Nickel–titanium alloy (Ni-Ti) rotary instruments must exert torque to cut and eradicate septic dentin during canal preparation; torsional stress, associated with friction between the instrument and dentin wall, accumulates in the instruments.

- dynamic torsional test

- force

- nickel-titanium rotary instrument

- root canal preparation

- screw-in tendency

- torque

1. Introduction

Nickel–titanium alloy (Ni-Ti) rotary instruments must exert torque to cut and eradicate septic dentin during canal preparation; torsional stress, associated with friction between the instrument and dentin wall, accumulates in the instruments [1,2]. The accumulated stress can be retained as residual stress—plastic deformation—after withdrawal of the instrument from the canal if the stress exceeds the elastic limit [3]. The engagement of rotary instruments, especially those with spiral-shaped active cutting edges, with the dentin wall can generate apically-directed screw-in forces, causing the instrument to become locked in the canal [4]. When this occurs, additional torque is required for the instrument to continue rotating. Thus, torsional stress is instantly accumulated in the instrument, leading to torsional fracture [5,6], which is dissimilar to cyclic fatigue fracture caused by the repeated tension/compression stresses at the curvature [7]. Furthermore, screw-in forces may cause the instrument to engage beyond the apical foramen [8] and result in the extrusion of microbes into periapical tissue [9], root weakening, and cracks in the apical area [10].

Numerous studies have been conducted to examine the dynamic torque and force characteristics of Ni-Ti instrument systems to identify factors having an impact on the stress generated within the rotary instruments. Though potential influencing factors, such as instrument pitch length [11,12,13,14] and instrument rake angle [11,15], have been discussed and debated, no single-most important factor has been identified. Thus, there continues to be debate on how the stress generated within Ni-Ti instruments during root canal instrumentation can be limited to a level at which clinical safety is ensured.

2. Data, Model, Applications and Influences

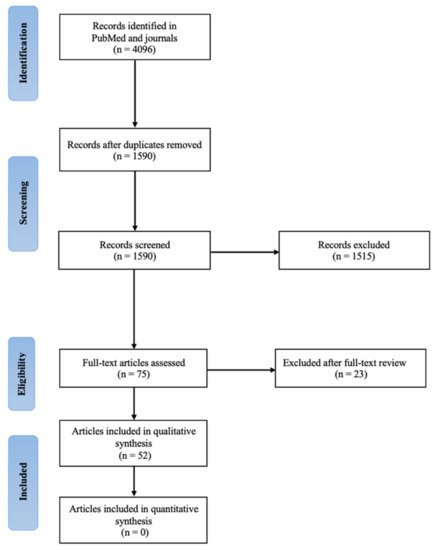

As shown in Figure 1, 4096 articles were identified. After duplicates were removed and preliminary screening was conducted, 75 articles underwent full-text review. Fifty-two studies (Table 1) were eligible for inclusion.

Figure 1. Summary of the search processs.

Table 1. Summary of reviewed studies analyzing torque and force generated by nickel-titanium rotary instruments during root canal preparation.

| Author/Year | Type of Study | Type of Sample | Instrument | Preparation Technique | Result |

|---|---|---|---|---|---|

| Blum et al., 1999 [23] | In vitro | Mandibular incisors | ProFile | Step-back & crown-down | Students > Endodontist (T) Students < Endodontist (F) Step-back > crown-down |

| Blum et al., 1999 [32] | In vitro | Mandibular incisors | ProFile | Step-back & crown-down | Contact area- 10 mm (Step-back) and 5 mm (crown-down) from the tip Step-back > crown-down (T & F) |

| Sattapan et al., 2000 [28] | In vitro | Maxillary/mandibular central and lateral incisors | Quantec Series 2000 | Single file | Small canal > medium canal |

| Peters et al., 2002 [17] | In vitro | Extracted human teeth/plastic blocks | Profile | Crown-down | Straight canal blocks > curved canal blocks > natural teeth (T) Curved canal blocks > natural teeth > straight canal blocks (F) |

| Peters et al., 2003 [29] | In vitro | Maxillary molars | ProTaper | Single-length | F3 > F2 > F1 > S1 > S2 (T) F3 > S1 > F2 > F1 > S2 (F) |

| Blum et al., 2003 [30] | In vitro | Maxillary central incisors/ mandibular central or lateral incisors | ProTaper | Single-Length | Narrow canal > large canal (T) Large canal > narrow canal (F) |

| Hübscher et al., 2003 [31] | In vitro | Maxillary molars | FlexMaster | Crown-down-like modified sequence | Constricted canal > wide canal (T & F) |

| Diemer et al., 2004 [13] | In vitro | Resin blocks | Hero | Single file | Shorter pitch length > longer pitch length (T & F) |

| Da Silva et al., 2005 [34] | In vitro | Maxillary/mandibular central and lateral incisors | Race 720, Race 721, Profile | Single-length | Profile > Race 720 > Race 721 (T & F) |

| Schrader et al., 2005 [33] | In vitro | Plastic blocks | Profile | Crown-down | 35/0.04 had peak T and F in 4% taper sequence 40/0.06 and 35/0.04 had peak T and F in combination of 4% and 6% taper, respectively |

| Peters et al., 2005 [54] | In vitro | Dentin discs | ProFile, ProTaper | Single file | Glyde > Control > EDTA > H2O for ProFile (T) Glyde > H2O > EDTA > Control for ProTaper (T) Glyde > H2O > Control > EDTA for ProFile (F) Control > H2O > Glyde > EDTA for ProTaper (F) ProTaper > ProFile (T) ProFile > ProTaper (F) |

| Boessler et al., 2007 [55] | In vitro | Dentin discs | ProFile | Single file | Dry Control > NaOCL 1% > H2O > HEPB 18% (T) Dry Control > H2O > NaOCL 1% > HEPB 18% (F) |

| Boessler et al., 2009 [56] | In vitro | Dentin discs | ProTaper | Single-length | Electropolished > machined (T) Machined > electropolished (F) |

| Diop et al., 2009 [40] | In vitro | Human cadaveric mandivular central/lateral incisors | ProTaper | Single file | Apical > coronal (T & F) Right > left (F) Posterior > anterior (F) |

| Ha et al., 2010 [15] | In vitro | Resin blocks | K3, Mtwo, NRT, ProFile, ProTaper | Single file | ProTaper > K3 > NRT-safe tip > NRT-active tip > Mtwo > ProFile (F) |

| Son et al., 2010 [18] | In vitro | Resin blocks | ProTaper, ProFile | Single-length | 0° > 10° > 20° > 30° canal curvature (F) |

| Sung et al., 2010 [24] | In vitro | Resin blocks | ProFile, GT rotary, K3 | Single-length | Greater taper > smaller taper (F) |

| Bardsley et al., 2011 [36] | In vitro | Plastic blocks | Vortex | Crown-down | 200 rpm > 400 rpm > 600 rpm (T & F) |

| Peters et al., 2012 [37] | In vitro | Plastic blocks | Hyflex CM | Single-length & crown-down | Single-length > crown-down (T & F) |

| Ha et al., 2012 [8] | In vitro | Endo-training blocks | PathFile, NiTiFlex, ProTaper | Single file | #13 > #15 > #18 > #20 (T & F) |

| Diemer et al., 2013 [19] | In vitro | Resin blocks | HeroShaper, Prototypes | Single file | H6 > H0 > H4 (T) H0 > H6 > H4 (F) |

| Pereira et al., 2013 [41] | In vitro | Plastic blocks | ProTaper Next | Single-length | 250 rpm > 300 rpm > 350 rpm (T & F) |

| Arias et al., 2014 [27] | In vitro | Maxillary incisors/mandibular molars | ProTaper Next, ProTaper Universal | Single-length | Small canals > large canals (T & F) |

| Pereira et al., 2015 [43] | In vitro | Plastic blocks | ProTaper Universal, Profile Vortex, Vortex Blue, Typhoon Infinite Flex | Single-length | Typhoon > ProTaper Universal > Vortex Blue > ProFile Vortex (T) ProTaper Universal > ProFile Vortex > Vortex Blue > Typhoon (F) |

| Ha et al., 2015 [9] | In vitro | Resin block | G-1, G-2, uG glide path files | Single file | G-2 > uG > G-1 (F) |

| Peixoto et al., 2015 [11] | In vitro | Acrylic blocks | Mtwo, Race, ProTaper Universal | Single file | ProTaper Universal > Race > Mtwo (T) ProTaper Universal > Mtwo > Race (F) |

| Arias et al., 2016 [35] | In vitro | Mandibular molars | PathFile, ProGlider | Single-length & Single file | PathFile 1 > PathFile 2 > ProGlider (T & F) ProGlider (16/.02, single file) > PathFile (16/.02, Sequence) (T & F) |

| Moreinos et al., 2016 [59] | In vitro | Simulated metal block canal | Gentlefile, ProTaper Next, Revo-S | Single-length | ProTaper X1 > Revo-S SC2 > Gentlefile 1 (F) Revo-S SC3 > ProTaper X2 > Gentlefile 2 (F) |

| Kwak et al., 2016 [14] | In vitro | Resin blocks | OneG, pG, OneG heat-treated, pG heat-treated glide path files | Single file | pG > OneG > OneG heat-treated > pG heat-treated (F) |

| Ha et al., 2016 [4] | In vitro | Resin blocks | Mtwo, Reciproc 25, ProTaper Universal, ProTaper Next | Single file | Reciproc 25 > ProTaper Universal > ProTaper Next > Mtwo (F) |

| Jamleh et al., 2016 [51] | In vitro | Premolar teeth | Twisted File, Twisted File Adaptive, ProTaper Universal, ProTaper Next | Single-length | ProTaper Universal > ProTaper Next > Twisted File > Twisted File Adaptive (L) |

| Arias et al., 2017 [26] | In vitro | Mandibular molars | PathFile, ProGlider, ProTaper Gold | Single-length | Glide path reduced the torque of shaping files |

| Tokita et al., 2017 [47] | In vitro | Resin canal models | Twisted File Adaptive | Single-length | CR > torque-sensitive reciprocation > time-dependent reciprocation (T) Time-dependent reciprocation > CR > torque-sensitive reciprocation (F) |

| Ha et al., 2017 [45] | In vitro | Resin Canals | One G | Single-length | 4/6 pecking depath > 2/4 pecking depath (F) |

| Fukumori et al., 2018 [22] | In vitro | Resin canals | EndoWave | Single file | EndoWave (30/0.06) > EndoWave (30/0.04) (T & F) |

| Kwak et al., 2018 [25] | In vitro | Resin blocks | WaveOne, WaveOne Gold | Single file | WaveOne > WaveOne Gold (T) Without Glide Path > with Glide Path (T) |

| Jamleh et al., 2018 [58] | In vitro | Maxillary premolar teeth | WaveOne, WaveOne Gold | Single file | WaveOne > WaveOne Gold (F) |

| Nishijo et al., 2018 [50] | In vitro | Endo training blocks | Hyflex EDM Glide Path File (EDM), Hyflex GPF, Scout Race (Race) | Single file | Hyflex EDM Glide Path File > GPF > Race (CR) (F) Hyflex EDM Glide Path File > Race > Hyflex GPF (Reciprocation) (F) |

| Gambarini et al., 2019 [53] | In vitro | Maxillary anterior teeth | Twisted File | Single file | Inward pecking motion > outward brushing motion (T) |

| Abu-Tahun et al., 2019 [46] | In vitro | Resin canals | One G, Hyflex EDM | Single file | No glide path > 5 insertions > 10 insertions > 15 insertions > 20 insertions (T) |

| Kwak et al., 2019 [20] | In vitro | Resin blocks | ProTaper Universal, ProTaper Gold, WaveOne, WaveOne Gold | Single-length & Single file | ProTaper Universal > WaveOne > ProTaper Gold > WaveOne Gold (F) |

| Nayak et al., 2019 [52] | In vitro | Resin blocks | WaveOne Gold, Self-adjusting file, 2Shape | Single-length &single file | WaveOne Gold > 2Shape 2 > 2Shape 1 > self-adjusting file (F) |

| Kwak et al., 2019 [49] | In vitro | Resin blocks | K3XF, Twisted File Adaptive | Single-length | K3XF (CR) > K3XF (adaptive motion) > TFA (adaptive motion) (T) |

| Maki et al., 2019 [42] | In vitro | Resin canal blocks | ProTaper Next | Single-length | High and/or medium-speed > low-speed (clockwise T) High-speed > medium-speed > low-speed (F) |

| Gambarini et al., 2019 [21] | In vivo | Double-rooted maxillary premolars | ProTaper Next, EdgeFile | Single-length | ProTaper Next > EdgeFile (T & preparation time) |

| Bürklein et al., 2019 [39] | In vitro | Maxillary incisors | K-flexofile stainless steel, F6 SkyTaper & EndoPilot, DentaPort ZX OTR, VDW.silver | Balanced-force, single-length | Balanced-force > rotary (F) Rotary > balanced-force (T) No significant differences among 3 motors (T) |

| Almeida et al., 2020 [12] | In vitro | Acrylic blocks | ProTaper Next, ProTaper Universal | Single-length | ProTaper Next X2 > ProTaper Next X1 > ProTaper Universal S1 > ProTaper Universal F1 (T) ProTaper Next X1 > ProTaper Universal S2 > ProTaper Next X2 > ProTaper Universal F1 (F) |

| Maki et al., 2020 [57] | In vitro | Resin blocks | Reciproc, Reciproc Blue | Single file | Reciproc > Reciproc Blue (T & F) |

| Lee et al., 2020 [3] | In vitro | Molars | ProTaper Next, One Curve, Hyflex EDM, Twisted File Adaptive | Single-length | CR > adaptive motion (T) Hyflex EDM > One Curve > ProTaper Next > Twisted File Adaptive (T) |

| Htun et al., 2020 [48] | In vitro | Mandibular incisors | Hyflex EDM glide path file, stainless steel K-file | Single file | CR > OGP > stainless steel manual (T in positive domain) CR > stainless steel manual > OGP (T in negative domain) OGP > stainless steel manual > CR (F in positive domain) OGP > CR > stainless steel manual (F in negative domain) |

| Kimura et al., 2020 [38] | In vitro | Resin blocks | Endowave | Single file, crown-down | Single file (CR) > single file (OTR) (clockwise & counterclockwise T) crown-down (CR) > crown-down (OTR) (clockwise T) crown-down (OTR) > crown-down (CR) (counterclockwise T) |

| Peters et al., 2020 [44] | In vitro | Plastic blocks | TruNatomy, ProTaper Next | Single-length | ProTaper Next X2 > ProTaper Next X3 > ProTaper Next X1 > TruNatomy 36 > TruNatomy 26 > TruNatomy 20 (T) ProTaper Next X1 > ProTaper Next X2 > ProTaper Next X3 > TruNatomy 36 > TruNatomy 26 > TruNatomy 20 (F) |

From these studies, we identified the following 26 factors that influence Ni-Ti rotary instrument torque and force: type of sample [17], canal curvature [17,18], cross-sectional design [11,15,19,20,21], taper [21], blade [15], pitch length [11,12,13,14,15], helix angle [13,15,20], rake angle [11,12,15], cutting efficiency [11,12], instrument size [9,11,12,22,23,24], glide-path preparation [25,26], canal size [27,28,29,30,31], contact area [32,33], preparation technique [8,23,32,33,34,35,36,37,38], preparation time [21,39], insertion depth [17,23,28,29,30,31,32,33,34,35,36,37,38,40,41,42,43,44,45], insertion rate [41,46], displacement [40], motor [39], kinematics [3,4,20,38,47,48,49,50,51,52], operative motion [53], rotational speed [36,41], pecking speed [42], lubricant [54,55], experience of the operators [23], and metallurgy [14,20,21,43,44,50,56,57,58,59].

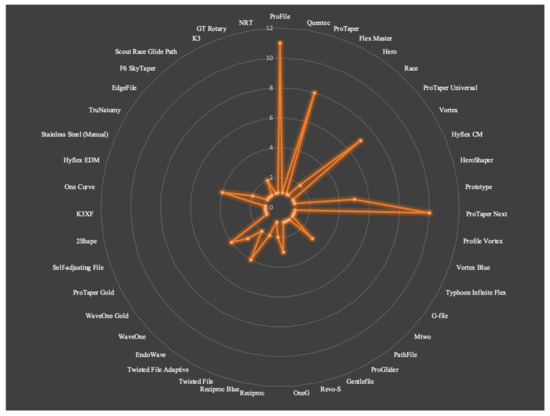

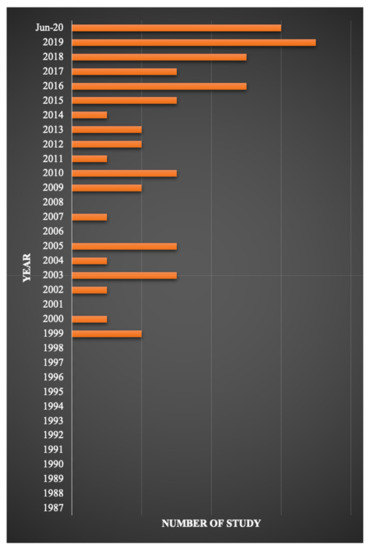

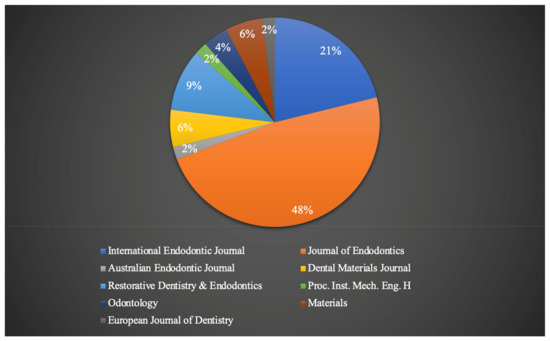

Pro-branded systems, such as ProFile, ProTaper Next, ProTaper and ProTaper Universal, were most frequently investigated (Figure 2). The highest numbers of articles were published in 2019 and in the first half of 2020 (Figure 3), and 48% of the articles included in this review were published in Journal of Endodontics (Figure 4).

Figure 2. Instrument systems used in the studies included in the review.

Figure 3. Publication year of the articles included in the review.

Figure 4. Journals in which articles included in the review were published (by percentage). “Proc. Inst. Mech. Eng. H” refers to “Proceedings of the Institution of Mechanical Engineers, Part H: Journal of Engineering in Medicine”.

The main findings obtained from the present systematic review can be summarized as: Higher torque or force generation was related to convex triangle cross-sectional design, regressive taper, short pitch length, large instrument size, small canal size, single-length preparation technique, long preparation time, deep insertion depth, low rate of insertion, continuous rotation (torque), reciprocating motion (force), lower rotational speed and conventional alloy.

This entry is adapted from the peer-reviewed paper 10.3390/app11073079