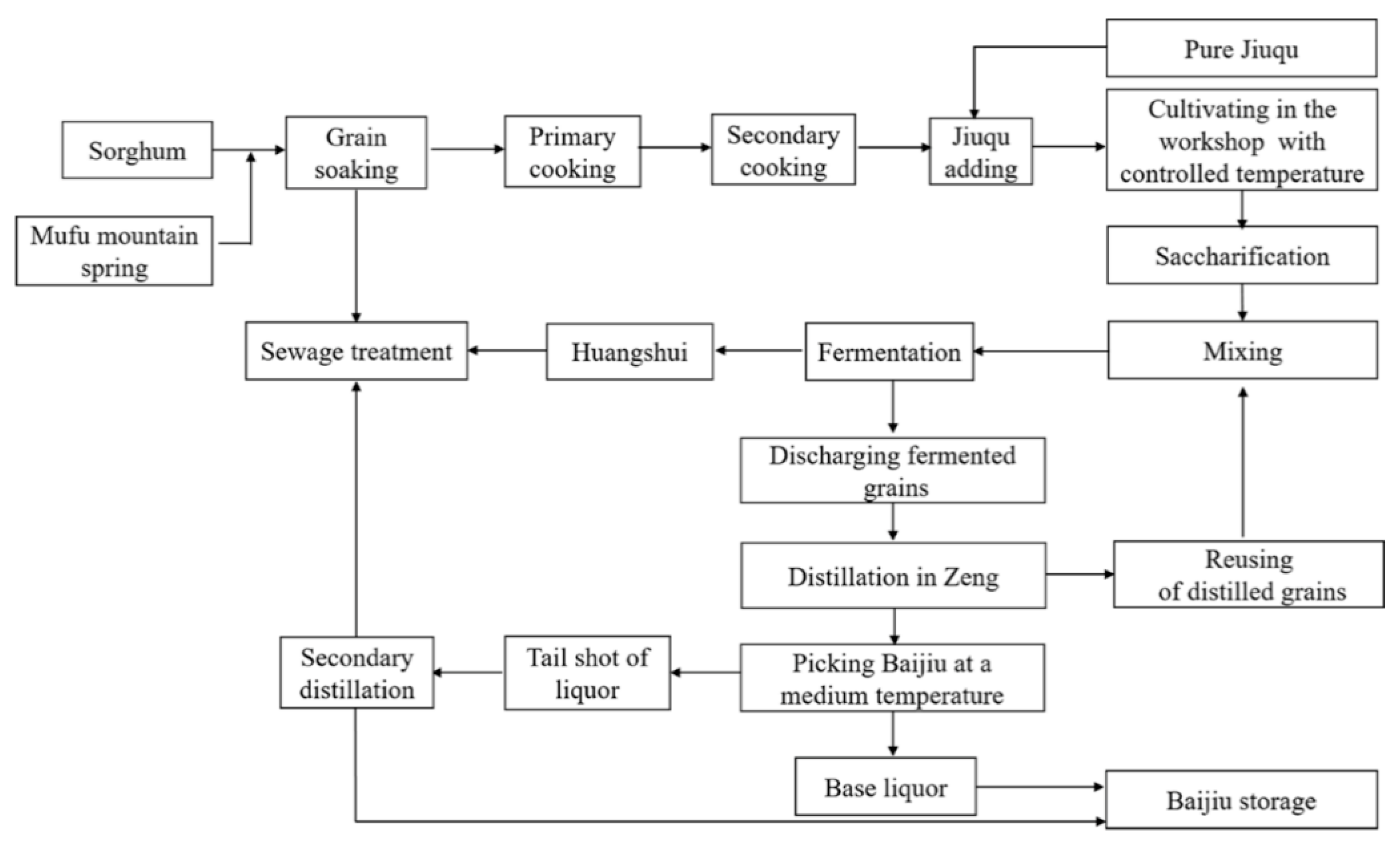

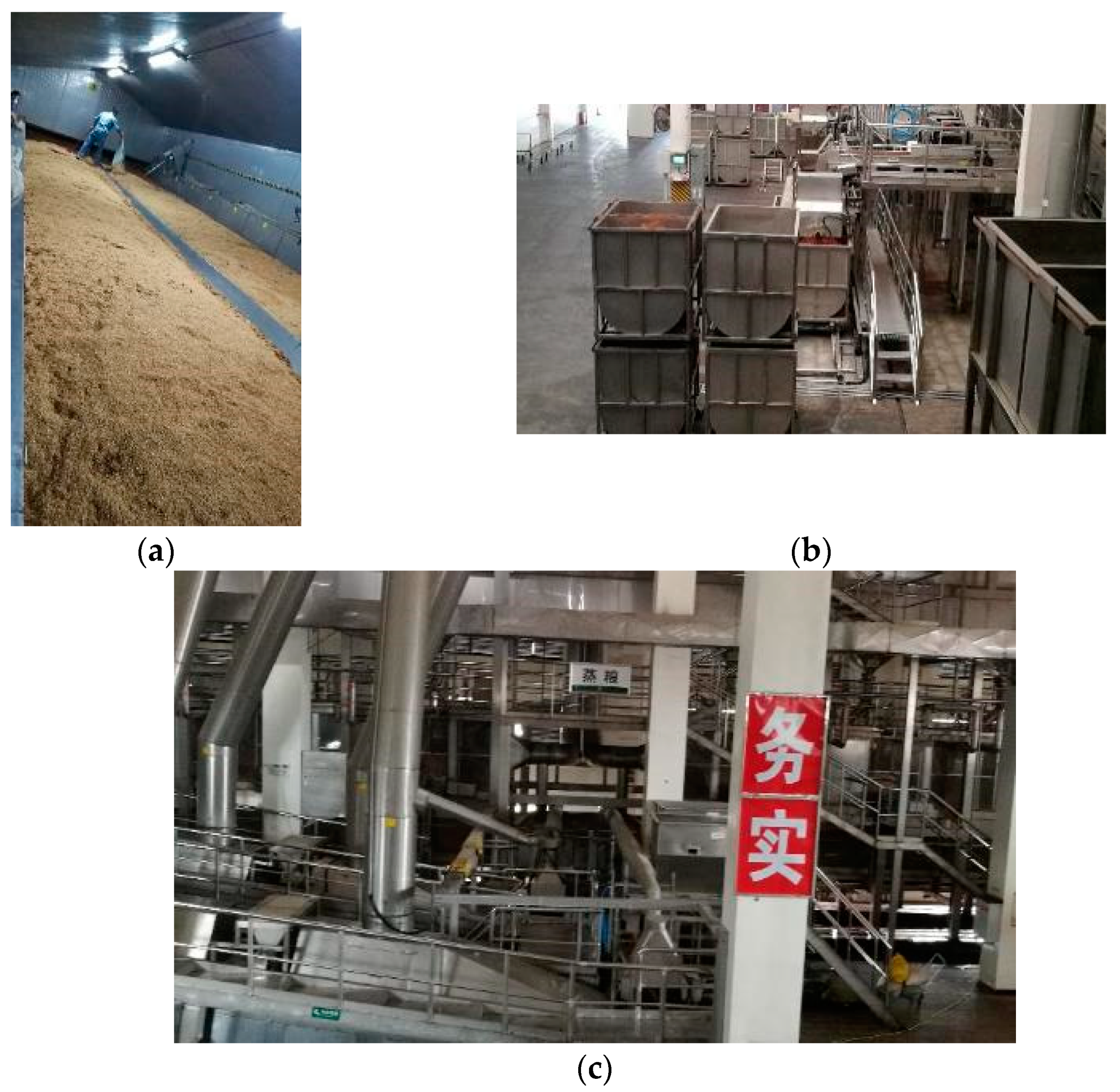

Relatively speaking, the degree of automation and intelligence for the Xiaoqu MFB produced by SSF is higher because of the use of the SSFT. For example, in 2010, Fenglin distillery of Jingpai Co., Ltd. (Huangshi, China) used an SSFT as the fermentation container for the brewing of Xiaoqu MFB for the first time [7]. Then, a complete automatic production line including grain steaming, cooling, Jiuqu addition, saccharification, fermentation, and distillation was gradually established as the “digital intelligent brewing demonstration workshop of Chinese Baijiu”. The production process is shown in Figure 9, and it is described as follows [8]. First, the raw grains were soaked in a stainless-steel tank for 20–24 h; then, they were transported by self-weight to a rotary grain steaming pot for high-pressure cooking. After cooking, the steamed grains were cooled down, and the Jiuqu was automatically added and mixed with the steamed grains. Then, the mixture was transported by a chain plate conveyor belt at a slow speed to saccharification workshops equipped with temperature-controlling equipment as shown in Figure 10a. After saccharification for 24 h, screw conveyors were used to evenly mix the saccharified and distilled grains, and movable fermentation tanks were used as the fermentation containers, as shown in Figure 10b. The fermentation tanks were placed in a fermentation chamber with a temperature control system for 15–18 days. After fermentation, the tanks with the fermented grains were placed on turnover machines by the forklift trucks, so as to discharge the grains to be transported to the distillation part by conveyor belts. The steamer-filling was conducted by intelligent robots, and automatic liquor picking was realized based on an online monitoring of the alcohol content. The obtained base liquor was weighed on site and was transported to the storage tanks directly through a pipeline. The distilled grains were discharged into another container through an openable bottom of the steamer. During the entire production process, only one or two workers were required to inspect the production line in the workshop as shown in Figure 10c; another few workers monitored the production parameters in the control center. The number of workers in the brewing workshop was reduced by 80% after the above production line was used, whereas the production efficiency was greatly improved.

Figure 9. Automatic brewing process of solid-state fermentation for Xiaoqu light flavor Baijiu (kindly provided by Fenglin distillery of Jingpai Co., Ltd., Huangshi, China).

The main reasons for realizing the complete automation of the production line of SSF for Xiaoqu MFB are as follows: (1) there is no need to move the materials in and out of the pit layer by layer, (2) the fermentation does not need the pit mud, and (3) the effects of the automation production on the Baijiu quality are small.

3. Conclusions and Prospects

With the rapid development of information technology, countries worldwide have proposed important strategic plans for the development of their manufacturing industries. For example, China’s “Made in China 2025” and Germany’s “Industry 4.0” aim to promote the automatic and intelligent upgrading of the manufacturing industry, which is crucial for increasing production efficiency and promoting industrial transformation. The production of Chinese Baijiu adopts a unique solid-state brewing process, which is quite different from the liquid-state brewing processes for other distilled spirits. Thus, the automatic production equipment for liquid-state brewing is not completely applicable to the production of Chinese Baijiu, especially for SSF and SSD processes. The relevant automatic equipment can only be developed independently in China, so as to improve production efficiency and obtain stable product quality. Generally speaking, the Baijiu manufacturing industry presents the wide popularization of mechanization, continuous development of automation, and budding of intellectualization. An “intelligent brewing” workshop based on information technology (such as Internet of Things, cloud computing, big data analysis, and intelligent robots) has been applied in Baijiu production. Currently, the following problems and challenges remain concerning the upgrading and development of the Baijiu industry.

(1) Control of the SSF process: Owing to the limited understanding of the SSF mechanisms, it is difficult to transfer pits for other flavor types of Baijiu, especially for NFB and JFB, from underground to overground. As a result, the manual work is necessary for the relevant operation for fermentation of these liquors, and the monitoring of the fermentation parameters is also difficult. As for the control of SSF processes of Baijiu, that is even more difficult. In other words, fermentation is the most difficult process insofar as realizing automatic and intelligent upgrading for Baijiu production. In the future, research on the mechanisms of SSF, especially the metabolic mechanisms of the microbial community, should be strengthened to develop artificial pit muds and novel fermentation tanks, or to study fermentation technologies without mud for NFB or JFB.

(2) Accuracy of the digital sensors: At present, the construction of the digital workshop for Qu-making and the intelligent liquor picking process strongly depend on the efficient and accurate responses of the sensors. The working efficiency of the sensors is closely related to their working environment. For example, pollution of the probe at the sensing end, or changes in the pH and/or flow type may affect the sensing accuracy. However, at present, there is a lack of comprehensive and systematic studies on the applicability, efficiency, and maintenance of sensors in different environments.

(3) Security of intelligent monitoring on the Internet: Owing to the rapid development of the Internet of Things, the parameters of the Baijiu production workshop can be transmitted to a cloud as big data for people to monitor, judge, and make decisions. These data are the most confidential production information for a manufacturer, and should be transmitted with higher security requirements; otherwise, there is high risk of the leakage of technical secrets. Thus, the data security problem cannot be ignored in network control.

(4) Intelligent ranking of Baijiu: The online technology for the accurate cutting of liquor distillates according to the contents and types of aromatic substances (instead of just ethanol content) must be further developed, which will save manpower and greatly increase the production efficiency. The key lies in the rapid identification of the different trace amounts of aromatic substances. The establishment of a quantitative relationship between the aromatic components and sensory evaluations (from tasters) is a very challenging research direction.

(5) Costs for upgrading technology and equipment in Baijiu manufacturing: At present, only large-scale Baijiu plants can afford transformations of digital and intelligent workshops and equipment. Small-scale Baijiu enterprises are limited by costs and cannot accept an automatic production line. Therefore, the cost of intelligent equipment (such as steamer-filling robots) is expected to be reduced to meet acceptable limits for such Baijiu manufacturers.

(6) Automatic and intelligent production changing the original flavor of the liquor and affecting consumer acceptance: This is something that many producers are very worried about, although the liquor flavors produced by a modern production line are very close to the corresponding traditional flavors. Nevertheless, modern production lines must be further improved to enhance the flavor of Baijiu; simultaneously, producers should put aside their misgivings and have faith in modern production techniques.

At present, the development directions for the liquor industry are oriented toward the modernization of production, internationalization of the market, and improving the health of products under the dual guidance of flavor and health. The industrial upgrading of Baijiu production represents the general trend for brewers worldwide. Intelligent equipment is being developed, such as robot inspectors for liquor storehouses and workshop displays via virtual reality technology. The upgrading of the Baijiu industry will usher in an era of “intelligent brewing” for Baijiu and provide a good reference for other brewing industries around the world.

This entry is adapted from the peer-reviewed paper 10.3390/foods10030680

References

- Jin, G.; Zhu, Y.; Xu, Y. Mystery behind Chinese liquor fermentation. Trends Food Sci. Technol. 2017, 63, 18–28.

- Ministry of Industry and Information Technology. Annual Report of China Food Industry; Light Industry Press: Beijing, China, 2020.

- Liu, H.; Sun, B. Effect of fermentation processing on the flavor of Baijiu. J. Agric. Food Chem. 2018, 66, 5425–5432.

- Li, Y.; Qi, S.; Qiu, L.; Meng, F. Research progress in and discussion on mechanized production of baijiu. Liquor Mak. Sci. Technol. 2016, 10, 82–84.

- Xie, Q. Practice on new technology for liquor making equipment mechanization. Liquor Mak. 2012, 39, 43–49, 61.

- Zhao, L.; Zhang, D.; Guo, X.; Meng, F.; Lai, A.; Zhao, D. Introduction to automated and intelligent production of nongxiang baijiu. Liquor Mak. Sci. Technol. 2017, 4, 82–87.

- Wang, Y. The application progress and prospect of liquor mechanization brewing process equipment. Yunnan Chem. Technol. 2019, 46, 39–44.

- Huang, Z.; Zhao, J.; Liu, S.; Li, D.; Jiang, H.; Jia, D.; Tian, X. Introduction to xiaoqu qingxiang baijiu production technology present situation and development trend. Liquor Mak. 2018, 45, 17–19.