1. Introduction

Failure is a potential occurrence in any human invention such as buildings, spaceships, electronic devices, and medical devices. All these products or structures are susceptible to damage due to many factors, one being environmental factors, such as environmental threats like mechanical stresses, chemical abrasion, ultra-violet irradiations, thermal loading, and pressure. Generally, materials tend to be damaged at the micro- or macrolevel. At the microlevel, cracking for instance, affects the material’s characteristics, while at the macrolevel, serious damage can occur from cracking as it can cause the material or structure to destruct, which, in turn, leads to more catastrophic impact [

1].

Take for example a concrete structure subjected to microcracking due to the weakness of concrete in tension. Fatigue loading can reduce the concrete’s toughness, which leads to the increment of permeability, and hence, can ultimately lead to the reduction of the concrete’s structural integrity, durability, and life span. In medical application, microcracking, wear and tear, fatigue, and material deformation and loss often arise from cyclic loading or aggressive usage, which can cause mechanical failure in biomedical implants [

2]. Surface scratching and microcracking in the coating system may promote the formation of cracks, which eventually leads to macroscopic damage, up to the point where the coating loses its aesthetic as well as its external protective function. Exposure to a high electric field may also have the potential to cause mechanical damage in dielectric and insulating elements, which can lead to the failure of electronic devices and electrical equipment.

Other examples of major material failure modes that are routinely encountered in composite materials in aerospace application are fiber-matrix debonding, matrix microcracking, and impact damage. These examples of damage initiation may lead to more serious damage or can also contribute to catastrophic failure. These catastrophic failures may cause significant impacts on repair, maintenance, and the rehabilitation of existing and new structures. Apparently, deterioration of products or structure is an ongoing and concerning problem. The consequential effects of damage may have far reaching implications if the damage is not controlled at an early stage. Thus, this catastrophic failure can have a significant influence on the economic, social, and environmental impacts. Therefore, preliminary action should be addressed at the microlevel to prevent serious damage from happening.

Self-healing methods, which refer to the ability of a system to recover after initial damage, have the potentials to address these challenges. Self-healing technology can mitigate the molecular level functionality, enabling the repair, impart reprocess ability, or longer lifetimes of products. The concept of self-healing was inspired from natural or biological process, for example, blood clotting or reparation of fractured bones. This concept was then incorporated at a wider range of engineering applications. In some cases, manual repair works can be difficult, especially if the cracks or damages are invisible, or their locations cannot be easily accessed.

Therefore, self-healing process provides the best solution because the system has the capability to repair itself as per the biological system, without the need for any human detection or repair by manual intervention. One of the strategies to address the microcrack or inaccessible damage sites is by using self-healing polymers. This is because self-healing polymers have high efficiency to recover the properties of the components on three basis stages; which are (1) triggering, (2) the healing material is transported to the damage site, and (3) remodeling by the chemical repair process [

3]. With the application of the self-healing method in each system, the lifetime of the material may be extended, which in turn can reduce the cost of maintenance and improve product safety.

Self-healing technologies were progressively developed in various kinds of applications. Market research has portrayed the increase of self-healing products at a value of USD $381.65 M in 2019 and is expected to stretch to USD $943.38 M by 2027. The building industry segment held approximately 56.5% of the market, as this industry is the largest consumer for self-healing material. Other sectors, such as automotive and transportation, energy generation, electronics and semiconductors, and the medical sector, have also contributed to the increasing of the self-healing material market [

4].

In developing self-healing technology, many innovations have been explored including research from the National University of Singapore (NUS) Institute for Health Innovation and Technology and NUS Materials Science and Engineering. They have developed a durable, low-power material for next-generation electronic wearables and soft robots. This unique material has very high dielectric permittivity and self-healing properties, which enables it to store more electronic charges at lower voltages and a higher brightness when used in a light-emitting capacitor device. The material is a transparent, elastic rubber sheet made up of a unique blend of Fluor elastomer and surfactant. This innovation is called the HELIOS (which stands for healable, low-field illuminating optoelectronic stretchable) device [

5]. Another innovation developed at the University of Technology in the Netherlands is the self-healing “bio” concrete that uses nutrients (peptone and yeast extract) and Bacillus Subtilis without urea as a microbial adjuvant, and this could also be an effective way to promote microbial CaCO

3 precipitation in sufficient quantities to enhance sustainability and to promote self-healing of concrete [

6].

To date, the number of publications with various applications of self-healing materials has risen dramatically [

7,

8,

9,

10,

11,

12]. For instance, B. Aissa et al. summarized the main technologies that are currently being developed specifically in thermosetting composites polymeric system [

12]. Besides that, Qiang et al. also reviewed on recently developed self-healing conductive materials and their applications [

7]. Most of the recent reviews reported the emerging of self-healing materials in specific applications with their self-healing mechanism. A comprehensive review on the self-healing mechanisms, approaches, polymeric materials used, and their applications is still limited. Thus, due to the remarkable and emerging self-healing products to date, this review paper summarizes the self-healing polymer technologies in different types of applications, such as in electronics, coating, aerospace, the medical field, and construction. We discuss thoroughly on their principles, interaction mechanisms, self-healing polymeric materials used, and their respective effectiveness. The different types of self-healing polymers for various types of applications are explored. In the successive section, the healing process is classified and described according to the self-healing mechanism (embedded, vascular, and intrinsic polymer-based system). Finally, in order to gain an overall insight into the self-healing materials, the advantages and disadvantages of the self-healing approach in every application and the current challenges of self-healing technologies are also discussed. Therefore, this review paper is expected to significantly give a broader idea of self-healing polymers, which in turn proves to be the solution to increasing the life cycle of materials, and also concurrently advocates a safer environment in all the applications involved.

2. Self-Healing Polymer Principle and Mechanism

Self-healing is described as a method which has the ability to perceive any unfunctional device or system without human intervention and make the necessary adjustments to restore itself back to its normal condition. The self-healing method is expected to detect and repair the microcracking in products or system that help to recover the mechanical or functional performance of the material. It represents the next generation of technology, which helps to greatly improve important performance of products, as it has been built in into various applications for structural, electronic, medical and aerospace products [

13,

14,

15,

16]. This approach is very significant in situations where repairing or inspection is difficult, hazardous, and costly [

17].

Over the last decade, self-healing methods have attracted a lot of attention in the research community and numerous studies have explored them in order to develop various self-healing capabilities, particularly using polymeric materials. Polymeric materials are formed by the bonding of monomer and polymer chains and they are one of the most extensively researched materials in self-healing because of their versatility in polymer systems. For instance, a self-healing process that requires relatively low temperature can be easily achieved by the modification and functionalization of polymer system and can effectively fill the cracks because of the higher viscosity of polymer. Besides that, the self-healing polymers also can transform physical energy into a chemical and/or physical response to heal the damage. Polymers are in demand as they offer a light weight material with good processability and chemical stability [

18]. In particular, efficient self-healing polymers and polymer-based fiber-reinforced composites are of high significance because these materials are utilized in numerous engineering fields, such as for cars, ships, spacecraft, electronics, and biomedicine [

19,

20,

21].

2.1. General Self-Healing Mechanism

There are two types of self-healing mechanisms which are the extrinsic and intrinsic self-healing mechanisms. Normally, nearly all self-healing mechanisms take place at room temperature. In the extrinsic mechanism, the healing agent embedded in the polymer matrix recovers the damage, whereas in the intrinsic mechanism, the chemical bonding of the matrix itself has the ability to restructure in existence of the external action [

3].

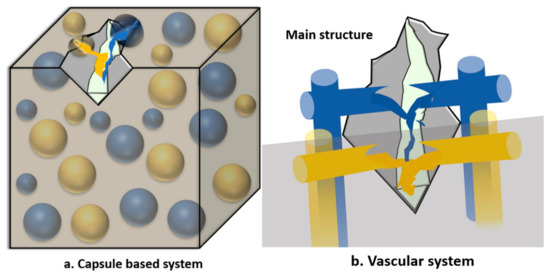

In the extrinsic mechanism, the self-healing approach is via the presence of an intentionally added external healing agent, which can be encapsulate or in vascular network. As the damage occurs, the component, the capsule or the vascular network tends to break down and release the healing agents into the damaged regions. Furthermore, the healing agents and catalysts can be sequestered in four different ways: capsule-catalyst, multicausal, latent functionality, and phase-separated. The micro-capsulate diameter and surface morphology influence the behavior of the capsule rapture, and the healing agent is released [

3].

However, the encapsulated method has certain disadvantages, as it allows for healing only once, with the capsule break and release of the healing agent. On the other hand, the vascular self-healing systems offer multiple healing reactions, where healing agents and catalysts are sequestered in networks in the form of capillaries or hollow channels. The restorative agent is embedded into a network vessels or hollow canals, which are pumped through a thin nanosized or micro sized of vascular tube network, and then the healing agent is released upon the appearance of microcracking. Throughout years of exploration, self-healing vascular systems have been improved from 2D to 3D interconnected networks, which enhances the self-healing agent flowability and increases the mechanical properties of the composite. Particularly, the vascular self-healing method is like the capsule-based method, defined as the need of a healing agent, but through different approaches. The healing mechanisms for the embedded and vascular methods are illustrated in .

Figure 1. The extrinsic mechanism via (a) microcapsule and (b) vascular network.

Many researchers have explored the development of encapsulated and vascular self-healing. Fernando et al. (2019) developed an epoxy self-healing coating by using encapsulated epoxy ester resin in poly(urea-formaldehyde-melamine) microcapsules. The filled microcapsules were incorporated into an epoxy three-layer coating system. The coating system containing the microcapsules showed a significant self-healing effect when stressed by a mechanical defect, and the higher concentration (15 wt%) of microcapsules provided better self-healing protection with better anticorrosive performance [

22]. Naveen et al. (2020) focused on self-healing microcapsules encapsulated with carbon nanotubes for improved thermal and electrical properties. In this study, multiwalled nanotubes (CNTs) were successfully incorporated with the dicyclopentadiene (DCPD) core and encapsulated by an urea-formaldehyde (UF) shell, to form dual-core microcapsules. The development of dual-core microcapsules with the DCPD–CNT–UF combination was found to improve the mechanical, thermal, and electrical properties of the resin cast specimens without compromising on self-healing efficiency [

23]. Li et al.’s (2013) studies showed that cementitious materials with microcapsules consist of healing adhesives. The adhesive materials, like diglycidyl ether of biphenyl and epoxy resin (E) and poly styrene-divinylbenzene (stn-DVB), were mixed with a cement paste to achieve self-healing capability. They demonstrated a significant improvement in the strength parameters [

24].

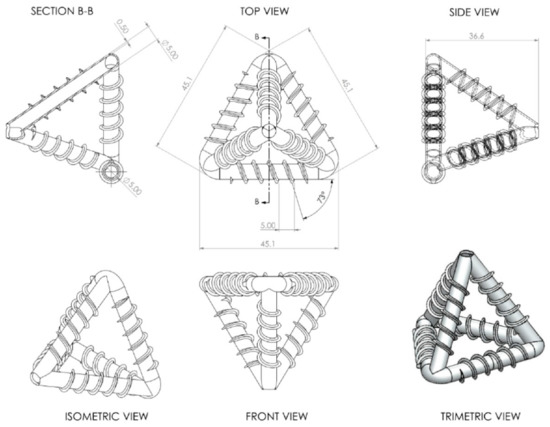

Meanwhile, for the vascular network system, De Nardi et al. (2020) proposed mini-vascular networks (MVNs) as an alternative for the vascular method. The MVNs considered in this study were 3D-printed tetrahedral units (TETs) of interconnected hollow ligaments that had a characteristic dimension (i.e., maximum ligament length) approximately twice the size of the maximum aggregate particle size of the cementitious composite. A tetrahedral shape is also advantageous because the ligaments are straight between the anchor points (apices), which means the ligaments are more likely to break when crossed by a crack (see ) [

25].

Figure 2. Mini-vascular networks (MVNs) of 3D-printed tetrahedral units (TETs) obtained from the authors of [

25].

Compared to the extrinsic mechanism, the intrinsic self-healing mechanism does not need an external agent to repair the damage [

3]. This process allows for multiple and repeatable self-repair after numerous of damage or healing [

26]. Besides that, intrinsic self-healing polymer materials have various advantages like (i) fast self-healing of functions due to the absence of diffusion and polymerization control steps and (ii) adaption in restoring low-volume defects/cracks because of their sensitive reversible dynamic bonds in molecular scale [

26]. Intrinsic self-healing can be achieved through the inherent reversibility of molecular interactions of the matrix polymer, which evades complex problems such as the integration and compatibility of healing agents. Materials with intrinsic healing properties are triggered by external stimuli, such as electrical or photo stimuli, heat or pressure, or the reaction of substances when introduced together, to prompt them to heal. For intrinsic self-healing, molecular mechanisms can occur from physical interactions and/or chemical interactions. The healing process is achieved by tailoring dynamic bond interactions from the molecular level or formulating interplay between the diffusion and entanglement of polymer chains [

26]. Chemical bond interaction-based self-healing can be further classified into covalent and non-covalent bond interactions.

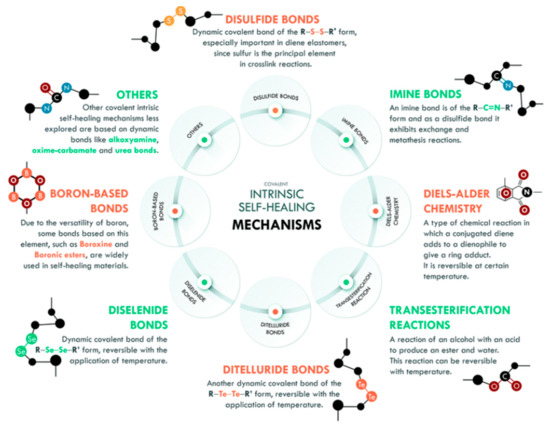

2.1.1. Covalent Bond Interaction

The formation of chemical bonds between different molecules or functional groups of a polymer can be described by the reversibility of the covalent bond, where the opening and closing of the bonding sites results in an equilibrium which serves as the basis for the self-healing process [

27]. Besides that, external conditions such as temperature, pressure or electrical stimuli can affect the chemical bonds. Generally, this mechanism can be accomplished with a high or low temperature. However, changes in the pH value, irradiation, moisture, or catalytic activity also can affect the disconnection and reconnection of the active sites [

27]. The reversibility of the cross-links in the polymers provides a wide range of possible binding concepts with regards to the polymer structure itself. The network formation is held either in the main chain, side chain, or with a multifunctional linker, for example disulfide bonds, Diels–Alder chemistry, imine bonds, di-selenide bonds, boron-based bonds, transesterification reactions, ditelluride bonds, and others (see ).

Figure 3. Covalent intrinsic mechanism obtained from the authors of [

28].

2.1.2. Non-Covalent Bond Interaction

Intrinsic self-healing mechanisms of the non-covalent nature comprise weak interactions that can occur between different families of atoms, such as van der Waals interactions, p–p stacking, dipole–dipole interactions, hydrogen bonding, ionic interactions, metal–ligand coordination, and host–guest interactions as well as materials associated by non-covalent bonds, i.e., supramolecular polymers or gels, which can self-heal with or without external stimuli, as shown in . Because the non-covalent systems have lower bonding energy than the covalent systems, they typically have higher healing efficiencies, which allows for the restoration of the broken bonds, even at room temperature. The hydrogen bond is the most used in non-covalent interactions of elastomer, which have been combined with other interactions of the same nature to create self-healing materials with various performances [

28].

Figure 4. Non-covalent intrinsic mechanism obtained from the authors of [

28].

A few studies on the intrinsic dynamic covalent and non-covalent healing mechanism have been reported. Chen et al. (2019) recently reported the self-healing method based on intrinsic dynamic non-covalent mechanism, where polyurethane (urea) elastomer is formed by van der Waals forces and hydrogen bonds. Self-healing polyurethane demonstrated that the dynamic cross-linking between hydrogen bonds and van der Waals forces is the basic driving force for the self-healing ability of the material, and temperature is the key factor that affects hydrogen bonding and van der Waals forces [

29]. Elena et al. (2017) also reported on the self-healing non-covalent interaction by using diphenyl disulfide-based compounds. The self-healing properties of disulfide-based material are mainly created through the capacity to generate sulfinyl radicals by breaking the disulfide S-S bond, and the ability of these radicals to attack neighboring disulfides. Additionally, the hydrogen bond interactions are established between chains. The presence of hydrogen bonds in the repeating unit of the polymer plays a role in the crystallization of the material, stabilizing adjacent chains [

30]. Kuhl et al. (2018) focused on the exchange reactions of the reversible urethane moieties. Reversible covalent urethane units were used for the design of new self-healing polymers, which had efficiencies of up to 85%, while the material exhibited good mechanical properties with high E-moduli [

31].