The importance of energy demands that have increased exponentially over the past century has led to the sourcing of other ideal power solutions as the potential replacement alternative to the conventional fossil fuel. However, the utilisation of fossil fuel has created severe environmental issues. The identification of other renewable sources is beneficial to replace the energy utilisation globally. Biomass is a highly favourable sustainable alternative to renewable resources that can produce cleaner, cheaper, and readily available energy sources in the future. The palm oil industry is essentially ideal for the availability of abundant biomass resources, where the multifaceted residues are vital for energy production through the conversion of biomass waste into value-added products simultaneously. This article discusses the utilisation of palm oil and its residues in the energy and transportation sector. Assessment and evaluation on the feasibility of palm oil and its residues were made on the current valorisation methods such as thermochemical and biochemical techniques. Their potential as transportation fuels were concurrently reviewed. This is followed by a discussion on future challenges of palm oil industries that will take place globally, including the prospects from government and non-government organisations for the development of palm oil as a sustainable alternative replacement to fossil fuel. Hence, this review aims to provide further insight into the possibilities of palm oil and its residues towards sustainable development with reduced environmental-related issues.

- biofuel

- bioenergy

- oil palm residues

- renewable energy

- thermochemical process

- biochemical process

- pyrolysis

- direct combustion

- anaerobic digestion

- gasification

- agropolitics

1. Introduction

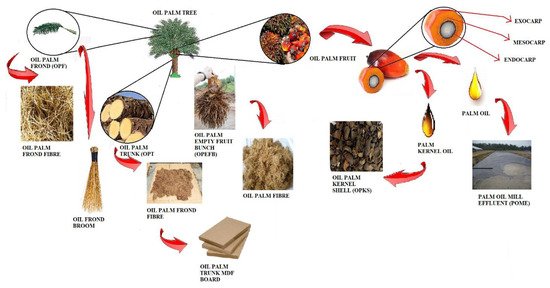

2. Palm Oil Origin, Products and By-Products with Their Characteristics and Current Utilisation

| Confectionery, Baking, and Food | ||

|---|---|---|

| Usage | Year | References |

| Baking fats | 2020 | Meng, Xiaoyu, et al. [27], |

| Shortening | 2019 | Goh et al. [28] |

| Imitation meat emulsifier | 2013 | Rafidah Abd Hamid [29] |

| Fat substitution in a chicken nugget | 2009 | Alina et al. [30] |

| Margarine | 2019 | Makeri, Mohammad, et al. [31] |

| Medicinal properties | ||

| Replacement of Vitamin E (α−tocotrienol) | 2010, 2015 | Sen et.al [32], Ali and Woodman [33] |

| Lubricant in human joints | 2019 | Sapawe, Norzahir, Muhammad Farhan Hanafi, and Syahrullail Samion [34] |

| Suppression of cancer cell | 2013 | Loganathan et al. [35] |

| Antioxidant for diabetes mellitus | 2020 | Alabi, Olabiyi, and Oguntibeju [36] |

| Industries | ||

| Hydrogenated biofuel | 2020 | Boonrod, Bulin, et al. [37], |

| Mix biodiesel | 2017, 2018 | Khalil et al. [38], Cordero-Ravelo and Schallenberg-Rodriguez [39]. |

Structural and Chemical Properties

| Composition | Cellulose | Hemicellulose | Lignin | Ash | Ref. |

|---|---|---|---|---|---|

| I (%) | 25.0 ± 1.7 | 25.7 ± 3.3 | 25.5 ± 0.5 | 5.8 ± 0.2 | [55] |

| II (%) | 34.4 ± 0.7 | 26.7 ± 0.2 | 12.45 ± 0.45 | 4.85 ± 0.15 | [56] |

| III (%) | 20.7 | 23.3 | 49.5 | [57] | |

| IV (%) | 34.5 | 31.8 | 25.7 | 4.3 | [58] |

| V (%) | 40.7 | 26.1 | 26.2 | [59] |

| Ultimate Analysis (%) | Materials | |||||

|---|---|---|---|---|---|---|

| I | II | III | IV | V | ||

| C | 43.17 | 42.80 | 50.29 | 41.60 | 42.60 | |

| H | 6.09 | 6.20 | 6.35 | 6.80 | 5.71 | |

| O | 49.75 | 50.44 | 42.82 | 50.40 | 51.00 | |

| N | 0.90 | 0.47 | 0.48 | 0.40 | 0.42 | |

| S | 0.09 | 0.09 | 0.08 | 0.90 | 0.29 | |

| Proximate Analysis (%) | M | 10.10 | 7.30 | 4.90 | 2.10 | 6.15 |

| VM | 74.90 | 82.40 | 75.40 | 76.70 | 80.55 | |

| AC | 5.60 | 7.51 | 8.70 | 4.30 | 3.02 | |

| FC | 9.40 | 10.09 | 15.90 | 16.90 | 16.43 | |

| HHV (MJ/kg) | 17.15 | 16.9 | 19.5 | 17.2 | 17.00 | |

| Ref. | [64] | [57] | [57] | [65] | [66] | |

3. Palm Oil and Its Residues for Sustainable Biofuel and Bioenergy Production

3.1. Palm Oil as a Biofuel (Transportation)

3.2. Oil Palm Residues Valorisation into Biofuel and Bioenergy Production

3.2.1. The Production of Solid Biofuel (Densification)

3.2.2. The Production of Liquid Biofuel

3.2.3. The Production of Gaseous Biofuel

4. Major Challenges, Perspectives, and a Future Sustainable Approach

4.1. Agropolitical Issues

4.2. World Players in Sustainable Palm Oil Goal

4.3. Goals and Sustainable Palm Oil Approach

5. Conclusions

This entry is adapted from the peer-reviewed paper 10.3390/su13063110

References

- IEA. International Energy Agency, World Energy Outlook 2018: Highlights; IEA: Paris, France, 2018; Available online: https://www.iea.org/reports/world-energy-outlook-2018/electricity (accessed on 20 July 2020).

- Gomiero, T. Are biofuels an effective and viable energy strategy for industrialized societies? A reasoned overview of potentials and limits. Sustainability 2015, 7, 8491–8521.

- Sulaiman, C.; Abdul-Rahim, A.S.; Ofozor, C.A. Does wood biomass energy use reduce CO2 emissions in European Union member countries? Evidence from 27 members. J. Clean. Prod. 2020, 253, 119996.

- Kim, G.; Choi, S.-K.; Seok, J.H. Does +9biomass energy consumption reduce total energy CO2 emissions in the US? J. Policy Model. 2020, 42, 953–967.

- Walters, J.P.; Archer, D.W.; Sassenrath, G.F.; Hendrickson, J.R.; Hanson, J.D.; Halloran, J.M.; Vadas, P.; Alarcon, V.J. Exploring agricultural production systems and their fundamental components with system dynamics modelling. Ecol. Model. 2016, 333, 51–65.

- Mba, O.I.; Dumont, M.J.; Ngadi, M. Palm oil: Processing, characterization and utilization in the food industry—A review. Food Biosci. 2015, 10, 26–41.

- Dumelin, E.E. The Environmental Impact of Palm Oil and Other Vegetable Oils. Fuel Chem. 2009, 13, 420–427.

- Othman, H.; Darus, F.M.; Nor, M.H.M.; Amit, S. Re-evaluation of nutrients requirement for oil palm planting on peat soil. Plants 2014, 90, 161–177.

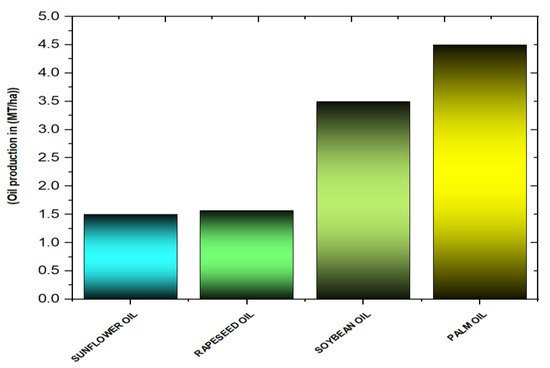

- Fong, L. Palm Oil Alternatives Use More Land, Produce less Yield. Malaysiakini. Available online: https://www.malaysiakini.com/letters/468459 (accessed on 24 July 2020).

- Rebitanim, N.A.; Hanafi, M.M.; Idris, A.S.; Abdullah, S.N.A.; Mohidin, H.; Rebitanim, N.Z. GanoCare® Improves Oil Palm Growth and Resistance against Ganoderma Basal Stem Rot Disease in Nursery and Field Trials. Biomed Res. Int. 2020, 2020, 1–16.

- Versatility and Technical Advantages of Palm Oil. Available online: http://www.arabis.org/index.php/articles/articles/marketing/versatility-and-technical-advantages-of-palm-oil (accessed on 15 February 2021).

- Barcelos, E.; Rios, S.D.A.; Cunha, R.N.; Lopes, R.; Motoike, S.Y.; Babiychuk, E.; Skirycz, A.; Kushnir, S. Oil palm natural diversity and the potential for yield improvement. Front. Plant Sci. 2015, 6, 190.

- Monthly Palm Oil Trade Statistics: January–December 2019, M.P.O.C. Available online: http://mpoc.org.my/monthly-palm-oil-trade-statistics-2019/ (accessed on 29 July 2020).

- Yusoff, M.N.A.M.; Zulkifli, N.W.M.; Sukiman, N.L.; Chyuan, O.H.; Hassan, M.H.; Hasnul, M.H.; Zulkifli, M.S.A.; Abbas, M.M.; Zakaria, M.Z. Sustainability of Palm Biodiesel in Transportation: A Review on Biofuel Standard, Policy and International Collaboration Between Malaysia and Colombia. Bioenergy Res. 2020, 236, 155–163.

- Mutsaers, H. The challenge of the oil palm: Using degraded land for its cultivation. Outlook Agric. 2019, 48, 190–197.

- Global Palm Oil Demand to Fall by 4% on Pandemic Impact. The Malaysian Reserve. Available online: https://themalaysianreserve.com/2020/11/11/global-palm-oil-demand-to-fall-by-4-on-pandemic-impact/ (accessed on 7 January 2021).

- Ahmad, F.B.; Zhang, Z.; Doherty, W.O.S.; O’Hara, I.M. Evaluation of oil production from oil palm empty fruit bunch by oleaginous micro-organisms. Biofuels Bioprod. Biorefining 2016, 10, 378–392.

- Singh, R.P. Cost effectiveness of palm oil in comparison to other oils and fats in the country with special emphasis on lower income group. Indian J. Community Health 2014, 26, 37–44.

- Megashah, L.N.; Ariffin, H.; Zakaria, M.R.; Hassan, M.A. Properties of Cellulose Extract from Different Types of Oil Palm Biomass. IOP Conf. Ser. Mater. Sci. Eng. 2018, 368, 012049.

- Sagar, H.S.S.C.; Mabano, A.; Roopa, R.; Sharmin, M.; Richard, F.-J.; Clause, J. India in the Oil Palm Era: Describing India’s Dependence on Palm Oil, Recommendations for Sustainable Production, and Opportunities to Become an Influential Consumer. Trop. Conserv. Sci. 2019, 12, 1–9.

- Zakaria, K.; Kunchu, J.A.B.; Salleh, K.M.; Nambiappan, B.; Hassan, N.A.M.; Azam, A.H.M. Demand for Palm Oil in the Balkans using Autoregressive Distributed Lag (ARDL) (Permintaan Minyak Sawit di Balkan menggunakan Lat Tertabur Autoregresif). J. Ekon. Malays. 2019, 53, 145–152.

- Tengku, Z.; Abdul, W.A. An overview of the palm oil sector: Countries and companies. Glob. Palm Oil Conf. 2015, 1, 1–20.

- Sujadi, S.; Hasibuan, H.A.; Rivani, M.; Purba, A.R. Oil Content and Chemical Composition in the Parts of Oil Palm Fruit from 8 IOPRI Varieties. J. Penelit. Kelapa Sawit 2016, 24, 67–76.

- Boateng, L.; Ansong, R.; Owusu, W.B.; Steiner-Asiedu, M. Coconut oil and palm oil’s role in nutrition, health and national development: A review. Ghana Med. J. 2016, 50, 189–196.

- Zhang, J.; Wang, C.-R.; Xue, A.-N.; Ge, K.-Y. Effects of red palm oil on serum lipids and plasma carotenoids level in Chinese male adults. Biomed. Environ. Sci. 2003, 16, 348–354.

- Kushairi, A.; Loh, S.K.; Azman, I.; Hishamuddin, E.; Ong-Abdullah, M.; Izuddin, Z.B.M.N.; Razmah, G.; Sundram, S.; Parveez, G.K.A. Oil palm economic performance in Malaysia and R&D progress in 2017—Review Article. J. Oil Palm Res. 2018, 30, 163–195.

- Meng, X.; Liu, C.; Cao, C.; Zheng, Z.; Su, Q.; Liu, Y. L-ascorbyl palmitate modify the crystallization behavior of palm oil: Mechanism and application. LWT 2020, 1089, 12299.

- Goh, K.M.; Wong, Y.H.; Abas, F.; Lai, O.M.; Cheong, L.Z.; Wang, Y.; Wang, Y.; Tan, C.P. Effects of shortening and baking temperature on quality, MCPD ester and glycidyl ester content of conventional baked cake. LWT 2019, 116, 108553.

- Hamid, R.A. Application of Palm Emulsion in Vegetarian Nuggets. In Malaysian Palm Oil Board Inf Ser. (MPOB TT.541); June 2013. Available online: http://palmoilis.mpob.gov.my/publications/TOT/TT541.pdf (accessed on 20 July 2020).

- Alina, A.R.; Babji, A.S.; Affandi, S. Nutritional quality of palm fat substituted chicken nuggets. Nutr. Food Sci. 2009, 39, 181–188.

- Makeri, M.; Sahri, M.M.; Ghazali, H.M.; Ahmad, K.; Muhammad, K. Polymorphism, textural and crystallization properties of winged bean (Psophocarpus tetragonolobus, D.C) oil-based trans-fatty acids free ternary margarine blends. LWT 2019, 100, 158–166.

- Sen, C.K.; Rink, C.; Khanna, S. Palm oil–derived natural vitamin e α-tocotrienol in brain health and disease. J. Am. Coll. Nutr. 2010, 29, 314S–323S.

- Ali, S.F.; Woodman, O.L. Tocotrienol Rich Palm Oil Extract Is More Effective Than Pure Tocotrienols at Improving Endothelium-Dependent Relaxation in the Presence of Oxidative Stress. Oxidative Med. Cell. Longev. 2015, 2015, 1–10.

- Sapawe, N.; Hanafi, M.F.; Samion, S. The Use of Palm Oil as New Alternative Biolubricant for Improving Anti-Friction and Anti-Wear Properties. Mater. Today Proc. 1126, 2019, 19–1135.

- Loganathan, R.; Selvaduray, K.R.; Nesaretnam, K.; Radhakrishnan, A.K. Differential and antagonistic effects of palm tocotrienols and other phytonutrients (carotenoids, squalene and coenzyme Q10) on breast cancer cells in vitro. J. Oil Palm Res. 2013, 25, 208–215.

- Alabi, T.D.; Olabiyi, F.A.; Oguntibeju, O.O. Palm oil: Its antioxidant potential in diabetes mellitus. In Diabetes; Academic Press: Cambridage, UK, 2020; pp. 285–291.

- Boonrod, B.; Prapainainar, P.; Varabuntoonvit, V.; Sudsakorn, K.; Prapainainar, C. Environmental impact assessment of bio-hydrogenated diesel from hydrogen and co-product of palm oil industry. Int. J. Hydrogen Energy 2020, 46, 10570–10585.

- Khalil, I.; Aziz, A.R.A.; Yusup, S.; Heikal, M.; El-Adawy, M. Response surface methodology for the optimization of the production of rubber seed/palm oil biodiesel, IDI diesel engine performance, and emissions. Biomass Convers. Biorefinery 2017, 7, 37–49.

- Cordero-Ravelo, V.; Schallenberg-Rodriguez, J. Biodiesel production as a solution to waste cooking oil (WCO) disposal. Will any type of WCO do for a transesterification process? A quality assessment. J. Environ. Manag. 2018, 228, 117–129.

- Nwankwojike, B.N. Development of Abrasive Selection Model/Chart for Palm Frond Broom Peeling Machine Design. Int. J. Eng. Res. Appl. 2014, 4, 84–90.

- Ibrahim, Z.; Aziz, A.A.; Ramli, R.; Mokhtar, A.; Omar, R.; Lee, S. Production of Medium Density Fibreboard (MDF) from Oil Palm Trunk (OPT). J. Appl. Sci. 1174, 2014, 14–1179.

- Deka, D.; Tayung, K.; Jha, D.K. Harnessing Fungal Endophytes for Plant and Human Health. In Sustainable Development and Biodiversity 15: Endophytes: Biology and Biotechnology, 1st ed.; Maheshwari, D.K., Ed.; Springer: Berlin/Heidelberg, Germany, 2014; pp. 67–82.

- Fabiani, C.; Pisello, A.L.; Barbanera, M.; Cabeza, L.F. Palm oil-based bio-PCM for energy efficient building applications: Multipurpose thermal investigation and life cycle assessment. J. Energy Storage 2020, 28, 101129.

- Momoh, E.O.; Osofero, A.I. Recent developments in the application of oil palm fibers in cement composites. Front. Struct. Civ. Eng. 2020, 14, 94–108.

- Ishak, F.A.; Jamil, M.H.; Abd Razak, A.S.; Zamani, N.H.A.; Ab Hamid, M.R. Development of Animal Feed from Waste to Wealth using Napier Grass and Palm Acid Oil (PAO) from Palm Oil Mill Effluent (POME). Mater. Today Proc. 1618, 2019, 19–1627.

- Halim, R.M.; Ramli, R.; Che Mat, C.M.; Hadi, N.A.; Abu Bakar, N.; Aziz, A.A.; Highly Digestible Palm Kernel Cake (PKC) For Animal Feed. Malaysian Palm Oil Board. 2017. Available online: http://palmoilis.mpob.gov.my/publications/TOT/tot2017/TT619-Rohaya.pdf (accessed on 25 July 2020).

- Kum, W.H.; Zahari, M.W. Utilisation of Oil Palm By-Products as Ruminant Feed in Malaysia. J. Oil Palm Res. 1029, 2011, 23–1035.

- Nadlene, R.; Sapuan, S.M.; Jawaid, M.; Ishak, M.R.; Yusriah, L. A Review on Roselle Fiber and Its Composites. J. Nat. Fibers 2016, 13, 10–41.

- Liu, Z.; Li, L.; Liu, C.; Xu, A. Pretreatment of corn straw using the alkaline solution of ionic liquids. Bioresour. Technol. 2018, 260, 417–420.

- Kalita, E.; Nath, B.K.; Deb, P.; Agan, F.; Islam, M.R.; Saikia, K. High quality fluorescent cellulose nanofibers from endemic rice husk: Isolation and characterization. Carbohydr. Polym. 2015, 122, 308–313.

- Shimizu, F.L.; Monteiro, P.Q.; Ghiraldi, P.H.C.; Melati, R.B.; Pagnocca, F.C.; de Souza, W.; Sant’Anna, C.; Brienzo, M. Acid, alkali and peroxide pretreatments increase the cellulose accessibility and glucose yield of banana pseudostem. Ind. Crop. Prod. 2018, 115, 62–68.

- Kumar, A.K.; Sharma, S. Recent updates on different methods of pretreatment of lignocellulosic feedstocks: A review. Bioresour. Bioprocess. 2017, 4, 7.

- Dash, M.; Dasu, V.V.; Mohanty, K. Physico-chemical characterization of Miscanthus, Castor, and Jatropha towards biofuel production. J. Renew. Sustain. Energy 2015, 7, 043124.

- Monlau, F.; Barakat, A.; Trably, E.; Dumas, C.; Steyer, J.P.; Carrère, H. Lignocellulosic materials into biohydrogen and biomethane: Impact of structural features and pretreatment. Crit. Rev. Environ. Sci. Technol. 2013, 43, 260–322.

- Zakaria, M.R.; Hirata, S.; Hassan, M.A. Combined pretreatment using alkaline hydrothermal and ball milling to enhance enzymatic hydrolysis of oil palm mesocarp fiber. Bioresour. Technol. 2014, 169, 236–243.

- Yunos, N.S.H.M.; Baharuddin, A.S.; Yunos, K.F.M.; Hafid, H.S.; Busu, Z.; Mokhtar, M.N.; Sulaiman, A.; Som, A.M. The Physicochemical Characteristics of Residual Oil and Fibers from Oil Palm Fruit Bunches. BioResources 2015, 10, 14–29.

- Safana, A.A.; Abdullah, N.; Sulaiman, F. Potential Application of Oil Palm Wastes Charcoal Briquettes for Coal Replacement. Palm Oil 2018, 2018, 53.

- Hashim, F.S.; Yussof, H.W.; Zahari, M.K.A.M.; Rahman, R.A.; Illias, R.M. Physicochemical and Morphological Characterisation of the Native and Alkaline Pre-treated Fibre Pressed Oil Palm Frond for Fermentable Sugars Production. Chem. Eng. Trans. 2017, 1087, 56–1092.

- Kong, S.H.; Loh, S.K.; Bachmann, R.T.; Rahim, S.A.; Salimon, J. Biochar from oil palm biomass: A review of its potential and challenges. Renew. Sustain. Energy Rev. 2014, 39, 729–739.

- Virmond, E.; de Sena, R.F.; Albrecht, W.; Althoff, C.A.; Moreira, R.F.P.M.; José, H.J. Characterisation of agroindustrial solid residues as biofuels and potential application in thermochemical processes. Waste Manag. 1952, 2012, 32–1961.

- Kylili, A.; Christoforou, E.; Fokaides, P.A. Environmental evaluation of biomass pelleting using life cycle assessment. Biomass Bioenerg 2015, 84, 107–117.

- Obuka Nnaemeka, S.P.; Onyechi Pius, C.; Okoli Ndubuisi, C. Palm Oil Biomass Waste a Renewable Energy Resource for Power Generation. Saudi J. Eng. Technol. 2018, 3, 680–691.

- Elbersen, H.W.; Meesters, K.P.H.; Bakker, R.R.C. Valorization of palm oil (mill) residues. In Identifying and Solving the Challenges; NL Agency: Utrecht, The Netherlands, 2013.

- Faizal, H.M.; Shamsuddin, H.S.; Heiree, M.H.M.; Hanaffi, M.F.M.A.; Rahman, M.R.A.; Rahman, M.M.; Latiff, Z.A. Torrefaction of densified mesocarp fibre and palm kernel shell. Renew. Energy 2018, 122, 419–428.

- Alias, N.B.; Ibrahim, N.; Hamid, M.K.A.; Hasbullah, H.; Ali, R.R.; Kasmani, R.M. Investigation of oil Palm Wastes’ Pyrolysis by Thermo-gravimetric Analyzer for Potential Biofuel Production. Energy Procedia 2015, 75, 78–83.

- Inayat, M.; Sulaiman, S.A.; Naz, M.Y. Thermochemical Characterization of Oil Palm Fronds, Coconut Shells, and Wood as A Fuel for Heat and Power Generation. Matec Web Conf. 2018, 205, 1–6.

- Mahmood, W.M.F.W.; Ariffin, M.A.; Harun, Z.; Ishak, N.A.I.; Ghani, J.A.; Rahman, M.N.A. Characterisation and Potential use of Biochar from Gasifier Oil Palm Waste. J. Eng. Sci. Technol. 2014, 10, 45–54.

- Ng, W.P.Q.; Lam, H.L.; Ng, F.Y.; Kamal, M.; Lim, J.H.E. Waste-to-wealth: Green potential from palm biomass in Malaysia. J. Clean. Prod. 2012, 34, 57–65.

- Salleh, S.F.; Roslan, M.E.M.; Rahman, A.A.; Shamsuddin, A.H.; Abdullah, T.A.R.T.; Sovacool, B.K. Transitioning to a sustainable development framework for bioenergy in Malaysia: Policy suggestions to catalyse the utilisation of palm oil mill residues. Energy. Sustain. Soc. 2020, 10, 1–20.

- Frey, H.C. Trends in onroad transportation energy and emissions. J. Air Waste Manag. Assoc. 2018, 68, 514–563.

- Nasir, M.K.; Noor, R.M.; Kalam, M.A.; Masum, B.M. Reduction of fuel consumption and exhaust pollutant using intelligent transport systems. Sci. World J. 2014, 2014, 836375.

- Zhang, H.; Li, Z.; Zhang, L. Research on relationship model between fuel consumption of transportation vehicles and speed in region of Hohhot. In IOP Conference Series: Earth and Environmental Science; IOP Publishing Ltd.: Bristol, UK, 2018; Volume 188, p. 012072.

- Mathews, J.; Ardiyanto, A. Estimation of Greenhouse Gas Emissions for Palm Oil Biodiesel Production: A Review and Case Study within the Council Directives 2009/28/EC of the European Parliament. J. Oil Palm Environ. Health 2015, 6, 25–41.

- Dioha, I.J.; Ikeme, C.H.; Nafi, T.; Soba, N.I.; Yusuf, M.B.S. Effect of Carbon to Nitrogen Ratio on Biogas Production. Int. Res. J. Nat. Sci. 2013, 1, 1–10.

- Azizi, K.; Moraveji, M.K.; Najafabadi, H.A. A review on bio-fuel production from microalgal biomass by using pyrolysis method. Renew. Sustain. Energy Rev. 2018, 3046, 82–3059.

- Hosseini, S.E.; Wahid, M.A. Necessity of biodiesel utilization as a source of renewable energy in Malaysia. Renew. Sustain. Energy Rev. 2012, 5732, 16–5740.

- Nursyairah, J.; Harrison, L.L.N.; Loh, S.K.; Rusnani, A.M.; Daryl, J.T.; Yung, C.L.; Ropandi, M.; Wan Hasamudin, W.H.; Puah, C.W.; Yahaya, H.; et al. National Biodiesel Implementation in Malaysia: An Update. Palm Oil Eng. Bull. 2017, 125, 21–25.

- Pouliot, S. The Economics of Canada Biofuel Policies. Fare Share 2018, 1, 8–9.

- Wolinetz, M.; Hein, M.; Moawad, B. Tracking biofuel consumption, feedstocks and avoided greenhouse gas emissions Errata about Navius Research. Vancouver. 2019. Available online: https://www.naviusresearch.com/publications/2019-biofuels-in-canada/ (accessed on 25 July 2020).

- Masjuki, H.H.; Kalam, M.A.; Mofijur, M.; Shahabuddin, M. Biofuel: Policy, standardization and recommendation for sustainable future energy supply. Mediterr. Green Energy Forum 2013, 42, 577–586.

- Kuss, V.V.; Kuss, A.V.; da Rosa, R.G.; Aranda, D.A.G.; Cruz, Y.R. Potential of biodiesel production from palm oil at Brazilian Amazon. Renew. Sustain. Energy Rev. 2015, 1013, 50–1020.

- Nongbe, M.C.; Ekou, T.; Ekou, L.; Yao, K.B.; le Grognec, E.; Felpin, F.X. Biodiesel production from palm oil using sulfonated graphene catalyst. Renew. Energy 2017, 106, 135–141.

- Roschat, W.; Siritanon, T.; Yoosuk, B.; Promarak, V. Biodiesel production from palm oil using hydrated lime-derived CaO as a low-cost basic heterogeneous catalyst. Energy Convers. Manag. 2016, 108, 459–467.

- Chen, G.; Shan, R.; Shi, J.; Liu, C.; Yan, B. Biodiesel production from palm oil using active and stable K doped hydroxyapatite catalysts. Energy Convers. Manag. 2015, 98, 463–469.

- Kareem, S.O.; Falokun, E.I.; Balogun, S.A.; Akinloye, O.A.; Omeike, S.O. Enzymatic biodiesel production from palm oil and palm kernel oil using free lipase. Egypt. J. Pet. 2017, 26, 635–642.

- Nahian, M.R.; Islam, M.N.; Khan, S. Production of Biodiesel from Palm Oil and Performance Test with Diesel CI Engine. Int. Conf. Mech. Ind. Energy Eng. 2016, 2016, 26–27.

- Pullen, J.; Saeed, K. An overview of biodiesel oxidation stability. Renew. Sustain. Energy Rev. 2012, 5924, 16–5950.

- El-Araby, R.; Amin, A.; el Morsi, A.K.; El-Ibiari, N.N.; El-Diwani, G.I. Study on the characteristics of palm oil–biodiesel–diesel fuel blend. Egypt. J. Pet. 2018, 27, 187–194.

- Senthilkumar, S.; Sivakumar, G.; Manoharan, S. Investigation of palm methyl-ester bio-diesel with additive on performance and emission characteristics of a diesel engine under 8-mode testing cycle. Alex. Eng. J. 2015, 54, 423–428.

- Vieira da Silva, M.A.; Gil Ferreira, B.L.; da Costa Marques, L.G.; Soares Murta, A.L.; de Freitas, M.A.V. Comparative study of NOx emissions of biodiesel-diesel blends from soybean, palm and waste frying oils using methyl and ethyl transesterification routes. Fuel 2017, 194, 144–156.

- Ganjehkaviri, A.; Jaafar, M.M.; Hosseini, S.; Musthafa, A. Performance Evaluation of Palm Oil-Based Biodiesel Combustion in an Oil Burner. Energies 2016, 9, 97.

- Zahan, K.A.; Kano, M. Biodiesel production from palm oil, its by-products, and mill effluent: A review. Energies 2018, 11, 2132.

- Acevedo, J.C.; Hernández, J.A.; Valdés, C.F.; Khanal, S.K. Analysis of operating costs for producing biodiesel from palm oil at pilot-scale in Colombia. Bioresour. Technol. 2015, 188, 117–123.

- Song, B.; Lin, R.; Lam, C.H.; Wu, H.; Tsui, T.H.; Yu, Y. Recent advances and challenges of inter-disciplinary biomass valorization by integrating hydrothermal and biological techniques. Renew. Sustain. Energy Rev. 2021, 135, 110370.

- Wang, A.G.; Austin, D.; Song, H. Catalytic Biomass Valorization. In Biomass Volume Estimation and Valorization for Energy; Tumuluru, J.S., Ed.; InTechOpen: London, UK, 2017.

- Vega-Nieva, D.J.; Garcia-Maraver, A.; Ortiz, L. Slagging and Fouling Risks Derived from the Combustion of Solid Biofuels. Wit Trans. State Art Sci. Eng. 2015, 85, 137–147.

- Lee, X.J.; Lee, L.Y.; Gan, S.; Thangalazhy-Gopakumar, S.; Ng, H.K. Biochar potential evaluation of palm oil wastes through slow pyrolysis: Thermochemical characterization and pyrolytic kinetic studies. Bioresour. Technol. 2017, 236, 155–163.

- Hawari, Y.; Halim, R.M.; Aziz, A.A. Review on Technologies Advancement for Particulate Emission Reduction in Palm Oil Mill. Palm Oil Eng. Bull. 2018, 129, 42–49.

- Suheri, P.; Kuprianov, V.I. Co-Firing of Oil Palm Empty Fruit Bunch and Kernel Shell in a Fluidized-Bed Combustor: Optimization of Operating Variables. Energy Procedia 2015, 79, 956–962.

- Sabil, K.M.; Aziz, M.A.; Lal, B.; Uemura, Y. Effects of torrefaction on the physiochemical properties of oil palm empty fruit bunches, mesocarp fiber and kernel shell. Biomass Bioenergy 2013, 56, 351–360.

- Hamid, M.F.; Idroas, M.Y.; Ishak, M.Z.; Alauddin, Z.A.Z.; Miskam, M.A.; Abdullah, M.K. An experimental study of briquetting process of torrefied rubber seed kernel and palm oil shell. Biomed Res. Int. 2016, 2016, 1679734.

- Ahmad, M.I.; Yusoff, R.Y.M.; Rasat, M.S.M.; Alauddin, Z.A.Z.; Soid, S.N.M.; Mohamed, M.; Amini, M.H.M.; Aziz, M.S.A.; Amin, M.F.M. Influence of torrefaction on chemical compositions of empty fruit bunch (EFB) biomass using microwave heating. Int. J. Adv. Appl. Sci. 2017, 4, 281–286.

- Nurdiawati, A.; Novianti, S.; Zaini, I.N.; Nakhshinieva, B.; Sumida, H.; Takahashi, F.; Yoshikawa, K. Evaluation of Hydrothermal Treatment of Empty Fruit Bunch for Solid Fuel and Liquid Organic Fertilizer Co-Production. Energy Procedia 2015, 79, 226–232.

- Wattana, W.; Phetklung, S.; Jakaew, W.; Chumuthai, S.; Sriam, P.; Chanurai, N. Characterization of Mixed Biomass Pellet Made from Oil Palm and Para-rubber Tree Residues. Energy Procedia 2017, 1128, 138–1133.

- Salomon, M.; Gómez, M.F.; Erlich, C.; Martin, A. Pelletization: An alternative for polygeneration in the palm oil industry. Biomass Convers. Biorefinery 2013, 3, 213–229.

- Emerhi, E.A. Physical and combustion properties of briquettes produced from sawdust of three hardwood species and different organic binders. Adv. Appl. Sci. Res. 2011, 2, 236–246.

- Brenda, M.G.; Innocent, E.E.; Daniel, O.; Abdu, Y.A. Performance of Biomass Briquettes as an Alternative Energy Source Compared to Wood Charcoal in Uganda. Int. J. Sci. Eng. Sci. 2017, 1, 55–60.

- Okot, D.K.; Bilsborrow, P.E.; Phan, A.N. Effects of operating parameters on maize COB briquette quality. Biomass Bioenergy 2018, 112, 61–72.

- Oke, P.; Olugbade, T.; Olaiya, G. Analysis of the Effect of Varying Palm Kernel Particle Sizes on the Calorific Value of Palm Kernel Briquette. Br. J. Appl. Sci. Technol. 2016, 14, 1–5.

- Sing, C.Y.; Aris, S.S. A study of biomass fuel briquettes from oil palm mill residues. Asian J. Sci. Res. 2013, 6, 537–545.

- Kpalo, S.Y.; Zainuddin, M.F.; Manaf, L.A.; Roslan, A.M. Production and Characterization of Hybrid Briquettes from Corncobs and Oil Palm Trunk Bark under a Low Pressure Densification Technique. Sustainability 2020, 12, 2468.

- Kan, T.; Strezov, V.; Evans, T.J. Lignocellulosic biomass pyrolysis: A review of product properties and effects of pyrolysis parameters. Renew. Sustain. Energy Rev. 2016, 1126, 57–1140.

- Lv, D.; Xu, M.; Liu, X.; Zhan, Z.; Li, Z.; Yao, H. Effect of cellulose, lignin, alkali and alkaline earth metallic species on biomass pyrolysis and gasification. Fuel Process. Technol. 2010, 91, 903–909.

- Abas, F.Z.; Ani, F.N.; Zakaria, Z.A. Microwave-assisted production of optimized pyrolysis liquid oil from oil palm fiber. J. Clean. Prod. 2018, 182, 404–413.

- Sukiran, M.A.; Kheang Loh, S.; Bakar, N.A. Pyrolysis of Oil Palm Biomass to Multiple Fuels and Products: Experiences of MPOB. Palm Oil Eng. Bull. 2017, 123, 21–26.

- Yoo, H.M.; Choi, H.S.; Lee, J.S.; Park, H.C.; Yang, W.S.; Seo, Y.C. The fast pyrolysis characteristics of palm empty fruit bunch: The yield and homogeneity of biocrudeoil affected by ash. Environ. Prog. Sustain. Energy 2014, 33, 706–710.

- Sukiran, M.A.; Loh, S.K.; Bakar, N.A. Conversion of Pre-Treated Oil Palm Empty Fruit Bunches Into Bio-Oil and Bio-Char via Fast Pyrolysis. J. Oil Palm Res. 2018, 30, 121–129.

- Rahayu, A.S.; Karsiwulan, D.; Yuwono, H.; Trisnawati, I.; Mulyasari, S.; Rahardjo, S.; Hokermin, S.; Paramita, V. Handbook: Pome-to-Biogas Project Development in Indonesia, 2nd ed.; Winrock International: Washington, DC, USA, 2015.

- Sharuddin, S.S.; Ramli, N.; Hassan, M.A.; Mustapha, N.A.; Amran, A.; Mohd-Nor, D.; Sakai, K.; Tashiro, Y.; Shirai, Y.; Maeda, T. Bacterial community shift revealed Chromatiaceae and Alcaligenaceae as potential bioindicators in the receiving river due to palm oil mill effluent final discharge. Ecol. Indic. 2017, 82, 526–529.

- Shakib, N.; Rashid, M. Biogas Production Optimization from POME by Using Anaerobic Digestion Process. J. Appl. Sci. Process Eng. 2019, 6, 369–377.

- Igoni, A.H.; Ayotamuno, M.J.; Eze, C.L.; Ogaji, S.O.T.; Probert, S.D. Designs of anaerobic digesters for producing biogas from municipal solid-waste. Appl. Energy 2008, 85, 430–438.

- Okonkwo, U.C.; Onokpite, E.; Onokwai, A.O. Comparative study of the optimal ratio of biogas production from various organic wastes and weeds for digester/restarted digester. J. King Saud Univ. Eng. Sci. 2018, 30, 123–129.

- Suksong, W.; Promnuan, K.; Seengenyoung, J.; O-Thong, S. Anaerobic Co-Digestion of Palm Oil Mill Waste Residues with Sewage Sludge for Biogas Production. Energy Procedia 2017, 138, 789–794.

- Trisakti, B.; Manalu, V.; Taslim, I.; Turmuzi, M. Acidogenesis of Palm Oil Mill Effluent to Produce Biogas: Effect of Hydraulic Retention Time and pH. Procedia Soc. Behav. Sci. 2015, 2466, 195–2474.

- Trisakti, B.; Irvan, M.; Turmuzi, M. Effect of temperature on methanogenesis stage of two-stage anaerobic digestion of palm oil mill effluent (POME) into biogas. IOP Conf. Ser. Mater. Sci. Eng. 2017, 206, 9.

- Zinatizadeh, A.A.; Mirghorayshi, M. Effect of Temperature on the Performance of an Up-flow Anaerobic Sludge Fixed Film (UASFF) Bioreactor Treating Palm Oil Mill Effluent (POME). Waste Biomass Valorization 2019, 10, 349–355.

- Wong, L.P.; Isa, M.H.; Bashir, M.J.K.; Chin, Y.H. Effect of hydraulic retention time on volatile fatty acid production and organic degradation in anaerobic digestion of palm oil mill effluent. Aip Conf. Proc. 2019, 2157, 7.

- Hosseini, S.E.; Bagheri, G.; Khaleghi, M.; Wahid, M.A. Combustion of Biogas Released from Palm Oil Mill Effluent and the Effects of Hydrogen Enrichment on the Characteristics of the Biogas Flame. J. Combust. 2015, 2015, 12.

- Bakar, N.A.; Soon, L.W.; Sukiran, M.A.; Kheang, L.S.; Bukhari, N.A. Co-firing of Biogas in Palm Oil Mill Biomass Boilers. Palm Oil Eng. Bull. 2016, 120, 23–26.

- Kheang, L.S.; Lian, L.D.; Sukiran, M.A. MPOB-BEE High Efficient Methane Fermentation System for Electricity Generation. Palm Oil Eng. Bull. 2016, 120, 11–14.

- Jonas, H.; Abram, N.K.; Ancrenaz, M. Addressing the Impact of Large-Scale Oil Palm Plantations on Orangutan Conservation in Borneo A Spatial, Legal and Political Economy Analysis; International Institute for Environment and Development (IIED): London, UK, 2017.

- IUCN. International Union for Conservation of Nature Contents 2016 (IUCN); IUCN: Grant, Switzerland, 2017.

- Houghton, M.; Abram, N.; Kler, H.; Greengrass, E.; Jay, D.; Redmond, I.; Cress, D. Palm Oil Paradox: Sustainable Solutions to Save The Great Apes; UNEP/GRASP 2016; UNEP: Nairobi, Kenya, 2016.

- Saieed, Z. Palm oil wrongly targeted | The Star. The Star Online. Available online: https://www.thestar.com.my/Business/Business-News/2015/02/28/Palm-oil-wrongly-targeted/?style=biz) (accessed on 23 July 2020).

- Food and Agriculture Organization of the United Nations. Available online: http://www.fao.org/home/search/en?page=2&query=FOREST ESTIMATION MALAYSIA AND THE EMISSION OF CO2&category=__NULL_VALUE__ (accessed on 14 February 2021).

- Thornton, P.K. Livestock production: Recent trends, future prospects. Philos. Trans. R. Soc. B Biol. Sci. 2010, 2853, 365–2867.

- Rosner, H. Palm Oil is Unavoidable. Can it be Sustainable? National Geographic (Magazine). Available online: https://www.nationalgeographic.com/magazine/2018/12/palm-oil-products-borneo-africa-environment-impact/ (accessed on 21 November 2020).

- RSPO, Guidance on Map Submission for Land Use Change Analysis (LUCA) for Independent Smallholders. Kuala Lumpur, Malaysia, RSPO. 2017. Available online: https://rspo.org/resources/archive/478 (accessed on 21 November 2020).

- Dislich, C.; Hettig, E.; Salecker, J.; Heinonen, J.; Lay, J.; Meyer, K.M.; Wiegand, K.; Tarigan, S. Land-use change in oil palm dominated tropical landscapes—An agent-based model to explore ecological and socio-economic trade-offs. PLoS ONE 2018, 13, e0190506.

- Abdul Ghani Wahab, Malaysia Oilseeds and Products Annual; USDA Foreign Agricultural Service: Washington, DC, USA, 2019.

- Alam, A.S.A.F.; Er, A.C.; Begum, H. Malaysian oil palm industry: Prospect and problem. J. Food Agric. Environ. 2015, 13, 143–148.

- Zarin, D.J.; Harris, N.L.; Baccini, A.; Aksenov, D.; Hansen, M.C.; Azevedo-Ramos, C.; Azevedo, T.; Margono, B.A.; Alencar, A.C.; Gabris, C.; et al. Can carbon emissions from tropical deforestation drop by 50% in 5 years? Glob. Chang. Biol. 2016, 1336, 22–1347.

- Page, S.E.; Hooijer, A. In the line of fire: The peatlands of Southeast Asia. Philos. Trans. R. Soc. B Biol. Sci. 2016, 371, 1–9.

- Forsyth, T. Public concerns about transboundary haze: A comparison of Indonesia, Singapore, and Malaysia. Glob. Environ. Chang. 2014, 25, 76–86.

- Varkkey, H. The Haze Problem in Southeast Asia: Palm Oil and Patronage; Routledge: London, UK, 2015.

- Maruli, A. Half of RI’s oil palm plantations foreign-owned, Antara Magazine. Financial Times Information Limited, Jakarta. 2011. Available online: https://en.antaranews.com/news/71375/half-of-ris-oil-palm-plantations-foreign-owned (accessed on 21 November 2020).

- Lipsey, R.E.; Sjöholm, F. Foreign direct investment and growth in East Asia: Lessons for Indonesia. Bull. Indones. Econ. Stud. 2011, 47, 35–63.

- Marlier, M.E.; DeFries, R.S.; Kim, P.S.; Koplitz, S.N.; Jacob, D.J.; Mickley, L.J.; Myers, S.S. Fire emissions and regional air quality impacts from fires in oil palm, timber, and logging concessions in Indonesia. Environ. Res. Lett. 2015, 10, 085005.

- Islam, R.; Ikhsan, O.M.F.; Khamis, K.A. The role of international political economy on transboundary haze: A comparison study among Malaysia, Indonesia and Singapore. Int. J. Manag. 2020, 11, 443–452.

- Statistik Perkebunan Indonesia Kelapa Sawit 2014–2016. Jakarta: Direktorat Jenderal Perkebunan. 2015. Available online: http://ditjenbun.pertanian.go.id/?publikasi=buku-publikasi-statistik-2014-2016 (accessed on 21 November 2020).

- Murniati, M.; Suharti, S. Towards zero burning peatland preparation: Incentive scheme and stakeholders role. Biodiversitas 2018, 1396, 19–1405.

- Nossal, K.R.; Stubbs, R. Mahathir’s Malaysia: An Emerging Middle Power? In Niche Diplomacy: Middle Powers after the Cold War; Copper, A.F., Ed.; Palgrave Macmillan: London, UK, 1997; pp. 147–163.

- Taheripour, F.; Hertel, T.W.; Ramankutty, N. Market-mediated responses confound policies to limit deforestation from oil palm expansion in Malaysia and Indonesia. Proc. Natl. Acad. Sci. USA 2019, 1919, 1163–19199.

- Etter, A.; McAlpine, C.; Wilson, K.; Phinn, S.; Possingham, H. Agriculture, undefined ecosystems, and undefined 2006, Regional patterns of agricultural land use and deforestation in Colombia. Agric. Ecosytems Environ. 2006, 114, 369–386.

- Amsterdam Declarations Partnership. Available online: https://ad-partnership.org/commodities/palm-oil/ (accessed on 11 August 2020).