Baked clay bricks (Impunyu) is the dominant wall construction material in Rwanda. Clay deposits in the country’s lowlands are utilized for baked clay bricks. Despite the ongoing campaign, the use of wood by some local brick producers is unfriendly to the environment. Recent research has called for alternative methods in order to reduce the cost and impact on the environment. Earlier efforts with compressed earth blocks were saddled with weight and a substantial use of cement for good surface texture and adequate resistance against surface erosion. This research explored the potentials of using an appropriate dose of clay (from Muhanzi), volcanic light aggregate (Amakoro, (from Musanze)), and cement to produce unbaked shelled compressed earth blocks (SCEB). SCEB is a compressed earth block with an outer shell and inner core of different cement content or materials, compressed into a unit block. The result is a masonry unit with a higher surface resistance, durability, and desirable architectural effect produced with a 60% reduction in cement content. A weight reduction of 12% was achieved with an optimum content of 33% of the volcanic lightweight aggregate. A cost reduction of 25% was recorded over conventional compressed earth brick walls and a 54% over sand-cement block walls. Possible future trends were also identified with appreciable prospects in earthen architecture.

1. Introduction

In Rwanda, about 75% of buildings are constructed with baked clay bricks [

1]. The industrial subsector Masterplan for Construction Materials for Rwanda identified an abundance of available local construction materials, such as clay, wood, sand, and stone [

2]. The hilly terrain of Rwanda creates a natural movement of surface water from the hills to the valley. Soils on the hills are generally stony, while clay and silt are washed from the highlands into the valleys, leaving large deposits of clay in some valleys. The efforts to utilize the existing local materials may well explain the popularity of baked clay bricks in the construction industry. While the formal brick industries are conscious of environmental issues posed by choice of firing materials by the use of rice or coffee husks (waste biomaterials), the informal local brick producers most often use wood with environmental effect on the forests. Furthermore, most firing burners are inefficient with incomplete combustion and substantial carbon emission. In the informal sector, the baked brick production can be seen to be cumbersome and labor intensive. Humanitarian News [

3] reported of environmental concern as brick makers quarry near banks destroying natural vegetation. Since poor people directly depend on natural resources and natural services for their survival, a clear link between poverty reduction and environmental degradation is established [

4].

While the baked bricks have firing issues, the cement stabilized soil blocks require 7 to 12% cement of content to produce a block of adequate resistance against surface erosion. The opinion that the addition of cement to earth raised fundamental sustainability questions against earth construction was laid to rest by the analysis made by Walker and Standards Australia [

5], which indicated that clay bricks consume between 1.0 and 7.0 GJ per ton, of which 80% to 90% is used in drying and firing, thus replacing firing with cement stabilization and reducing the energy consumed in the block production process by at least 50%.

Attempts were made at solving the limitations of ‘earth’ as a building material [

6,

7,

8,

9]. The prospect of durability of earth walls is dependent on how well the forces of erosion on its surface are resisted. This is of the utmost importance to social acceptability and the future of earthen architecture [

10]. Rammed earth and compressed earth are areas of focus of modern research in a continuous efforts to explore and improve sustainable earthen architecture.

The analysis of Egenti et al. [

11] is shown in ; it takes 43.5 kg of cement to produce blocks for 1 m

2 of compressed earth wall of 200 mm thickness with 12% stabilization. The subject of cement content in compressed earth walls, for desirable effect and durability should be addressed critically and minimized.

Table 1. Summary of the analysis of Egenti et al. [

11].

| Block |

Composition |

Block Thickness |

Area of Wall Covered |

Cement (kg) |

| Compressed Earth Block (CEB) |

12% cement |

200 mm solid |

1 m2 |

43.5 kg |

1.1. Shelled Compressed Earth Blocks

In a bid to reduce the amount of cement while maintaining quality of blocks, shelled compressed earth blocks (SCEB) was evolved by Egenti et al. [

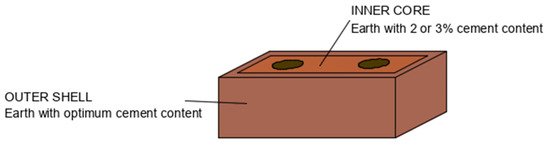

12] as shown in . SCEB is a compressed earth block of two layers of different materials or percentages of cement content, compressed into a block. The inner layer/core may constitutes up to 60% of the total volume of a unit block and may be stabilized with 0–3% cement. The outer layer/shell of about 40% of total volume of unit block can be stabilized with higher (8–12%) cement content. All were mechanically compressed into a single unit block. The structure of SCEB and wall is illustrated in . The structure gives adequate strength and surface resistance to the exposed part of the earth block with less overall cement content and cost. A quality earthen architecture can be achieved with substantial reduction in cement with SCEB.

Figure 1. The structure of shelled compressed earth block [

12].

The SCEB wall is a framework of shell in a supportive and interwoven structure and the inner core in a protective confinement [

12].

1.2. Earth Walls in Urban and Rural Areas

Earth walls are environmentally friendly with less use of cement and low embodied energy. While the challenges and desired characteristics of compressed earth building are simple and few in rural areas, they are more demanding in the urban areas as shown in .

Table 2. Desirable characteristics of compressed earth blocks (CEB) in urban and rural areas.

This research aims to produce a model of compressed earth masonry units of high surface resistance with less cement and less weight for affordable and sustainable housing in Rwanda.

2. Architectural and Building Opportunities

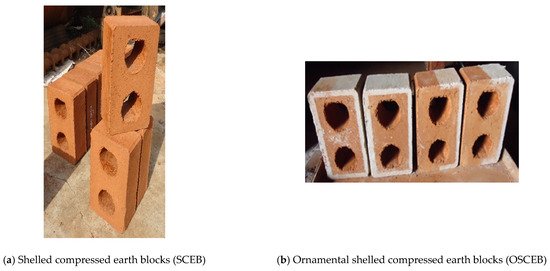

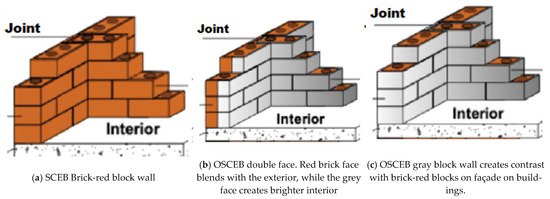

Beyond cement reduction, the concept of a shelled block provides the opportunity for ornamental SCEB (OSCEB). The OSCEB adopts a wide range of compressible earth materials such as Kaolin (white clay), grey clay soil, red clay soil, volcanic sand, etc., to make blocks of desirable colors, textures, and effects, as shown in . The possible application in earthen architecture is shown in .

Figure 11. Shelled and Ornamental Shelled Compressed Earth Blocks.

Figure 12. SCEB and OSCEB application in walls.

3. Compressed Earth Buildings in Rural Areas

The task of using compressed earth for affordable housing in rural areas is less challenging than it is in urban areas. Rural environments may have the advantage of on-site mining of earth and a family and friends labor force for a self-help building process. The conventional compressed earth blocks with 3–5% cement content is adequate for building stability with no attachment to polished wall surfaces. The challenges of compressed earth in rural area is limited to the compressed earth presses and technical know-how. Cooperatives and governmental agencies can make compressed earth presses and trained personnel available at sectorial offices for use in various cells in their respective jurisdiction.

4. Conclusions

Enhancing compressed earth masonry units can provide an alternative wall construction systems to baked clay bricks with an appreciable effect on environment and cost. The challenges of conventional compressed earth masonry units were explored and a model of shelled compressed earth block was evolved with a 60% reduction in the use of cement. The reduction in cement without a reduction in comfort and aesthetic appeal balances the triple bottom line of sustainability, i.e., environment, economic, and sociocultural. In this study, the use of lightweight volcanic aggregate (amakoro) reduced the weight of the unit block by 12%, which further reduced with bigger blocks of larger inner core. The estimated cost of the SCEB wall compared to common wall materials showed a reduction of 15% over conventional compressed earth block wall and a 54% cost reduction over sand-cement block wall. Therefore, shelled compressed earth provides opportunities for ornamenting blocks with more architectural uses for affordable housing in urban areas. In rural areas, compressed earth presses and technical know-how can be made available for people to build their own houses.

This entry is adapted from the peer-reviewed paper 10.3390/su13084188