Recent research efforts to develop advanced–/ultrahigh–strength medium-Mn steels have led to the development of a variety of alloying concepts, thermo-mechanical processing routes, and microstructural variants for these steel grades. However, certain grades of advanced–/ultrahigh–strength steels (A/UHSS) are known to be highly susceptible to hydrogen embrittlement, due to their high strength levels. Hydrogen embrittlement characteristics of medium–Mn steels are less understood compared to other classes of A/UHSS, such as high Mn twinning–induced plasticity steel, because of the relatively short history of the development of this steel class and the complex nature of multiphase, fine-grained microstructures that are present in medium–Mn steels. The motivation of this paper is to review the current understanding of the hydrogen embrittlement characteristics of medium or intermediate Mn (4 to 15 wt pct) multiphase steels and to address various alloying and processing strategies that are available to enhance the hydrogen-resistance of these steel grades.

- medium–Mn steel

- hydrogen embrittlement

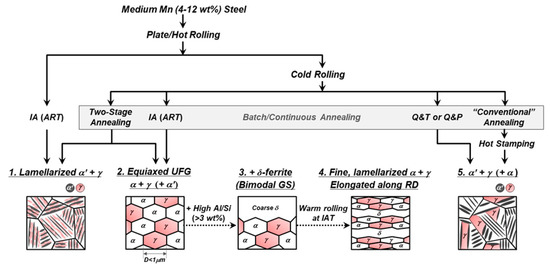

1. Thermomechanical Processing and Metallurgy of Medium–Mn Steels

2. Alloying and Microstructural Effects on HE Characteristics

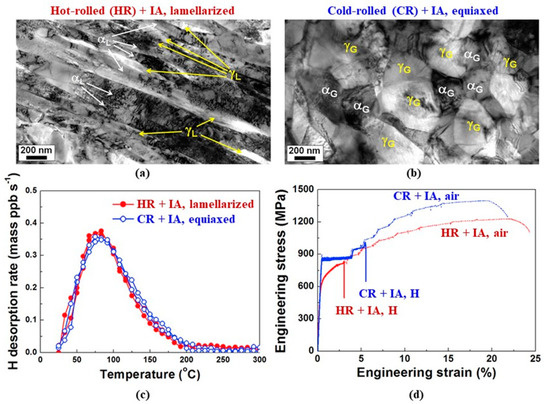

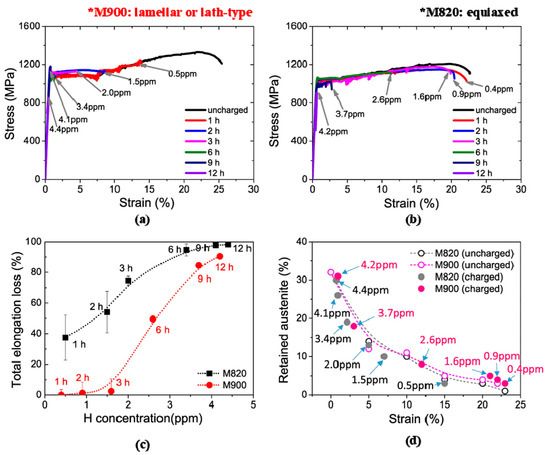

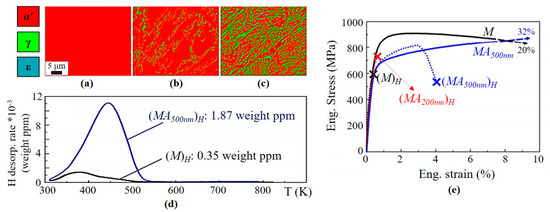

2.1. Equiaxed Versus Lamellarized Morphology

| Chemical Composition (wt.%) | Product Type or Starting Microstructure |

Heat Treatment | Microstructure (Morphology and Austenite Fraction) | H content, wppm | H-induced Elongation Loss, Pct | Remarks | Ref. |

|---|---|---|---|---|---|---|---|

| Fe-0.01C -9Mn-3Ni- 1.4Al |

Plate-type: as-quenched martensite |

IA or ART at 600 C for 8 h | Lamellarized α′ + γ (33–36 vol pct) |

1.87 | ~92 | “Equiaxed” absorbed much greater H content for a given H-charging condition. | Cameron et al. [35] |

| Cold-rolled, martensite |

IA at 600 °C for 1 h | Equiaxed α + γ (~40 vol pct) |

15.6 | ~91 | |||

| Fe-0.1C- 7Mn-0.5Si |

Hot-rolled | IA at 640 °C for 30 min | Lamellarized α′ + γ (47 vol pct) |

~1.2 | ~87 | “Equiaxed” had a higher ultimate tensile strength and was more H-resistant than lamellarized. | Han et al. [36] |

| Cold-rolled | IA at 640 °C for 30 min | Equiaxed α + γ (50 vol pct) |

~1.2 | ~74 | |||

| Fe-0.06C- 11.7Mn-2.9Al-0.2Si |

Cold-rolled | IA at 675 °C for 2 h | Larger, mixed lamellarized and equiaxed α + γ (55.2 vol pct) |

3.1 | ~58 | “Larger mixed” microstructure was more H-resistant than finer, lamellarized condition. | Shen et al. [37] |

| 10.0 | ~75 | ||||||

| 25.9 | ~83 | ||||||

| Cold-rolled | Aus. at 800 °C for 20 min + IA at 650 °C for 15 min | Finer, lamellarized α + γ (53.1 vol pct) |

2.4 | ~86 | |||

| 7.6 | ~87 | ||||||

| 34.6 | ~87 | ||||||

| Fe-0.11C- 7.2Mn-1.0Si |

Cold-rolled | Aus. at 900 °C for 10 min + IA at 650 °C for 4 min |

Lamellarized α + γ (32 vol pct) |

0.4 | 0 | “Lamellarized” was more H-resistant than equiaxed. Tested with samples having similar austenite fraction and mechanical stability. |

Jeong et al. [10] |

| 0.9 | ~1 | ||||||

| 1.6 | ~3 | ||||||

| 2.6 | ~50 | ||||||

| 3.7 | ~85 | ||||||

| 4.2 | ~90 | ||||||

| Cold-rolled | Aus. at 820 °C for 10 min + IA at 650 °C for 2 min |

Equiaxed α + γ (32 vol pct) |

0.5 | ~38 | |||

| 1.5 | ~54 | ||||||

| 2.0 | ~75 | ||||||

| 3.4 | ~95 | ||||||

| 4.1 | ~98 | ||||||

| 4.4 | ~98 |

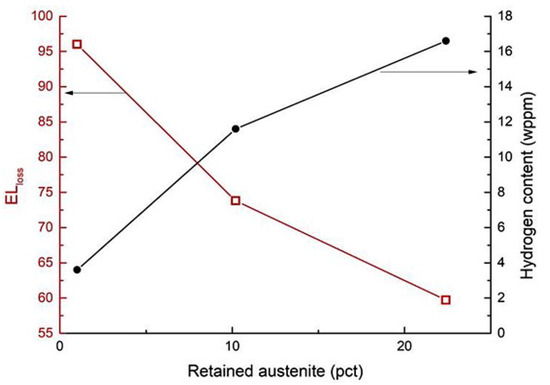

2.2. Retained Austenite and Mechanically–Induced Martensitic Transformation

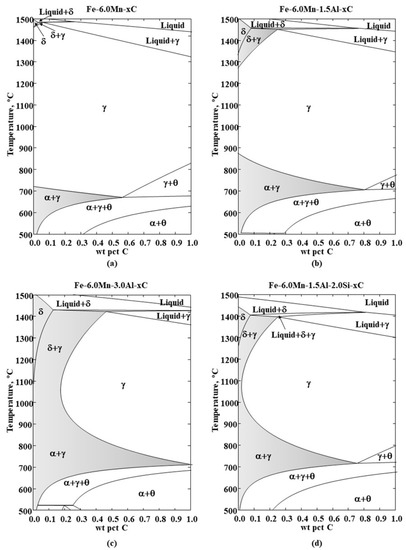

2.3. Al- and Si-Alloyed Medium-Mn Steels Containing Coarse δ-Ferrite Grains

| Product Type | Chemical Composition (wt.%) | IA Temperature /Hold Time |

Microstructure (Morphology and Austenite Fraction) | H Content, Wppm | H-Induced Elongation Loss, Pct | Authors’ Interpretation | Ref. |

|---|---|---|---|---|---|---|---|

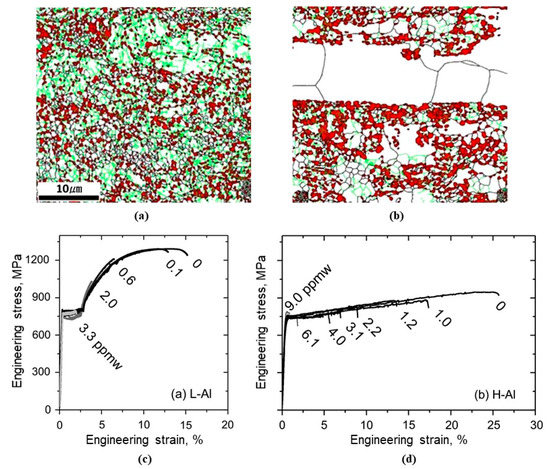

| Cold-rolled | Fe-0.12C- 4.6Mn- 0.55Si- 1.1Al |

720 °C/2 min | Equiaxed α + γ (26 vol%) |

0.1 | ~16 | HE is more pronounced for the low‑Al alloy containing less stable austenite. Martensitic decomposition of the austenite leaves the inherited H in a more mobile state. |

Ryu et al. [48] |

| 0.6 | ~56 | ||||||

| 2.0 | ~77 | ||||||

| 3.3 | ~87 | ||||||

| Fe-0.12C- 5.8Mn- 0.47Si- 3.1Al |

780 °C/2 min | Equiaxed α + γ (30 vol%) + coarse δ |

1.0 | ~31 | |||

| 1.2 | ~47 | ||||||

| 2.2 | ~65 | ||||||

| 3.1 | ~72 | ||||||

| 4.0 | ~78 | ||||||

| 6.1 | ~92 | ||||||

| 9.0 | ~96 | ||||||

| Hot-rolled | Fe-0.22C- 6.1Mn- 3.1Al |

740 °C/3 min | Lamellarized α′ + γ (24.8 vol%) |

3.9 | 13.5 | The presence of δ can promote Mn enrichment in reverted γ. H-resistance increases with increasing stability and fraction of γ. H-induced cracking occurs along the boundaries of δ and UFG regions. |

Wang et al. [49] |

| 5.2 | 25.8 | ||||||

| 7.9 | 39.8 | ||||||

| 740 °C/30 min | Lamellarized α′ + γ (37.4 vol%) |

3.2 | 79.2 | ||||

| 4.1 | 82.1 | ||||||

| 7.4 | 88.2 | ||||||

| Fe-0.18C- 6.1Mn- 2.9Al-0.6Si |

740 °C/3 min | Lamellarized α′ + γ (15.2 vol%) + coarse δ |

2.2 | 46.7 | |||

| 2.8 | 68.3 | ||||||

| 5.8 | 70.3 | ||||||

| 740 °C/30 min | Lamellarized α′ + γ (31.4 vol%) + coarse δ |

5.0 | 76.5 | ||||

| 6.2 | 91.9 | ||||||

| 7.2 | 89.1 | ||||||

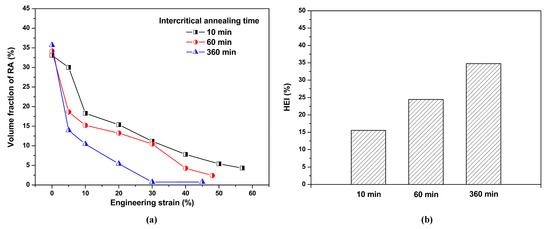

| Warm-rolled at IA temperature | 0.20C- 5.0Mn- 3.0Al-0.6Si |

750 °C/10 min | Equiaxed α + γ (33.1 vol%) + coarse δ |

1.4 | ~16 | HE became increasingly significant with increasing γ grain size. H-resistance relates to the γ mechanical stability. |

Shao et al. [44] |

| 750 °C/1 h | Equiaxed α + γ (34.2 vol%) + coarse δ |

1.3 | ~24 | ||||

| 750 °C/6 h | Equiaxed α + γ (35.7 vol%) + coarse δ |

1.1 | ~35 | ||||

| Hot-rolled | 0.20C-4.9Mn-3.1Al-0.6Si | 750 °C/1 h | Lamellarized α′ + γ (~26 vol%) + coarse δ |

0.9 | ~78 | Warm rolling, i.e., fine lamellar structure, significantly enhances the H-resistance. | Zhang et al. [50] |

| 750 °C/1 h + 89%‑reduction warm-rolled | Fine, lamellarized α + γ (~15 vol%) + coarse δ |

1.6 | ~28 |

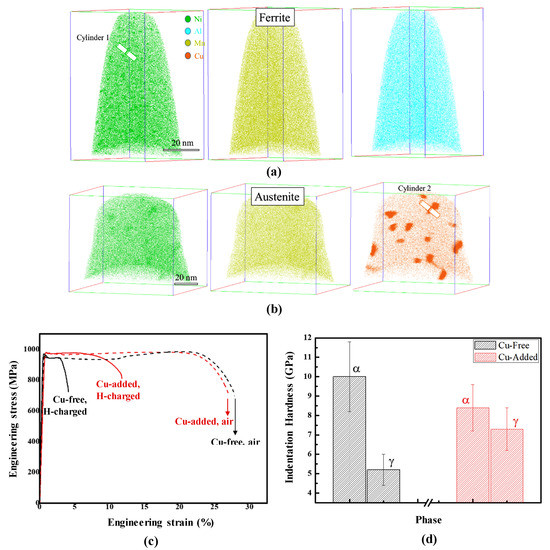

2.4. Other Alloying Elements and Precipitates

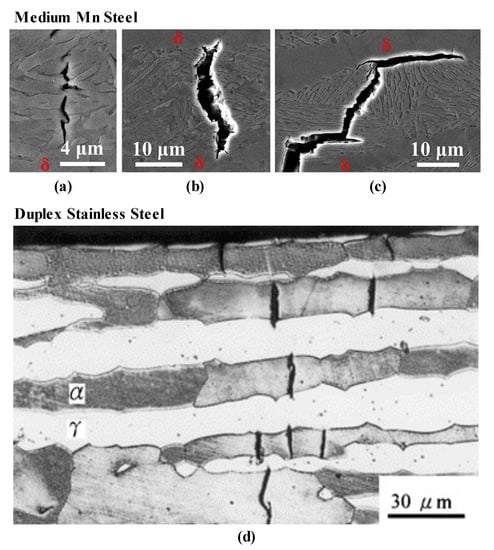

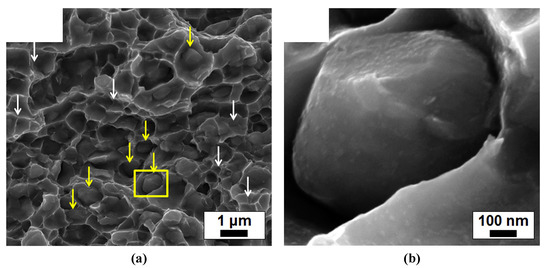

2.5. H–Induced Crack Initiation and Propagation

| Chemical Composition (wt. %) | Product Type | Heat Treatment | Microstructure (Austenite Fraction) |

Fracture Surface Appearances and Crack Initiation Sites | Refs. |

|---|---|---|---|---|---|

| Fe-0.1C- 7Mn-0.5Si |

Hot-rolled | IA at 640 °C for 30 min |

Lamellarized α′ + γ (47 vol%) |

Cracking along prior γ grain boundaries. Rugged facets, likely associated with fracture of mechanically-induced α′. |

Han et al. [36] |

| Cold-rolled | IA at 640 °C for 30 min | Equiaxed α + γ (50 vol%) | Dimples with granular features.The granular features are likely associated with intergranular cracking along equiaxed γ grain boundaries. | ||

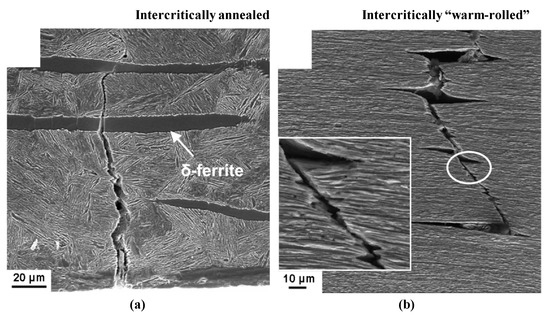

| Fe-0.22C- 6.1Mn-3.1Al |

Hot-rolled | IA at 740 °C for 3 min and 30 min |

Lamellarized α′ + γ (24.8–37.4 vol%) |

Cracking preferentially along γ/α phase boundaries. Cracking along prior γ grain boundaries or across the lamellar structure. |

Wang et al. [49] |

| Fe-0.18C- 6.1Mn-2.9Al-0.6Si |

Hot-rolled | IA at 740 °C for 3 min and 30 min | Lamellarized α′ + γ (15.2–31.4 vol%) + coarse δ |

Cracking at the phase boundaries, preferentially along (γ or α)/δ phase boundaries. | |

| 0.20C-5.0Mn-3.0Al-0.6Si | Warm-rolled at IA temperature | IA at 750 °C for 10 min, 1 h, and 6 h | Equiaxed α + γ (33.1–35.7 vol%) + coarse δ | Dimples with granular features. The granular features likely associated with cracking in the region of mechanically-induced α′. |

Shao et al. [44] |

| 0.20C-4.9Mn-3.1Al-0.6Si | Hot-rolled | IA at 750 °C for 1 h | Lamellarized α′ + γ (~26 vol%) + coarse δ |

Cracking across the lamellar structure or along γ/α′ phase boundaries. A few cracks along prior γ grain boundaries. |

Zhang et al. [50] |

| IA at 750 °C for 1 h + 89% reduction warm rolled | Fine, lamellarized α′ + γ (~15 vol%) + coarse δ |

Micro-delamination cracking at γ/α′ interfaces along the rolling direction. Larger-scale crack deflections near δ-ferrite layers. |

This entry is adapted from the peer-reviewed paper 10.3390/met11020358