Wearing face masks, use of respirators, social distancing, and practicing personal hygiene are all measures to prevent the spread of coronavirus disease (COVID-19). This pandemic has revealed the deficiency of face masks and respirators across the world. Therefore, significant efforts are needed to develop air filtration and purification technologies, as well as innovative, alternative antibacterial and antiviral treatment methods. It has become urgent—in order for humankind to have a sustainable future—to provide a feasible solution to air pollution, particularly to capture fine inhalable particulate matter in the air.

- air pollutants

- COVID-19

- face masks

- respirators

- nanofibers filter media

1. Introduction

World population growth, industrialization, and urbanization have initiated the production of enormous quantities of contaminants being emitted into the air, with no notion of how they could affect human health. Recently, air contaminant concentrations have risen above Air Quality Guidelines (AQG) issued by the World Health Organization (WHO) in many developed countries, leading to environmental protection policies for all individuals across the world. Air pollution severely destroys life quality and poses an immediate danger to public health [1]. Symptoms, such as weeping, coughing, angina, and difficulty breathing, are related to air pollution immediately after exposure, and may also cause more subtle, long-term harm to human health. People are typically ignorant about the impacts of long-term exposure to their health (as well as the fact that long-term exposure may worsen their medical conditions). Air pollution accesses the human body via the respiratory tract, and it also has systemic influences that can harm several organs [2][3].

In metropolises, because of these severe environmental problems, people wear masks or respirators for filtering polluted outdoor air, and air filtration equipment is becoming more common indoors as well. Indeed, using reception-based solutions via improving masks and respirators as effective means to capture hazardous particulates [4]. Air filtration is a promising, efficient, and practical technique used against air pollutants. Even now, extensive efforts are employed to enhance highly efficient air filter media, with a focus on improving filter efficiency [5][6][7][8]. Although conventional air filtration media, such as high-efficiency particulate air (HEPA) filters, have a high efficiency of filtration (of approximately 99.97%) for airborne particles (0.1–0.5 μm), their performance is still low for particulate matter (PM) in the sub-micrometer. Another drawback of using thicker filtering media is the high-pressure drop or energy costs to offset the resulting flow resistance. Such disadvantages of traditional high-performance filters can be mitigated using an electrospinning technique to prepare nanofiber-based filters. Carbon-based air filters are designed to trap air pollutants and fabricated as protective masks. Because of their high surface area, abundance, stable chemical structure, low resistance, and high functionalization ability with other materials, carbon materials are promising candidates for air purification. Particularly, since the diameter of carbon nanofibers is comparable to the free path of the air molecules (66 nm under normal conditions), they overcome the inherent problem between filtration efficiency and pressure drop [9][10]. They can be used to remove volatile organic compounds, nanoparticles, and bacterial contaminants in the air [10].

Electrospinning permits fiber production, with nanoscale diameters varying between 40 and 2000 nanometers as excellent candidates for biomedical applications [11][12]. In addition, electrospun nanofiber filters possess a high ratio of surface area/volume that significantly increases the possibility of pollutant deposition on the surface of the fiber, and consequently develops the performance of the filter with a relatively low-pressure drop [13]. This review is intended to condense previous research into a concise, easy-to-read document, focusing on the efficacy of face masks and respirators containing nanomaterials in their structures.

2. The Composition of Surgical Masks and N95 Respirators

The filtering materials of face masks and respirators are made of nonwoven fabric, considered disposal after use because their reuse significantly degrades their filtering performance. The salient benefit of nonwoven technology concerns the potential to manufacture fabrics and structures that cost much lower than other fabric technology, such as woven and knitted. Most surgical mask industries use spunbond melt-blown spunbond (SMS) technology for producing surgical masks. The suitable polymer materials for surgical mask manufacturing are PP, polyethylene terephthalate (PET), polystyrene, polycarbonate, polyethylene (PE), polyester, etc. [14][15][16][17]. PP is usually used to produce surgical masks by fabricating spunbond nonwoven layers (20 g/m2) and melt-blown nonwoven sheets (25 g/m2) [18]. It is relatively cheap and has low melt viscosity for easy processing. In addition, these polymers are transparent, lightweight, and provide high-optical clarity; thus, they could be three-dimensionally (3D) printed as face masks for COVID-19 protection [19].

A standard surgical mask is usually comprised of three layers: a soft nonwoven absorbent (layer being inner), a melt-blown (the layer at middle), and a nonwoven hydrophobic (layer being outer). Each layer has a specific function: the inner layer is purposed to absorb moisture, sweat, and the spit of the wearer; the middle layer of the surgical mask is designed as an electret filter to prevent germs from coming in or exiting from the mask; and the outer layer is purposed to repulse water, bodily fluids, and blood. Masks are manufactured by machines where the layers are ultrasonically welded together, and the masks are labeled with ear strings and nose strips. Masks are first sterilized before being exported.

The N95 respirator is comprised of many layers of PP nonwoven fabric. The two external protective layers are produced using a spunbond to cover both the inner and outer of the N95 respirator. There is a layer of pre-filtration between these spunbond layers, which may be as thick as 250 g/m2, making it stiffer and thicker, so it can be flexible enough to form the required shape. The last layer is a nonwoven melt-blown electret material of high-quality that controls filtration competence. The full respirators are manufactured by converted equipment, welding the layers by ultrasonic and adding belts and strips of metal to regulate the mask over the user’s face. Finally, respirators are sanitized before shipment.

3. Electrospun Nanofibers and Their Applications in Face Masks and Respirators

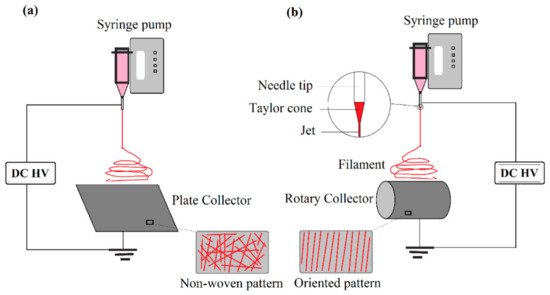

Electrospinning is a novel technique to manufacture nanofibers, as it provides a quick procedure, low expense, and precise control of the nanofiber compositions and geometric features. In electrospinning, high voltages apply to melts or polymer solution droplets to eliminate the tension of liquid surface and ultrafine fibers with diameters between 40 and 2000 nm to be created (Figure 1) [20]. Selecting a suitable solution concentration, appropriate voltage, and the space between the supporting collector and the syringe tip is of considerable importance for synthesizing uniform nanofibers. As an essential part of this technology, nanofiber-based filter media are the main components for enhancing filtration performance [21][22][23][24][25].

Figure 1. Electrospinning process (adapted with permission from Reference [26]).

Electrospun nanofiber-based filter media possess a high ratio of surface/volume, low-pressure drop, good interconnectivity of voids, and controllable connectivity and morphology, rendering them desirable to achieve excellent filtering. Because of its fragility, electrospun nanofibers can not be used individually at filter media, it should be deposited onto a substrate, usually fabric as nonwoven. Glass, polyester, nylon, and cellulose are the common substances used to support the electrospun nanofibers. The substrate should have excellent mechanical properties to enable pleating, fabrication of filter, and toughness in usage [27]. For the filtration propose, substrates are selected for pleating, filter fabrication, durability in use, and filter cleaning.

Currently, most researchers who are interested in the air filter industry are searching for technology based on nanofibers to enhance dust interception capability and filtration quality. There are already several applications of commercialized filters, as well as those in progress. Using nanofibers in face masks and respirators is better than the available commercialized. The active filters used in commercial face masks and respirators right now employ small diameter PP fibers in the range of 500–1000 nm; these filters achieve filtration with the help of static electricity. The pore size decreases as the fiber diameter decreases, and the distribution of fibers per unit area becomes denser. The electrostatic assisted melt-blown improves filtration quality by creating a small charge in the fabric, which increases the fabric’s adsorption capability.

However, such filters can lose their static electricity after wearing for an extended period and when exposed to water, thereby reducing their filtration efficiency, so this type of filter is designed to be disposable. This is not the case for nanofibers that do not depend on static electricity to filter contaminants; they use smaller pores and reasonable distribution of pores to physically filter aerosols that contain harmful dust or viruses [28].

Several studies and patents on nanofibers have been identified in different face masks and respirator applications [29][30][31]. Munzarová (2013) developed barrier fabrics based on nanofibers via electrospinning to be laminated onto face masks. This barrier protects from the permeation of microorganisms, dust particles, and allergens [32]. Skaria and Smaldone (2014) produced a prototype nanofiber-based filter media fitted face mask compared to the N95 respirator. They found that the prototype significantly reduced airflow resistance, resulting in greater face mask compliance and increased filtration efficiency, similar to that obtained when using an N95 respirator [33].

With a slightly different perspective, Li and Gong (2015) informed of the development of nanofiber-based polysulfone for mask filtration, utilizing electrospinning to be coated onto nonwoven PP, aiming to avoid the inhalation of harmful pollutants in contaminated haze air. The nanofiber mat thickness was modified at different collective preparation periods (15 min < 30 min < 60 min), and these three nanofiber masks were compared with nonwoven disposable face masks, nonwoven operative room masks, N95 and R95 respirators, and Ito PM2.5. It was observed that electrospun nanofiber masks might be efficient at filtering out PM2.5 particles and, at the same time, maintain good breathability [34]. Similarly, Akduman (2019) prepared a nanofiber layer of cellulose acetate (CA) and polyvinylidene fluoride (PVDF) with 100% mechanical filtration for face masks and respirators capable of meeting the specifications of N95 respirators. The effect of nanofiber mat thickness, nanofiber diameters, and pore size on filtration efficiency was compared [35][36]. The mean diameter of PVDF nanofibers (236.50 nm) was smaller than the diameter CA (319.02 nm) nanofibers. Therefore, CA nanofibers showed better filtration efficiency [36].

The use of solution blow spinning (SBS) nanofibers is a significant step in developing a composite mask [37][38]. Noel et al. (2019) used the SBS nanofibers method in composite multilayered filter masks; they prepared three different nanofiber fabrics types, cellulose diacetate (CDA), polyacrylonitrile (PAN), and PVDF. They demonstrated that the presence of functionalities of different molecules in the electrospun nanofibers had a significant effect on the efficiency of filtration, i.e., PAN nanofiber had the best filtration efficiency (0.05 Pa−1) of the quality factor and good air permeability, whereas, among all the nanofibers studied, PVDF air filter quality was the lowest, with (0.02 Pa−1) of the quality factor [39].

Moreover, titanium dioxide (TiO2), carbon nanotubes (CNTs), and silver (Ag) have been easily used as additional materials for coating electrospun nanofibers. Nanostructured TiO2 was of considerable interest to different coating materials because of its remarkable catalysis of UV rays and shielding properties [40][41]. Ruan et al. (2020) fabricated and developed the polyacrylonitrile-co-polyacrylate (PAN-co-PMA):TiO2 membrane of the electrospun nanofiber [42]. The electrospun nanofiber membrane features, such as permeability of air, PM trapping, and aerosol inspection, were evaluated methodically. For two types of nanofiber membranes, the microfiber nonwoven, the nanofiber membrane, and the nonwoven fabric bracket were built up into a multi-layer structure electrostatic force. The PAN-co-PMA:TiO2 nanofiber membrane bonding system demonstrated effective PM2.5 removal and superior air permeability (284–339 mm/s) [42]. Several studies have manifested the use of activated carbon, and carbon nanofiber (AC/CNF) composite was found to be a suitable alternative for the respirator cartridge due to being lightweight and its appropriate absorption ability [43]. In the study by Jahangiri et al. (2013), the granulated (AC/CNF) was utilized to absorb and remove VOCs from breathing air in the respiratory mask cartridges. The findings demonstrated that the breakthrough period was longer for this cartridge than for other types [44].

It is known that incorporating antimicrobial agents, such as silver, with nanofibers, exhibits antimicrobial properties in the filters [45]. They were mainly distributed on the nanofiber surface. Microorganisms can be killed when they contact silver nanoparticles during filtration [46], for example, nanosilver-embedded polyacrylonitrile nanofibers [47]. Yang et al. (2017) demonstrated the thermal management effect in the nano-fiber-based face mask with a nylon 6/nano PE model system that manifests high efficacy for PM2.5 capturing (99.6%) with lower pressure drop [23]. Moreover, they modified the nano PE substrate with silver. The fiber/Ag/nano PE mask filter reveals a value of (87.0%) as IR reflectance is high and might be utilized in winter or summer to protect the wearer from contaminated air and render the face warm or cool/comfortable [23].

Additionally, for protection against bacteria and viruses, nanofibers comprising superabsorbent polymers (SAPs) have been produced in order to provide greater convenience, adding additional functions, as well as medical care. To this end, many researchers have fabricated electrospun superabsorbent nanofibers to increase material absorption ability, to be utilized as personal hygiene products, microbe bio-filters, and disposable face masks [48][49]. Sivri (2018) used nanofibers electrospun of (PVA/SAP) aqueous polymer solutions to be coated onto face masks for developing virus barrier functions and liquid absorption functions. It was found that all face masks were successfully coated with nanofiber, according to Fourier transform infrared spectroscopy (FTIR) investigations and scanning electron microscopy (SEM). Air permeability and capacity to absorb liquids showed that the coating with nanofiber improved the face mask’s hydrophilicity while permeability of air decreased reversely [50].

The coronavirus pandemic outbreak has prompted a lack of face masks and respirators in the world. Therefore, there is an immediate need for a secure disinfection method, and reuse them, with minimum loss of efficiency and integrity [51][52][53][54]. Lee et al. (2019) developed high-performance membrane filters of polybenzimidazole (PBI) nanofiber that can be utilized for dustproof masks or other air filters. They indicated that the PBI nanofiber filter membrane achieved high filtration efficiency (~98.5%) at a significantly lower pressure drop (130 Pa), in contrast to the commercial face mask. They also demonstrated the PBI filter reusability membrane, due to its thermal, mechanical, and chemical stability, after the proposed cleaning process [55]. An injection molded autoclavable, scalable, conformable (iMASC) system was designed and produced by James et al. (2020) for aerosol-based protection N95 content filters that can be installed and replaced as desired. To understand the masking potential with various face forms and sizes, the finite element (FE) analysis tested the deformability of the iMASC system. The iMASC system has been shown to match several various face shapes and sizes with success, utilizing a test method confirmed by Occupational Safety and Health Administration (OSHA). These data support more qualification tests required for use in the healthcare sector [56].

Nazek et al. (2020) have improved a nanoporous flexible Si-based template on a silicon-on-insulator (SOI) wafer utilizing potassium hydroxides (KOH) etching, utilizing the template as a hard mask through a reactive ion etching process for transferring patterns onto a lightweight (<0.12 g) and flexible polymeric membrane. The flexible membrane might be utilized on the N95 mask as reusable to boost its filtration efficiency against particles sub-300 nm, including COVID-19. Furthermore, N95 mask reusability contributes toward eliminating the challenges surrounding single-use face mask shortages [57].

This entry is adapted from the peer-reviewed paper 10.3390/membranes11040250

References

- WHO. Health effects of particulate matter. In Policy Implications for Countries in Eastern Europe, Caucasus and Central Asia; WHO: Geneva, Switzerland, 2013; Volume 1, pp. 2–10.

- Burnett, R.; Chen, H.; Szyszkowicz, M.; Fann, N.; Hubbell, B.; Pope, C.A.; Apte, J.S.; Brauer, M.; Cohen, A.; Weichenthal, S. Global estimates of mortality associated with long-term exposure to outdoor fine particulate matter. Proc. Natl. Acad. Sci. USA 2018, 115, 9592–9597.

- Cohen, A.J.; Brauer, M.; Burnett, R.; Anderson, H.R.; Frostad, J.; Estep, K.; Balakrishnan, K.; Brunekreef, B.; Dandona, L.; Dandona, R. Estimates and 25-year trends of the global burden of disease attributable to ambient air pollution: An analysis of data from the Global Burden of Diseases Study 2015. Lancet 2017, 389, 1907–1918.

- Legare, P.; Dwyer, G.E.; Murphy, A.; Smith, S.J. Air Filtration Device. US9744493B2; (Patent), 2017. pp. 1–13.

- Wang, N.; Yang, Y.; Al-Deyab, S.S.; El-Newehy, M.; Yu, J.; Ding, B. Ultra-light 3D nanofibre-nets binary structured nylon 6–polyacrylonitrile membranes for efficient filtration of fine particulate matter. J. Mater. Chem. A 2015, 3, 23946–23954.

- Xu, J.; Liu, C.; Hsu, P.-C.; Liu, K.; Zhang, R.; Liu, Y.; Cui, Y. Roll-to-roll transfer of electrospun nanofiber film for high-efficiency transparent air filter. Nano Lett. 2016, 16, 1270–1275.

- Bian, Y.; Wang, R.; Wang, S.; Yao, C.; Ren, W.; Chen, C.; Zhang, L. Metal–organic framework-based nanofiber filters for effective indoor air quality control. J. Mater. Chem. A 2018, 6, 15807–15814.

- Al-Attabi, R.; Morsi, Y.; Schütz, J.A.; Cornu, D.; Maghe, M.; Dumée, L.F. Flexible and reusable carbon nano-fibre membranes for airborne contaminants capture. Sci. Total Environ. 2021, 754, 142231.

- Xiao, J.; Liang, J.; Zhang, C.; Tao, Y.; Ling, G.-W.; Yang, Q.-H. Advanced Materials for Capturing Particulate Matter: Progress and Perspectives. Small Methods 2018, 2, 1800012.

- Sundarrajan, S.; Tan, K.L.; Lim, S.H.; Ramakrishna, S. Electrospun Nanofibers for Air Filtration Applications. Procedia Eng. 2014, 75, 159–163.

- Wu, H.; Fan, J.; Chu, C.-C.; Wu, J. Electrospinning of small diameter 3-D nanofibrous tubular scaffolds with controllable nanofiber orientations for vascular grafts. J. Mater. Sci. Mater. Med. 2010, 21, 3207–3215.

- Zhang, M.; Li, X.; Li, S.; Liu, Y.; Hao, L. Electrospun poly(l-lactide)/zein nanofiber mats loaded with Rana chensinensis skin peptides for wound dressing. J. Mater. Sci. Mater. Med. 2016, 27, 136.

- Wang, S.-X.; Yap, C.C.; He, J.; Chen, C.; Wong, S.Y.; Li, X. Electrospinning: A facile technique for fabricating functional nanofibers for environmental applications. Nanotechnol. Rev. 2016, 5, 51–73.

- Abdelrazeq, H.; Khraisheh, M.; Al Momani, F.; McLeskey, J.T.; Hassan, M.K.; Gad-el-Hak, M.; Tafreshi, H.V. Performance of electrospun polystyrene membranes in synthetic produced industrial water using direct-contact membrane distillation. Desalination 2020, 493, 114663.

- Parangusan, H.; Ponnamma, D.; Hassan, M.K.; Adham, S.; Al-Maadeed, M.A.A. Designing Carbon Nanotube-Based Oil Absorbing Membranes from Gamma Irradiated and Electrospun Polystyrene Nanocomposites. Materials 2019, 12, 709.

- Benson, N.U.; Fred-Ahmadu, O.H.; Bassey, D.E.; Atayero, A.A. COVID-19 pandemic and emerging plastic-based personal protective equipment waste pollution and management in Africa. J. Environ. Chem. Eng. 2021, 9, 105222.

- Kurian, B.P.; Daniel, S.; Ghosh, S.; Paul, P.; Reddy, M.A.; Das, L.; Darshan, J.; Roy, A.D. The Need of Understanding the Importance and Use of Face Masks. J. Curr. Med Res. Opin. 2021, 4, 762–772.

- Chellamani, K.P.; Veerasubramanian, D.; Balaji, R.S.V. Surgical face masks: Manufacturing methods and classification. J. Acad. Ind. Res. 2013, 2, 320–324.

- Ishack, S.; Lipner, S.R. Applications of 3D printing technology to address COVID-19–related supply shortages. Am. J. Med. 2020, 133, 771–773.

- Reneker, D.H.; Chun, I. Nanometre diameter fibres of polymer, produced by electrospinning. Nanotechnology 1996, 7, 216.

- Abbas, J.A.; Said, I.A.; Mohamed, M.A.; Yasin, S.A.; Ali, Z.A.; Ahmed, I.H. Electrospinning of polyethylene terephthalate (PET) nanofibers: Optimization study using taguchi design of experiment. IOP Conf. Ser. Mater. Sci. Eng. 2018, 454, 012130.

- Barhate, R.S.; Sundarrajan, S.; Pliszka, D.; Ramakrishna, S. Fine chemical processing: The potential of nanofibres in filtration. Filtr. Sep. 2008, 45, 32–35.

- Yang, A.; Cai, L.; Zhang, R.; Wang, J.; Hsu, P.-C.; Wang, H.; Zhou, G.; Xu, J.; Cui, Y. Thermal management in nanofiber-based face mask. Nano Lett. 2017, 17, 3506–3510.

- Yang, C. Aerosol Filtration Application Using Fibrous Media-An Industrial Perspective. Chin. J. Chem. Eng. 2012, 20, 1–9.

- Yasin, S.A.; Abbas, J.A.; Saeed, I.A.; Ahmed, I.H. The application of green synthesis of metal oxide nanoparticles embedded in polyethylene terephthalate nanofibers in the study of the photocatalytic degradation of methylene blue. Polym. Bull. 2020, 77, 3473–3484.

- Esfahani, H.; Jose, R.; Ramakrishna, S. Electrospun ceramic nanofiber mats today: Synthesis, properties, and applications. Materials 2017, 10, 1238.

- Thavasi, V.; Singh, G.; Ramakrishna, S. Electrospun nanofibers in energy and environmental applications. Energy Environ. Sci. 2008, 1, 205–221.

- Liu, C.; Hsu, P.-C.; Lee, H.-W.; Ye, M.; Zheng, G.; Liu, N.; Li, W.; Cui, Y. Transparent air filter for high-efficiency PM2.5 capture. Nat. Commun. 2015, 6, 6205.

- Loesecke, D.; Murphey, B. Machinery and processing: An overview of engine filtration. Filtr. Sep. 2008, 45, 17–19.

- Shabafrooz, V.; Mozafari, M.; Vashaee, D.; Tayebi, L. Electrospun nanofibers: From filtration membranes to highly specialized tissue engineering scaffolds. J. Nanosci. Nanotechnol. 2014, 14, 522–534.

- Conlon, M. A Facemask Having One or More Nanofiber Layers. WO2014143039A1, 18 September 2014.

- Munzarová Nanocon, M. Barrier fabric containing nanofiber layer. In Proceedings of the Nanocon, Brno, Czech, 16–18 October 2013; pp. 16–19.

- Skaria, S.D.; Smaldone, G.C. Respiratory source control using surgical masks with nanofiber media. Ann. Occup. Hyg. 2014, 58, 771–781.

- Li, X.; Gong, Y. Design of Polymeric Nanofiber Gauze Mask to Prevent Inhaling PM2.5 Particles from Haze Pollution. J. Chem. 2015, 2015, 460392.

- Akduman, C.; Akcakoca, K.E.P. Nanofibers in face masks and respirators to provide better protection. IOP Conf. Ser. Mater. Sci. Eng. 2018, 460, 012013.

- Akduman, C. Cellulose acetate and polyvinylidene fluoride nanofiber mats for N95 respirators. J. Ind. Text. 2019, 50, 1528083719858760.

- Salva, J.M.; Gutierrez, D.D.; Ching, L.A.; Ucab, P.M.; Cascon, H.; Tan, N.P. Solution blow spinning (SBS)-assisted synthesis of well-defined carboxymethyl cellulose (CMC) nanowhiskers. Nanotechnology 2018, 29, 50LT01.

- Zhuang, X.; Yang, X.; Shi, L.; Cheng, B.; Guan, K.; Kang, W. Solution blowing of submicron-scale cellulose fibers. Carbohydr. Polym. 2012, 90, 982–987.

- Tan, N.P.B.; Paclijan, S.S.; Ali, H.N.M.; Hallazgo, C.M.J.S.; Lopez, C.J.F.; Ebora, Y.C. Solution blow spinning (SBS) nanofibers for composite air filter masks. ACS Appl. Nano Mater. 2019, 2, 2475–2483.

- Chen, D.; Wei, L.; Meng, L.; Wang, D.; Chen, Y.; Tian, Y.; Yan, S.; Mei, L.; Jiao, J. High-performance self-powered UV detector based on SnO2-TiO2 nanomace arrays. Nanoscale Res. Lett. 2018, 13, 92.

- Mahmoud, H.A.; Narasimharao, K.; Ali, T.T.; Khalil, K.M.S. Acidic peptizing agent effect on anatase-rutile ratio and photocatalytic performance of TiO2 nanoparticles. Nanoscale Res. Lett. 2018, 13, 48.

- Ruan, D.; Qin, L.; Chen, R.; Xu, G.; Su, Z.; Cheng, J.; Xie, S.; Cheng, F.; Ko, F. Transparent PAN:TiO2 and PAN-co-PMA:TiO2 Nanofiber Composite Membranes with High Efficiency in Particulate Matter Pollutants Filtration. Nanoscale Res. Lett. 2020, 15, 7.

- Mauter, M.S.; Elimelech, M. Environmental applications of carbon-based nanomaterials. Environ. Sci. Technol. 2008, 42, 5843–5859.

- Jahangiri, M.; Adl, J.; Shahtaheri, S.J.; Rashidi, A.; Ghorbanali, A.; Kakooe, H.; Forushani, A.R.; Ganjali, M.R. Preparation of a new adsorbent from activated carbon and carbon nanofiber (AC/CNF) for manufacturing organic-vacbpour respirator cartridge. Iran. J. Environ. Health Sci. Eng. 2013, 10, 15.

- Montazer, M.; Malekzadeh, S.B. Electrospun antibacterial nylon nanofibers through in situ synthesis of nanosilver: Preparation and characteristics. J. Polym. Res. 2012, 19, 9980.

- Rahman, M.M.; Ashwin, P.; Thakkar, I. Use of Nano Fibers in Filtration—A Review. Int. J. Sci. Res. Dev. 2016, 4, 1067–1072.

- Karthick, A.; Nallathambi, G. Nano silver incorporated electrospun polyacrylonitrile nanofibers and spun bonded polypropylene composite for aerosol filtration. J. Ind. Text. 2017, 46, 1342–1361.

- Brochocka, A. Filtration Properties of Nonwoven Structures with Superabsorbents for Respiratory Protective Devices. Fibres Text. East. Eur. 2017, 25, 62–67.

- Majchrzycka, K.; Okrasa, M.; Jachowicz, A.; Szulc, J.; Brycki, B.; Gutarowska, B. Application of Biocides and Super-Absorbing Polymers to Enhance the Efficiency of Filtering Materials. Molecules 2019, 24, 3339.

- Sivri, Ç. Improvement of protective and comfort properties of face masks using superabsorbent polymer containing nanofibers. Int. J. Cloth. Sci. Technol. 2018, 30.

- Celina, M.; Martinez, E.; Omana, M.A.; Sanchez, A.; Wiemann, D.; Tezak, M.; Dargaville, T.R. Extended use of face masks during the COVID-19 pandemic-Thermal conditioning and spray-on surface disinfection. Polym. Degrad. Stab. J. 2020, 179, 109251.

- Liao, L.; Xiao, W.; Zhao, M.; Yu, X.; Wang, H.; Wang, Q.; Chu, S.; Cui, Y. Can N95 respirators be reused after disinfection? How many times? ACS Nano 2020, 14, 6348–6356.

- Rubio-Romero, J.C.; del Carmen Pardo-Ferreira, M.; García, J.A.T.; Calero-Castro, S. Disposable masks: Disinfection and sterilization for reuse, and non-certified manufacturing, in the face of shortages during the COVID-19 pandemic. Saf. Sci. J. 2020, 129, 104830.

- Suen, L.K.P.; Guo, Y.P.; Ho, S.S.K.; Au-Yeung, C.H.; Lam, S.C. Comparing mask fit and usability of traditional and nanofibre N95 filtering facepiece respirators before and after nursing procedures. J. Hosp. Infect. 2020, 104, 336–343.

- Lee, S.; Cho, A.R.; Park, D.; Kim, J.K.; Han, K.S.; Yoon, I.-J.; Lee, M.H.; Nah, J. Reusable polybenzimidazole nanofiber membrane filter for highly breathable PM2. 5 dust proof mask. ACS Appl. Mater. Interfaces 2019, 11, 2750–2757.

- Byrne, J.D.; Wentworth, A.J.; Chai, P.R.; Huang, H.-W.; Babaee, S.; Li, C.; Becker, S.L.; Tov, C.; Min, S.; Traverso, G. Injection Molded Autoclavable, Scalable, Conformable (iMASC) system for aerosol-based protection: A prospective single-arm feasibility study. BMJ Open 2020, 10, 039120.

- El-Atab, N.; Qaiser, N.; Badghaish, H.S.; Shaikh, S.F.; Hussain, M.M. A Flexible Nanoporous Template for the Design and Development of Reusable Anti-COVID-19 Hydrophobic Face Masks. ACS Nano 2020, 14, 7659–7665.